Professional Documents

Culture Documents

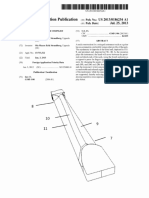

Bolt On Acoustic Guitar Neck

Uploaded by

JayMorgan50%(2)50% found this document useful (2 votes)

2K views1 pagebolt on guitar neck acoustic steel string luthier guitarmaking guitarbuilding

Original Title

Bolt On acoustic guitar neck

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbolt on guitar neck acoustic steel string luthier guitarmaking guitarbuilding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

2K views1 pageBolt On Acoustic Guitar Neck

Uploaded by

JayMorganbolt on guitar neck acoustic steel string luthier guitarmaking guitarbuilding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

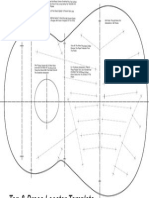

This Drawing or Drawings Are To Used For One

Use Only And Not Reproduced For Any Other

Purpose Than Construction Of This Particular

Instrument.

Reproduction, Distribution or Sales For Any Other

Use Is Strictly Prohibitied And Falls Under U.S

Copyright Laws For Ultimate Guitar OnLine 2010

Sheet Number

Revisions:

Date: Feb 15, 2010

Note: These Plans Are

Drawn Full Scale Are Are

Labeled in mm & Fractional

Inches

A

A

A

A

A

A

6

3

.

5

1

5

2

.

4

19.0

1

2

.

7

4

4

.

4

41.3

41.3

39.0 41.3 41.3

645.2

9

.

5

5

4

.

6

3

4

.

6

3

7

.1

4

1

.3

4

1

.3

3

8

.5

6

3

.

0

1

9

.

0

1

9

.

0

51.7

3

5

.

5

22.6 6.0 22.6

51.2

4

.

5

1

2

.

0

4

.

8

57.5

49.3

7

9

.

3

26.3

23.1

101.7 95.0 88.9 101.5

1

2

.

0

6

.

0

9

.

7

5.0 2.5

389.0

1

2

.

0

9

.

7

1

0

.

0

1

0

.

0

1

2

.

0

106.2

8

.

0

8

.

0

6

.

0

8

.

0

388.8

3

.

0

5

.

0

3.5 102.0 7

6

.

0

3

.

0

5

.

0

8

.

0

2.0 31.0 20.4 36.0 7

8

.

0

25.4 11.4

20.1

1

5

2

.

4

3

2

.

1

1

2

.

0

6

4

.

2

1

2

.

0

3

2

.

1

1

0

.

9

1

0

.

9

1

0

.

9

1

0

.

9

1

0

.

9

6

5

.

8

3

5

.

5

8

1

.

5

3

5

.

5

3.6

6.6

20.1

1

5

2

.

4

6

5

.

8

3

5

.

5

8

1

.

5

3

5

.

5

3.6

6.6

25.4

3

2

.

1

6

.

8

8

1

.

5

3

2

.

1

1

0

.

9

1

0

.

9

1

0

.

9

1

0

.

9

1

0

.

9

8

2

.

5

3

.

0

9

.

0

59.3 148.4 59.3

267.0

1

.

2

4

.

8

3

.

0

9

.

0

3.5 27.1 206.6 29.1

8

.

0

90.1

266.3

3

.

0

9

.

0

1

.

2

4

.

8

3.5 27.1 204.6 29.1

264.3

8

.

0

3

.

0

7

.

0

9

.

0

8

.

0

156.3 8.0

145.9 8.0

9.2 40.5 110.2 181.5 47.5

3

.

0

7

.

0

3

.

0

7

.

0

9

.

0

9.2 52.8 67.9 59.3 152.1 44.0 3.8

20.8 16.0

1

2

.

1

8

.

0

5.2 234.8 5.2

245.2

1

1

.

8

1

2

.

0

1

2

.

0

2

.

4

2

.

7

7

.

0

62.1 137.5 62.1

261.7

261.7

2.3 257.2 2.2

8

.

0

2

.

0

2

.

8

7

.

0

61.5 122.3 61.5

245.2

67.1 209.4 67.1

3

.

4

3

.

5

5

.

0

6.0 331.4 6.0

343.5

4

.

0

3

.

2

4

.

8

73.3 202.0 73.3

348.7

343.5

4.7 339.3 4.7

348.7

1

9

.

0

1

9

.

3

479.2

3

6

1

.

2

2

7

4

.

7

645.2

6

3

.

5

7

6

.

2

36.2 34.2 32.3 30.5 28.7 27.1 25.6 24.2 22.8 21.5 20.3 19.2 18.1 17.1 16.1 15.2 14.4 13.6 12.8 12.1

6

3

.

0

2

7

.

5

5

7

.

1

4

.

8

139.7 19.0 4.8

1

0

4

.

7

4.6 21.7 25.0 26.7

19.5

139.8

357.8

10.0 39.3

4.6 21.7 25.0 25.0

3

0

.

0

3

2

.

4

10.0

2

2

.

0

1

9

.

0

2

2

.

0

6

3

.

0

R 4,686.3

R 140.5

R 48.3

15.11

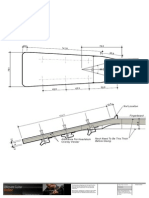

10mm x 16mm L Brass Cross

Dowels.

2" Brass Connector Bolts

Brace Key Numbers. Refer To

Brace Diagram Plan For

Bracing Layouts

!"" $%

&'"" (%

!"" $%

!"" (%

!"" $%

!"" (%

!"" $%

)"" (%

!"" $%

&'"" (%

!"" $%

&*"" (%

!"" $%

!"" (%

!"" $%

&+"" (%

!"" $%

&+"" (%

Neck Width At The Nut Is Another Dimension That Varies

Per Each Players Specifications. Standard Nut Width Is

1-3/4" or 44.4 mm As Shown Here. Fingerstyle Guitarist's

Prefer A Nut Width Of 1-7/8" Or 47.6 mm. There Will Be

Instances Where The Player May Require Even Wider

Widths. By The Way A Classical Guitar Nut Width Is

2-1/8" or 54 mm.

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

String Slots Should Be Filed Out With

Gaged Nut Files To Precisely Match The

String Gages.

Fret Wire Detail

The Top Trim For The Headstock Is Traditionally Made From

The Same Wood As The Back And Sides. It is Usually

Leftover Stock And Is About 2.2mm Thick. Glue Maple Or

Maple/Ebony Veneer Beneath For Additional Detail - This Is

A Personal Preference. Glue These Pieces Before Any

Headstock Work Is Started.

Rosette Reinforcing Beneath

The Concentric Rossette

Inlays To Strengthen The Top

Plate. Round Edges Where

They Join The Top.

Back Block or Butt Block. Vertical Grain Cedar Or Spruce

Minimum 20 Grains/In. Some Luthiers Shave This Block or

Angle It Away From The Top As This Block Often Gives A

Guitar A "Hump" In The Top And Can Cause Cracking.

