Professional Documents

Culture Documents

Equivalent ASME en Materials

Uploaded by

arianaseriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equivalent ASME en Materials

Uploaded by

arianaseriCopyright:

Available Formats

9 9 M Ma at te er ri ia al ls s

LID 1757.00

edition: 13.04.2012

9.7-5

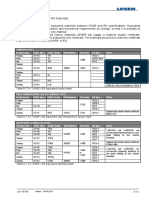

9.7.3 Equivalent ASME / EN Materials

The following chart shows equivalent materials between ASME and EN specifications. Equivalent

means that chemical composition and mechanical requirements do overlap, so that it is possible to

fulfill both requirements with one material.

In case of LESER standard (stock) materials LESER will supply a material double certificate,

certifying both ASME and EN material in one certificate. For materials procured to order the certificate

may show only one material ASME or EN.

CARBON STEEL

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging SA 105 105 10222-2

Plate SA 515 70 VdTV 350/1

Bar SA 105 105 10273

Tubular

1.0460

C22.8

Casting SA 216 WCB J03002 1.0619 10213-2

Supplied with three fold material

certificate WCB/WCC/1.0619

Forging

Plate SA 515 65

Bar

Tubular SA 672 B 65

Casting SA 352 LCB

Supplied with five fold material

certificate LCB/LCC/WCB/WCC/ 1.0619

Table 9.7.3-1: ASME / EN equivalent carbon steel

HIGH TEMPERATURE ALLOY CARBON STEEL

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging 10222-2

Plate 10028-2

Bar SA 739 B11 10273

Tubular

1.7335

10216-2

Casting SA 217 WC6 J12072 1.7357 10213-2

Supplied with double material certificate

WC6/1.7357

Table 9.7.3-2: ASME / EN equivalent high temperature carbon steel

AUSTENITIC STAINLESS STEEL

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging SA 182 F316 10222-5

Plate SA 240 316 10028-7

Bar SA 479 316 10272

Tubular SA 312 TP316

S31600 1.4401

10216-5

10217-7

1.4401/316 and 1.4404/316L are

commercially frequently produce as one

grade fulfilling all four material

standards.

Casting SA 351 CF8M J92900 1.4408 10213-4

Supplied with double material certificate

CF8M/1.4408

Forging SA 182 F316L 10222-5

Plate SA 240 316L 10028-7

Bar SA 479 316L 10272

Tubular SA 312 TP316L

S31603

1.4404

or

1.4435

10216-5

10217-7

1.4401/316 and 1.4404/316L are

commercially frequently produced as

one grade fulfilling all four material

standards.

Casting SA 351 CF3M J92800 1.4409 10213-4

Table 9.7.3-3: ASME / EN equivalent stainless steel

9 9 M Ma at te er ri ia al ls s

LID 1757.00

edition: 13.04.2012

9.7-6

SUPER AUSTENITIC STAINLESS STEEL

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging SA 182 F44 10222-5

Plate SA 240 10028-7

Bar SA 479 10272

Tubular SA 312

S31254

S31254 1.4547

10216-5

Commercial designation:

254 SMO, 6Mo Material

CK3MCuN: Code Case 1750-20

Casting SA 995 CK3MCuN J93254

Forging SB 462 10222-5

Plate SB 688 10028-7

Bar SB 691 10272

Tubular SB 690

N08367 N08367 1.4529

10216-5

Commercial designation:

AL6XN, 6Mo Material

1.4529 is similar but not absolute

identic to N08367. Both materials have

an overlapping chemical composition

for all elements, however N08926 is the

full UNS equivalent for 1.4529.

