Professional Documents

Culture Documents

CAD-based Simulation of The Hobbing Process

Uploaded by

Gabriel Marius0 ratings0% found this document useful (0 votes)

113 views11 pagescAD simultation

Original Title

CAD-based Simulation of the Hobbing Process

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentcAD simultation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

113 views11 pagesCAD-based Simulation of The Hobbing Process

Uploaded by

Gabriel MariuscAD simultation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

ORIGINAL ARTICLE

CAD-based simulation of the hobbing process

for the manufacturing of spur and helical gears

V. Dimitriou & A. Antoniadis

Received: 20 May 2007 / Accepted: 28 February 2008

# Springer-Verlag London Limited 2008

Abstract Targeting an accurate and realistic simulation of the

gear hobbing process, we present an effective and factual

approximation based on three-dimensional computer-aided

design. Hobbing kinematics is directly applied in one gear

gap. Each generating position formulates a spatial surface path

which bounds its penetrating volume into the workpiece. The

three-dimensional surface paths generated from the combina-

tion of the relative rotations and displacements of hob and work

gear are used to split the subjected volume, creating concur-

rently the chip and the remaining work gear solid geometries.

The developed software programHOB3Dsimulates accurately

the manufacturing of spur and helical gears, exploiting the

modeling and graphics capabilities of a commercial CAD

software package. The resulting three-dimensional solid

geometrical data, chips and gears provide the whole geomet-

rical information needed for further research, such as prediction

of the cutting forces, tool stresses and wear development as

well as the optimization of the gear hobbing process.

Keywords Gear hobbing

.

Manufacturing simulation

.

CADmodeling

1 Introduction

Gear hobbing is a widely applied manufacturing process for

the construction of any external tooth form developed

uniformly about a rotation center. Compared to conven-

tional machining, such as turning and milling, the hobbing

process is a sophisticated metal removal technology.

Whileit is the most widely used process for the roughing

of gears, its complexity and cost keep this technique poorly

known. The kinematics principle of the process is based on

three relative motions between the workpiece and the hob

tool. For the production of spurs or helical gears, the

workpiece rotates about its symmetry axis with a certain

constant angular velocity, synchronized with the relative

gear hob rotation. The worktable or the hob may travel

along the work axis with the selected feed rate, depending

on the hobbing machine that is used.

For the simulation of the gear hobbing process variant

approximations have been proposed for the development of

numerical and analytical models, aiming at the determination

of the undeformed chip geometry, cutting force components

and tool wear development [1, 2]. The industrial weight of

these three simulation results is associated with the

optimization of the efficiency per unit cost of the gear

hobbing process. The undeformed chip geometry is an

essential parameter to determine the cutting force compo-

nents, as well as to predefine the tool wear development,

both of them important cost related data of hobbing process

[3]. For the effective specification of the tolerances on hob

design parameters and allowable alignment errors, Kim [4]

proposes a method of representing the geometry of a hob

tooth profile in parametric form and of determining the

surface equation of a generated gear as a function of hob

design parameters and generating motion specifications

through a mathematical model of the generation process.

The simulation of meshing of face hobbed spiral bevel and

hypoid gears and mathematic models of tooth surface

generations are presented by Fan, and a tooth contact

analysis program was developed [5].

Int J Adv Manuf Technol

DOI 10.1007/s00170-008-1465-x

V. Dimitriou

Technological Educational Institute of Crete,

Chania, Crete, Greece

A. Antoniadis (*)

Technical University of Crete,

Chania, Crete, Greece

e-mail: antoniadis@dpem.tuc.gr

The research work presented in [611] provided the

basic knowledge for the numerical modeling of the gear

hobbing process and later on newer approximations were

proposed based on a similar modeling strategy [1217].

These approximation methods are proposed for the deter-

mination of the hobbing process results, but the main

characteristic of these methods is the reduction of the actual

three-dimensional process to planar models, primarily for

simplification reasons. The application of these former

approximations is leading to planar results, without to

represent the exact solid geometry of the real chips and

gears, with accuracy directly dependent from various input

parameters such as the number of the calculation planes.

Furthermore, any post-processing of the extracted chip and

gear planar geometries, e.g., finite element analysis,

requires additional data processing which leads to supple-

mentary interpolations of the two-dimensional results.

Focusing on the realistic and accurate simulation of the gear

hobbing process, without inevitable modeling insufficiencies,

we present an approach for the simulation of manufacturing

spur and helical gears in this research work. A software

program called HOB3D, originally presented in [18], is used

for the guidance of an existent commercial CAD system,

exploiting its powerful modeling and graphics capabilities.

HOB3D is built in terms of a computer code in Visual Basic,

extending this capability to other cutting processes based on

the same cutting principle. The resulting solid models output

formats offer realistic parts, chips and work gears, easily

managed for further individual research or as an input to any

other CAD, CAM or FEA commercial software systems.

2 HOB3D modeling procedure

The rolling principle between the hob and the workpiece

makes the gear hobbing process different from conventional

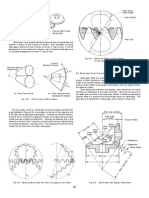

milling. As presentedin Fig. 1, the process problem is

basically prescribed from the geometrical characteristics of

the gear to be cut, the hob that will be used and the

involved kinematics between them.

The geometry of a resulting gear is basically described by

six parameters: module (m), number of teeth (z

2

), outside

diameter (d

g

), helix angle (h

a

), gear width (W) and pressure

angle (a

n

). The correlation of these parameters automati-

cally yields the module (m) of the hob tool, whereas other

tool geometrical parameters as external diameter (d

h

),

number of columns (n

i

), number of origins (z

1

), axial pitch

() and helix angle (), are options to be chosen.