Note: Most Luthiers Make A Template From Either Wood Or

Plastic With The Neck Profile, Heal Shape And Interior Neck

Block And Foot Profile - All In One Template. Make Another Copy

Of This Plan To Make Your Own. Just Use Spray Adhesive To

Attach The Pattern And Cut It Out With Your Band Sand. Cut A

Little Big (Away From The Line) And Finish Sand With A Spindle

Sander Right Down To The Line

Longitudinal Section

Back Block or Butt Block. Vertical

Grain Cedar Or Spruce Minimum

20 Grains/In. Some Luthiers Shave

This Block or Angle It Away From

The Top As This Block Often Gives

A Guitar A "Hump" In The Top And

Can Cause Cracking.

Guitar Top Plate. Usually Braced Dead Level (No Arch) Use Only #1 or AAA Top Materials -

This Is The Single Most Important Piece Of Wood Used In A Guitar.

Materials Vary Quite A Bit, But Usually Consist Of Spruce Or Cedar From Many Different

Regions. Spanish Cedar, Canadian Red Cedar And Many Others. Must Be Vertical Grain

Wood With No Run-out, Even Grain Across The Top And 20 Grain/In Minimum. Spruces Can

Be Englemann, Sitka Or European.

Top Thickness Varies As Well And Is A Function Of Top Stiffness And Wood Density. For

Instance Cedar Will Usually Need To Be Slightly Thicker Than Spruce Because The Specific

Density Of Cedar Is Less Than That Of Cedar. A Good Starting Place If About 3.2 mm Or

About 1/8" Thickness.

Quite Often It Looks Great To Use A Contrasting Wood On The

Peghead For Some Extra Detail, Such A Burled Wood, Bird's

Eye Wood Or Pleated Grain. Most Luthier Supply Houses Have

A Wide Variety Of Wood You Can Select From

If You Decide To Place Binding On The Edge Of

The Fingerboard, Make Sure You Follow The

Direction On UGOL Website On Fret Repair.

www.ultimate-guitar-online.com/fret-repair-

part1.html Where There Are Extensive Fret Repair

And Installation Articles, Tools Required And

Methods For Installing Frets On Fingerboards With

Binding.

Mother Of Pearl Position Dots Are A Matter Of Each Guitar

Players Taste And Varies From No Position Dots At All To

Position Dots At The 3rd, 5th, 7th, 12th and 15th Frets To Very

Elaborate Vines And Other Inlays.

To Install Round Position Dots, Mark The Center Of Each Dot

With A sharp-Pointed Scratch Awl.

Chuck -Up A Brad Point Drill Bit In Your Drill Press And Drill

Holes For The Dots As Close To The Depth Of The Dot As

Possible. Usually Try To Have The Dot Just A Bit Above The

Fretboard Surface.

Mixup Some Ebony Sawdust With 2-part Epoxy Into A

Toothpaste Consistency. Take A Bit On The Tip Of Your Finger

And Work It Into Each Dot Hole. Now Take Each Position Dot

And Work It Down Into Each Filled Hole. Wipe Away The Excess

With Your Finger, But Make Sure You Don't Scoop It Out Of The

Position Dot Cavity.

Let Dry Thoroughly And Sand Smooth With A Power Sander Or

Sanding Sticks, Until The Dot And Fretboard Are Level.

Special Precaution: Do Not Inhale Any Of The MOP Dust. Wear

A Good Dust Mask. The Dust In A Carcynogyn And Is Very A

Very Dangerous Health Risk.

Inlay Position Dot Tutorial

Certain Luthiers Tune The Top By Making The Top

Progressively Thinner As It Reaches The Guitar Edge

And Remain Full Thickness At The Top. If You Do

This Do Not Reduce The Edges More Than .5 mm.

D

Acoustic Guitar Rosettes

Are Usually Handmade By

The Luthier. Form Them

Around Small Wooden

Drums And Glue With Push

Pins Holding The Layers

Together.

A Lot Of Acoustic Guitar Makers Reinforce The

Guitar Sides With Cloth Tape, Dipped In Glue And

Aheared The The Guitar Sides. This Will Help

Reduce Cracking. I Prefer To Use Small Mahogany

Side Braces, 6mm Wide x 3.2 mm Thick. Chamfer

All Edges And Space Around The Top. I've Never

Had A Side Crack To Contend With - Besides They

Look Really Cool!

3mm Thick Top Reinforcement To

Prevent Top Cracking Alongside

Fretboard. Typical Each Side Of

Fretboard.

Drill These Holes Only After You Have

Purchased Your Tuning Machines. Make

Holes About 1mm Larger Than The Roller.

Drill These Holes First To Minimize Tear-Out

Of The Tuner Slots.

#1 Quality Hondurous Mahogany Neck

Select Only Vertical Grain Wood For Your

Neck.

Drill Holes In Head With Drill Press. To Prevent

Tear-Out Place A Scrap Piece Of Wood Beneath

Exit Hold Of Drill. Make Sure To Pre-purchase

Your Machine Heads To Get The Hole Diameter

Exact.

Many Luthiers Trim The Perimeter Of The

Peghead With Multi-layer Purfling of Wood Or

Plastic. I Prefer Wood.

Make Sure To Use High Quality Tuning Machines

Such As Grover or Schaller. Good Plating Is

Essential To Resist Weather And Perspiration

A Nice Touch Is To Counter-Sink The

Washer Portion Of The Machine

Heads Slightly Into The Guitar Head.

Use A Forstner Flat-Bottom Bit For

This Operation and Chuck It In A Drill

Press. Be Sure To Drill The

Countersink Before The Hole For The

Machine Head Posts.

Typical Acoustic Guitar "Belly Bridge" With Saddle,

Saddle Channel, And Bridge Pins. This Shows An

Option Of Countersinking The Bridge Pins Into The

Bridge For Addtional Detail. The Amount You

Countersink Is A Person Preference.

Try To Keep Your String Angle From The Pin To The

Saddle At About 20 Degrees Or So.

The Bridge Plate Is One Of The More Important Pieces

Of The Guitar Top Plate To Get Right. First Glue All The

Top Braces To The Top, Cleanup The Glue And Shape

And Sand The Braces. Then Fit The Bridge Plate In

Very Carefully. It Should Be A Hardwood Plate, Approx

3mm Thick. Grain Should Run 90 Degrees To The Top.

Back Braces - Vertical Grain Minimum 20 Grain/In.

Cedar Or Spruce #1 Quality. Cope Out Ends Of

Bracing.

Side And Back Material: Many Different Woods Can Be

Used. For Bright Tones Go With One Of The

Rosewoods Such As Indian Rosewood or Brazilian

Rosewood. Koa Is Bright As Is Zircote And Madagascar

Rosewood. For Warm Tone Use Walnut. Most

Traditional Acoustic Guitars Are Constructed From

Indian Rosewood Or Mahogany.

!"" $%

&+"" (%

Heavy Dashed Lines Indicate Single Cutaway

Used By Many Luithers. This Allows The Guitar

Player To Reach Approximately 3 to 4 Frets Higher

On The Fretboard Without The Guitar Body

Blocking Their Left Hand

Optional Fretboard Support. See

Section Below For Detail

F

G

Neck Block. This Is A Very

Important Structural Element.