Casting SA 351 CN3MN J94651

Forging SB 462 n/a

Plate SB 463 17750

Bar SB 473 17752

17751 Tubular

SB 464

SB 468

N08020 N08020 2.4660

17751

Commercial designation:

Alloy 20

Carpenter 20 CB 3

TM

AL 20

TM

Carlson Alloy C20

TM

Nickelvac 23

TM

Nicrofer 3620 Nb

TM

Casting SA 351 CN7M J95150

Table 9.7.3-4: ASME / EN equivalent super austenitic stainless steel

DUPLEX / SUPER DUPLEX

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging SA 182 F51 10222-5

Plate SA 240 10028-7

Bar SA 479 10272

Tubular SA 789

S31803

S31803 1.4462

10216-5

10217-7

Commercial designation: Alloy 2205

Casting SA 351 CD3MN J92205 1.4470 10213-4

Forging SA 182 F55 n/a

Plate SA 240 10028-7

Bar SA 479 10272

Tubular SA 790

S32760

S32760 1.4501

10216-5

10217-7

Commercial designation: Zeron 100

Casting SA 995 CD3NWCuN J93380 (1.4508) 1.4508 is obsolete

Forging SA 182 F61 n/a

Plate 10028-7

Bar SA 479 S32550 10272

Tubular

S32550 1.4507

10216-5

Commercial designation: Alloy 255

Casting CD4MCuN J93372 1.4517 10213-4

Table 9.7.3-5: ASME / EN equivalent duplex / super duplex steel

9 9 M Ma at te er ri ia al ls s

LID 1757.00

edition: 13.04.2012

9.7-7

NICKEL BASE MATERIALS

Product form ASME Spec. ASME Grade UNS Number EN Grade EN Spec. Notes

Forging SB 462 / 564

Plate SB 575 DIN 17750

Bar SB 574 DIN 17752

Tubular

SB-619/622/

626

N06022 N06022 2.4602

DIN 17751

Commercial designation:

Hastelloy C-22

2.4602 chemical composition:

DIN 17744

Casting SA 494 CX2MW N26022

Forging SB 462 / 564

Plate SB 575 DIN 17750

Bar SB 574 DIN 17752

Tubular SB 622

N10276 N10276 2.4819

DIN 17751

Commercial designation:

Hastelloy C-276

2.4819 chemical composition:

DIN 17744

Casting SA 494 CW-12MW N30002 2.4686

Forging SB 574

Plate SB 575 DIN 17750

Bar SB 574

DIN 17752

VDTV 424

Tubular SB 622

N06455 N06455 2.4610

DIN 17751

Commercial designation:

Hastelloy C-4

CW2M is not listed in ASME VIII

2.4610 chemical composition:

DIN 17744

Casting SA 494 CW2M

Forging SB 164 DIN 17754

Plate SB 127 DIN 17750

Bar SB 164 DIN 17752

Tubular SB 165

N04400 2.4360

DIN 17751

Commercial designation:

Monel 400

2.4360 chemical composition:

DIN 17744

Casting SA 494 M35-1 N24135

Forging SB 546

Plate SB 443 DIN 17750

Bar SB 446 DIN 17752

Tubular SB 444

N06625 N06625 2.4856

DIN 17751

Commercial designation:

Inconel 625

2.4856 chemical composition:

DIN 17744

Casting SA 494 CW-6MC N26625

Table 9.7.3-6: ASME / EN equivalent nickel base materials

You might also like

- Ball ValveDocument4 pagesBall Valveadjie_adzaNo ratings yet

- Study Notes - Google Project Management Professional CertificateDocument4 pagesStudy Notes - Google Project Management Professional CertificateSWAPNIL100% (1)

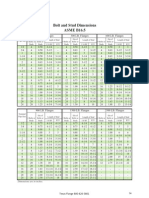

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- Assignment November11 KylaAccountingDocument2 pagesAssignment November11 KylaAccountingADRIANO, Glecy C.No ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialstvsshindeNo ratings yet

- Steel Grade Equivalency TableDocument2 pagesSteel Grade Equivalency TableBudy GedhaBlackNo ratings yet

- International Standard ReferenceDocument14 pagesInternational Standard ReferenceKARTHIGEYAN.RNo ratings yet

