Professional Documents

Culture Documents

Rudder

Uploaded by

tribleprinceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rudder

Uploaded by

tribleprinceCopyright:

Available Formats

Rudder Design

Georgie Keane

Rudder Design

Session 1

4/20/2011 Ship Design SESS2009 3

Assignment 2

Start Tuesday 26th October 2010

Hand in Wednesday 17th November 2010

Written report. Maximum sides plus

appendices of calculations

4/20/2011 Ship Design SESS2009 4

Purpose of assignment

Using the given design requirements and

experimental data calculate the minimum

rudder stock diameter.

Understand the concept of a balanced

rudder.

Check the minimum requirement for the

stock diameter and plate scantlings using

Lloyds rules.

Produce a sketch of the rudder showing the

overall profile, section shape, layout and

scantlings.

4/20/2011 Ship Design SESS2009 5

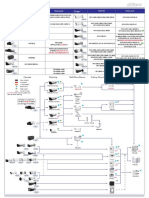

Rudder

Types

4/20/2011 Ship Design SESS2009 6

4/20/2011 Ship Design SESS2009 7

4/20/2011 Ship Design SESS2009 8

4/20/2011 Ship Design SESS2009 9

Points of

the rudder

4/20/2011 Ship Design SESS2009 10

Rudder Force

Components

4/20/2011 Ship Design SESS2009 11

Loads at rudder stock

4/20/2011 Ship Design SESS2009 12

Purpose of assignment

Using the given design requirements and

experimental data calculate the minimum

rudder stock diameter.

Understand the concept of a balanced

rudder.

Check the minimum requirement for the

stock diameter and plate scantlings using

Lloyds rules.

Produce a sketch of the rudder showing the

overall profile, section shape, layout and

scantlings.

4/20/2011 Ship Design SESS2009 13

Assignment.

Rudder dimensions rudder design data on handout

Rudder Torque experimental data on handout

interpolate for correct J

Torque = N x

Minimise Torque range of stock positions (20% -35% cord)

record absolute maximum torques

stock position to minimise maximums

Root bending moment = R y

Equivalent bending moment = M/2 +1/2 M

2

+ Q

2

Discuss

Lloyds Rules

Rudder Blade section

Drawing

4/20/2011 Ship Design SESS2009 14

4/20/2011 Ship Design SESS2009 15

4/20/2011 Ship Design SESS2009 16

Experimental rig

Rudder Design

Session 2

4/20/2011 Ship Design SESS2009 18

Purpose of assignment

Using the given design requirements and

experimental data calculate the minimum

rudder stock diameter.

Understand the concept of a balanced

rudder.

Check the minimum requirement for the

stock diameter and plate scantlings using

Lloyds rules.

Produce a sketch of the rudder showing the

overall profile, section shape, layout and

scantlings.

4/20/2011 Ship Design SESS2009 19

Assignment.

Rudder dimensions rudder design data on handout

Rudder Torque experimental data on handout

interpolate for correct J

Torque = N x

Minimise Torque range of stock positions (20% -35% cord)

record absolute maximum torques

stock position to minimise maximums

Root bending moment = R y

Equivalent bending moment = M/2 +1/2 M

2

+ Q

2

Discuss

Lloyds Rules

Rudder Blade section

Drawing

4/20/2011 Ship Design SESS2009 20

Rudder Stock

4/20/2011 Ship Design SESS2009 21

Rudder crosshead and

hydraulics

4/20/2011 Ship Design SESS2009 22

Rudder torque

4/20/2011 Ship Design SESS2009 23

Minimizing torque

Stock Position (%)

4/20/2011 Ship Design SESS2009 24

Loads at rudder stock

Rudder Design

Session 3

4/20/2011 Ship Design SESS2009 26

Design Considerations

Hydrodynamic considerations:-

Minimum Drag

Good directional stability

High manoeuvrability

Rudder propeller interaction

Structural considerations:-

Ease of construction and maintenance

Structural reliability

Weight

4/20/2011 Ship Design SESS2009 27

Choice of Section

Aspect Ratio. Structural consideration

Efficiency

Thickness : Cord ratio. Efficiency

Nose radius

Tapered Sections. Position of Cp(span)

Down wash

4/20/2011 Ship Design SESS2009 28

NACA Sections.