Construct From Vertical Grain

Honduras Mahogany

Typically Acoustic Guitars Have A Radius On The

Top Of The Fretboard. This Is Optional. Fingerstyle

Guitar Players May Prefer A Flat Fretboard And

Flatpickers May Prefer A Radius Fretboard. I Build

All Of My Guitars With A Flat Fretboard, Unless

The Guitar Cliet Wishes Otherwise.

The Intersection Joint Of The Major Structural Braces or The "X" Brace

Is Usually Constructed By Running One Of The Braces Through And

Butting The Other Brace On Either Side And Glueing. Then Cloth Dipped

In Glue Is Wrapped Around The Joint. I Feel This Is An Inferior Structural

Joint For Such An Important Brace. I Prefer To Cope Out One Brace And

Provide A Tongue And Groove Joint Here This Allows Both Braces To

Run Though And Gives A Large Glueing Area For The Braces. Refer To

The Bracing Diagrams For This Technique.

B

G

!"" $%

&'"" (%

There Are Two Basic Ways To Introduce Reinforcement To

The Guitar Neck. The First Is With A Hardened Aluminum

Bar Of Aircraft Quality - See The Neck Detail For That.

The Second Method Is With An Adjustable Truss Rod. I

Would Recommend A 2-Way Adjustable Rod. The

Installation Instructions Will Come With The Rod Assembly

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

Acoustic Guitar Bridges Are Usually

Called A Belly Bridge Because They

Have A Rounded Belly Shape On The

Bottom Of The Bridge. Try To Match

The Bridge Wood To The Fretboard

Wood - Usually Ebony. Refer To 2

Style Included Here Under The

Templates Page Of This Document.

Laminate Honduras Mahogany Left Overs From

The Neck Blank (Before You Rip The Blank Down

The Middle). If you like you can provide a

decorative centerstripe down the center of the

neck (a classical guitar technique) for a unique

look for your acoustic guitar.

Heel trip cap wood is usually ebony. Thickness

can vary and you can add multi-layer maple and

rosewood/ebony veneer to add some detail.

The Neck Thickness Varies Quite A Bit From

Guitar To Guitar. Typically A Thinner Neck Is

Faster, In That It Plays Easier - The Tradeoff Is

That A Thin Neck Is Weaker And Is More Likely To

Give You Neck Warpage Issues Than A Thicker

Neck.

Position Dots In The Side Of The Fretboard. The

Material If Available From Luthier Supply Houses

In Long Sticks. Just Drill The Proper Sized Hole

And Trim and Sand The Dots Flush.

!"" $%

!"" (%

Neck Section At Narrow

Point Of Heal

Neck Section At 7th

Fret

Solid Ebony Fretboard or Indian

Rosewood.

If The Fretboard Is To Be Bound With

Purfling, Use Wood Veneer With

Multi-Layer Colored Banding Such As

Rosewood, Maple, Ebony Etc.

This Neck Shows A 6mm x 12mm Bar

Of Aircraft Aluminum In The Center

Of The Neck. You Can Also Choose

To Use An Adjustable Truss Rod.

When Fretting An Bound Fingerboard Cut Back

Tang Of Frets To Back Side Of Purfling. See The

Following Article:

www.ultimate-guitar-online.com/fret-repair-

part7.html

If Using The Aluminum Bar, Epoxy The Bar In

Place At Put An Aluminum Stop At Each End Of

The Bar To Prevent The Bar From Moving

Methods - Continued:

Now you should assemble the guitar neck. I recommed Honduras Mahogany because it is light and

strong. Cut the portion to be used for the neck right down the center and flip the pieces so the grain

is opposed on each half. Add your center strip if desired and glue up. Cut the neck shape utilizing

the template provide in these documents with a band saw first. Prepare this joint so it is perfectly

tight. Next, cut the blank to size and capture any blocks you can to glue to the heel/foot assembly.

Gule the stacked Mahogany pieces to the neck for the guitar heel. Be sure to allow enough for the

dovetail or tongue of the neck.

Glue Your Headstock trim to the head of the guitar, including any wood laminate banding beneath

the trim.

Next rough-cut the heel and dovetail/or tongue/endblock shape of the neck on the bandsaw,

keeping things true and plumb. Remember to always cut a bit outside the lines to allow for slight

error. Now rough cut the head after tracing with your headstock template. Sand the sides to final

shape and size and drill you machinehead holes in the head. Now countersink the top of the head

for the machine head washers.

If you wish to trim out your headstock with purfling, now is the time to rout that channel and install

your wood purfling trims. Glue up with rubber bands or elastic upholstery tape. After it is dry

carefully sand or scrape the edges.

Next rough-shape the neck with a 4-way rasp, using the rough cut blade. Get the neck to within

about 1/16" of final thickness and width. Carefully shape the heel, constantly checking your

progress against the template you made.

Once the neck fits in the sides precisely, trim the butt joint of the sides and glue the butt block on

the bottom of the sides. Make sure to carefully fit the butt and neck block to the contour of the sides

and make sure the blocks are vertical grain. Once the blocks are in place, cut your kerfing for the

top and back and glue them in place with small clamps or wooden clothes pins with rubber bands.

Sand the top of the kerfing dead level with a large sandpaper block. Glue the top down to the

kerfing with rubber bands, elastic tape or spool clamps. Do not use too much force as everything

must fit precisely.

Final fit and glue the neck. Check the latteral and vertical positioning of the neck as this is

extremely important at this time. The foot and top of the block may need some additional trimming

when the back and top are fit.

Rout the channel for either the aluminum reinforcing rod or the adjustable truss rod - your choice.

Epoxy the aluminum bar in place including the shaped end pieces as shown in the neck section.

Allow the rod to be recessed slightly below the surface of the wood as it is tough to sand this metal

down.

With the sides rough-cut to contour, glue in the lining to receive the back plate. This lining can be

either kerfed lining or solid pre-bent lining. Glue with wooden clothespins with rubber bands

wrapped on them to strengthen their tension or use mini spring clamps. Make sure you have even

glue squeeze out and clean it up as you did on the braces.

Now fit the back to the sides and neck with the side following the contour of the inside form. Since

the braces for the back are slightly arched (about 4 to 6 mm ) carefully mark the trim marks for the

sides. This will vary with every aspect of the guitar beause the inherent nature of it's shape.

Materials:

Assemble the proper materials before you begin your project. If you don't have your tone wood

already, there are several great suppliers including LMI (Luthier's Merchantile) which has a wide

range of top and back and side wood available. If this is your first guitar, you may want to try wood

that is a bit less expensive for your first try, such as mahogany for backs and sides or walnut, which

is about 50 to 33% of the cost of the Rosewoods etc. A popular choice for a great flatpick acoustic

guitar is a good set of Hondourous Mahogany with straight grain - this was used on the classic

Martin D18's and is still popular today. A bonus is thay Mahogany is easy to bend, sand, finish and

stain - plus it's rather inexpensive. So this is a great choice for a first guitar, or second, or third.....

When you order wood make sure you order wood that is at least 1" oversized in each direction so

you can eliminate splits etc. 2" is even better and quite often accomodated with tone wood

suppliers. Make sure the tops and backs are bookmatched for grain pattern.