As soon as the geometrical parameters of the two

combined parts are set, the kinematics chain has to be

initialized. The helix angle of the hob and the work gear

prescribe the setting angle (

s

) between the parts and the

way that their relative motions will take place. Three

distinct cutting motions are required: the tool rotation about

its axis, the tool axial displacement and the workpiece

revolution about its axis. By these means, the direction of

the axial feed (f

a

) prescribes two different hobbing

strategies: the climb (CL) and the up-cut (UC). In case of

helical gears, two additional variations exist, the tool helix

angle () compared to the helix of the gear (h

a

). If the

direction of the gear helix angle is identical to the hob helix

angle the type of the process is set to equi-directional (ED),

if not to counter-directional (CD) one.

As presented in Fig. 2, after the initialization of the input

data the solid geometry of the work gear is created in the

CAD environment and one hob tooth rake face profile is

mathematically and visually formed. At the same moment

the assembly of the effective cutting hob teeth (N) is

determined and the kinematics of gear hobbing process is

directly applied in one three-dimensional tooth gap of the

Fig. 1 Essential parameters of gear hobbing

Int J Adv Manuf Technol

gear due to the axisymetric configuration of the problem.

Moreover, a three-dimensional surface is formed for every

generating position (e.g., successive teeth penetrations),

combining the allocation of the hob and the work gear,

following a calculated spatial spline as a rail. These three-

dimensional surface paths are used to identify the unde-

formed chip solid geometry, to split the subjected volume

and to create finally the chip and the remaining work gear

solid geometries.

3 HOB3D simulation strategy

In this approach every rotation and displacement that is

taking place between the hob and the work gear during the

simulation of the process are directly transferred to the hob. As

presented in Fig. 3, the global coordinate system of the two

parts is fixed to the center of the upper base of the

workpiece, providing a steady reference system to the

travelling hob. The presented scheme of kinematics has

been adopted and in previous numerical approximation

research works, mentioned at the introduction.

Without any loss of generality, the hob is considered to

have a tooth numbered-named: Tooth 0. The identification

vector v

0

of Tooth 0 has its origin C

H

on the Y

h

axis of the

hob and its end at the middle of the rake face, forming a

module that equals to d

h

/2. This vector determines the

direction of the Z

h

axis of the hob coordinate system

X

h

Y

h

Z

h

and is initially placed as an offset of the global

Z-axis, set at a vertical distance L

1

from the origin of the

L

1

: Vertical distance hob - gear

L

2

: Horizontal distance hob - gear

w o r k g e a r

Z

d

E

F

G

H

O

d

f

h

a

Pitch circle

d =

helix

arc of

pitch circle

d

a

/2

2 df sin(h )

a

mz

2

Gear hobbing kinematics

1

: angle Hob rotation

2

: Gear angle rotation

Fig. 3 HOB3D simulation kinematics scheme

CAD based Gear Hobbing Simulation Program HOB3D

*

d

h

: out diameter mm side [ ]

Input Data

H

o

b

G

e

o

m

e

t

r

y

W

o

r

k

g

e

a

r

G

e

o

m

e

t

r

y

C

u

t

t

i

n

g

C

o

n

d

i

t

i

o

n

s

m : module [mm]

z

2

: number of teeth

h

a

: helix angle [deg]

m : module [mm]

n

i

: number of columns

z

1

: number of hob origins

d

g

: outside diameter [mm]

f

a

: axial feed [mm/wrev]

t : depth of cut [mm]

v : [m/min]

Calculations

Generation of Workgear solid geometry

Determination of N effective cutting teeth

Generation of 3D-spline

path of hob tooth

Mathematical description of the hob tooth rake face

workgear

path of a

hob tooth

G

e

a

r

h

o

b

b

i

n

g

p

r

o

c

e

s

s

-

R

e

s

u

l

t

s

3D surface geometrical descriptio

of the hob tooth kinematic

F

o

r

a

c

t

i

v

e

t

e

e

t

h

Computation of the

underformed chip

geometry

...

tooth

profile

spline

tooth revolving

direction

n

solid

...

...

cutting speed

Fig. 2 Flowchart of the

program HOB3D

Int J Adv Manuf Technol

fixed XYZ global system, determining the region where the

cutting starts. Once the simulation parameters are settled,

the work gear solid model is generated and the assembly

of the effective cutting hob teeth is enabled. The moment

that the gear hobbing simulation starts is considered as time

zero. At this time (t =0) the planes YZ and Y

h

Z

h

are parallel

and their horizontal distance, steady for the whole simula-

tion period, is set to: L2 dh=2 dg=2 t. The

distance L

2

practically determines the cutting depth, user

defined as an input parameter. To determine the setting

angle

s

, the X

h

Y

h

Z

h

hob coordinate system is rotated about

the X

h

axis, so that the simulation process becomes

completely prescribed.

Using the spatial vector v

0

, it is easy to compute the

identification vectors v

i

of each of the N effective teeth

relatively to v

0

, taking into account the hob geometrical

CAD based Gear hobbing kinematics

Y

Z

X

Chip solid

geometry

identification

Chip solid geometry

Work

gear

chip cross

section

detail A

h

max

path of a

hob tooth

chip

tooth

c

u

t

t

in

g

p

la

n

e

cutting plane

A

tooth

revolving

position

rake face

n

1i

C

Hi

n

2i

d

h

hob revolving

direction

3d spline

path

work

gear

work

gear

v

i

Fig. 4 Three-dimensional kinematics scheme in the CAD environment

HOB3D algorithmic diagram

Initialization

of input data

Initialization of program

parameters

Mathematical determination

of Vector v

0

Generation

of Work Gear cylinder

Mathematical determination

of spatial vectors

v , (C n ) and (C n )

i H 1 i H 2 i

Application of forward

kinematics to vectors

v , (C n ) and (C n )

i H 1 i H 2 i

Mathematical description of

3D spline points,3D planes

and corresponding profiles

Creation of 3D spline points,

3D planes and profiles,

3D spline trajectory

Generation of i-cutting tooth

3D surface path

Subtraction of i-chips

solid geometry

i = l

i=f

Numerical implementation CAD system implementation

End

N Y

i = i+1

Determination of N effective

cutting teeth

Fig. 5 Algorithmic diagram of

the program HOB3D

Int J Adv Manuf Technol

input parameters. The independent parameter

1

counts the

rotational angle of hob tool about its axis Y

h

during the

cutting simulation. The parameter

2

declares the rotational

angle of the hob tool about the work gear and f

a

the axial feed

of the hob.