Aero foil sections described by a 4 digit

number e.g. 0015

First two digits camber : cord ratio (00

if symmetrical)

Second two digits thickness : cord ratio

(10-20% for ships rudders)

4/20/2011 Ship Design SESS2009 29

NACA Sections

4/20/2011 Ship Design SESS2009 30

NACA 0010

4/20/2011 Ship Design SESS2009 31

Rudder Thickness

4/20/2011 Ship Design SESS2009 32

4/20/2011 Ship Design SESS2009 33

You might also like

- 4 Basic - Bell CrankDocument26 pages4 Basic - Bell Crankkaime_scribd50% (2)

- RUDDER AND RUDDER STOCK INSPECTION GUIDEDocument12 pagesRUDDER AND RUDDER STOCK INSPECTION GUIDEJORGENo ratings yet

- 900 - Power TransmissionDocument10 pages900 - Power TransmissionPhamLeDanNo ratings yet

- Mosaad 86 PDFDocument294 pagesMosaad 86 PDFdoğancan uzunNo ratings yet

- Piping Layout PresentationDocument56 pagesPiping Layout Presentationhirenkumar patel89% (9)

- Details of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationDocument31 pagesDetails of WDETAILS OF WATER SAMPLING STATION - Pdfater Sampling StationHong Leong KuNo ratings yet

- Versant ModifiedDocument57 pagesVersant ModifiedAryan Kharadkar100% (3)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsRating: 4.5 out of 5 stars4.5/5 (3)

- Tug - BUYUKDEREDocument6 pagesTug - BUYUKDEREudelmarkNo ratings yet

- Ship Wheel PDFDocument18 pagesShip Wheel PDFCarlos LuizNo ratings yet

- Hiper2010 MelbourneDocument310 pagesHiper2010 MelbournemaciuluNo ratings yet

- Guide For Power PredictionDocument11 pagesGuide For Power PredictionpagliasoNo ratings yet

- Operation & Maintenance ManualDocument21 pagesOperation & Maintenance ManualMohammed BasionyNo ratings yet

- New Method Estimates Tug DimensionsDocument8 pagesNew Method Estimates Tug DimensionsHussien ElmasryNo ratings yet

- Damen Year Book No1Document132 pagesDamen Year Book No1minhloc4100% (1)

- Propeller CatalogDocument156 pagesPropeller CatalogPoowadol NiyomkaNo ratings yet

- INDIAN MARITIME UNIVERSITY NSTL Lab reportDocument4 pagesINDIAN MARITIME UNIVERSITY NSTL Lab reportAnkit GhoshNo ratings yet

- Design of Ship RuddersDocument82 pagesDesign of Ship RuddersGerard Sarg100% (1)

- MSC 85-3-2 Intact Stability Code 2008Document99 pagesMSC 85-3-2 Intact Stability Code 2008Habib SusiloNo ratings yet

- Propeller Blade SealsDocument9 pagesPropeller Blade Sealswaleed yehiaNo ratings yet

- Tanker stability report analysisDocument42 pagesTanker stability report analysisNikola DjordjevicNo ratings yet

- Design and Performance of Bow ThrustersDocument48 pagesDesign and Performance of Bow ThrustersSofiya SofiNo ratings yet

- Offshore Hydro MechanicsDocument570 pagesOffshore Hydro MechanicsAsier DCNo ratings yet

- Research in Seamanship: Group 1 - Batch 1Document16 pagesResearch in Seamanship: Group 1 - Batch 1Jlria Mae Bjocx100% (1)

- RudderDocument24 pagesRudderPrince AbanidNo ratings yet

- User Guide: Siemens PLM SoftwareDocument32 pagesUser Guide: Siemens PLM Softwareabc123go100% (1)

- Marine Engineering & Naval Architecture DictionaryDocument848 pagesMarine Engineering & Naval Architecture Dictionaryandevari100% (1)

- Tank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Document143 pagesTank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Hung LeNo ratings yet

- 2 - Estimation of General Characteristics of Fishing Vessels BDocument18 pages2 - Estimation of General Characteristics of Fishing Vessels BJuan SilvaNo ratings yet

- Chapter Vi Resistance PredictionDocument18 pagesChapter Vi Resistance PredictionAbraham RakuljicNo ratings yet

- In-Service Performance of Aluminum Structural DetailsDocument114 pagesIn-Service Performance of Aluminum Structural DetailsMahdiNo ratings yet

- Product Sheet Stan Tug 1606Document2 pagesProduct Sheet Stan Tug 1606Roda NiagaNo ratings yet

- Naval ArchitectureDocument11 pagesNaval ArchitecturePrabhat ChoudharyNo ratings yet

- Koelbel Steps PDFDocument54 pagesKoelbel Steps PDFOnggo Firstha Nichita100% (1)

- Design of Propulsion Systems For High-Speed CraftDocument17 pagesDesign of Propulsion Systems For High-Speed Craftaeromexpower2009No ratings yet

- RB - Aluminium A60 Hinged DoorDocument2 pagesRB - Aluminium A60 Hinged DoorHayden Kyle KeigleyNo ratings yet

- 14000 TEU container ship benchmark dataDocument15 pages14000 TEU container ship benchmark dataChahbi RamziNo ratings yet