Neck blanks can be most any hardwood but it seems that Genuine Mahogany is the most popular

choice for it's strength to weight ratio. This is a very lightweight but very strong wood. Fretboards

should be clear Ebony, Rosewood is quite often used on lesser priced guitars, but I like the strength

and smoothness of the Ebony.

Most suppliers will have brace wood available, which is split from to log so there isn't any runout in

the wood - look for this in the literature. Also look for 16-20 lines/inch of grain.

You will also need additional wood to make up the purfling around he edges and you will need

maple or some other type of white wood if you want white stripping accents at your purflings.

Usually the outer layer of purfling or binding is thickest - 2mm or more and is made from the same

wood as the guitar back and sides.

We did not get into the details of how purfling is put on this guitar as that is more of a construction

issue and not a guitar plan issue. Any number of guitar construction books will guide you in the

proper techniques of installing purfling, where it should be and how to laminate it and bend it.

Buy good fret stock with at least 18% silver content. Steward MacDonald has a good assortment of

fretwire as does LMI. Sizes are noted on plans.

Nuts and Saddles? Bone, bone or bone. No plastic. Only use the best quality bone you can get.

Buy good tuning machines. Make sure they have good plating on them and the metal is a heavy

gauge. Either sealed gears or open gears are suitable for a good guitar. I like Schaller or Grover.

Bridge: I prefer to make my own out of Ebony to match the fretboard. Bridge Pins? Ebony of course

with mop dots is a nice touch. Bridge shape is a matter of taste. The standard belly bridge is hard to

beat for strength and tone qualities as shown on these plans.

Interior blocking for neck and butt blocks - Use Genuine Mahogany or Honduras Mahogany as it is

more commonly kinown. Grain should be vertical and no knots. This can be obtained at specialty

lumber suppliers and those that specialize in instrument woods.

Methods:

Start by sanding your top plate, back plate and sides to rough thickness (within 1mm of final

thickness). Carefully glue the center joints of the back and sides together. When gluing the back,

you will want to insert your decorative center strip at the same time. This should be pre-assembled

if you have multiple colors.

To prepare the joints, sand carefully with sandpaper glued to a perfectly straight edge. I like to use

adhesive backed sandpaper in rolls and stick it to the side of a 24" metal level. Trim the sandpaper

carefully. Use 120 grit paper and do not use a lot of force. The plates are joined most easily with a

cam-action jig while using a piece of wood on the top to keep things in alignment. Of course use

waxed paper wherever you risk having your wood stuck to the jig - or coat the jig with wax.

Once glued (If you use Rosewood, be sure to get all of the resin out of the wood with acetone

before you glue anything. Trace your top and back on the wood - use a white pencil for dark wood.

Then run the top and back through a wide stationary belt sander - or use scrapers and hand

sanding methods.

When I started out making guitars, I couldn't afford all the expensive stationary sanders etc,,

that makes the work so simple now. I used to get one side of the plate completely flat, then I

would chuck up a small bit in the drill press and set it to stop at the desired thickness of my

plate. I would then drill dimples over the entire surface of the unfinished side and simple

sand until all of the dents were gone - pretty slick!

After you have your thickness completed on the top plates. trace the guitar contour and carefully cut

the outline out. Make the cut line at least 1/8" outside the line to give you some give.

Get the sides bent, either with a bending jig or on a bending iron. You can also boil the sides and

clamp them to an outside form for a few days to a week. Be sure to overbend a bit to allow for

springback.

While the sides are curing, rout the channel for the rossette trim in the top plate and insert and glue

those pieces. I use a dremel router with a steel stud sticking up through the center of the soundhold

(the sound hole is not cut out at this point.) Once the rossette is installed, rout out the soundhole

with the router too.

Now is the time to install all of your bracing on the top and back. As I mentioned I use a dowel jig. I

plan on detailing these jigs in an upcoming book on guitar construction, but do not have plans on

the jig at this point. It works fast and really secures the bracing evenly and uniform. It also gives you

a lot of fingerspace to allow gluing all of the braces in a single operation without a lot of clamps to

work around.

Typically the braces are only roughed-out for their final shaping is done after they are glued. After

the glue is mostly dry, remove the plate and get all of the glue squeeze out off the bracing and plate

with a sharp small chisel. The glue should be dry enough to not be liquid but not fully adhered to the

wood.

Once the braces have had at least a couple of hours to dry, shape them and round them with small

planes, finger planes, chisels and sanding sticks. Final shape and sand them with 220 sandpaper

until satin smooth.

Tips and Techniques:

Always make sure your tools are razor sharp and not dull. Buy good sharpening stones or

sharpening grinders such as the Tormek sharpener. It is also important to knock off the burr on your

chisels and other hand tools.

If you use stationary tools, make sure the blades on your bandsaw, tablesaw, jointer etc. are also

very sharp and you do not have to force wood through the machines. If given a choice, always use

carbide-tipped blades. Some of these hardwoods are tough to cut without a good carbide blade.

Setup of power tools is extremely important too - follow included direction or obtain good books on

proper setup of bandsaws, table saws etc. You can't believe what a difference this will make.

You can never have enough jigs, templates etc. in guitar-making. If you plan to continue beyond this

guitar and make several others, templates and jigs are a must more making your work a lot easier.

If you are starting from scratch, building guitars, make sure you make excellent quality forms for

your guitar. Both inside and outside forms for the body assembly. Look at LMI's side bending

machine. It works great and you can pump out a lot of bent sides in a short time.

Put together the templates we have shown here at a bare minimum. You should have a template to

trace your basic guitar boddy shape, your top and back brace locations, Your neck and foot profile

and the headstock layout, showning all the drilling locations for the tuning machine rollers and string

slots. Also it comes in handy to have back brace curvature templates, brace scalloping patterns, fret

slot location templates and bridge templates.

There are a lot of great little tools and gadgets available for Guitar Lutherie - Here are a few:

Thumb Planes - Available from Luthier supply houses - they are primarilary used for violins.

Spindle Sander - This is a tabletop stationary tool.

Dremel Router with roller bearing bushings - or other small hand-held mini-routher.

Note Stewmac has a lot of adapters available for the Dremel such as purfling routers, bits

etc.

Fret cutting jig - this is available from Stewmac also. Give you precise control over fret sawing.

Make a jig to glue your bracing. This consists of 2 plywood plates with dowel supports at each

corner. The braces are glued using bent dowels that span between the two plates.

Make sure your shop is held an a very constant humidity level all year long. Never vary more than

5% between 45 and 55%. This will minimize cracking, shrinkage and give overall durability to

guitars you plan to sell or gift.

Some of the other great little tools I love are:

Japanese Saws that cut both ways

Lots of the German Cam Clamps - both 6" and 8"

1" Spring Clamps - A whole 2# coffee can full of these

A great set of instrument maker's chisels in 1mm 2mm 4mm and 6mm sizes

Fret file, dovetail saws, fret end dressing tool, fret rocker etc. see my fret repair series for

detail on these and a lot more tools

Look at www.ultimate-guitar-online.com/woodworking-hand-tools.html for hand tools required and:

www.ultimate-guitar-online.com/woodworking-power-tools.html for stationary tools recommended.