- Piping Material Equivalent GradesDocument19 pagesPiping Material Equivalent GradesTejas DesaiNo ratings yet

- Torque Values Klingersil Topgraph Topchem (B16.5) PDFDocument2 pagesTorque Values Klingersil Topgraph Topchem (B16.5) PDFrached100% (2)

- Sales Proposal Sales Proposal Template 1.doctemplate 1Document5 pagesSales Proposal Sales Proposal Template 1.doctemplate 1arianaseriNo ratings yet

- Economics Exam Technique GuideDocument21 pagesEconomics Exam Technique Guidemalcewan100% (5)

- EP07 Measuring Coefficient of Viscosity of Castor OilDocument2 pagesEP07 Measuring Coefficient of Viscosity of Castor OilKw ChanNo ratings yet

- EPMS System Guide For Subcontractor - V1 2Document13 pagesEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Flange Bolt Tightening ProcedureDocument5 pagesFlange Bolt Tightening ProcedureArya100% (1)

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Document1 pageTorque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....Shijumon Kp100% (2)

- Stud Bolt LengthDocument1 pageStud Bolt LengthSanthosh100% (1)

- Material Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)Document12 pagesMaterial Comparison Tables (ASTM KS, JIS, DIN, BS, NBN, NF, UNI)mihailspiridonNo ratings yet

- Pipe Sizes Chart PDFDocument1 pagePipe Sizes Chart PDFMukesh Kumar Jha100% (1)

- JIS Flange InformationDocument3 pagesJIS Flange Informationmcoswald83No ratings yet

- Valve Material Specifications: Forged Cast Key Physical PropertiesDocument1 pageValve Material Specifications: Forged Cast Key Physical PropertiesdenyNo ratings yet

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocument5 pagesPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNo ratings yet

- ASTM Cross Reference Material Specs.Document2 pagesASTM Cross Reference Material Specs.septixNo ratings yet

- Commonly Used Piping MaterialsDocument1 pageCommonly Used Piping MaterialsMOHAMMAD ASIFNo ratings yet

- Equivalent Steel GradesDocument6 pagesEquivalent Steel GradesPapaiNo ratings yet

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNo ratings yet

- Asme Section Ii A-2 Sa-961Document12 pagesAsme Section Ii A-2 Sa-961Anonymous GhPzn1xNo ratings yet

- All Material and Filler & PWHTDocument20 pagesAll Material and Filler & PWHTMOHANNo ratings yet

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- Specs Chart PDFDocument1 pageSpecs Chart PDFsojeckNo ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangel kishoreNo ratings yet

- Equivalent MaterialDocument1 pageEquivalent Materialmuhammadf SardarNo ratings yet

- Piping Material EquivalentsDocument1 pagePiping Material EquivalentspejnorozyNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Material EquivalentDocument88 pagesMaterial EquivalentGabriel Milicu67% (3)

- TDC For Pipes - Sa 106 GR.BDocument2 pagesTDC For Pipes - Sa 106 GR.BRenny DevassyNo ratings yet

- A. For Welding Sa 210 Gra1 To Sa 210 GR A1Document1 pageA. For Welding Sa 210 Gra1 To Sa 210 GR A1911targa100% (1)

- Jis Standard Steel PDFDocument5 pagesJis Standard Steel PDFMochammad Zaki NasrullohNo ratings yet

- Astm Material TableDocument1 pageAstm Material Tableharoub_nasNo ratings yet

- Welder Performance Qualification (WPQ)Document2 pagesWelder Performance Qualification (WPQ)alokbdasNo ratings yet

- Material ComparisonDocument10 pagesMaterial ComparisonMardeOpamenNo ratings yet

- EHB en File 9.7.3 Equivalent ASME en MaterialsDocument3 pagesEHB en File 9.7.3 Equivalent ASME en MaterialsAdhitya DarmadiNo ratings yet

