Professional Documents

Culture Documents

Hi 1.6 (2000)

Uploaded by

mishraenggOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hi 1.6 (2000)

Uploaded by

mishraenggCopyright:

Available Formats

\/

ANSI/HI 1.6-2000

American National Standard for

Centrifugal Pump Tests

Sponsor

Hydraulic Institute

www.pumps.org

Approved October 27, 1999

American National Standards Institute, Inc.

f l

4

American

National

8tandard

Published By

Approval of an American National Standard requires verification by ANSI that the

requirements for due process, consensus and other criteria for approval have been met

by the standards developer.

Consensus is established when, in the judgement of the ANSI Board of Standards

Review, substantial agreement has been reached by directly and materially

interests. Substantial agreement means much more than a simple majority, but not nec-

essarily unanimity. Consensus requires that all views and objections be considered,

and that a concerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence does

not in any respect preclude anyone, whether he has approved the standards or not,

from manufacturing, marketing, purchasing, or using products, processes, or proce-

dures not conforming to the standards.

The American National Standards Institute does not develop standards and will in no

circumstances give an interpretation of any American National Standard. Moreover, no

person shall have the right or authority to issue an interpretation of an American

National Standard in the name of the American National Standards Institute. Requests

for interpretations should be addressed to the secretariat or sponsor whose name

appears on the title page of this standard.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at

any time. The procedures of the American National Standards Institute require that

action be taken periodically to reaffirm, revise, or withdraw this standard. Purchasers of

American National Standards may receive current information on all standards by call-

ing or writing the American National Standards Institute.

Hydraulic Institute

9 Sylvan Way, Parsippany, NJ 07054-3802

www.pumps.org

Copyright 2000 @ Hydraulic Institute

AII rights reserved.

No publication may be reproduced in any form,

in an electronic retrieval system or otherwise, without prior

written permission of the publisher.

Printed in the United States of America

ISBN 1-880952-30-0

\

(

/\

\-. ...-

Contents

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. v

Page

1.6

1.6.1

1.6.2

1.6.3

1.6.4

1.6.5

1.6.6

1.6.7

1.6.8

1.6.9

1.6.10

1.6.11

1.6.12

1.6.13

1.6.14

Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

Types of tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 1

Hydrostatic test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Net positive suction head required test (optional). . . . . . . . . . . . . . . 19

Mechanical test (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Priming time test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Measurement of rate of flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Head - measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 30

Speed measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Temperature measurement and instruments . . . . . . . . . . . . . . . . . . 32

Model tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

\d

) Appendix A References.......................................... 35

Appendix B Index.............................................. 36

Figures

1.113 - Horizontal unit - (Single or double suction)

(Double suction not shown) . . . . . . . . . . . . . . . . . . . . . .

1.114 - Vertical single suction pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

double suction pump .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Test with suction lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 11

or closed tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 13

performance (all data is corrected to rated speed) . . . . . . . . .. 16

1.119 - Suppression type NPSH test with constant level sump. . . . . . . . . . .. 19

1.120 - Level control NPSH test with deep sump supply. . . . . . . . . . . . . . . . . 20

1.121 - Vacuum and/or heat control NPSH test with closed loop . . . . . . . . . . 20

1.122 - NPSH test with rate of flow held constant . . . . . . . . . . . . . . . . . . . . . . 21

NPSH test with suction head held constant. . . . . . . . . . . . . . . . . . . . . 21

1.124 - NPSH test with flow rate held constant . . . . . . . . . . . . . . . . . . . . . . . . 22

1.125 - Suction line for static lift test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.126 - Pressure tap opening ..................................... 26

.

l

.

l

-l

1.127 - Welded-on pressure tap opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.128 - Single tap connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

manifold connecting pressure taps. . . . . . . . . . . . . . . . . . . . . . . 30

1.130 - Gauge connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Tables

2

1.19 - Subscripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3

1.20 - Recommended instrument calibration interval .. . . . . . . . . . . . . . . . .. 12

Straight pipe required following any fitting before venturi meter

in diameters of pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Straight pipe required following any fitting before nozzle or

orifice plate meter in diameters of pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.23 - Straight pipe required following downstream pressure tap of

a nozzle or orifice plate meter before any fitting in diameters of pipe . . . . . . .. 28

IV

/\

Foreword (Not part of Standard)

Purpose and aims of the Hydraulic Institute

The purpose and aims of the Institute are to promote the continued growth and

well-being of pump manufacturers and further the interests of the public in such

matters as are involved in manufacturing, engineering, distribution, safety, trans-

and other problems of the and to this end, among other things:

a) To develop and publish standards for pumps;

b) To collect and disseminate information of value to its members and to the

public;

c) To appear for its members before governmental departments and agencies

and other bodies in regard to matters affecting theindustry;

increase the amount and to improve the quality of pump service to the public;

e) To and research activities;

f) To promote the business interests of its members but not to engage in busi-

ness of the kind ordinarily carried on for profit or to perform particular services

for its members or individual persons as distinguished from activities to

improve the business conditions and lawful interests of all of its members.

Purpose of 5tandards

1) Hydraulic Institute Standards are adopted in the public interest and are

designed to help eliminate misunderstandings between the manufacturer,

the purchaser and/or the user and to assist the purchaser in selecting and

obtaining the proper product for a particular need.

2) Use of Hydraulic Institute Standards is completely voluntary. Existence of

Hydraulic Institute Standards does not in any respect preclude a member

from manufacturing or selling products not conforming to the Standards.

Definition of a 5tandard of the Hydraulic Institute

Quoting from Article XV, Standards, of the By-Laws of the Institute, Section B:.

An Institute Standard defines the product, material , process or procedure with

reference to one or more of the following: nomenclature, composition, construc-

tion, dimensions, tolerances, safety, operating characteristics, performance, qual-

ity, rating, testing and service for which designed."

Comments from users

Comments from users of this Standard will be appreciated, to help the Hydraulic

Institute prepare even more useful future editions. Questions arising from the con-

tent of this Standard may be directed to the Hydraulic Institute. It will direct all

such questions to the appropriate technical committee for provision of a suitable

answer.

If a dispute arises regarding contents of an Institute publication or an answer pro-

vided by the Institute to a question such as indicated above, the point in question

shall be referred to the Executive Committee of the Hydraulic Institute, which then

shall act as a Board of Appeals.

V

Revisions

The Standards of the Hydraulic Institute are subject to constant review, and revi-

sions are undertaken whenever it is found necessary because of new develop-

ments and progress in the art. If no revisions are made for five years, the

standards are reaffirmed using the ANSI canvass procedure.

Scope

This Standard is for centrifugal , sealless centrifugal and regenerative turbine

pumps of all industrial types except vertical multistage diffuser type. It includes

detailed procedures on the setup and conduct of hydrostatic and performance

tests of such pumps.

Several methodologies to test centrifugal and vertical pump equipment are avail-

able to pump manufacturers, users and other interested parties. The United

States has two sets of pump test standards which approaches to

conducting and evaluating pump One, promulgated by the American

Society of Mechanical Engineers (ASME) and designated PTC 8.2, Centrifugal

Pumps, provides for two levels of tests in which the test procedures are less

restrictive. The ASME Code relies on the to the test to agree beforehand

on the Scope and Conduct of the test and does not specify how the test results

shall be used to compare with guarantee. The ASME is especially suited to highly

detailed pump testing, whereas HI Standards detail test scope, conduct and

acceptance criteria, and are thus suited to commercial test practices. ASME

Codes do not permit the use of acceptability tolerances in reporting results, while

the HI Standards do. It is recommended that the specifier of the test standard

become familiar with both the ASME Code and the HI Standards before selecting

the one best suited for the equipment to be tested, since there are a number of

other differences between the two which may the accuracy or cost of the

tests.