Above all else make sure everything fits together perfectly before gluing. Do not force anything as

stress is a guitar ruins the tone. When in doubt take a few extra hours of sanding trimming and pre-

assembly to get everything as perfect as you can.

Edge Purfling. I Prefer Solid Wood Over

Plastic As Plastic Is An Insulator. The

Edges Of The Guitar Need To Be Routed

And Stepped To Receive The Levels Of

Purfling And Trim. Round The Edges Of All

Purflings To Remove All Sharp Edges And

Allow Finish To Adhere.

F

C

E

A

Back Block or Butt Block. Vertical Grain

Honduras Mahogany. Some Luthiers

Shave This Block or Angle It Away

From The Top As This Block Often

Gives A Guitar A "Hump" In The Top

And Can Cause Cracking.

!"" $%

&+"" (%

!"" $%

&+"" (%

!"" $%

)"" (%

&*"" $%

&'"" (%

&*"" $%

&'"" (%

!"" $%

&,"" (%

!"" $%

&,"" (%

Kerfed Lining Made From Either Basswood Or

Mahogany. Make This Lines On The Bandsaw With A

Stop Jig Set Up So Your Kerfing Looks Perfectly

Spaced. Attention To Detail - Always Important.

The Soundhole Reinforcing Plate Is Made From The Same

Material As The Top Plate (i.e. Spruce) And Is Slightly

Larger Than The Rossette Size (About 1/8"). Glue It So

That The Grain Runs 90 Degrees To The Top. Fit It After

The Top Bracing Is In Place, To Fit It Perfectly Around The

Braces.

Side Braces: Made From Honduras Mahogany. 6mm x

3.2mm. Chamfer All Edges And Glue To The Guitar Sides

Optional Fingerboard Support. I Use This To

Provide Additional Support To The Fretboard

While Allowing Easier Installation Of Frets In

This Area And Reduces Fret Hammer

Bounce.

Use Either A Neck Dovetail Joint At The

Neck/Body Or A Tongue And Groove With

Through-Drilled Dowels For A Better Fit.

Tone Bracing For Top. Spruce Or Cedar. Vertical

Grain, No Run-Out. Min. 20 Grains/Inch.

Side Braces: Made From Honduras Mahogany.

6mm x 3.2mm. Chamfer All Edges And Glue To

The Guitar Sides

Edge Purfling. I Prefer Solid Wood Over

Plastic As Plastic Is An Insulator. The

Edges Of The Guitar Need To Be Routed

And Stepped To Receive The Levels Of

Purfling And Trim. Round The Edges Of All

Purflings To Remove All Sharp Edges And

Allow Finish To Adhere.

To Cover Up The Center Seam Inside The Guitar Body And Give The

Joint Additional Strength Use A Strip Of Maple 3mm Thick. Run Betwen

The Braces And Round-Off As Shown. The Best Way To Install This Is

As One Long Piece And Carefully Cut And Chisel Out The Channels

For The Back Braces.

Arch The Back Of The Guitar For Sound Reflectance Quality And To

Allow Some Tollerance For Humidity Changes. This Arch Should Be

Approximately 4 to 6mm Across The Wide Part Of The Back Plate

Take Care To Shape The Butt And Neck Blocks To Carefully Follow

The Curvature Of The Back Plate.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar

Often The Coped Ends Of The Top And Back Braces

Are Cut Through The Guitar Sides. Make Sure Your

Purfling For The Top And Bottom Plates Will Cover This

Channel Adequately Though.

Round The Back Edge Of The

Bridge. Refer To Longitudinal

Section

A

B

C

D E

F

G

(2) Of These Braces Are Required. Make Them

Mirror Images Of Each Other.

(2) Of These Braces Are Required. Make Them

Mirror Images Of Each Other.

Coping Out This Brace Is Optional. It Weakens The Structure

Of The Guitar, But Gives Slightly Better Sound Production.

Cut This Channel Very Carefully And Precisely. It Is Essential

That This Be A Very Tight Joint - Only Enough Room For Glue.

Cut Out With A Dovetail Saw With A Depth Stop

Bridge Plate Template

Belly Bridge Template

Round The Back Edge Of The

Bridge. Refer To Longitudinal

Section

Belly Bridge Variation

Neck Block. This Is A Very

Important Structural Element.

Construct From Vertical Grain

Honduras Mahogany

Back Braces - Vertical Grain Minimum 20

Grain/In. Cedar Or Spruce #1 Quality.

Cope Out Ends Of Bracing.

Back Material: Many Different Woods Can

Be Used. For Bright Tones Go With One

Of The Rosewoods Such As Indian

Rosewood or Brazilian Rosewood. Koa Is

Bright As Is Zircote And Madagascar

Rosewood. For Warm Tone Use Walnut.

Most Traditional Acoustic Guitars Are

Constructed From Indian Rosewood Or

Mahogany.

Back Plate Layout & Brace Layout

Dark Line Indicates Outside

Perimeter of Guitar. Light Line Is

Inside Of Sides.

&*"" $% -%./01

&'"" (% -%/+01

&*"" $% -%./01

&'"" (% -%/+01

!"" $% -%2&01

&,"" (% -%/+01

!"" $% -%2&01

&,"" (% -%/+01

&*"" $% -%./01

&'"" (% -%/+01

&*"" $% -%./01

&'"" (% -%/+01

!"" $% -%2&01

&,"" (% -%/+01

!"" $% -%2&01

&,"" (% -%/+01

To Cover Up The Center Seam Inside The Guitar Body And Give The

Joint Additional Strength Use A Strip Of Maple 3mm Thick. Run Betwen

The Braces And Round-Off As Shown. The Best Way To Install This Is

As One Long Piece And Carefully Cut And Chisel Out The Channels

For The Back Braces.

Arch The Back Of The Guitar For Sound Reflectance Quality And To

Allow Some Tollerance For Humidity Changes. This Arch Should Be

Approximately 4 to 6mm Across The Wide Part Of The Back Plate

A

B

C

D

A D C B

Back Block or Butt Block. Vertical

Grain Honduras Mahogany. Some

Luthiers Shave This Block or Angle

It Away From The Top As This Block

Often Gives A Guitar A "Hump" In

The Top And Can Cause Cracking.