2

and f

a

are dependent from

1

and their values

are determined according to the values of

1

angle (see also

the upper part of Fig. 3). The forward kinematics of each of

the N effective cutting hob teeth occur in one gear tooth space

(gap). Hereby, after the determination of v

0

and considering

that the identification vector of the first of the N cutting hob

tooth v

f

is determined relatively to v

0,

the forward kinematics

are firstly applied to v

f

and sequentially to the following

vectors v

i

, until the last cutting hob tooth of the work cycle v

l,

simulating precisely the real manufacturing process.

In case of simulating helical gears fabrication, a

differential angular amount is added on the rotating system

of the gear, in order to increase or decrease the angular

velocity of the rotating workpiece, ensuring the proper

meshing of the hob-cutting and gear-cut angles. Depending

on the type of the hobbing process a new angular parameter

d has to be inserted to the whole kinematical chain for the

acceleration or deceleration of

2

. The calculation of the

parametrical value of d is taking place on the pitch circle

as it is detailed schematically presented in the lower part of

Fig. 3, constituting a section of significant importance.

As illustrated at Fig. 4, the prescribed kinematics chain

is used for the construction of a three-dimensional spline

path in the CAD environment. This spline path occurs from

the interpolation of points generated from the v

i

vector of

the cutting hob teeth, that is properly transformed and

rotated by the help of the simulation parameters

1

,

2

and f

a

. Following the same tactic, the unit vectors (C

H

n

1

)

i

and (C

H

n

2

)

i,

described in the same Figure, are shifted and

rotated for the generation of a plane properly positioned

into the three-dimensional space, for every revolving

position of the i-th cutting tooth.

The profile of the cutting hob tooth is formed on the

two-dimensional space that is created by each one of these

Fig. 6 Maximum chip thickness on the revolving positions of every generating position of a full work cycle

Int J Adv Manuf Technol

spatial planes, as presented in the middle of Fig. 4. By the

proper lofting of the constructed open profiles following the

rail of the constructed spatial spline, a three-dimensional

open surface is created in one gear-gap tooth space. This

surface path represents the generating position of the i-th

cutting tooth and bounds its penetrating volume into the

workpiece. With the aid of this surface path, the solid

geometry of a chip is identified for every generating

position, using the Boolean operations and the graphics

capabilities of the CAD environment. The chip geometry is

restricted by the external volume of the instantly formed

working gear gap, bounded outside the created surface. The

identified solid geometry is then subtracted from the

workpiece leading to the generation of the continuous

three-dimensional solid geometries of the chip and the

remaining work gear. Because of the output form of the

solid resulting parts of the simulation process, any kind of

post-processing is primitively enabled. As can be seen at

the lower right section of Fig. 4 in detail A, the maximum

thickness of an extracted solid geometry of a chip at a

certain revolving position is detected. All of the images

presented in Fig. 4 were captured from the CAD environ-

ment during a simulation performed from HOB3D. The

words, phases and arrows were added afterwards with the

help of commercial image processing software for the better

explanation of the images.

All of the previously mentioned simulation tasks are

controlled by the developed program HOB3D that manipu-

lates the modeling capabilities of the CAD system, forcing

the generation of the geometrical entities in it, collecting the

occurring geometrical data from it, and making all of the

programmed numerical calculations. The continuous interac-

tion of the CAD system with the numerical calculations

environment of the program is algorithmically described at

Fig. 5. After the insertion of the input data from the user the

program parameters are initialized. The work gear cylinder

geometry is generated and the number N of the effective

cutting teeth is computed. The spatial vector v

0

is mathe-

matically determined. The cutting tooth number parameter i

is set to f (first cutting tooth number) and the vector v

i

and

the correspondent unit vectors (C

H

n

1

)

i

and (C

H

n

2

)

i,

essential

for the construction of the spatial planes, are relative to v

0

mathematically determined. The forward kinematics of the

hobbing procedure is applied to these vectors. The resulting

numerical data, prescribing the 3D spline points and the 3D

planes, are used for the generation of the corresponding

entities in the CAD environment. The generated 3Dpoints are

interpolated for the construction of the 3D spline in the CAD

environment. For each created spatial plane, the correspon-

dent tooth profile is mathematically formed and sketched in

the CAD system. The profiles are lofted properly, following

the 3D spline trajectory forming the 3D surface path of the

i-cutting tooth. The solid geometry included in the spatial

surface is subtracted from the work gear and saved as the

i-chip geometry (see the enlargement detail of Fig. 4). The

i-counter takes the value i+1 and the same procedure is

repeated until i became equal to l (last cutting tooth number).

For the reduction of the computational effort and time,

the overall rotation of the hob about its axis Y

h

is restricted

from 0 to 180 degrees (0

1

180) for every generating

position of each effective cutting hob tooth i. This way only

the motions that affect the resulting solid geometries are

taking place, without any influence to the process suffi-

ciency, during the entire simulation process. After the

completion of the sequential construction of every spatial

surface and the subtraction of the chip solid geometries, the

gear gap is generated, formed by the collective work of

every generating position.

m d z n h z t f =5mm, =125mm, =1, =12, =0, =30, =11mm, =4mm/wrev

h 1 i a 2 a

Chip Thickness Development for Up-Cut and Climb Hobbing

Generating Positions

C

h

i

p

T

h

i

c

k

n

e

s

s

0.6

[mm]

0.4

0.3

0.2

0.1

0

-18 14 -2 -10 6

-18

14

-2 -10 6

Up-Cut hobbing Climb hobbing

Generating Positions

Fig. 7 Maximum chip thickness of the generating positions of a full work cycle for UC and CL gear hobbing cases

Int J Adv Manuf Technol

4 HOB3D simulation results

The developed program HOB3D is used for the simulation

of manufacturing of spur and helical gears, and its post-

processing code is used for the determination of the solid

chip thickness development. The proposed program was

verified and validated in a previous research work [18], by

the usage of the resulting three-dimensional solid geome-

tries of the gear gaps generated by HOB3D. These gap

profiles were compared to the standard ones introduced by

Petri [19] and DIN 3972 [20] and the calculated mean error

was less than 10 m for the working depth of produced

gears. Such negligible deviations satisfy the computational

accuracy expectations, and verify the sufficiency of the

developed code.