80th the ASME and HI Standards can be used for testing in either field or factory

installations. The detailed requirements of the ASME Test Code are intended to

reduce the effect of various installation arrangements on performance results and

are applied more to field testing. The HI Standard specifies test piping and more

controllable conditions which is more suitable to factory testing. The HI Standards

do not address field testing. Surveys have shown that both ASME and HI Stan-

dards have been applied successfully to applications from small chemical pumps

(1 hp) to large utility pumps (over 5000 hp).

Units of Measurement

Metric units of measurement are used; and corresponding US units appear in

brackets. Charts, graphs and sample calculations are also shown in both metric

and US units.

Since values given in metric units are not exact equivalents to values given in US

units, it is important that the selected units of measure to be applied be stated in

reference to this standard. If no such statement is provided, metric units shall govern.

VI

/'

/

J

/

Consensus for this standard was achieved by use of the Canvass

Method

The following organizations, recognized as having an interest in the standardiza-

tion of centrifugal pumps were contacted prior to the approval of this revision of

the standard. Inclusion in this list does not necessarily imply that the organization

concurred with the submittal of the proposed standard to ANSI.

A. R. Wilfley & Sons

ANSIMAG Inc.

Bechtel Corp

Black & Veatch

Brown & Caldwell

Camp Dresser & McKee, Inc.

Carver Pump Company

Cheng Fluid Systems, Inc.

Crane Company, Chempump Div.

Cuma S.A.

Dean Pump Div. , Metpro Corp.

DeWante & Stowell

Dow Chemical

EnviroTech Pumpsystems

Essco Pump Division

Exeter Energy Ltd. Partnership

Fairbanks Morse Pump Corp.

Fluid Sealing Association

Franklin Electric

GKO Engineering

Grundfos Pumps Corp.

lII inois Dept. of Transportation

IMC - Agrico Chemical Corp.

Ingersoll. Dresser Pump Company

ITT Fluid Handling (B & G)

ITT Fluid Technology

T Industrial Pump Group

Iwaki Walchem Corp.

J.P. Messina Pump & Hydr. Cons

John Crane, Inc.

Krebs Consulting Service

KSB, lnc.

M.W. Kellogg Company

Malcolm Pirnie, Inc.

Marine Machinery Association

Marley Pump Company

Marshall Engineered Products

Company

Montana State University

MWI , Moving Water Industries

Oxy Chem

Pacer Pumps

Paco Pumps, Inc.

Pinellas Cty, Gen. Serv. Dept.

The Process Group, LLC

Raytheon Engineers & Constructors

Reddy-Buffaloes Pump, Inc.

Robert Bein, Wm. Frost & Assoc.

Scott Process Equipment Corp.

Settler Supply Company

Skidmore

South Florida Water Mgmt. Dist.

Sta-Rite Industries, Inc.

Sterling Fluid Systems (USA), Inc.

Stone & Webster Engineering Corp.

Sulzer Bingham Pumps, Inc.

Summers Engineering, Inc.

Systecon, Inc.

Val-Matic Valve & Mfg. Corp.

Yeomans Chicago Corp.

Zoeller Engineered Products

VII

This page intentionally blank.

/ ~ \ l

~

/ ' \

1.6 Test

1.6.1 5cope

This standard is limited to the testing of centrifugal

pumps with clear water. The tests conducted under

these standards shall be made and reported by quali-

fied personnel.

This standard only applies to tests of the pump unless

stated otherwise.

The type of test(s) performed, and the auxiliary equip-

ment to be used, should be agreed upon by the pur-

chaser and manufacturer prior to the test.

It is not the intent of this standard to limit or restrict

tests to only those described herein. Variations in test

procedures may exist without violating the intent of this

standard. Exceptions may be taken if agreed upon by

the parties involved without sacrificing the validity of

the applicable parts of this standard.

This standard is intended to provide uniform proce-

dures for hydrostatic, hydraulic, and mechanical per-

formance testing of centrifugal pumps and recording of

\-./. the test results. This standard is intended to define test

procedures which may be invoked by contractual

agreement between a purchaser and manufacturer. It

is not intended to define a manufacturer's standard

practice

... /

1.6.2 Types of tests

This standard describes the following tests:

a) Performance test to demonstrate hydraulic and

mechanical integrity;

Optional tests as follows when specified:

b) Hydrostatic test of pressure-containing components;

c) Net positive suction head required test (NPSHR

test);

d) Mechanical test;

e) Priming time test.

For airborne sound testing see HI 9.1-9.5-2000,

Pumps - General Guidelines.

HI Centrifugal Pump Tests - 2000

1.6.2.1 Test conditions

Unless otherwise specified, the rate of flow, head, effi-

ciency, NPSHR and priming time are based on shop

tests using water corrected to 20

0

C (68

0

F). If the facil-

ity cannot test at rated speed because of limitations in

power, electrical frequency or available speed chang-

the pump may be tested at between 80% and

120% of rated speed. It is permissible on pumps

greater than 225 kw (300 hp) to test at speeds

between 60% and 140% of rated speed.

1.6.3 Terminology

The following terms are used to designate test param-

eters or are used in connection with pump testings:

1.6.3.1 5ymbols

See Table 1 .18.

1.6.3.2 5ubscripts

See Table 1.19.

1.6.3.3 5pecified condition point

Specified condition point is synonymous with rated

condition point.

1.6.3.4 Rated condition point

Rated condition point applies to the rate of flow, head,

speed, NPSH and power of the pump as specified by

the purchase order

1.6.3.5 Normal condition point

Normal condition point applies to the rate of flow,

head, speed, NPSH and power at which the pump will

normally operate. It may be the same as the rated con-

dition point.

1.6.3.6 Best efficiency point (BEP)

The rate of flow and head at which the pump effi :iency

is a maximum.

1.6.3.7 5hut

The condition of zero flow where no liquid is flow-

ing through the pump, but the pump is primed and

operating.

1\.)

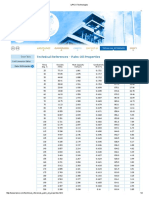

Table 1.18 - Symbols

Conversion

Symbol Term Metric unit Abbreviation US Customary Unit Abbreviation factor

a

A Area square millimeter mm

L

square inches in

L

645.2

(beta) Meter or orifice ratio dimensionless dimensionless

D Diameter millimeter mm inches In 25.4

(delta) Difference dimensionless dimensionless

percent % percent %

g Gravitational acceleration meter/second/sq uared m/s

2

feetlsecond/sq uared ftlsec

2

0.3048

y(gamma) Specific weight pounds/cubic foot

h Head meter feet R 0.3048

H Total head meter feet R 0.3048

n Speed revolutions/minute rpm revolutions/minute rpm

NPSHA Net positive suction head meter feet

0.3048

available

NPSHR Net positive suction head meter m feet R 0.3048

required

NS Specific speed NS = nQYo/H% dimensionless dimensionless 1.162

v (nu) Kinematic viscosity millimeter squared/sec feet squared/second ft2/

sec 92,900

pi = 3.1416 dimensionless dimensionless

p Pressure kilopascal kPa pounds/square inch pSI 6.895

P Power kilowatt kW horsepower hp 0.7457

q Rate offlow cubic meter/hour m

3

/h cubic feetlsecond

101.94

Q Rate offlow cubic meter/hour m

3

/h US gallons/minute gpm 0.2271

p (rho) Density kilogram/cubic meter kg/m

3

pound mass/cubic foot Ibm/ft

3

16.02

s Specific gravity dimensionless dimensionless

Temperature degrees Celsius

degrees Fahrenheit

CF-32) x %

Torque Newton - meter N.m pound-feet Ib-ft 1.356

V Velocity meter/second m/s feetlsecond ftlsec 0.3048

X Exponent none none none none

Z Elevation gauge distance above meter feet 0.3048

or below datum

a Conversion factor x US units = metric units.

1.6.3.8 Volume

The unit of volume shall be one of the following:

Metric: cubic meter;

US units: US gallon;

US units: cubic foot.