- EHB en File 9.7.3 Equivalent ASME en MaterialsDocument3 pagesEHB en File 9.7.3 Equivalent ASME en MaterialsRamuAlagappanNo ratings yet

- Equivalent ASME EN MaterialsDocument3 pagesEquivalent ASME EN MaterialsVajid MadathilNo ratings yet

- EHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFDocument3 pagesEHB - en - File - 9.7.3 Equivalent ASME EN Materials PDFks2000n1No ratings yet

- Catalog Valve KSBDocument58 pagesCatalog Valve KSByoboo100% (1)

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- Comparison Table For Tubes, Line Pipes and FittingDocument2 pagesComparison Table For Tubes, Line Pipes and FittingNamye Yelus100% (1)

- 61502Document10 pages61502balajivangaruNo ratings yet

- Butt Weld Fitting B16.9 A.403Document16 pagesButt Weld Fitting B16.9 A.403Jimmy ChanNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- API 594 Dual PLT CheckDocument18 pagesAPI 594 Dual PLT Checkandy131078No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Din Equivalent MaterialsDocument3 pagesDin Equivalent Materialspadmgovi23No ratings yet

- Pipe FittingsDocument7 pagesPipe FittingsLucky JaswalNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- Ati 316 316l 317 317l Tds En2 v1Document15 pagesAti 316 316l 317 317l Tds En2 v1arianaseriNo ratings yet

- Data Sheet - UMEB - IP55Document2 pagesData Sheet - UMEB - IP55arianaseriNo ratings yet

- 1.vendor List - Rev.6Document174 pages1.vendor List - Rev.6arianaseri100% (1)

- ProNest Programming Guide PDFDocument48 pagesProNest Programming Guide PDFBurhan ÇamNo ratings yet

- Engineers Australia Code of Ethics 2010Document3 pagesEngineers Australia Code of Ethics 2010matthew1ferreiraNo ratings yet

- VistiDocument3 pagesVistiarianaseriNo ratings yet

- Brochure Air Cooled CondenserDocument8 pagesBrochure Air Cooled CondenserFathur Rahman Handoko100% (1)

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetGopal RamalingamNo ratings yet

- Reference DataDocument20 pagesReference DataarianaseriNo ratings yet

- Ati Corrosion Resistant Titanium Alloys Tds En4 v1Document5 pagesAti Corrosion Resistant Titanium Alloys Tds En4 v1HMMSPNo ratings yet

- 30-05-09 Proposal Caribbean Emergency Legislation Project Activity 201 2Document19 pages30-05-09 Proposal Caribbean Emergency Legislation Project Activity 201 2Amit OzaNo ratings yet

- Neway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdDocument18 pagesNeway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdarianaseriNo ratings yet

- Joint VentureDocument12 pagesJoint VentureJeree Jerry AzreeNo ratings yet

- Ni-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationDocument2 pagesNi-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationpvdangNo ratings yet

- WKM Pow R Seal Gate Valves BrochureDocument28 pagesWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- 5S Checklist ReaderDocument1 page5S Checklist ReaderarianaseriNo ratings yet

- 6 Polley Compabloc FDocument5 pages6 Polley Compabloc FarianaseriNo ratings yet

- لکش 1 یهد ششوپ کیتامش شیامن CVD و PVDDocument5 pagesلکش 1 یهد ششوپ کیتامش شیامن CVD و PVDarianaseriNo ratings yet

- 04 035 042 Corrugated GasketsDocument8 pages04 035 042 Corrugated Gasketsdane05No ratings yet

- Manual BPV UkDocument12 pagesManual BPV UkarianaseriNo ratings yet

- OG Brochure - Alloys InsertDocument2 pagesOG Brochure - Alloys InsertarianaseriNo ratings yet

- Grooved Kempchen PDFDocument11 pagesGrooved Kempchen PDFAnonymous Iev5ggSRNo ratings yet

- James Walker o Ring GuideDocument32 pagesJames Walker o Ring Guidecvishwas1159No ratings yet