4.1 Simulation of the manufacturing process of spur gears

HOB3D is used for the simulation of manufacturing of a

spur gear. The input data of the UC case processed and the

output chip solid geometries of every generating position

are presented in Fig. 6. The cutting direction of the hob tool

is indicated at the left of the gigure and the observation of

chips is taking place from the site of the hob. Examining

the three-dimensional solid geometries of the displayed

chips, we see that it is obvious that so much as the extreme

geometrical changes of the chip shapes are sufficiently

determined, even if it is parted from more than one domain.

The developed post-processing code of the program is

used for the maximum thickness measurement of every

chip of the work cycle on each revolving position. Ninety-

one (0 to 90) assigned revolving positions (rp) that belong

to the kinematics of each generating position (gp) are used.

In case of intersection of a spatial plane of an rp with the

solid geometry of the chip, the maximum thickness (h

max

)

is identified and recorded. This sequence leads to the

generation of the maximum thickness diagrams that are

presented below each chip at Fig. 6. As shown in the right

of the diagrams the measurement is taking place at a

number of nineteen revolving positions that range from the

45th to the 63th rp.

For the improvement of the visualization of the resulting

diagrams, Fig. 6 is parted from two sections (upper and

lower). At the upper section of the figure the sixteen first

generated chips are presented, corresponding to the gener-

ating positions 18 to 3. The range of the maximum

thickness at these diagrams is from 0 to 0.6 mm. As can be

observed, the values of the chip thicknesses are close to

zero at the first revolving positions and approach their

maxima close to the end of the chip. If the chip generated at

the position 18 is excluded because of the supreme

thickness value of 0.57 mm that reveals from the chip of

the generating position 17 until 3 the maximum thick-

nesses are oscillating from 0.3 mm to 0.1 mm with a

descending rate. The reduction of the values of the chip

thicknesses holds on and for the chips generated at the

Fig. 8 Schematic representation

of four different gear hobbing

strategies

Int J Adv Manuf Technol

positions 2 to 13. That is the reason why the range of the

diagrams at these next sixteen generating positions (gp: 2

to 13) presented in the lower part of the figure, varies form

0 to 0.1 mm. It can be easily observed that the supreme

values of the chip thicknesses are following the same

descending route as the first sixteen and from the higher

value of 0.1 mm that appears at the generating position 2,

the work cycle stops at the generating position 13, where

the maximum chip thickness value is very close to zero.

The simulation data of the UC case are reused for the

approximation of the results of a CL case by changing only

the sign of the axial feed (f

a

) input. After the evaluation of

the chip solid geometries, the post-processor of HOB3D is

mobilized for the measurement of the maximum chip

thickness, in the same sense that was previously described.

The maximum thicknesses of each generating position are

recorded and plotted to Fig. 7 for both of the UC and CL

cases.

As shown in the two graphs of Fig. 7, the first effective

(penetrating) generating position of both of the cases is the

one prescribed from the cutting hob tooth with i =18 (v

f

=

v

18

). For the UC case the last effective generating position

is the one prescribed from the cutting hob tooth with i =13

(v

l

=v

13

) while for the CL case v

l

=v

14

. Except from the first

generating position of the UC where the measured

maximum chip thickness approximates the value of 0.6

millimetres, it is observed that the measured results for both

of the cases are oscillating in a range of 0 mm to 0.3 mm

approximately. The supreme values of the measured

maximum thicknesses of the UC and CL cases is

0.57 mm at gp=18 and 0.32 mm at gp=14, respectively.

4.2 Simulation of the manufacturing of helical gears

In the case of manufacturing helical gears, four different

hobbing strategies may be prescribed, depending on the

process parameters that will be chosen, as it was thoroughly

described at the HOB3D modeling procedure paragraph.

The schematic representation of these strategies for the

manufacturing process of a helical gear with positive helix

angle (h

a

>0) is presented in Fig. 8.

HOB3D is used for the simulation of manufacturing of a

helical gear with helix angle h

a

=30 by these four

strategies. The values of the input data of the examined

Chip Maximum Thickness Development for UC-CD, CL-CD, UC-ED and CL-ED Hobbing Processes

M

a

x

i

m

u

m

c

h

i

p

t

h

i

c

k

n

e

s

s

M

a

x

i

m

u

m

c

h

i

p

t

h

i

c

k

n

e

s

s

0.52

0.39

0.26

0.13

0

0.52

0.39

0.26

0.13

0

Generating Positions

UC-CD CL-CD

CL-ED UC-ED

-7 22 17 -20 7 -17 -11 -8 -14 -5 -2 1 4 -7 22 -1 5 11 17

m d z n h z t f = mm, =1 mm, =1, = , = , = , = mm, =4mm/wrev 3.82 47 6 30 9.7

h 1 i a 2 a

24

Generating Positions

[mm]

[mm]

Fig. 9 Maximum chip thickness graphical representation of the generating positions of a full work cycle for UC-CD, CL-CD, UC-ED and CL-ED

gear hobbing cases

Int J Adv Manuf Technol

cases are identical for each one of them except from the

tool helix angle () and the axial feed (f

a

). The sign of these

parameters denotes the hobbing strategy of each case, as

presented in Figs. 8 and 9.