The specific weight of water at a temperature of 20

0

C

(68

0

F) shall be taken as 9.89 kN/m

3

(62.3 IbIft

3

). For

other temperatures, proper specific weight corrections

shall be made using values from the ASME steam

tables.

1.6.3.9 Rate offlow (capacity) (Q)

The rate of flow of a pump is the total volume through-

put per unit of time at suction conditions. It assumes

no entrained gases at the stated operating conditions.

1.6.3.10 Speed (n)

The number of revolutions of the shaft in a given unit

of time. Speed is expressed as revolutions per minute

HI Centrifugal Pump

1.6.3.11 Datum

The reference line or center of the pump shaft from

which all elevations are measured. The elevation head

(Z) to the datum is positive when the gauge is above

datum and negative when the gauge is below datum.

The datum elevation is defined as follows:

For horizontal units, it shall be the centerline of the

pump shaft, Figure 1.113.

For vertical single suction pumps, it shall be the

entrance eye to the first stage impeller, Figure

1.114.

For vertical double suction pumps, it shall be the

center of the 1.115.

1.6.3.12 Head (h)

Head is the expression of the energy content of the liq-

uid referred to a datum. It is expressed in units of

energy per unit weight of liquid. The measuring unit for

head is meter (feet) of liquid:

Table 1.19 - Subscripts

Subscript Term Subscript Term

Test condition or model Motor

2 Specific condition or prototype ot Operating temperature

a Absolute OA Overall unit

Atmospheric p Pump

b Barometric S Suction

d Discharge Theoretical

dvr Driver input V Velocity

g Gauge vp Vapor pressure

max Maximum W Water

mm Minimum

3

HI Centrifugal Pump Tests - 2000

and datum elevation

Figure 1.113 - Horizontal unit - (Single or double

suction) (Double suction not shown)

Pump centerline

Figure 1.114 - Vertical single suction pump

Pump centerline

Figure 1.115 - Vertical double suction pump

4

1.6.3.12.1 Gauge head (hg)

The pressure energy of the Ii quid determined by a

pressure gauge or other pressure measuring device.

(Metric) hg

9.8s

(Pg)

(US units) h(J = "v'

r s

1.6.3.12.2 Velocity head (hv)

The kinetic energy of the liquid at a given section.

Velocity head is expressed by the following equation:

h..

v 2(g)

1.6.3.12.3 Elevation head (Z)

The potential energy of the liquid due to its elevation

relative to a datum level , measured to the Iiquid sur-

face or center of the pressure gauge.

1.6.3.12.4 Total suction head (hs)

The total suction head is the algebraic sum of the suc-

tion gauge head, the suction velocity head, and the

suction elevation head:

hs = h_ + h.. + Z_

.S

The gauge head is positive when the suction ga,uge

reading is above atmospheric pressurE; and negative

when the reading is below atmospheric pressure.

The velocity head is computed for the liquid velocity at

the point of gauge attachment.

On pumps submerged in an open sump or open wet

well , where the suction piping is considered

pump:

hs = Zw

Where:

Zw = Vertical distance of the sump free water

surface from datum.

--<

\

1.6.3.12.5 Total suction lift

When the total suction head is negative, it is often

called total suction lift.

1.6.3.12.6 Total discharge head (h

d

)

The total discharge head is the algebraic sum of the

discharge gauge head, discharge velocity head, and

the discharge elevation head. It is computed for the

liquid velocity at the discharge pressure tap, and the

elevation head Zd' measured at the pressure gauge:

h.... = h_ +h.. +Z

d - "gd ' "vd

1.6.3.12.7 Total head (H)

This is the measure of the work increase per unit

weight of the liquid, imparted to the liquid by the pump,

and is therefore the algebraic difference between the

total discharge head and the total suction head.

a) Where positive suction head exists, the total head

is the total discharge head minus the total suction

head:

H = hd-h

s

or

H=(hgd+hvd+Zd)(hgs+hvs+Zs)

Combining terms, the general expression for total

head is:

H=(hgd-hgs)+(hvd-hvs)+(Zd-Zs)

pumps submerged in sumps:

H = h_ +h"

:1 d Vd

c) Where negative suction head exists, the total head

is the total discharge head plus the total suction

lift.

Since the complete characteristics of a pumping sys-

tem determine the total head requirements, this value

can only be specified by the user.

1.6.3.12.8 Atmospheric head (h

atm

)

Local atmospheric pressure expressed in meters

(feet).

HI Centrifugal Pump Tests - 2000

1.6.3.12.9 Effects of compressibility of liquid on

total head

In the preceding formulas, the work accomplished in

compressing the liquid has been ignored. To evaluate

the total head more accurately when pumping to high

pressure, this factor should be taken into consider-

ation. For most liquids, it may be assumed that a

straight line relationship exists between pressure and

volume. With this assumption, the above total head

formula becomes:

H =

It is suggested that this relationship be used if the

ference between Yd and near best point,

is 0.2% or more.

Example: (Metric) Correction of total head for com-

pressibility. Given Water Conditions:

t

s

= 177

0

C (suction temperature);

Ps = 1380 kPa (suction pressure);

t

d

= 182

0

C (discharge temperature);

Pd = 32400 kPa (discharge pressure);

At suction conditions:

Ps = 1480 17rC

From steam tables, Suction specific volume = 890.5

kg/m

3

At discharge conditions:

Pd = 32500 kPa; t

d

= 182

0

C

From steam tables, Discharge specific volume =

904.5 kg/m

3

Specific volume = 1/specific weight = 1/ythen:

5

HI Centrifugal Pump Tests - 2000

This value should be added to the terms:

(hvd hvs)and (Zd Zs)

to obtain the total head.

Example: (US units) Correction of total head for

compressibility. Given Water Conditions:

t

s

= 350

0

F (suction temperature);

Ps = 200 psig (suction pressure);

t

d

= 360

0

F (discharge temperature);

Pd = 4700 psig (discharge pressure);

Reference: Keenan and Keys, Steam Ther-

modynamic Properties of Water, John Wiley and

Sons, lnc.

At suction conditions:

Ps = 215 350

0

F

From steam tables, Suction specific volume =

.01800 ft3/lb

At discharge conditions:

Pd = 4715 360

0

F

From steam tables, Discharge specific volume =

Specific volume = 1/specific weight = 1/ythen:

(.01772 + .01800)

2=11,57O ft

value should be added to the terms:

(hll.-h

ll

) and

a .5

to obtain the total head.

6

1.6.3.12.10 Net positive suction head available

(NPSHA)

Net positive suction head available (NPSHA) is the

total suction head of liquid absolute, determined at the

suction nozzle and referred to datum, less the abso-

lute vapor pressure of the liquid in head of liquid

pumped:

NPSHA = - h"n

-a

Where:

h ", = Total suction head in Meters (feet) absolute

-a

= hatm+h

s

or

NPSHA = hatm+hs-hvp

Example: (Metric) A four-stage boilerfeed pump

having a 100-mm inside diameter suction and a 75-

mm inside diameter discharge is rated at a flow rate

of 91 m

3

/h against a total head of 274 m handling

water at 116

0

C, and running at 3550 rpm. The suc-

tion gauge reading is 145 kPa and the gauge center

location is 0.15 m below impeller inlet datum, and

atmospheric pressure is 98 kPa.

To calculate the net positive suction head available

(NPSHA) to the pump in the field:

1000

NPSHA P,m) + h",

(gxp)' a

P

vp

= 172 kPa (from steam tables)

y = Specific weight = 947.3 kg/m

3

Velocity in the 100-mm inside diameter suction:

v=

91

= 3.2 m/s

.,2

Velocity head (h

v

) =

5' 2g

m

n/- FO nu

--

n

u

q

u

s

v

h

:38 .S

r=\

( 1000

h_ = 144.8xl IVVV 1+0.52-0.15 = 16.2 m

s - \..947.3 x 9.81)

\-.-/

1000

NPSHA = ,... ,, (98-172) + 16.2 = 8.2 m

9.81 x 947.3

(US units) A four-stage boiler feed pump

having a 4-inch inside diameter suction and a 3-

inch inside diameter discharge is rated at a flow

rate of 400 gpm against a total head of 900 feet

handling water at 240

o

F, and running at 3550 rpm.