- Ma30 WDocument2 pagesMa30 WarianaseriNo ratings yet

- Cameron Back Pressure ValveDocument1 pageCameron Back Pressure Valvekaveh-bahiraeeNo ratings yet

- High Perf Metals Brochure v1Document5 pagesHigh Perf Metals Brochure v1arianaseriNo ratings yet

- 2015 Membership ApplicationDocument4 pages2015 Membership ApplicationarianaseriNo ratings yet

- Smo 254 Uns S31254Document8 pagesSmo 254 Uns S31254sateesh chandNo ratings yet

- Fouling in Plate Heat Exchangers Some Practical ExperienceDocument18 pagesFouling in Plate Heat Exchangers Some Practical ExperienceKarina Yesenia Salinas100% (1)

- 01 - TechDocs, Acft Gen, ATAs-05to12,20 - E190 - 202pgDocument202 pages01 - TechDocs, Acft Gen, ATAs-05to12,20 - E190 - 202pgေအာင္ ရွင္း သန္ ့No ratings yet

- JIMMA Electrical&ComputerEngDocument219 pagesJIMMA Electrical&ComputerEngTewodros71% (7)

- Consumer Protection ActDocument34 pagesConsumer Protection ActshikhroxNo ratings yet

- Previews 1633186 PreDocument11 pagesPreviews 1633186 PreDavid MorenoNo ratings yet

- Developpments in OTC MarketsDocument80 pagesDeveloppments in OTC MarketsRexTradeNo ratings yet

- LP Week 8Document4 pagesLP Week 8WIBER ChapterLampungNo ratings yet

- Bichelle HarrisonDocument2 pagesBichelle HarrisonShahbaz KhanNo ratings yet

- Initial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Document1 pageInitial Police Report: Calamba City Police Station Brgy Real, Calamba City, Laguna E-Mail: 545-1694/545-6789 Loc 8071Jurish BunggoNo ratings yet

- Writ Petition 21992 of 2019 FinalDocument22 pagesWrit Petition 21992 of 2019 FinalNANDANI kumariNo ratings yet

- NCP - Impaired Urinary EliminationDocument3 pagesNCP - Impaired Urinary EliminationFretzgine Lou ManuelNo ratings yet

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0No ratings yet

- Operating Instructions: Rotary Lobe PumpDocument77 pagesOperating Instructions: Rotary Lobe PumpRuslan SlusarNo ratings yet

- Not CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08Document151 pagesNot CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08hocine gherbiNo ratings yet

- Final - Anarchy One-Sheet Sell SheetDocument2 pagesFinal - Anarchy One-Sheet Sell SheetMaddanie WijayaNo ratings yet

- Communicating Value - PatamilkaDocument12 pagesCommunicating Value - PatamilkaNeha ArumallaNo ratings yet

- Fortnite Task Courier Pack 1500 V Bucks - BuscarDocument1 pageFortnite Task Courier Pack 1500 V Bucks - Buscariancard321No ratings yet

- FINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Document45 pagesFINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Edmar Cielo SarmientoNo ratings yet

- Fashion DatasetDocument2,644 pagesFashion DatasetBhawesh DeepakNo ratings yet

- Army Aviation Digest - Apr 1971Document68 pagesArmy Aviation Digest - Apr 1971Aviation/Space History LibraryNo ratings yet

- Electronics 11 02566Document13 pagesElectronics 11 02566卓七越No ratings yet

- Acceptable Use Policy 08 19 13 Tia HadleyDocument2 pagesAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689No ratings yet

- PCM Cables: What Is PCM Cable? Why PCM Cables? Application?Document14 pagesPCM Cables: What Is PCM Cable? Why PCM Cables? Application?sidd_mgrNo ratings yet

- Pantone PDFDocument53 pagesPantone PDF2dlmediaNo ratings yet

- TransistorsDocument21 pagesTransistorsAhmad AzriNo ratings yet

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Document14 pagesFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlNo ratings yet