After the evaluation of the chip solid geometries for each

one of the four different strategies, the post-processor of

HOB3D is mobilized for the measurement of the maximum

chip thickness, by the same tactic that was formerly

described. The maximum thicknesses of each generating

position are recorded and plotted to Fig. 9 for the UC-CD,

CL-CD, UC-ED and CL-ED test cases.

As shown in the four graphs of Fig. 9, the first effective

(penetrating) generating position of the UC-CD case is the

one prescribed from the cutting hob tooth with i =22 (v

f

=

v

22

) and the last from i =7 (v

l

=v

7

). This is the reason why

the black arrow in the graph is pointing to the left so as to

denote the sequence of the cutting teeth. The same holds for

the CL-CD case were v

f

=v

7

and v

l

=v

20

. This is a result of

the left-hand rotation of the workpiece and the numbering

of the hob tool teeth that is used. As can be seen in the two

graphs of the -ED cases, the arrow is pointing to the reverse

direction (from left to right) because of the right-hand

rotation of the gear and the numbering of the hob tool teeth

that is used. At the UC-ED case v

f

=v

7

and v

l

=v

18

and at

the CL-ED case v

f

=v

20

and v

l

=v

7

.

It should be observed that for all of the four cases the

maximum chip thicknesses are oscillating in the same

range of 0 mm to 0.52 mm, and the supreme value of

each one of them approximates the value of the 0.5 mm.

Also, it should be noted that the diagrams of the UC-CD

case and CL-ED case appear the same behavior of

oscillations and the same holds for the CL-CD and UC-

ED cases.

The 3D chip solid geometries, produced from HOB3D,

for the simulation of the UC-ED gear hobbing process, are

presented in Fig. 10. The input data of the case processed

are presented in the bottom of the Figure. The cutting

direction of the hob tool is indicated at the left of the Figure

and the observation of chips is taking place from the site of

the hob. Examining the three-dimensional solid geometries

of the displayed chips, we find it obvious that so much as

the extreme geometrical changes of the chip shapes are

sufficiently determined, even when the chip is parted from

more than one domain.

m d z n h z t f =3.82mm, =147mm, =1, =6, =30, =24, =9.7mm, =-4mm/wrev, hobbing

h 1 i a 2 a

Up-Cut

mm 0.36 0

R

e

v

o

l

v

i

n

g

P

o

s

i

t

i

o

n

s

60

45

50

55

mm 0.51 0

60

45

50

55

R

e

v

o

l

v

i

n

g

P

o

s

i

t

i

o

n

s

Maximum Chip Thickness Development at succesive Generating Positions

gp: -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5

C

u

t

t

i

n

g

d

i

r

e

c

t

i

o

n

45

7 8 9 10 11 12 13 14 15 16 17 18 6

C

u

t

t

i

n

g

d

i

r

e

c

t

i

o

n

Fig. 10 Maximum chip thickness on the revolving positions of every generating position of a full work cycle of a UC-ED gear hobbing process

Int J Adv Manuf Technol

The developed post-processing code of the program is

used again for the maximum thickness measurement of

every chip of the work cycle on each revolving position.

Ninety-one (0 to 90) assigned revolving positions that

belong to the kinematics of each generating position are

used. In case of intersection of a spatial plane of a revolving

position with the solid geometry of the chip, the maximum

thickness is identified and recorded. This sequence leads to

the generation of the maximum thickness diagrams that are

presented below each chip at Fig. 10. As shown in the right

of the diagrams, the measurement is taking place at a

number of sixteen revolving positions that range from the

45th to the 60th revolving position.

For the improvement of the visualization of the resulting

diagrams, Fig. 10 is parted from two sections (upper and

lower). At the upper section of the figure the first 13

generated chips are presented, corresponding to the gener-

ating positions 7 to 5. The range of the maximum

thickness at the diagrams is from 0 to 0.36 mm. As can

be observed, the values of the chip thicknesses from the

generating position 7 to 5 have an ascending rate and from

a maxima value of 0.025 mm at the gp:7 approach the

value of 0.36 mm at the gp: 5. As can be observed, these

maximum thickness values appear to a position close to the

middle of the successive revolving positions. The increment

of the values of the chip thicknesses holds on and for the

chips generated at the positions 6 to 10. That is the reason

why the range of the diagrams at the next thirteen (gp: 6 to

18) generating positions, presented in the lower part of the

figure varies form 0 to 0.51 mm. It can be observed that

the maximum value of the chip thickness approaches the

supreme value of 0.51 mm at the last revolving position of

the chip generated at the position 10. From the generating

position 11, the maximum thickness values have a descend-

ing order, until the last (gp: 18) where the maximum chip

thickness value is very close to zero.

5 Conclusion

In the current research work, an advanced and validated

simulation program called HOB3D, based on a commercial

CAD environment, was proposed and used for the

simulation of the gear hobbing process, for the manufac-

turing of spur and helical gears. In contradistinction to

former research attempts, in the present investigations, the

kinematics of gear hobbing is directly applied in one-tooth

three-dimensional space by the construction of spatial

surface paths, for every generating position. The kinematics

involves the rotations and displacements of the two rolling

parts (hob and work gear) for every manufacturing case of

gear hobbing process. These three-dimensional surface

paths are used to split the subjected volume and directly

create the chip and the remaining work gear continuous

solid geometries.

Considering the quality and the output format of the

resulting solid geometries enables the direct post-processing

of them for further investigations eliminating the need of

inter or extrapolations required until now. The thicknesses

of the extracted chip solid geometries are measured,

recorded and plotted by HOB3D to graphs for two different

types of spur gear manufacturing and four different types of

the manufacturing of a helical gear. The results of the

present work hold significant industrial and research

interest, including the accurate prediction of dynamic

behavior and tool wear development in gear hobbing

procedure. By the completion of the research work

(prediction of cutting forces, wear, tool failure, etc), and

the fulfilment of the research software HOB3D, it may

constitute a part module of a CAD system.