The suction gauge reading is 21 psig, the gauge

center location is 0.5 feet below impeller inlet

datum, and atmospheric pressure is 29 inches Hg.

29 13.6

P", tm = 29" of Hg 14.2 psia

:J LfTI 12 2.31

NOTE: specific gravity of 13.58 and

ft of liquidx s

P

atm

in psi

rm ... ,..._. 2.31

To calculate the net positive suction head available

(NPSHA) to the pump in the field:

144

NPSHA=7(Pa Pvp)+hs

P

vp

= 25.0 psia (from steam tables)

y = Specific weight = 59.1 Ib/ft

3

Velocity in the 4-inch inside diameter suction:

400 x .321

10.2 ftlsec

:(4)2

,,2

Velocity head (hv)

s' 2g

1.6 feet

s 2 x 32.2

h_=h_+h..+Z_

21 x 144

= 52.3 feet

59.1

144

NPSHA 14.2 - 25.0) + 52.3 = 26.1 feet

59.1

(NPSHR)

Net positive suction head required

Net positive suction head required (NPSHR) is the

total suction head of liquid absolute determined at the

first stage impeller datum less the absolute vapor

HI Centrifugal Pump

pressure of the liquid in head of liquid pumped,

required to prevent more than 3% loss in total head

from the first stage of the pump at a specific rate of

flow.

1.6.3.13 Power (P)

1.6.3.13.1 Pump input power (P

p

)

The power delivered by the driver to the pump input

shaft. It is also called brake horsepower.

1.6.3.13.2 Electric driver input power (P mot)

The electrical input to the driver expressed in kilowatls

(horsepower).

1.6.3.13.3 Pump output power (Pw)

The power imparted to the liquid by the pump. It is also

called water horsepower.

QxHxs

(Metric) P w

367

QxHxs

(US units) P w

w 3960

1.6.3.13.4 Pump efficiency (llp)

The ratio of the pump output power (Pw) to the pump

input power (P

p

); that the ratio of the liquid horse-

power to the brake horsepower expressed in percent:

100

.p

1.6.3.13.5 Overall efficiency (1l 0A)

The ratio of the pump output power (Pw) to the energy

supplied to the driver (Pmot) expressed in percent. This

takes into account losses in both the pump

and the driver:

p

x 100

mot

1.6.4 Hydrostatic test

1.6.4.1 Hydrostatic test objective

To demonstrate that the pump when subjected to

hydrostatic pressure(s) will not leak or fail structurally.

For purposes of this requirement, the containment of

liquid means only prevention of its escape through

7

HI Centrifugal Pump Tests - 2000

the external surfaces of the pumps, normally to

atmosphere.

1.6.4.2 Hydrostatic test parameters

Each part of the pump which contains liquid under

pressure shall be capable of withstanding a hydro-

static test at not less than the greater of the following:

150% of the pressure which would occur in that

part when the pump is operating at rated condi-

tion for the given application of the pump, except

thermoset

125% of the pressure which would occur in that

part when the pump is operating at rated speed for

a given application, but with the pump discharge

valve closed.

Due to the irreversible damage that can occur to the

reinforcement of thermoset parts that are put under

excessive pressure, hydrostatic test pressure shall be

1.1 times the maximum design pressure. The manu-

facturer should be able to verify through test records

that adequate sampling was done to prove that the

can sustain 1.5 times the design pressure. When

a 1.5 hydrostatic test pressure on thermoset parts is

requested, all parties should agree to the conse-

quences of possible irreversible damage.

In all instances, suction pressure must be taken into

account.

8

Components or assembled pumps: The test shall

be conducted on either the liquid-containing com-

ponents or the assembled pump.

Components: The test shall be conducted on the

liquid-containing components such as the casing

and end covers. Care must be taken not to impose

pressure in excess of 150% of design on areas

designed for lower pressure operation. Test

flanges or cylinders can be used for isolating dif-

ferential pressure.

Assembled pump: The test shall be conducted on

the entire liquid-containing area of the pump, but

care must be taken not to impose pressure in

excess of 150% of design on areas such as suc-

tion volutes or mechanical seal areas.

Test duration: Test pressure shall be maintained

for a sufficient period of time to permit complete

examination of the parts under pressure. The

hydrostatic test shall be considered

when no leaks or structural failure are observed

for a minimum of 3 minutes for pumps 75 kW (100 /"\

horsepower) and below, or 10 minutes above

75 kW (100 horsepower).

Test Iiquid: Test liquid shall be water or oil having a

maximum viscosity of 32 Cst (150 SSU) at test

temperature.

Temperature: If the part tested is to operate at a

temperature at which the strength of material is

below the strength of the material at room temper-

the hydrostatic test pressure shall be multi-

plied by a factor obtained by dividing the allowable

working stress for the material at room tempera-

ture by that at operating temperature. This pres-

sure thus obtained shall then be the minimum

pressure at which hydrostatic pressure shall be

performed. The data sheet shall list the actual

hydrostatic test pressure.

1.6.4.3 Hydrostatic test procedure

Items to be tested shall have all the openings ade-

quately sealed. Provisions shall be made to vent all

the air at the high points on the item. The item shall be

filled with the test liquid, pressurized, and the test

pressure shall be maintained for the duration of the

test. No leakage through the item tested shall be visi-

ble; however, leakage through the stuffing-box packing

shall be permitted.

1.6.4.4 Hydrostatic test records

Complete written or computer records shall be kept of

all information and kept on file, available to

the purchaser by the test facility, for two years. This

information shall include:

by model , size, serial number;

b) Test liquid;

c) Maximum allowable working pressures and

temperature;

d) Hydrostatic test pressure and test duration;

e) Date of test;

f) Identity of personnel in charge.

1.6.5 Performance test

1.6.5.1 Performance test acceptance tolerances

The acceptance tolerance applies to the specified con-

dition point only, not to the entire performance curve.

While pumps must be closely checked for satisfactory

mechanical operation during performance testing, the

degree and extent of such checking is independent of

the level of acceptance tolerances.

The minimum number of test points for level A" shall

be 7, and the minimum number for level B" shall be 5.

See Section 1.6.5.3 for descriptions of levels A and B.

When testing at rated speed is not practical , test

speed shall not be less than 80% nor more than 120%

of the rated speed. It is permissible on pumps greater

than 225 kW (300 horsepower) to test at speeds

between 60% and 140% of rated speed. Results are to

be adjusted to rated speed. Any greater change in

speed shall be by mutual agreement.

1.6.5.2 Witnessing of tests

The purchaser or purchaser's designated representa-

tive may witness the test when requested by the pur-

\ __ / chaser in the purchase order.