Bridge Plate

Drill 10mm Holes Through Head

Block And Tenon For Cross Dowel

Installation

2

1

5

/

3

2

"

3

/

4

"

2

1

/

2

"

14 3/32"

6

"

3

1

/

4

"

3/4"

1

/

2

"

1

3

/

4

"

2

1

/

2

"

25/32"

5 1/2"

1 5/8"

1 5/8"

1 17/32" 1 5/8" 1 5/8"

3

"

25 13/32"

1 15/16"

3

/

8

"

2

5

/

3

2

"

3

1

/

8

"

1 1/32"

1

3

/

8

"

4" 3 3/4" 3 1/2" 4"

5 1/2" 3/4" 3/16"

1

1

5

/3

2

"

1

5

/8

"

1

5

/8

"

1

1

/2

"

13/16" 5/8"

1 7/16" 1 11/32" 1 9/32" 1 3/16" 1 1/8" 1 1/16" 1" 15/16" 29/32" 27/32" 13/16" 3/4" 23/32" 11/16" 5/8" 19/32" 9/16" 17/32" 1/2" 15/32"

29/32"

3

/

1

6

"

2

1

5

/

3

2

"

1

3

/

3

2

"

3

/

4

"

2 1/32"

3/16" 27/32" 31/32" 1 1/16"

1

1

3

/

3

2

"

7/8" 1/4" 7/8"

2"

3

/

1

6

"

1

5

/

3

2

"

3

/

1

6

"

1 29/32"

184 1/2"

2

1

/

4

"

2 1/4"

4

1

/

8

"

1

5

/

3

2

"

1

/

3

2

"

3

/

1

6

"

1

/

4

"

1

/

8

"

9

/

3

2

"

3

/

8

"

3/16" 3/32"

1

/

8

"

1

1

/

3

2

"

1

/

8

"

1

1

/

3

2

"

1

5

/

3

2

"

3

/

8

"

1

/

8

"

9

/

3

2

"1

1

/

3

2

"

1

/

8

"

9

/

3

2

"1

1

/

3

2

"

1

3

/

3

2

"

1

3

/

3

2

"

1

/

8

"

1

1

/

3

2

"

1

5

/

3

2

"

1

/

3

2

"

3

/

1

6

"

1

/

8

"

3

/

1

6

"

5

/

1

6

"

5

/

1

6

"

5

/

1

6

"

7

/

3

2

"

1

/

4

"

1

/

8

"

3

/

1

6

"

5

/

1

6

"

2 11/32" 5 27/32" 2 11/32"

10 1/2"

15 5/16"

3/8" 2 3/32" 2 11/16" 2 11/32" 6" 1 23/32" 5/32"

15 5/16"

1/8" 1 1/16" 8 1/8" 1 5/32"

10 1/2"

1/8" 1 1/16" 8 1/16" 1 5/32"

10 13/32"

1/16" 1 7/32" 13/16" 1 13/32" 1/32"

3 9/16"

1/8" 4" 1/32"

4 3/16"

5

/

1

6

"

5

/

1

6

"

5

/

1

6

"

5

/

1

6

"

6 5/32" 5/16"

5 3/4" 5/16"

3/8" 1 19/32" 4 11/32" 7 5/32" 1 7/8"

1" 7/16"

25/32"

6

"

1

1

/

4

"

1

5

/

3

2

"

2

1

7

/

3

2

"

1

5

/

3

2

"

1

1

/

4

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

2

1

9

/

3

2

"

1

1

3

/

3

2

"

3

7

/

3

2

"

1

1

3

/

3

2

"

5/32"

1/4"

25/32"

6

"

2

1

9

/

3

2

"

1

1

3

/

3

2

"

3

7

/

3

2

"

1

1

3

/

3

2

"

5/32"

1/4"

1"

1

1

/

4

"

9

/

3

2

"

3

7

/

3

2

"

1

1

/

4

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

7

/

1

6

"

5 17/32"

1

5

/

3

2

"

10 5/16"

9 21/32"

2 7/16" 5 13/32" 2 7/16"

2 13/32" 4 13/16" 2 13/32"

2 5/8" 8 1/4" 2 5/8"

1

/

8

"

1

/

8

"

3

/

1

6

"

3

/

3

2

"

1

/

8

"

9

/

3

2

"

3

/

3

2

"

3

/

3

2

"

9

/

3

2

"

1

5

/

3

2

"

1

5

/

3

2

"

13 23/32"

5

/

3

2

"

1

/

8

"

3

/

1

6

"

2 7/8" 7 15/16" 2 7/8"

1

5

/

3

2

"

13 17/32"

3/32" 10 1/8" 3/32"

10 5/16"

5

/

1

6

"

5

/

1

6

"

7/32" 9 1/4" 7/32"

9 21/32"

1/4" 13 1/16" 1/4"

13 17/32"

3/16" 13 11/32" 3/16"

13 23/32"

3

/

4

"

3

/

4

"

18 7/8"

1

4

7

/

3

2

"

1

0

1

3

/

1

6

"

25 13/32"

Methods - Continued:

Next is the time to trim the plates, rout purfling grooves around the edges of the guitar and fit the

purfling. With groove cleaned out, nice tight fit and everything cut to length, glue on the purfling.

When using wood prufling, be sure to prebend the wood so it will fit with as little stress as possible.

Glue the purfling with your glue, and bind to the channel with the same upholstery tape as was

used for the top and back. This can also be done with the guitar inside the inside form if you desire.

Rough sand the sides, back and top plates and round the edge of the purfling.

Next sand the fingerboard to thickness, cut to correct width and final sand the edges on a stationary

belt sander. Cut the fret grooves and locate the fretboard on the neck. Lightly clamp it and drill 2

small holes down through the fret groove at the body and nut ends of the fretboard. Place small

locator nails in the holes and double check the fingerboard location before gluing. Double check all

the latteral and vertical locations with a precise straight edge. Now install any edge binding on the

fretboard that you may wish to install. Final sand everything and make sure the fretboard is dead

level. Glue the fretboard in place.

Final shape the neck to the fretboard size, shape the heel and finish sand. Place a heel trim on the

bottom of the heel. Dry-fit the tuning machines and make any adjustments so there is no binding or

forcing in place. Fit the nut and bridge. Mark the bridge location with a light pencil or scribe mark.

Install masking tape over the bridge location and cut it to shape using the bridge. You finish the

guitar without the bridge in place, remove the masking tape and glue the bridge. A great tip to locate

the bridge is to drill down through the outside bridge pin holes and secure the bridge with 2 stove

bolts, tighted with finger pressure only.

Give all wood surfaces a final sanding with 220 grit sandpaper, install the frets and prepare to install

the finish.

There are many different opionions on finish material from urethane to varnish to lacquers. Do your

research and decide on what suite you best. Remember the thinner the finish the better sound you

will get with a solid wood guitar.

Finishing is a whole different operation in and of itself is too lengthy to discuse in this format. I

sugguest you get a good book on instrument finishing from one of the suppliers.

This was a quick overview of guitar construction and I have not had the room to go into any great

detail on anything. At Ultimate Guitar OnLine, we plan on publishing an ebook on guitar

construction in the near future, so watch for that.

Good Luck and most of all HAVE FUN!

Check Us Out At:

www.ultimate-guitar-online.com

http://ultimate-guitar-building.com

david@ultimate-guitar-online.com

Our sites have a LOT of tips on such things as fret installation, neck adjustments and

recommendations etc. Check out the articles and come back often as we are adding content all the

time.

Scale Length

Alternate Neck Connection Method Using

2" Bolts & Brass Cross-Dowels - Plan

These Are The Tone Braces. This Is What

Really Prohibits An Acoustic Guitar From

Being Easily Changed From A Right Hand To

A Left-Handed Guitar. Refer To The

Reference Photo, Which Indicates a

Standard Right Handed Guitar Placement

Lateral Section

Hex Truss Rod Adjustment Nut

Truss Rod Cap

2" Brass Connector Bolts

Access Hole For

Truss Rod Nut

Alternate Neck Connection Method Using

2" Bolts & Brass Cross-Dowels - Elevation

Guitar Sides

Guitar Neck Block. Vertical Grain Hondurous

Mahogany.