- Resistance Prediction of Cruising Motor Catamarans PDFDocument125 pagesResistance Prediction of Cruising Motor Catamarans PDFuchiiha_camiNo ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- Tuning A Twin-Screw Rudder InstallationDocument6 pagesTuning A Twin-Screw Rudder Installationaeromexpower2009No ratings yet

- SSC-436 The Effect of Fabricaton Tolerances On Fatigue Life of Welded JointsDocument100 pagesSSC-436 The Effect of Fabricaton Tolerances On Fatigue Life of Welded JointsBeniamine SarmientoNo ratings yet

- PROP DRAWINGDocument4 pagesPROP DRAWINGbongoyozoNo ratings yet

- SeaBoats ID1127Document14 pagesSeaBoats ID1127nipper7No ratings yet

- Fishing Vessel Terminology GuideDocument27 pagesFishing Vessel Terminology GuideJohn Karuwal100% (1)

- Propulsion and ShaftingDocument31 pagesPropulsion and ShaftingPriscila KImNo ratings yet

- Jack Up TestDocument3 pagesJack Up TestGermán AguirrezabalaNo ratings yet

- TRAFI 494 131 03 04 01 00 2016 EN Jaaluokkamaarays 2017Document65 pagesTRAFI 494 131 03 04 01 00 2016 EN Jaaluokkamaarays 2017Maxim100% (1)

- Buy 4.5 M Rubberised Inflatable Boat (Rescue Boats) Online - GeMDocument10 pagesBuy 4.5 M Rubberised Inflatable Boat (Rescue Boats) Online - GeMCO2DNU NCCNo ratings yet

- Stability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactDocument6 pagesStability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactfahmiNo ratings yet

- Aplicacion de Helices CicloidalesDocument51 pagesAplicacion de Helices CicloidalesMerrel RossNo ratings yet

- 000 010 A01 Space Identifcation PlanDocument1 page000 010 A01 Space Identifcation Planbuturca sorinNo ratings yet

- Wave Restance For High-Speed CatamaransDocument30 pagesWave Restance For High-Speed CatamaransKay OosterwegelNo ratings yet

- Deflection Measuringsystemfor Floating DrydocksDocument6 pagesDeflection Measuringsystemfor Floating DrydocksGermán AguirrezabalaNo ratings yet

- Schilling Rudder - Wikipedia, The Free EncyclopediaDocument3 pagesSchilling Rudder - Wikipedia, The Free EncyclopediaAhmad HajivandNo ratings yet

- What Are Ship Bottom Plugs or Dock PlugsDocument11 pagesWhat Are Ship Bottom Plugs or Dock PlugsstamatisNo ratings yet

- 1978 ITTC Performance PredictionDocument31 pages1978 ITTC Performance PredictionqursenNo ratings yet

- MO Aluminium Catamarans Rule Developments Supporting Document V1.0Document37 pagesMO Aluminium Catamarans Rule Developments Supporting Document V1.0tyu100% (2)

- Naca Rudder HornDocument16 pagesNaca Rudder HornMuhammad Lukman100% (1)

- Crew Boat 20 MDocument1 pageCrew Boat 20 MokaNo ratings yet

- Arquitectura Naval para IngenierosDocument109 pagesArquitectura Naval para IngenierosRafael Medina100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Windship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985From EverandWindship Technology: Proceedings of the International Symposium on Windship Technology (WINDTECH ' 85), Southampton, U.K., April 24-25, 1985C SatchwellNo ratings yet

- How Bell Crank Mechanism Works in Formula Cars - QuoraDocument3 pagesHow Bell Crank Mechanism Works in Formula Cars - QuoratribleprinceNo ratings yet

- ASTM - Valve StandardsDocument2 pagesASTM - Valve StandardsArash AbbasiNo ratings yet

- Prefer Header For HTTPDocument18 pagesPrefer Header For HTTPtribleprinceNo ratings yet

- Bellcrank - Wikipedia, The Free EncyclopediaDocument2 pagesBellcrank - Wikipedia, The Free EncyclopediatribleprinceNo ratings yet

- Concrete - PropertiesDocument1 pageConcrete - PropertiestribleprinceNo ratings yet

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- Introduction To Piping EngineerDocument46 pagesIntroduction To Piping EngineerFebrianto Edy PratamaNo ratings yet

- Introduction To Piping EngineerDocument46 pagesIntroduction To Piping EngineerFebrianto Edy PratamaNo ratings yet

- PIN December 2015 WebDocument35 pagesPIN December 2015 WebtribleprinceNo ratings yet

- Piping DrawingDocument38 pagesPiping Drawingtribleprince100% (4)