1.6.5.3 Acceptance levels

The test has two levels of acceptance, A

and B, for the quantitative values. Acceptance level

A" is usually applied to those pumps that are manu-

factured for specific conditions of service. Acceptance

level B" is usually applied to those pumps that are

mass produced for stock. If not specified, level A will

apply.

a) In making level "A" tests, no minus tolerances or

margin shall be allowed with respect to rate of

f1ow, total head or efficiency at the rated or speci-

fied conditions;

b) Acceptance of the pump test results shall be

judged at rated rate of flow and rpm with applica-

ble total head and efficiency as follows:

Performance Tolerance

Acceptance level A B

\-./

Under 60 m (200 ft)

o to 680 m

3

/h (2999 gpm)

HI Centrifugal Pump Tests - 2000

Performance Tolerance (continued)

Acceptance level A B

I'm -HDB nunuo nunu

nuhHr

d1d

nHnonH

U6a

From 60 m (200 ft) to

150 m (500 ft),

any f1 0w rate

+

150 m (500 ft) and over, +

any f1 0w rate

Minimum efficiency at rated Tl p or Tl OA

rpm and rate of f10w

(For Level = contract pump efficiency)

(For Level = published, nominal efficiency)

c) Alternatively, the pump test results may be judged

at rated total head and rpm versus rate of flow as

follows:

Performance Tolerance

Acceptance level A B

Rate of flow tolerance

at rated total head

+ +

Minimum efficiency at

rated rpm and total head

Tl p or Tl OA .

d) Examples in metric units follow for a pump rated

227 m"/h, 30.5 m, 80% efficiency, water with 1.0

specific gravity:

1) Per Para b, level A at rated rate of flow and

rpm, test total head range;

30.5 x 1.08 = 33 m max;

30.5 x 1.0 = 30.5 m min;

2) Per Para b, level B at rated rate of flow and

rpm, test total head range;

9

HI Centrifugal Pump

30.5 x 1.05 = 32 m max; Examples in US units follow for a pump rated 1000

gpm, 100 ft, 80% efficiency, water with 1.0 specific

30.5 x .97 = 29.6 m min; gravity:

Based on minimum efficiency = 1) Per Para b, level A at rated rate of flow and

rpm, test total head range;

100/[(120/80) - .2] = 76.9%;

100 x 1.08 = 108 ft max;

Test power range = 22.8 kW min; 25.7 kW

max. 100 x 1.0 = 100 ft min:

3) Per Para c, level A at rated total head and 2) Per Para b, level B at rated rate of flow and

rpm. rpm, test total head range;

Test rate of flow range at rated total head: 100 x 1.05 = 105 ft max;

227 x 1.1 = 250 m

3

/h max; 100 x .97 = 97 ft min;

227 x 1.0 = 227 m

3

/h min; Based on minimum efficiency =

Test power at rated total head and rpm = 100/[(120/80) - .2] = 76.9%;

Pw

Test power range = 30.6 hp min; 34.5 hp max.

3) Per Para c, level A at rated total head and

and: rpm.

227 x 30.5 = 23.6 kW min;

Test rate of flow range at rated total head:

100

1000 x gpm max;

250 x 30.5 = 26 kW max:

1000 x 1.0=1000 gpm min;

367x 100

Test power at rated total head and rpm =

4) Per Para c, level B at rated total head and

Pw

rpm.

Test rate of flow range:

(1000)(100) =31.6hp m-n;

227 x 1.05 = 238 m

3

/h max;

227 x .95 = 216 m

3

/h min; and:

Test max power at rated total head and rpm =

(11 00)(100) =34.7hp max,

238 x 30.5 = 25.7 kW;

100

4) Per Para c, level B at rated total head and rpm.

Test min power at rated total head and rpm = Test rate of flow range:

216 x 30.5 = 22.4 kW;

1000 x 1.05 = 1050 gpm max;

100

1000 x .95 = 950 gpm min;

10

Test max power at rated total head and rpm =

(1050)(100)

34.5 hp;

(76.9'\

\. 100)

Test min power at rated total head and rpm =

(950)(100)

30 hp;

(80 '\

\.100)

5) Note that the driver horsepower required is

dictated by the acceptance level specified and

the tolerances.

If it is dismantle a pump after the

mance test for the sole purpose of changing rotation or

machining impellers to meet the tolerances, no re-test

shall be required unless the reduction in diameter

exceeds 5% of the original diameter.

1.6.5.4 Peormance test instrumentation

1.6.5.4.1 Introduction

Test instruments shall be selected so that they can

provide measurements with accuracy shown in Sec-

tion 1.6.5.4.2 at BEP. Instruments need not be cali-

brated specifically for each test, but are to be

periodically calibrated by the manufacturer or suitable

Refer to Section 1.6.5.4.3 for suitable interval

between calibrations for test instruments.

1.6.5.4.2 Fluctuation and accuracy

Acceptable

f1uctuation of Accuracy of the

test readings instrument as a

Actual :1:% ofthe :1:% ofthe

Measurement values values

Rate offlow 2.0 1.5

Differential

head 2.0 1.0

Discharge

head 2.0 0.5

Suction head 2.0 0.5

lnput power 2.0 1.5

Pump speed 0.3 0.3

NOTE: Since itself is a derived quantity, its accu-

.racy may be computed from the other instrument accuracies

listed in the table, applying the root mean square law. It is

common practice to use the actual recorded test readings for

HI Centrifugal Pump

computation of efficiency for fulfillment of the manufacturer's

guarantee and to disregard the of instrument accuracy.

1.6.5.4.3 Suitable interval between calibration for

test instruments

Measuring and test equipment and measurement

standards shall be calibrated at periodic intervals as

listed in Table 1.20. Intervals shall be shortened as

required to ensure continued accuracy as evidenced

by the results of preceding calibrations and may be

lengthened only when the results of previous calibra-

tions provide definite indications that such action will

not adversely the accuracy of the system.

1.6.5.5 Peormance test setup

This section contains general guidelines for perfor-

mance test setup, to ensure accurate and repeatable

test results. See Figures 1.116 and 1.117.

The performance test may utilize, but is not limited;

to, the following:

a) Facility or purchaser-furnished driver. Depending

on the method used to measure pump input

power, efficiency data may be required;

b) Facility or purchaser-furnished speed-change unit,

if required. To accurately establish pump input

power, efficiency data of speed changer may be

required;

c) A suction pipe or hose from the booster pump,

closed tank or open sump, properly sized for the

pump being tested. The f10w into the pump is to be

free from swirl and have a symmetrical velocity

distribution;

Priming connection

Optional

throttle

valve

Suction

same as Figure 1.117

or 1.119

-1 _ Water level variance

J Optional baffle: spacing between

suction and discharge pipes is to

be equal to or greater than 6

times the sum of the nominal

pipe diameters. When spacing

must be reduced, a baffle as

shown is required

Figure - Test with suction lift

11

HI Centrifugal Pump Tests - 2000

d) A suction pressure gauge, compound gauge or

pressure transducer suitable for measuring the

complete range of pressures whether positive or

negative;

e) A discharge pipe or hose with a pressure break-

down (throttling) device;

f) A discharge pressure gauge or pressure trans-

ducer(s) for measuring the complete range of

pressures;

Table 1.20 - Recommended instrument calibration interval

3

Rate offlow Power (continued)

Quantity meter Torque bar

Weighing tanks 1 yr Calibrated motor

Volumetric tank 10 yr KW Transducer

Rate meters

Venturi

c

permanent

Nozzle

c

Strain gauges

Orifice plate

c

Transmission gear to 375 kW (500 HP)

Weir

c

Transmission gears above 375 kW (500 HP)

Turbine 1 yr Speed

Magnetic flow 1 yr Tachometers

Rotometer 5 yr Eddy current drag

Propeller 1 yr Electronic

Ultrasonic 5 yr Frequency responsive devices

Pressure Vibrating reed

Bourdon tube (pressure gauge) 4mo Electronic

Manometers Not req'd Photocell

Dead weight tester 1 yr Stroboscopes

Transducers 4mo Torque meter (speed)

Digital indicator 1 yr Temperature

Power Electric

Dynamometer w/scale 6 yr Mercury

Dynamometer w/load scale 6mo

a Use instrument manufacturer's recommendation if shorter than listed above.

b Unless electrical or mechanical failure.

C Calibration is not required unless it is suspected there are critical dimensional changes.