Neck Heel. Same Wood As Neck. This Is The

Contour At The Narrow Point Of The Heel. Quite

Often This Contour Changes Depending On

Luthier Construction Method.

Dashed Lines Indicate Wood Dowels Placed

Through The Neck Block And Tongue Portion Of

The Neck.

Dashed Lines Indicate Outline Of Heal At Back Or

Bottom Of Heel.

Guitar Sides

Guitar Neck Block. Vertical Grain Hondurous

Mahogany.

Neck Heel. Same Wood As Neck. This Is The

Contour At The Narrow Point Of The Heel. Quite

Often This Contour Changes Depending On

Luthier Construction Method.

Dashed Lines Indicate Outline Of Heel At Back Or

Bottom Of Heel.

Dashed Lines Indicate Two-Way

Truss Adjustment Rod. Cut Channel

As Per Truss Rod Suppliers Specs

10mm Diamter Holes For Brass

Cross Dowels - 2 Required

Outline of Heel

Shaded Areas Are Hardwood Laminate Pieces

Epoxy Glued To the Tenon. Run Grain 90

Degrees To The Neck Grain

You might also like

- Classic3plan 2Document1 pageClassic3plan 2Michele Pacilli100% (1)

- Classic 2 TemplatesDocument1 pageClassic 2 TemplatesDaniel Garfo100% (3)

- Making A Guitar Neck PDFDocument8 pagesMaking A Guitar Neck PDFhoskencues100% (1)

- Classic 3 PlanDocument1 pageClassic 3 PlanMichele PacilliNo ratings yet

- LuthieryDocument29 pagesLuthieryapi-249392674100% (2)

- Martin V Joint NeckDocument1 pageMartin V Joint Neckandua40100% (2)

- Progetto TorresDocument1 pageProgetto TorresMichele Pacilli50% (2)

- Guitar Making - Building NotesDocument12 pagesGuitar Making - Building NotesMarkNo ratings yet

- Building A Resonator 40021252011Document57 pagesBuilding A Resonator 40021252011Jose Carlos100% (2)

- Introduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarFrom EverandIntroduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarRating: 1 out of 5 stars1/5 (1)

- Instructions Neck AngleDocument21 pagesInstructions Neck Angleandua40100% (2)

- Construction Notes For A Steel String Guitar - SampleDocument32 pagesConstruction Notes For A Steel String Guitar - SampleDennistoun75% (4)

- GuitarBuildingJigsTools v1.1Document16 pagesGuitarBuildingJigsTools v1.1Mochamad Rizal Jauhari86% (7)

- Luthieria - Selmer Maccaferri NeckDocument9 pagesLuthieria - Selmer Maccaferri Neckmandolinero67% (9)

- Acoustic Guitar InnovationsDocument27 pagesAcoustic Guitar InnovationsAugusto Espejo100% (1)

- 16 Archtop Guitar BuildDocument123 pages16 Archtop Guitar Buildluis7oliveira_2100% (4)

- Guitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDaniel GarfoNo ratings yet

- Classic3plan 3Document1 pageClassic3plan 3Michele PacilliNo ratings yet

- Double Cut LP JRDocument34 pagesDouble Cut LP JRRXillusionist92% (12)

- Curso Luthier by Johnny GuitarDocument95 pagesCurso Luthier by Johnny GuitaradmlewisNo ratings yet

- Acoustic Guitar PlansDocument7 pagesAcoustic Guitar PlansFrançesko Astroza80% (5)

- Top Plate Brace Layouts: Classical Guitar Plan #3Document1 pageTop Plate Brace Layouts: Classical Guitar Plan #3Michele PacilliNo ratings yet

- Guitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsFrom EverandGuitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsNo ratings yet

- ItishDocument140 pagesItishGabriel Cano100% (6)

- Archtop Build Journal - Third Edition - Lo Res PDFDocument102 pagesArchtop Build Journal - Third Edition - Lo Res PDFOscar Camacho RosalesNo ratings yet

- ManZer GuitarsDocument18 pagesManZer Guitarsdedalus777100% (5)

- Acoustic Guitar MakingDocument1,000 pagesAcoustic Guitar MakingRicardo Luis Martin Sant'Anna100% (9)

- Bending Iron For Guitar MakingDocument1 pageBending Iron For Guitar Makingpeter100% (1)

- Kasha Guitar PlanDocument1 pageKasha Guitar PlanAndrey BalalinNo ratings yet

- Master Class Guitar MakingDocument50 pagesMaster Class Guitar MakingCharles Alfaro83% (18)

- (Luthieria) Acoustic Guitar MakingDocument63 pages(Luthieria) Acoustic Guitar MakingKa LuthieriaNo ratings yet

- Voicing The Steel String Guitar by Dana BourgeoisDocument12 pagesVoicing The Steel String Guitar by Dana Bourgeoisandrea_albrile100% (1)

- Acoustic Guitar Building InstructionsDocument40 pagesAcoustic Guitar Building InstructionsLeeUnder100% (2)

- 11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFDocument22 pages11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFBatik Kambangsri100% (4)

- 72 Custom - Deluxe Telecaster PlanDocument7 pages72 Custom - Deluxe Telecaster PlanPhilip Gregory Sougles50% (2)

- Guitar Plan Fender Jaguar TemplateDocument2 pagesGuitar Plan Fender Jaguar Templateethianluthier67% (3)

- Bracing Styles For Classical Guitars - This Is Classical GuitarDocument9 pagesBracing Styles For Classical Guitars - This Is Classical Guitarmenique100% (1)

- Guitar Making Guide - Jon SevyDocument170 pagesGuitar Making Guide - Jon Sevyaboutsoundcraft100% (5)

- Archtop Guitar ManualDocument123 pagesArchtop Guitar ManualCarlo351100% (13)

- Archtop Build Journal - Fifth Edition - (Low Res)Document122 pagesArchtop Build Journal - Fifth Edition - (Low Res)Jose Maria Hidalgo100% (1)

- Guitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDocument1 pageGuitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (3)

- French PolishingDocument34 pagesFrench Polishingaboutsoundcraft89% (9)

- Soundboards DF PDFDocument17 pagesSoundboards DF PDFalberto reyes100% (2)

- Archtop Guitar PlansDocument1 pageArchtop Guitar PlansBart Stratton83% (6)

- The Art and Craft of Making Classical GuitarsFrom EverandThe Art and Craft of Making Classical GuitarsRating: 2 out of 5 stars2/5 (1)

- Guitar Makers: The Endurance of Artisanal Values in North AmericaFrom EverandGuitar Makers: The Endurance of Artisanal Values in North AmericaNo ratings yet

- GuitarDocument11 pagesGuitarvakarmeNo ratings yet

- Assembling An Electric GuitarDocument42 pagesAssembling An Electric GuitarLionello Vanoni100% (2)