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadNo ratings yet

- Screw Down Non Return ValveDocument2 pagesScrew Down Non Return ValvetribleprinceNo ratings yet

- Field Fabrication and Installation of Piping SystemsDocument5 pagesField Fabrication and Installation of Piping SystemstribleprinceNo ratings yet

- Acceptable Design For Unequal Wall ThicknessDocument3 pagesAcceptable Design For Unequal Wall ThicknesstribleprinceNo ratings yet

- Acceptable Design For Unequal Wall ThicknessDocument3 pagesAcceptable Design For Unequal Wall ThicknesstribleprinceNo ratings yet

- Pipe laying and service installation manual: A guide for construction workersDocument78 pagesPipe laying and service installation manual: A guide for construction workerstribleprinceNo ratings yet

- Piping Coordination Systems - Mechanical Symbols For Isometric DrawingsDocument5 pagesPiping Coordination Systems - Mechanical Symbols For Isometric DrawingstribleprinceNo ratings yet

- Pipe Laying MetodeDocument27 pagesPipe Laying MetodeMochamad SafarudinNo ratings yet

- 02 AllDocument70 pages02 AllmodisuryaharshaNo ratings yet

- Good)Document62 pagesGood)shrinidheeNo ratings yet

- LinkagesDocument29 pagesLinkagesRubén GonzálezNo ratings yet

- Mechanisms TypesDocument359 pagesMechanisms TypestribleprinceNo ratings yet

- Dynamic Pipe Bursting - Nodig-ConstructionDocument2 pagesDynamic Pipe Bursting - Nodig-ConstructiontribleprinceNo ratings yet

- Grabenlos GB 01Document8 pagesGrabenlos GB 01tribleprinceNo ratings yet

- Advanced Radiographic Techniques PDFDocument21 pagesAdvanced Radiographic Techniques PDFelokfaiqNo ratings yet

- 2290 PDFDocument222 pages2290 PDFmittupatel190785No ratings yet

- 4608 Eed 01Document29 pages4608 Eed 01NickNo ratings yet

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Procedure for safely changing LWCV assembly with torques over 30,000 ft-lbsDocument2 pagesProcedure for safely changing LWCV assembly with torques over 30,000 ft-lbsnjava1978No ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajNo ratings yet

- Applying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteDocument15 pagesApplying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteayyishNo ratings yet

- Power Tube Biasing Operation Manual 15-01-08Document2 pagesPower Tube Biasing Operation Manual 15-01-08MitchNo ratings yet

- Sundar KandvalmikiDocument98 pagesSundar Kandvalmikifactree09No ratings yet

- CLIC Catalogue PDFDocument28 pagesCLIC Catalogue PDFsangram patilNo ratings yet

- GPS and The Quest For Pizza: National Aeronautics and Space AdministrationDocument1 pageGPS and The Quest For Pizza: National Aeronautics and Space Administrationvijay maddiNo ratings yet

- Myths of Greece and Rome PDFDocument247 pagesMyths of Greece and Rome PDFratheesh1981No ratings yet

- 2 - Alaska - WorksheetsDocument7 pages2 - Alaska - WorksheetsTamni MajmuniNo ratings yet

- BiologyDocument21 pagesBiologyHrituraj banikNo ratings yet

- L C R Circuit Series and Parallel1Document6 pagesL C R Circuit Series and Parallel1krishcvrNo ratings yet

- High Risk Medications in AyurvedaDocument3 pagesHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- DerbyCityCouncil Wizquiz Presentation PDFDocument123 pagesDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevNo ratings yet

- Electrical Machines Multiple Choice Questions - Mcqs - QuizDocument10 pagesElectrical Machines Multiple Choice Questions - Mcqs - Quiztooba mukhtarNo ratings yet

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNo ratings yet

- Electrical Units of MeasureDocument36 pagesElectrical Units of MeasureHyung BaeNo ratings yet

- Nitocote WP DDocument4 pagesNitocote WP DdaragNo ratings yet

- Qand ADocument5 pagesQand AJoshua PascasioNo ratings yet

- Medium Strength High Conductivity MaterialsDocument37 pagesMedium Strength High Conductivity MaterialsNut AssanaiNo ratings yet

- Aubrey Debut ScriptDocument5 pagesAubrey Debut ScriptKevin Jones CalumpangNo ratings yet

- Understanding Earth's History Through Rock CharacteristicsDocument1 pageUnderstanding Earth's History Through Rock CharacteristicsSharmaine AcNo ratings yet

- BELL B40C - 872071-01 Section 2 EngineDocument38 pagesBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)

- YOKOGAWADocument16 pagesYOKOGAWADavide ContiNo ratings yet

- Symbols For Signalling Circuit DiagramsDocument27 pagesSymbols For Signalling Circuit DiagramsrobievNo ratings yet