12

1 yr

Not req'd

b

3 yr

1 yr

1 yr

6mo

10 yr

20 yr

3 yr

10 yr

Not req'd

b

10 yr

10 yr

10 yr

5 yr

1 yr

2 yr

5 yr

r--\

/

HI Centrifugal Pump 2000

Pressure Gauge

Thermometer

Control Valve lor

Throttling Suction

Dampening Valve

Pressure Gauge

Return to sump Discharge

Dampening Device

_ Flow Meter il

I Located in Discharge

on

Test I I 2lJ I

D

Spring Loaded

Back Pressure Valve or

Adjustable Choke Valve

Note:

Position 01 these

devices may be reversed

in some set ups

Figure 1.117 - Open or closed tank

g) Throttling devices may be used for the suction

and discharge instruments, such as needle

valves or to dampen out the pres-

sure pulsations;

h) A means for measuring input power to the pump

shall be provided and be suitable for measuring

the complete range of power;

i) A means for measuring pump speed shall be

provided;

j) Test setups intended for NPSH testing shall be

provided with a means for lowering the suction

pressure to the pump, such as a suction throtlle

valve (with optional screen or straightening

vanes), variable level sump in an open system, or

a closed tank with a mechanism to create a vac-

uum or pressure;

k) A means for measuring the test

liquid shall be provided;

1) The actual dimensions of the suction and dis-

charge pipes where pressure readings are to be

taken shall be determined so that proper velocity

head calculations can be made;

1.6.5.6 Performance test data requirements

The following data shall be obtained prior to the test

run and writlen for the record to be retained for two

years (see sample data sheet on page 14):

a) Record of pump type, size and serial number;

b) To verify the liquid the temperature of

the liquid shall be taken before and after testing.

Temperature readings should be taken more often

when testing for NPSHR or high-power pumps.

c) Ambient conditions, such as temperature and

barometric pressure;

d) Records of critical installation dimensions, such as

tank internal dimensions, pipe internal dimensions

and lengths, and liquid levels (submergence) rela-

tive to datum;

e) Record of driver data, such as type, serial number,

horsepower, speed range, amperage, voltage and

efficiency;

'-......./ m) Flow measuring device(s).

f) Record of auxiliary equipment, such as vibration

monitors, temperature sensors, low- or high-

pressure monitors, leakage detectors, alarms,

etc.;

13

HI Centrifugal Pump

Summary of necessary data on pumps to be tested

The following information should be furnished on pumps

to be tested:

General:

1 . Owner's name

2. Plant location

3. Elevation above sea level

4. Type of service

Pump:

1. Manufactured by

2. Manufacturer's designation

3. serial number

4. Arrangement:

5. Inlet: single

6. Number of stages

7. Size suction: nominal

actual

8. Size discharge: nominal

actual

Intermediate transmission:

1. Manufactured by

2.

3. Serial number

4. Speed ratio

5. Efficiency

Driver:

1. Manufactured by

Serial number

3. Type:

4. Rated horsepower

5. Rated

6. Characteristics (voltage, frequency,

7. Calibration data

8. Driver efficiency

Specifying rated conditions

The following information is necessary in specifying

rated conditions:

1. Li quid pumped (water, oil , etc.)

2. Specific weight

3. Viscosity at pumping temperature

4.

5. Vapor pressure

6. Rate of flow

7. Total suction lift (hs)

8. Total suction head (hs)

14

9. Net positive suction head required

(NPSHR)

10. Total discharge head (h

d

)

11. Total head (H)

12. Output power (Pw)

13. Efficiency (llp)

14. Input power (P

p

)

15. Speed

Test information

Test information should be listed substantially as follows:

VJ

hU AU

1e as

ts

sye

eeht

n1234 e

G

Rate of flow:

1. Method of measurement

- G

2. Meter-make and serial number

3. Calibration data

Head:

1. Suction gauge-make and serial number

2. Calibration data

3. Discharge gauge-make and serial number

4. Calibration data

Power:

1. Method of measurement

2. Make and serial number of instrument

3. Calibration data

Speed:

1. Method of measurement

2. Make and serial number of instrument

3. Calibration data

g) Instrument calibration records and correction fac-

tors in accordance with instrumentation calibration

section;

h) Identity and authority level of test personnel in

charge of tests;

i) The actual dimension of the areas where pressure

readings are to be taken shall be determined so

that proper velocity head corrections can be

made.

1.6.5.7 Peormance test records

Complete written or computer records shall be kept of

all information relevant to a test and kept on file, avail-

able to the purchaser by the test facility, for two years.

The manufacturer's serial number, type and size, or

other means of identification of each pump and driver

(if calibrated and used to obtain the pump's efficiency)

involved in the test shall be recorded to avoid mistakes

in identity.

While these records apply to the complete unit, includ-

ing the driver, the standard itself applies only to tests

ofthe pump.

\ j 1.6.5.8 Calculations

1.6.5.8.1 Calculation of total suction head (hs)

= h_ +h..

:1 S s

1.6.5.8.2 Calculation of total discharge head (h

d

)

h .J = h_ +h.. +Z.J

d "gd. "v

d

.

1.6.5.8.3 Calculation of total head (H)

H = hd-hs

For definition of terms and algebraic summation of the

parts, see Section 1.6.3.12.

1.6.5.8.4 Calculation of input power

The input power (Po), when measured by transmission

dynamometer, is calculated from the following formula:

\-....../

HI Centrifugal Pump

2nLWn

(US units): P n

p 33,000 5250

Where:

L = Length of lever arm in m

W = Net force in N (Ib);

n = Pump speed in rpm;

,. = Torque in N.m (pound-feet).

The electrical horsepower input to an electric motor is

given by:

(Metric) P mot = kW

-nu

--

o m

p

s nH

U S U

Where:

kW = Electrical input power in kilowatts.

The input power to a pump driven by an electric motor

IS:

P- =

p mUL 100

1.6.5.8.5 Calculation of output power

The liquid horsepower (Pw) is computed by the foll.ow-

ing formula:

units:

P=QH(S)

w 366

b) US units:

P... =

W

df

-m

nE

.'-

When the specific weight of the liquid is 62.3 pounds

per cubic foot, which is the value for water at a stan-

dard temperature of 68

0

F, then:

15

/-\

In order to maintain hydraulic similarity with the field

operation, the following relationships are used for

determining the head, rate of flow, power and NPSHR

at the rated point. These relationships which follow

definite rules are known as the affinity laws. The

power relationship is based on the criteria that the effi-

ciency stays constant with change in speed.

HI Centrifugal Pump Tests - 2000

If the pump is handling a liquid with different specific

weight, or water at a temperature resulting in a specific

weight per cubic foot other than 62.3 pounds, the

above formula must be corrected so that:

P...

w 3960

= (::f

333

=

0

1

O

2

P-QH(S)

w

3960

Where:

If pump output is measured in pounds per square inch

,

the formula for output power

,

regardless of the specific

weight of the liquid

,

becomes:

rate of flow on test; - 0

1

rate of flow on installation; - O

2

P=QAP

w 1710

speed on test in rpm; - n1

speed on installation in rpm; - n2

Calculation of efficiency

The pump efficiency expressed in percent is calcu-

lated by:

1.6.5.8.6

head on test;

head on installation;

-

-

-

H

2

100

p P

p

/

power on test; - P

1

The overall efficiency of a motor-driven unit expressed

in percent is calculated by:

power on installation; - P

2

NPSHR

1

= NPSH on test;

f P\

\ mot/

NPSHR

2

= NPSH on installation.

Figure 1.118 - Pump (all data is

corrected to rated speed)

d

SPEED-RPM

Denotes head- rate olllow

kfor w| hich pump was sold

h\

g 3

EmclemIY

L..----"""

\

UET

/

v

/

Power(s= r

z EEL

/

1----""

v

/

NPSHR

-

L..----"""

1/

I I

Plotting performance test results

The total head, efficiency and power input are usually

plotted as ordinates on the same sheet with rate of

flow as the abscissa, as shown on Figure 1.118.

1.6.5.8.7

Performance test at other than rated 1.6.5.8.8

speed

Test of a full-sized pump at reduced 1.6.5.8.8.1

speed

Rate offlow

In tests at reduced speed, the relative power loss in

bearing and stuffing-box friction may be increased, an

effect which may be appreciable in small pumps. The

hydraulic friction losses may be relatively increased

when the Reynolds number for the water passages is

reduced, an which may be appreciable in small

pumps of low specific speed. Therefore, these factors

must be considered in determining an acceptable test

speed.

