Professional Documents

Culture Documents

Perkalink 900

Uploaded by

casual12Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perkalink 900

Uploaded by

casual12Copyright:

Available Formats

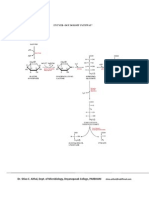

H

2

C CH

2

N N

O O

CH

3 H

3

C

O O

S

p

e

c

i

a

l

t

i

e

s

page 1 of 2

Product Data

PERKALINK 900

1,3-Bis(citraconimidomethyl)benzene

CAS Reg. No.: 119462-56-5

Molecular weight: 324

FUNCTION

Perkalink 900 is an antireversion agent which provides long term heat stability in sulfur vulcanized

compounds by substituting stable, flexible carbon-carbon crosslinks for the sulfur crosslinks that are

destroyed by reversion in the mold or during product service life.

MAJOR APPLICATIONS AND PROPERTIES

- Perkalink 900 is used in most sulfur vulcanized polymers such as NR, IR, SBR, BR or blends of these

elastomers to provide improved reversion resistance on overcure.

- Perkalink 900 is used to allow the use of higher curing temperature for improved productivity without

sacrificing performance properties.

- Perkalink 900 is used to control heat buildup and thermal degradation during product service life by

maintaining crosslink density through the generation of thermally stable carbon-carbon crosslinks

which compensates for the loss of reverted sulfur crosslinks.

- Perkalink 900 is used in high sulfur skim compounds to provide reduced heat generation and

retention of adhesion to brass plated steel reinforcing materials as well as enhanced thermal aging

resistance.

- Perkalink 900 is used in Exxpro bladder to reduce or eliminate sulfur, thus overcoming mold fouling.

- Perkalink 900 is regulated for use in articles in contact with food as specified under BgVV XXI,

Category 4. Perkalink 900 is not regulated for use in FDA food contact applications.

COMPOUNDING INFORMATION

Perkalink 900 is not reactive during the initial stages of vulcanization. Scorch and cure time are

therefore not affected. This means that it can be added without making other compound or process

modifications. Perkalink 900 begins to work when sulfur crosslinks are being destroyed (on overcure or

under elevated temperatures during service life). It is therefore most effective in compounds that are

sensitive to thermal degradation.

The dosage level of Perkalink 900 needs to be optimized based on the expected degree of reversion

(as determined by the accelerator/sulfur ratio). As a starting point, we recommend that the following

dosages be used:

Efficient to semi-efficient cure systems : 0.25 - 0.4 phr

Semi-efficient cure systems : <0.5 phr

Conventional cure systems : <0.75 phr

High sulfur compounds : <0.75 phr

We recommend that Perkalink 900 be added to the rubber compound during the first (non-productive)

mixing stage. Perkalink 900 has a melting point below 90C so dispersion will not be a problem.

All product names are registered trade marks. PK9003.SP/1000

The information and recommendations in this publication are provided without warranty as to completeness, correctness or suitability for any

particular purpose. The user of this publication assumes responsibility for and Flexsys shall not be liable for any injury, loss or damage arising

from any use or reliance upon its contents.

Copyright Flexsys 2000.

For further information please contact your local Flexsys office or regional Flexsys headquarters:

Regional Headquarters :

Tel. :

Fax :

Brussels

+32 2 714 32 11

+32 2 714 32 32

Akron

+1 330 666 41 11

+1 330 668 83 45

Singapore

+65 872 28 08

+65 872 28 18

page 2 of 2

pst

pastilles

off white pastilles

85.0

75

80-90

0.5

0.3

1260-1280

710-760

720-770

Regional Headquarters :

Tel. :

Fax :

Brussels

+32 2 714 32 11

+32 2 714 32 32

Akron

+1 330 666 41 11

+1 330 668 83 45

Singapore

+65 872 28 08

+65 872 28 18

HANDLING PRECAUTIONS

For detailed information on toxicological properties and handling precautions please refer to the current Safety

Data Sheet. This information sheet can be downloaded from our web site or requested from the nearest Flexsys

office and should be consulted before handling this product.

STORAGE RECOMMENDATIONS

Store Perkalink 900 in a cool, dry, well ventilated area, avoiding exposure of the packaged product to direct

sunlight.

PRODUCT INFORMATION

Perkalink 900

Product form

PRODUCT SPECIFICATIONS

Appearance

Active components

Melting point, initial

Melting point, final

Heat loss

Ash

TYPICAL PROPERTIES

Density at 20C

Bulk density

Compacted bulk density

(%) min.