References

1. Klocke F, Klein A (2006) Tool life and productivity improvement

through cutting parameter setting and tool design in dry high-

speed bevel gear tooth cutting. Gear Technol:4048

2. Rech J (2006) Influence of cutting edge preparation on the wear

resistance in high speed dry gear hobbing. Wear 216/56:505512

DOI 10.1016/j.wear.2005.12.007

3. Rech J, Djouadi MA, Picot J (2001) Wear resistance of coatings in

high speed gear hobbing. Wear 250/Part1:4553

4. Kim DH (2001) Geometry of hob and simulation of generation of

the cylindrical gears by conventional or climb hobbing operation.

Proceedings of the I MECH E Part D Journal of Automobile

Engineering 215/4:533544

5. Fan Q (2006) Computerized modeling and simulation of spiral

bevel and hypoid gears manufactured by gleason face hobbing

process. J Mech Des 128/6:13151327 DOI 10.1115/1.2337316

6. Sulzer G (1974) Leistungssteigerung bei der Zylinderradherstellung

durch genaue Erfassung der Zerspankinematik, Dissertation, TH

Aachen

7. Gutman P (1988) Zerspankraftberechnung beim Waelzfraesen,

Dissertation, TH Aachen

8. Venohr G (1985) Beitrag zum Einsatz von hartmetall Werkzeugen

beim Waelzfraesen, Dissertation, TH Aachen

9. Joppa K (1977) Leistungssteigerung beim Waelzfraesen mit

Schnellarbeitsstahl durch Analyse, Beurteilung und Beinflussung

des Zerspanprozesses, Dissertation, TH Aachen

10. Tondorf J (1978) Erhoehung der Fertigungsgenauigkeit beim

Waelzfraesen durch systematische Vermeidung von Aufbauschneiden,

Dissertation, TH Aachen

11. Antoniadis A (1988) Determination of the impact tool stresses

during gear hobbing and determination of cutting forces during

hobbing of hardened gears, Dissertation, Aristoteles University of

Thessaloniki

12. Antoniadis A, Vidakis N, Bilalis N (2002) Fatigue fracture

investigation of cemented carbide tools used in gear hobbing,

Part I: fem modeling of fly hobbing and computational interpre-

tation of experimental results. ASME J Manuf Sci Eng 124/

4:784791 DOI 10.1115/1.1511172

13. Antoniadis A, Vidakis N, Bilalis N (2002) Fatigue fracture

investigation of cemented carbide tools used in gear hobbing, Part

Int J Adv Manuf Technol

II: the effect of cutting parameters on the level of tool stresses - a

quantitive parametric analysis. ASME J Manuf Sci Eng 124/4:792

798 DOI 10.1115/1.1511173

14. Sinkevicius V (1999) Simulation of gear hobbing geometrical

size. Mechanika (Kaunas University of Technology Journal) 5

(50):3439

15. Sinkevicius V (2001) Simulation of Gear Hobbing forces.

Mechanika (Kaunas University of Technology Journal) 2

(28):5863

16. Komori M, Sumi M, Kubo A (2004) Method of preventing cutting

edge failure of hob due to chip crush. JSME Int J Ser C Mech Syst

Mach Elem Manuf 47(4):11401148

17. Komori M, Sumi M, Kubo A (2004) Simulation of hobbing for

analysis of cutting edge failure due to chip crush. Gear Technol,

6469

18. Dimitriou V, Vidakis N, Antoniadis A (2007) Advanced computer

aided design simulation of gear hobbing by means of 3-

dimensional kinematics modeling. ASME J Manuf Sci Eng 129

\5:911918 DOI 10.1115/1.2738947

19. Petri H (1975) Zahnhu - Analyse bei auenverzahnten Evolventen-

stirnraedern: Teil III Berechnung. Antriebstechnik 14(5):289297

20. DIN 3972 (1992) Bezugsprofile von Verzahnwerkzeugen fuer

Evolventen-Verzahnungen nach DIN 867. Taschenbuch 106,

Beuth Verlag, Berlin

Int J Adv Manuf Technol

You might also like

- Module IV: Gears and Gear TrainsDocument38 pagesModule IV: Gears and Gear TrainsSuraj VinayNo ratings yet

- AGMA gear standard reference guideDocument10 pagesAGMA gear standard reference guideponnivalavans_994423No ratings yet

- Involute Inspection Methods and Interpretation of Inspection ResultsDocument7 pagesInvolute Inspection Methods and Interpretation of Inspection Resultsvijay_khandgeNo ratings yet

- Rating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDocument6 pagesRating of Asymmetric Tooth Gears: Alex L. Kapelevich and Yuriy V. ShekhtmanDavide MaranoNo ratings yet

- Gear DesignDocument83 pagesGear DesignmuhammadaminjamalmutNo ratings yet

- Reverse Engineering of Spur GearDocument4 pagesReverse Engineering of Spur GearInaamNo ratings yet

- APR11 Bearing Software BrochureDocument8 pagesAPR11 Bearing Software BrochureDagim GirmaNo ratings yet

- Gear CorrectionDocument17 pagesGear CorrectionMurugesanNo ratings yet

- Numerical Gerotor DesignDocument18 pagesNumerical Gerotor Designsardhan.rajender84No ratings yet

- GEAR TOOTH PROFILESDocument5 pagesGEAR TOOTH PROFILESpremnathgopinathanNo ratings yet

- Effect of Increased Center Distance on Gear Teeth Contact Ratio and StressDocument21 pagesEffect of Increased Center Distance on Gear Teeth Contact Ratio and StressDavide MaranoNo ratings yet

- Gear Cutting Grinding and Measuring MethodsDocument15 pagesGear Cutting Grinding and Measuring Methodshumayun121No ratings yet

- Catalogue: Grippers & AccessoriesDocument32 pagesCatalogue: Grippers & AccessoriesVladimirAgeevNo ratings yet

- Thermal Lead Correction For High-Speed Gears: Sinto America, IncDocument92 pagesThermal Lead Correction For High-Speed Gears: Sinto America, IncRongbaaz BongNo ratings yet