- Your First 10 Acoustic Guitar Lessons: Master Essential Skills with Weekly Instruction and Guided Daily PracticeFrom EverandYour First 10 Acoustic Guitar Lessons: Master Essential Skills with Weekly Instruction and Guided Daily PracticeNo ratings yet

- Cigar Box Guitar: Tools Used in This ProjectDocument10 pagesCigar Box Guitar: Tools Used in This Projectbpearson02311132No ratings yet

- How To Build A Basic Cigar Box GuitarDocument7 pagesHow To Build A Basic Cigar Box GuitarLeon Claassen100% (1)

- Guitar Pickup - Make Your OwnDocument10 pagesGuitar Pickup - Make Your OwnVivek TeegalapallyNo ratings yet

- Wood For SoundDocument10 pagesWood For SoundJayMorgan100% (1)

- 9431 Archaeology GuidebookDocument200 pages9431 Archaeology GuidebookThiep Vu100% (3)

- La Ardila by Tomatito PDFDocument8 pagesLa Ardila by Tomatito PDFJayMorganNo ratings yet

- The Old Lime Tree S Rudnev PDFDocument4 pagesThe Old Lime Tree S Rudnev PDFJayMorgan50% (2)

- Sergey Orekhov ScoreDocument8 pagesSergey Orekhov ScoreJayMorganNo ratings yet

- Violin Varnish and How To Make ItDocument54 pagesViolin Varnish and How To Make ItMatt Hartwell100% (5)

- Youngs Modulus ResonanceDocument11 pagesYoungs Modulus ResonanceJayMorganNo ratings yet

- Anatomy of The Ship - HMS Beagle - Survey Ship ExtraordinaryDocument130 pagesAnatomy of The Ship - HMS Beagle - Survey Ship ExtraordinaryCadar Raul100% (4)

- Sergey Orekhov ScoreDocument8 pagesSergey Orekhov ScoreJayMorganNo ratings yet

- Making Toys & Mechanial in WoodDocument160 pagesMaking Toys & Mechanial in WoodJayMorgan100% (2)

- The Discovery of Mesopotamian MusicDocument43 pagesThe Discovery of Mesopotamian MusicJayMorgan100% (1)

- Sumerian GrammarDocument215 pagesSumerian GrammarBaskar Saminathnan100% (18)

- NyckelharpaDocument5 pagesNyckelharpaJayMorganNo ratings yet

- It Aint Rocket Science AcousticsDocument23 pagesIt Aint Rocket Science AcousticsJayMorganNo ratings yet

- What You Can Find Out by Hitting ThingsDocument18 pagesWhat You Can Find Out by Hitting ThingsJayMorganNo ratings yet

- V Acoustics 2Document6 pagesV Acoustics 2JayMorganNo ratings yet

- V Acoustics 1Document4 pagesV Acoustics 1JayMorganNo ratings yet

- The Sumerian Language, An Introduction To Its History and Grammatical Structure - Marie-Louise ThomsenDocument190 pagesThe Sumerian Language, An Introduction To Its History and Grammatical Structure - Marie-Louise ThomsenJulius Morrison100% (3)

- 2004 Ibanez CatalogueDocument22 pages2004 Ibanez CatalogueAsad50% (2)

- (Luthieria) Acoustic Guitar MakingDocument63 pages(Luthieria) Acoustic Guitar MakingKa LuthieriaNo ratings yet

- The Beauty of The BurstDocument527 pagesThe Beauty of The BurstRicardo Soares100% (2)

- Vintage Electric Guitars2010Document40 pagesVintage Electric Guitars2010Cleyton Milléo100% (1)

- SX ELECTRIC GUITAR - Team International+9 - 7 - 10 PDFDocument30 pagesSX ELECTRIC GUITAR - Team International+9 - 7 - 10 PDFmancool282100% (1)

- RETAIL Mayones Complete Price List 20150331Document25 pagesRETAIL Mayones Complete Price List 20150331tribudei88No ratings yet

- Review of Skylark and Songbird Fan Fret ModelsDocument4 pagesReview of Skylark and Songbird Fan Fret ModelsNicholas EeNo ratings yet

- Week 6-9 - Art and ArtisansDocument8 pagesWeek 6-9 - Art and ArtisansJon GaudielNo ratings yet

- Yamaha Erg121c Manual de UsuarioDocument22 pagesYamaha Erg121c Manual de UsuarioSERGIO CASTRONo ratings yet

- Guitar Fretboard - The Simple Method To Memorize The FretboardDocument53 pagesGuitar Fretboard - The Simple Method To Memorize The Fretboardsskourosyahoo.com85% (13)

- Artigo Violao 11 Cordas - Torres 11Document2 pagesArtigo Violao 11 Cordas - Torres 11baianosalvadorNo ratings yet

- Luthier PDFDocument8 pagesLuthier PDFasdwqq100% (1)

- Guitar LessonDocument151 pagesGuitar Lessonapi-3760846100% (6)

- Guitar Mag 519 PDFDocument156 pagesGuitar Mag 519 PDFfrancis de silva100% (2)

- 02 WholeDocument66 pages02 Wholebubba997No ratings yet

- Venetian Viols of The 16th-Century w1980 - EdmumDocument9 pagesVenetian Viols of The 16th-Century w1980 - EdmumArmando PlancarteNo ratings yet

- Pink Floyd: Icon Shows Us His Guitars!Document132 pagesPink Floyd: Icon Shows Us His Guitars!Pumpkn100% (2)

- Brian's Guitar: From Conception To BirthDocument84 pagesBrian's Guitar: From Conception To BirthhoranielNo ratings yet

- Blackjack Atx C-7Document3 pagesBlackjack Atx C-7f3rm1onNo ratings yet

- MUSIC 10 Q2 2nd ModulesDocument8 pagesMUSIC 10 Q2 2nd ModulescharlitoskNo ratings yet

- Trapezoidal Neck Strandberg US20130186254A1Document10 pagesTrapezoidal Neck Strandberg US20130186254A1Percy Stanbury Malaga100% (1)

- GUITAR ANATOMY - Parts of The Guitar and Tuning TechniqueDocument5 pagesGUITAR ANATOMY - Parts of The Guitar and Tuning TechniqueGeorge JefwaNo ratings yet

- Bass Asia LowDocument13 pagesBass Asia LowObsidian DrackNo ratings yet

- Sadowsky Setup Instructions New 12.8.20Document5 pagesSadowsky Setup Instructions New 12.8.20Sergio GuerraNo ratings yet

- Mayones Regius Elements Manual WebDocument64 pagesMayones Regius Elements Manual WebEgner QueroNo ratings yet

- The Ultimate Guitar Scales BookDocument114 pagesThe Ultimate Guitar Scales BookNacho Gallent100% (4)

- Dobro ScalesDocument70 pagesDobro Scalessizdoo100% (3)

- DIY How To Set Up A Fend 2Document2 pagesDIY How To Set Up A Fend 2joaotgil100% (1)

- Electric Guitar: Service ManualDocument6 pagesElectric Guitar: Service ManualSri KṛṣṇaNo ratings yet

- Buku Gitar 1Document29 pagesBuku Gitar 1R Heru Suseno PusponegoroNo ratings yet