(C) min.

(C)

(%) max.

(%) max.

(kg/m

3

)

(kg/m

3

)

(kg/m

3

)

Test method

FF97.5

FCL95.5

FF83.9

FF83.9

FGr97.7

FGr90.9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bioenergy Basics ExplainedDocument41 pagesBioenergy Basics Explainedcasual12No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Theory of Rubber CompoundingDocument19 pagesTheory of Rubber Compoundingrossifam777No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Designing RubberDocument14 pagesDesigning Rubbercasual12100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Al Material Matters v5n1Document32 pagesAl Material Matters v5n1casual12No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Al Material Matters V1n1-PolymerizationDocument12 pagesAl Material Matters V1n1-Polymerizationcasual12No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AlnovolDocument18 pagesAlnovolcasual12No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Lab 6-The Silver GroupDocument6 pagesLab 6-The Silver Groupsteph002100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Selective Laser SinteringDocument24 pagesSelective Laser SinteringRahul GandhiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Convection and Conduction Heat TransferDocument406 pagesConvection and Conduction Heat Transfertfemilian100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneDocument9 pagesEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresNo ratings yet

- Kandungan Obat Merek Dagang SediaanDocument1 pageKandungan Obat Merek Dagang SediaanRaden Mas Nur HaryonoNo ratings yet

- Welds CracksDocument8 pagesWelds Cracksaltaf94No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elzein M. Fahal, Et Al PDFDocument9 pagesElzein M. Fahal, Et Al PDFNiaz mahmudNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CarbonicAnhydrases Manuscript withDOIDocument11 pagesCarbonicAnhydrases Manuscript withDOIFadhil MiftahulNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Wall Colmonoy Surfacing Alloys Selector ChartDocument3 pagesWall Colmonoy Surfacing Alloys Selector ChartAjimKe'enNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Water Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolDocument11 pagesWater Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolLeonard PolancoNo ratings yet

- 31.PEAK Depressurization RATEDocument1 page31.PEAK Depressurization RATEDILIP MATALNo ratings yet

- Paper 4 Jun 2001 PhysicsDocument2 pagesPaper 4 Jun 2001 Physicssolarixe100% (1)

- Entner Duodroff PathwayDocument2 pagesEntner Duodroff PathwayDr. SHIVA AITHALNo ratings yet

- Chemistry 2pointsDocument4 pagesChemistry 2pointsjovanniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Effects of Substituent On Benzene RingDocument12 pagesEffects of Substituent On Benzene Ringyashfa khalidNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- ConversationDocument2 pagesConversationHiggilty PiggiltyNo ratings yet

- Practice 4ADocument22 pagesPractice 4ACamha NguyenNo ratings yet

- Problem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ADocument8 pagesProblem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ARadica AyuNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- W. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFahmed shakerNo ratings yet

- Solidification ShrinkageDocument4 pagesSolidification ShrinkagesubavlNo ratings yet

- Presentation 01Document28 pagesPresentation 01Rexona KhanomNo ratings yet

- Installation Details IguzziniDocument133 pagesInstallation Details IguzziniimtiazNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- CV en - Op - Gill Giovani Awonguino oDocument1 pageCV en - Op - Gill Giovani Awonguino oAuguste SuelieNo ratings yet

- 3 - 2021 Thermodynamics USTH Part 2Document13 pages3 - 2021 Thermodynamics USTH Part 2Pham Duc AnhNo ratings yet

- Balancing Redox Reactions Worksheets 1 & 2 (With Answers) PDFDocument2 pagesBalancing Redox Reactions Worksheets 1 & 2 (With Answers) PDFMohamed MeeranNo ratings yet

- Erba URIC ACID DESDocument2 pagesErba URIC ACID DEShexamed bme100% (1)

- Effectiveness of Liquid Oxygen BleachDocument4 pagesEffectiveness of Liquid Oxygen BleachSingh GurleenNo ratings yet

- Thermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument20 pagesThermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForAndres Camilo BenitezNo ratings yet

- Yemen LNG Upstream Facilities Project: Phase 1 Process Design Basis ManualDocument23 pagesYemen LNG Upstream Facilities Project: Phase 1 Process Design Basis Manualabdoamer.2553No ratings yet

- Specifying Duplex Systems - American Galvanizers AssociationDocument2 pagesSpecifying Duplex Systems - American Galvanizers AssociationNsidibe Michael EtimNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)