- Gear TrainDocument16 pagesGear Trainmudassir habibNo ratings yet

- Involute Spline Strength CalculationsDocument1 pageInvolute Spline Strength CalculationsRjgandhi65No ratings yet

- Hob Seminar (English)Document26 pagesHob Seminar (English)RizwanAliNo ratings yet

- Gear Grinding: Software UpdateDocument92 pagesGear Grinding: Software UpdategrazianogirottoNo ratings yet

- 0618 Gearsolutions PDFDocument64 pages0618 Gearsolutions PDFdesetekNo ratings yet

- An Investigation of The Fatigue and Fretting PerformanceDocument19 pagesAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNo ratings yet

- SME Course Review ChecklistDocument1 pageSME Course Review ChecklistAjay BalakrishnanNo ratings yet

- Effective FMEADocument51 pagesEffective FMEAAshok DevarajNo ratings yet

- A Comparison of Current AGMA ISO API Gear Rating Methods PDFDocument84 pagesA Comparison of Current AGMA ISO API Gear Rating Methods PDFNARENDRASINH PARMARNo ratings yet

- Gear TechnologyDocument52 pagesGear TechnologyJithinNo ratings yet

- Gear shaping and shaving process overviewDocument22 pagesGear shaping and shaving process overviewSumesh Vijayan0% (1)

- Kisssoft Tut 015 E BevelgearDocument22 pagesKisssoft Tut 015 E BevelgearJorge Ronald Cabrera ÑaupaNo ratings yet

- ANSI Replaces AGMA Gear Accuracy StandardsDocument5 pagesANSI Replaces AGMA Gear Accuracy StandardsCarlosQuelartNo ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Finite Element Analysis of Spur Gear Set PDFDocument85 pagesFinite Element Analysis of Spur Gear Set PDFCan CemreNo ratings yet

- 4319B - Flank Modifications in Bevel Gears Using A UMCDocument22 pages4319B - Flank Modifications in Bevel Gears Using A UMCRaul PerezNo ratings yet

- 0611 GearSolutionsDocument72 pages0611 GearSolutionspoorianaNo ratings yet

- Fine Boring ToolsDocument39 pagesFine Boring Toolsm_najmanNo ratings yet

- Precision Involute Gear Hob DesignDocument11 pagesPrecision Involute Gear Hob DesignKalyan ChakravarthyNo ratings yet

- Product Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Document598 pagesProduct Catalogue-300M Series Modular Planetary Gearboxes IE2-IE3 - ENG - R02 - 0Dispatch TranstechgearsNo ratings yet

- Rack and Pinion Gears InformationDocument6 pagesRack and Pinion Gears InformationifyNo ratings yet

- Cycloid Drive - Replaced by Planocentric Involute GearingDocument6 pagesCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeNo ratings yet

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFDocument6 pagesCycloid Drive - Replaced by Planocentric Involute Gearing PDFMax GrandeNo ratings yet

- Power Skiving PDFDocument11 pagesPower Skiving PDFmadhavikNo ratings yet

- Hobbing 0406Document6 pagesHobbing 0406feni4kaNo ratings yet

- Design and Analysis of Planetary Gearbox For All-Terrain VehicleDocument10 pagesDesign and Analysis of Planetary Gearbox For All-Terrain VehicleIJRASETPublications100% (1)

- Chuck Missler and The Curse of New Age ChristianityDocument32 pagesChuck Missler and The Curse of New Age ChristianityGregory HooNo ratings yet

- 577A Electrical Transient Interaction Between Transformers and The Power System PART 1Document176 pages577A Electrical Transient Interaction Between Transformers and The Power System PART 1Shailesh Chetty100% (1)

- gt0519 PDFDocument68 pagesgt0519 PDFАндрей ГайнановNo ratings yet

- Emerging Technologies Transform PharmaDocument42 pagesEmerging Technologies Transform PharmaRaja Medical StoreNo ratings yet

- How Hobbing Works: The Generating ProcessDocument1 pageHow Hobbing Works: The Generating ProcessPriyadarshini KrishnaswamyNo ratings yet

- Gear Grinding: SoftwareDocument68 pagesGear Grinding: SoftwareTungNo ratings yet

- Cycloidal Gear Box ProjectDocument17 pagesCycloidal Gear Box ProjectAjay NishadNo ratings yet

- Tseng 2004 Mechanism and Machine TheoryDocument15 pagesTseng 2004 Mechanism and Machine TheoryKhanh VqNo ratings yet

- A Method to Optimize Brass Synchronizer RingDocument6 pagesA Method to Optimize Brass Synchronizer RingaravindhNo ratings yet

- A Crowning Achievement For Automotive ApplicationsDocument10 pagesA Crowning Achievement For Automotive ApplicationsCan CemreNo ratings yet

- Final ReportDocument45 pagesFinal ReportKuppu Raj100% (1)

- Name: Roll No: AssignmentDocument6 pagesName: Roll No: Assignmentigualdi53No ratings yet

- The Application of Bevel GearsDocument6 pagesThe Application of Bevel GearsPrasanth ThiagarajanNo ratings yet

- Spur and Helical Gear Modeling in Pro-EDocument13 pagesSpur and Helical Gear Modeling in Pro-Ek_udhay100% (1)

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeDocument21 pagesDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Designing Parametric Bevel Gears in Catia V5Document21 pagesDesigning Parametric Bevel Gears in Catia V53pherNo ratings yet

- Gleason LTCA ExampleDocument8 pagesGleason LTCA ExamplereddykvsNo ratings yet

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 pageΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskNo ratings yet

- Measurements & Metrology (English)Document29 pagesMeasurements & Metrology (English)Kumar SubramanianNo ratings yet

- 2 Gear BasicsDocument6 pages2 Gear BasicsMohamed Adel RizkNo ratings yet

- Bonfiglioli Geared MotorDocument584 pagesBonfiglioli Geared MotorProdip SarkarNo ratings yet

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesDocument14 pagesCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasNo ratings yet