16

Sealless pumps incur significant eddy current losses

which are affected by speed. Impeller input power var-

ies approximately with the cube of rpm as they do in

conventionally sealed pumps. Eddy current losses are

to rpm squared. Therefore the following

power correction for speed is made:

P2 = (P 1 - EC

1

)(n2/n1)3 + EC

1

(n2/nd;

P

1

= Power on test in kW (bhp);

P

2

= Power on installation in kW (bhp);

EC

1

= Eddy current losses on test in kW (bhp).

Eddy current losses, EC

1

, are normally measured by

manufacturers during development studies. Values

from these tests may be used in lieu of measurements

during the contractural performance test.

1.6.5.8.8.2 Peormance test of full-sized pumps

at increased speed

Under unusual circumstances, it may be desirable to

carry out tests at higher speeds than specified for the

installation. This may be due to the limitations of avail-

able prime movers or correct electrical frequency. In

this case, if such tests do not exceed safe operating

\--..-/ limits of the pump, all of the above considerations con-

tinue to apply.

1.6.5.8.8.3 Peormance test correction to rated

speed

For purposes of plotting, the rate of flow, head and

power shall be corrected from the test values at test

speed to the rated speed of the pump. The corrections

are made as follows:

flow: O

2

=

Head: H'l = H.

rn'll3

Input power: P

2

= P

1

Example (Metric): A pump for 90.8 m

3

/h, 68.5 meters,

total head and 8 m NPSHA running at 3550 rpm is to

be tested at 2950 rpm. What head, rate of flow and

NPSHA should be used in the factory test?

)

HI Centrifugal Pump Tests - 2000

Applying the relationships given above, the head per

stage to be used in the factory test is:

m

7

,

nu-nU FO=b

5 0o no

--

qJh

H

H

The rate of flow to be used in the factory test is:

0

1

=

slnce:

- 68.50.75

then,

47.3

0

NPSH to be used in the factory test is:

= = 5.5 m

Example (US Units): A pump for 400 gpm, 225 feet

total head and 26.1 ft NPSHA running at 3550 rpm is

to be tested at 2950 rpm. What head, rate of flow and

NPSHA should be used in the factory test?

Applying the relationships given above, the head per

stage to be used in the factory test is:

=

The rate of flow to be used in the factory test is:

0

1

= = = 332

slnce:

17

HI Centrifugal Pump Tests - 2000

then

The NPSH to be used in the factory test is:

= 18ft

This will keep the specific speeds the same in the fac-

as in the field installation.

1.6.5.8.9 Performance test correction for

temperature variations

Variations in the temperature of the liquid pumped

cause changes in the specific weight and viscosity,

with resultant changes in the of the

pump.

Any reduction in specific weight, as caused by an

increase in temperature, results in a directly propor-

tional reduction in output and input power; therefore,

the efficiency is not changed.

Reduced viscosity of water at increased temperature

will have an influence on efficiency. For pumps in the

lower range of specific speed typically below 1750

(1500), such as high multi-stage boiler feed

pumps and large, single-stage hot water circulating

pumps, reduced viscosity will:

increase the internal leakage losses;

reduce disc friction losses;

reduce hydraulic skin friction or flow losses.

The net of a reduction in viscosity due to higher

temperature will depend on specific speed and on the

design details of the pump. Where substantiating data

are performance data from a cold water test

may be adjusted to hot water operating conditions on

the basis of the following formula:

t =

Where:

Efficiency at test temperature, decimal

value;

18

llot = Efficiency at operating temperature, deci-

mal value;

\

Vot = Kinemati<? viscosity at operating tempera-

Kinematic viscosity at test temperature,

mm

2

/s;

x = Exponent to be established by manufac-

turer's data (probably in the range of 0.01

toO.1).

Example: (Metric) Typical efficiency adjustment for

increased temperature. A test on water at 37.8

0

C

resulted in an efficiency of 80%. What will be the

probable efficiency at 177

0

C?

IV _"\X

=

nu \ll/

85

,

..

o-8

-n/-

4tnu

..

tt oo

llot = .826 = 82.6%

Example: (US units) Typical efficiency adjustment

for increased temperature. A test on water at 100

0

F

resulted in an efficiency of 80%. What will be the

probable efficiency at 350

0

F?

IV_"\X

=

r. 00000185,\0.1

or .- -'\. .0000076 )

llot = ,

llot = .826 = 82.6%

/-\

1.6.5.8.10 Performance test correction for

specific weight variations

If the test is run with a liquid of different specific weight

from that of the field installation, there will be a revision

in required input power which will be determined as

follows:

y2

(Pn)" = (Pn ) ,

P'2 ,. P'1 "y1

There is no change in

\

Sealless centrifugal pumps incur significant eddy cur-

rent losses which are not affected by specific weight

variations. Power correction for installation specific

weight different from test specific weight is made as

follows:

C E +

C E P

p

Where:

Power for a specific weight on test in kW

(bhp);

P

2

= Power for a specific weight on installation

in kW (bhp);

EC

1

= Eddy current losses on test in kW (bhp).

1.6.5.8.11 Performance test correction for

viscosity variations

/

)

Viscosity has a very definite effect on the operating

conditions of the pump with respect to head, rate of

flow, efficiency and input power. Pumps for viscous

service, which are tested with water, will require cor-

rections to approximate the performance with the vis-

cous liquid. (See ANSI/HI 1.3-2000, Centrifugal Pump

Operation. )

Thermometer Dampening Valve

Control Valve for

Throttling Suction

Pressure Gauge

HI Centrifugal Pump Tests - 2000

1.6.5.9 Performance test correction for solids in

suspenslon

Solids in suspension affect the operating performance

of the pump in varying degrees, depending on the per-

centage and nature of the solids. No definite correc-

tions can be recommended.

1.6.5.10 Report of test

AII parties to the test shall be furnished a copy of the

curve at constant speed.

1.6.6 Net positive suction head required test

(optional)

1.6.6.1 NPSHR test

To determine the NPSH required (NPSHR) by the

pump.

1.6.6.2 NPSHR test arrangements

Three typical arrangements are shown for determining

the NPSHR characteristics of pumps.

In the first arrangement, Figure 1.119, the pump is

supplied from a constant level supply through a throttle

valve which is followed bya section of pipe containing

straightening vanes or a minimum of seven diameters

Pressure Gauge

Dampening Device

Return to sump Discharge

Note:

Position of these

devices may be reversed

in some setups.

Figure 1.119 - Suppression type NPSH test with constant level sump

19

HI Centrifugal Pump Tests - 2000

of straight pipe to straighten flow. This arrangement

dissipates the turbulence produced by the throttle

valve and makes possible an accurate reading of suc-

tion pressure at the pump inlet.

This simple arrangement usually is satisfactory for

NPSHR greater than 3 meters (10 feet), although the

turbulence at the throttle valve tends to accelerate the

release of dissolved air or gas from the liquid which

takes place as the pressure on the liquid is reduced. A

test made with this arrangement usually indicates

higher NPSHR than that which can be expected with

deaerated liquid.

In the second arrangement, Figure 1.120, the pump is

supplied from a sump in which the liquid level can be

varied to establish the desired NPSH. This arrange-

ment provides an actual suction lift and hence more

nearly duplicates operating conditions of pumps on

water service. Care should be taken to prevent vortex-

ing as liquid level is varied. The priming connection

should be installed above the eye of the impeller either

in the suction pipe or on the pump.

In the third arrangement, Figure 1.121 , the pump is

supplied from a closed tank in which the level is held

constant and the NPSHA is adjusted by varying the air

or gas pressure over the liquid, by varying the temper-

ature of the liquid, or by both.

This third arrangement tends to strip the liquid of dis-

solved air or gas. It gives a more accurate measure-

ment of the pump uninfluenced by the

Suction

Priming connection

)Rdystem

same as Figure 1.117

or 1.119

OHue

-huov

h

ctI

i ___ Water level variance

Optional baffle: spacing belween

suclion and discharge pipes is 10

be equal to or grealer Ihan 6

limes Ihe sum of Ihe nominal

pipe diamelers. When spacing

musl be reduced, a baffle as

shown is required.