- Bevel Gear Transmission AnglesDocument6 pagesBevel Gear Transmission AnglesNabende UmarNo ratings yet

- Stress Reduction in Spur Gears Using Aero-Fin Shaped HolesDocument11 pagesStress Reduction in Spur Gears Using Aero-Fin Shaped HolesJojee MarieNo ratings yet

- Fittolerences (Read Only)Document10 pagesFittolerences (Read Only)ankitsarvaiyaNo ratings yet

- Manual S2LATDocument40 pagesManual S2LATGabriel MariusNo ratings yet

- Concentricity - GD&T BasicsDocument7 pagesConcentricity - GD&T BasicsGabriel MariusNo ratings yet

- Fastener HandoutDocument32 pagesFastener HandoutRaifan RaizerNo ratings yet

- BGS CursuriDocument63 pagesBGS CursuriGabriel MariusNo ratings yet

- Teme Referate TN2016 BDocument1 pageTeme Referate TN2016 BGabriel MariusNo ratings yet

- 15 Toughest Interview Questions and Answers!: 1. Why Do You Want To Work in This Industry?Document8 pages15 Toughest Interview Questions and Answers!: 1. Why Do You Want To Work in This Industry?johnlemNo ratings yet

- NASA-Reference Publication-1228-Fastener Design ManualDocument98 pagesNASA-Reference Publication-1228-Fastener Design ManualCharles B Godreau100% (2)

- BGS CursuriDocument63 pagesBGS CursuriGabriel MariusNo ratings yet

- Saptamana 7Document17 pagesSaptamana 7Gabriel MariusNo ratings yet

- Residual Stress Modeling in Machining ProcessesDocument186 pagesResidual Stress Modeling in Machining ProcessespptmnltNo ratings yet

- Output LogDocument3 pagesOutput LogGabriel MariusNo ratings yet

- Emuk Werkzeugmaschinen GMBH: Karlheinz Jung +49-7246-1392 Germany English, GermanDocument1 pageEmuk Werkzeugmaschinen GMBH: Karlheinz Jung +49-7246-1392 Germany English, GermanGabriel MariusNo ratings yet

- Wankel (Rotary) Engines: By: Hoa ChuDocument8 pagesWankel (Rotary) Engines: By: Hoa ChuGabriel MariusNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentGabriel MariusNo ratings yet

- Tensiuni Remanente (Eng)Document8 pagesTensiuni Remanente (Eng)Gabriel MariusNo ratings yet

- Whats New NX9.0.0 PDFDocument792 pagesWhats New NX9.0.0 PDFJesus Cruz SalvadorNo ratings yet

- Lecture 10Document49 pagesLecture 10Raja Waseem Sajjad BhattiNo ratings yet

- CHCCCS011 Student Assessment Theory Task 06122020Document28 pagesCHCCCS011 Student Assessment Theory Task 06122020周雪儿No ratings yet

- FEA Information Engineering Solutions June 2012Document68 pagesFEA Information Engineering Solutions June 2012ramsinntNo ratings yet

- Datasheet SimSci HEXTRAN PDFDocument3 pagesDatasheet SimSci HEXTRAN PDFHector ReNo ratings yet

- GSM Static SimulationsDocument24 pagesGSM Static Simulationstest321yNo ratings yet

- Implementing ADM1 For Plant-Wide Benchmark Simulations in Matlab/SimulinkDocument9 pagesImplementing ADM1 For Plant-Wide Benchmark Simulations in Matlab/SimulinkOmar AlmonteNo ratings yet

- Statistical Thinking v4 3Document67 pagesStatistical Thinking v4 3Tekalign FekaduNo ratings yet

- 20200811123634-M.Tech. Environmental EngineeringDocument9 pages20200811123634-M.Tech. Environmental Engineeringashish kumarNo ratings yet

- Tools for Tour GuidingDocument44 pagesTools for Tour Guidingleonardo vidal tovarNo ratings yet

- ProtaStructure Suite 2020 - Whats - NewDocument63 pagesProtaStructure Suite 2020 - Whats - NewgumimacithjNo ratings yet

- Customer Course CatalogDocument97 pagesCustomer Course Cataloglxd.hepNo ratings yet

- Dae Folder 2018Document40 pagesDae Folder 2018Brian KennedyNo ratings yet

- Process Modelling For SimulationDocument14 pagesProcess Modelling For SimulationNetti Siska NurhayatiNo ratings yet

- On The Rig Drilling SystemsDocument10 pagesOn The Rig Drilling Systemscippolippo123No ratings yet

- Emergency Steering Evasion Assistance Control Based On Driving Behavior AnalysisDocument19 pagesEmergency Steering Evasion Assistance Control Based On Driving Behavior AnalysisDRISHYANo ratings yet

- Model a TCP/IP WAN with OPNETDocument13 pagesModel a TCP/IP WAN with OPNETHong BaoNo ratings yet

- MTID322 Lab2 W21Document7 pagesMTID322 Lab2 W21ronyNo ratings yet

- HALP White PaperDocument13 pagesHALP White PaperBerry KueteNo ratings yet

- Simscape GsDocument32 pagesSimscape GsWeiNo ratings yet

- Scorbot-Er 4U Educational RobotDocument2 pagesScorbot-Er 4U Educational RobotJosé Manuel MoaNo ratings yet

- Zenon Driver ManualDocument50 pagesZenon Driver ManualTarang BorichaNo ratings yet

- Lammps Users ManualDocument1,191 pagesLammps Users ManualLuis Maria Pizarro Etchegoyen0% (1)

- Mathematical Modeling and Models For Optimal Decision-Making in Health CareDocument178 pagesMathematical Modeling and Models For Optimal Decision-Making in Health Careultimatekp144No ratings yet

- 12D110009 - 0 PDFDocument1 page12D110009 - 0 PDFPiyush DivyankarNo ratings yet

- ManipulationDocument107 pagesManipulationirteza_faruqiNo ratings yet