Figure 1.120 - Level control NPSH test with deep

sump supply

20

release of air or gas. This arrangement more nearly

duplicates service conditions where a pump takes its

supply from a closed vessel at or near its vapor pres-

sure. It is also acceptable to tst with a closed loop

without the closed tank on the suction side.

In each of these arrangements, water shall be used as

the test liquid. Aeration shall be minimized by taking

the following precautions:

submerged return lines;

reservoir sized for long retention time to allow air

to escape;

inlet line properly located to prevent vortexing;

reservoir bafftes to isolate inlet from return line;

tight pipe joints and stuffing boxes to guard

against air leakage into the system.

1.6.6.3 NPSHR test procedure

The cavitation characteristics of a pump can be deter-

mined by one of the following procedures:

/"\

Using one of the test arrangements shown, the pump

is run at constant rate of flow and speed with the suc-

tion condition varied to produce cavitation. Plots of

head shall be made for various NPSH values.

Gas Pressure

Heat

Exchanger

Flow

Distributor

--- ---

--- ---

Heating or

Cooling Coil

Suction

Figure 1.121 - Vacuum and/or heat control NPSH

test with closed loop

HI Centrifugal Pump 2000

NPSHR characteristics. The relationship between

model results and predicted full-size characteristics is

described in Section 1.6.13.

Accurate determination of the cavitation point requires

careful control of all factors which influence the opera-

tion of the pump. A minimum of five test points brack-

eting the point of change shall be taken, and the data

to determine when the performance breaks

away from that with excess NPSHA. Any change in

either a deficiency at a given rate of flow,

or change in sound or vibration, may be an indication

of cavitation. But because of the difficulty in detrmin-

ing just when the change starts, a drop in head of 3%,

which is the standard value in determining NPSHR, is

accepted as evidence that cavitation is present. The

3% head drop is based on the first stage head for

multi-stage pumps.

As NPSHA is reduced, a point is reached where the

curves break away from a straight-line trend, indicat-

\/ ing a condition under which the of the

may be impaired. The degree of impairment will

depend upon the specific speed, size and service of

the pump. Figure 1.122 shows results typical of a test

for NPSH at flow rates both greater and less than nor-

mal. The 3% drop in head is the standard to determine

NPSHR.

Another technique for determining the NPSH charac-

teristics is to hold the speed and suction head (hs)

constant and to rate of flow. For any given

suction head, the pump head may be plotted against

rate of flow. A series of such tests will result in a family

of curves, as shown in Figure 1.123. Where the curve

for any suction head (hs) breaks away from the enve-

lope by 3%, NPSHR is established.

The NPSHA value required to properly establish the

non-cavitating performance of a pump should be

determined from prior full-scale or model tests of the

specific pump in question. If no such prior test results

are available, a recommended NPSHA value of twice

the predicted NPSHR, for rated flow rates greater than

85% of the best efficiency point, or an NPSHA value of

at least two and a half times the NPSHR, for rated flow

rates below 85% of the best efficiency point, is recom-

mended for maximum assurance. It should be noted

that the average pump will give full at

NPSHA values only 1.3 times the NPSHR value at

flow rates above 85% of the best efficiency point and

1.7 times the NPSHR value at flow rates below 85% of

the best efficiency point. Accordingly, the test per-

formed at constant rate of flow, as shown in Figure

1.124, should begin with the non-cavitating

mance NPSHA value established above, or greater.

When it is impractical to conduct a test to the above

criteria on large pumps due to size, rate of flow or facil-

ity NPSHA, a model test may be used to determine

O

2

- 100% cap.

0

3

NPSHR values

\11 Q

c

v

o

When testing with water, an accurate temperature

measurement usually is sufficient to establish the

vapor pressure, but the degree of aeration of the water

may have a considerable influence on performance.

Consistent results are more readily obtained when the

water is deaerated.

NPSHA

Figure

Cases may arise in which the limitations of the factory

test facilities may preclude the securing of sufficient

NPSHA to produce the installation NPSHA. In such

cases, the NPSHR can be obtained by an increase in

the pump speed with a corresponding increase in

pumping head and flow rate instead of by a reduction

in NPSH available:

NPSHR values

3% reduction

in total head

ro

H

A-T

hH

-

qd

H

H

|

1

.hH

c

o

z

c

v

a} Correction to specified speed for net positive suc-

tion head

21

Figure 1.123 - NPSH test with suction head held

constant

Rate of flow

\-/

HI Centrifugal Pump Tests - 2000

H CU P N

!n-nH

fZ/llk s=

NQ

Where:

NPSH

1

= Net positive suction head at test speed;

NPSH

2

= Net positive suction head at specified

speed;

n1 = Test speed in rpm;

n2 = Specified speed in rpm;

01 = Test rate of flow;

02 = Rate of flow at specified speed;

b) NPSH - Experimental deviation from the square

law.

The affinity relationships define the manner in

which head, rate of flow, input power, and NPSHR

vary in a centrifugal or axial flow pump with

respect to speed changes. If a pump operates at

or near its cavitation limit. other factors also have

an and the limiting NPSHR value may vary

other than as the square of the speed. Some of

these factors are: thermodynamic on the

vapor pressure of the liquid, change in surface

tension, and test differences due to the relative air

content of the liquid.

.. 3% At rates of flow 85%

|

_ 1_ 2.5 x

, 3%

;y

W

NPSHA

NPSH test at constant rate of flow

Recommended NPSHA range for NPSHR

test when no previous data on pumps

full performance is available.

Figure 1.124 - NPSH test with flow rate held

constant

22

If the manufacturer can demonstrate that, with a

given pump under conditions, an expo- ./'-\

nent different than the square of the speed exists,

such exponent may be recognized and used

accordingly.

1.6.6.4 NPSHR test suction conditions

The total suction head is to be determined as specified

in Section 1.6.3.12.4.

The NPSHA on the test stand shall exceed the

NPSHR of the pump with sufficient margin throughout

the operating range to ensure that it will have no effect

on the pump performance. See Section 1.6.3.12.10 for

a description of NPSHA.

For pumps in free-surface systems, the approach

must be free of obstructions. The flow towards the

pumps must be uniform and free of eddies and vorti-

ces.

Intake structures should be designed as described in

the ANSI/HI 9.8-1998, Pump Intake Design.

1.6.6.5 NPSHR test records

Complete written or computer records of all data rele-

vant to the NPSHR tests shall be kept by the test facil-

ity and available to the purchaser for a minimum of two

years (see sample data sheet on page 14).

This information should include:

a) Specified NPSHR and NPSHA;

b) Height of suction gauge, above or below the

datum line;

c) Inside diameter of pipe at location of suction pres-

sure tap;

d) Observed data (each run);

- water temperature;

- suction pressure;

- shaft speed;

- discharge pressure;

- rate of flow.

setup;

/

./

f) Type of flow meter and calibration;

g) Type, number and calibration of pressure gauges;

h) Note any abnormal observation (noise, vibration,

etc.);

i) Identification of materials at liquid end of pump;

j) Type and serial number of pump and driver;

k) Date of test;

1) Identity of personnel in charge.

1.6.6.6 NPSHR test

AII parties to the test shall be furnished a copy of the

NPSHR curve or curves as described in Section

1.6.6.3.

1.6.7 Mechanical test (optional)

1.6.7.1 Mechanical test objective

To demonstrate the satisfactory mechanical operation

of a pump, at the rated conditions, including: vibration

levels; lack of leakage from shaft seals, gaskets, and

lubricated areas; and free running operation of rotating

When specified, bearing temperature stabiliza-

tion will be recorded.

\---/

These tests do not apply to submersible pumps as

described in ANSI/HI 1.1-1.2-2000 Figures 1.7 and

1.8.