Professional Documents

Culture Documents

Evolution of Motorola Flip Phones Design

Uploaded by

DattaSandesh0 ratings0% found this document useful (0 votes)

125 views48 pagesThe document discusses the evolution and success of the Motorola RAZR flip phone. It provides details on:

1. The RAZR's design emerged from a vision to create a significantly thinner phone than competitors, with an iconic new form. Its novel architecture distinguished it from existing product platforms.

2. The RAZR was successful due to its small size, integrated features like a camera and Bluetooth, durable materials, and ergonomic design that complemented users. Its sleek metallic design gave it a futuristic look.

3. The RAZR demonstrated that industrial design could differentiate products and satisfy customer needs, becoming an important tool for companies like Motorola to compete. Its iconic thin design

Original Description:

Basics Of Industrial Design.

Original Title

Chapter1 Industrial Design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the evolution and success of the Motorola RAZR flip phone. It provides details on:

1. The RAZR's design emerged from a vision to create a significantly thinner phone than competitors, with an iconic new form. Its novel architecture distinguished it from existing product platforms.

2. The RAZR was successful due to its small size, integrated features like a camera and Bluetooth, durable materials, and ergonomic design that complemented users. Its sleek metallic design gave it a futuristic look.

3. The RAZR demonstrated that industrial design could differentiate products and satisfy customer needs, becoming an important tool for companies like Motorola to compete. Its iconic thin design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

125 views48 pagesEvolution of Motorola Flip Phones Design

Uploaded by

DattaSandeshThe document discusses the evolution and success of the Motorola RAZR flip phone. It provides details on:

1. The RAZR's design emerged from a vision to create a significantly thinner phone than competitors, with an iconic new form. Its novel architecture distinguished it from existing product platforms.

2. The RAZR was successful due to its small size, integrated features like a camera and Bluetooth, durable materials, and ergonomic design that complemented users. Its sleek metallic design gave it a futuristic look.

3. The RAZR demonstrated that industrial design could differentiate products and satisfy customer needs, becoming an important tool for companies like Motorola to compete. Its iconic thin design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 48

INDUSTRIAL DESIGN

Evolution of Motorola Flip Phones

The new RAZR design emerged

from a product vision to be thin

to win considerably thinner

than other mobile telephones on

the market and striking in its

iconic new form.

The design required a new

architecture, entirely distinct from

the existing product platforms.

Sales to early adopters came

quickly after a successful market

introduction in which Hollywood

celebrities were shown with the

product.

The success can be attributed to several factors:

Small size and weight

RAZR, with slimmer form factor was more pocketable.

Thickness of 14 mm & a weight of 95 gms.

Performance features

RAZR featured an integrated camera, a large, backlit keypad

and a large, bright, color display for new video and graphic

applications.

Instead of a headset jack, the RAZR utilized Bluetooth

networking for wireless headset accessories.

Superior signal reception and transmission was achieved

with a novel layout in which the phones antenna was

positioned below the keypad.

Evolution of Motorola Flip Phones

Superior ergonomics

RAZRs sleek, ergonomic design complemented the human

face.

Shape of the handset, particularly the angled position of the

display w.r.t the keypad section, conformed to the user for

superior comfort.

Spacing and position of the buttons on the keypad were

based on accepted standards, and extensive testing allowed

for fast and accurate dialing.

Folding design allows the user to answer or end calls by

opening or closing the phone with one hand, aided by a

recess between the two sections of the clamshell.

New software for navigation and new shortcuts for entering

text facilitated use of text messaging and other applications.

Evolution of Motorola Flip Phones

Durability

RAZR can be dropped from a height of more than 1 m onto

a cement floor or sat upon in the open position without

sustaining any damage.

Can withstand temperature extremes, humidity, shock, dust

and vibration.

Materials to enhance both performance and appearance

RAZR includes a laser-cut keypad with laser-etched

patterns, magnesium hinge, ultra-thin anodized aluminum

housing, polycarbonate composite antenna housing, and

chemically annealed glass with a thin-film coating.

Appearance

Sleek design and metallic finishes gave the RAZR a

futuristic look associated with innovation.

Evolution of Motorola Flip Phones

Industrial designers are primarily responsible for the aspects of

a product that relate to the users experience-the products

appeal (how it looks, sounds, feels, smells) and its functional

interfaces ( how it is used).

Managers used industrial designers to style, or gift wrap, a

product after its technical features were determined.

The globalization of markets has resulted in the design and

manufacture of a wide array of consumer products.

Accordingly, companies such as Motorola are increasingly

using industrial design as an important tool for both satisfying

customer needs and differentiating their products from those of

their competition.

Evolution of Motorola Flip Phones

The birth of ID is often traced to western Europe in early 1900s.

In the United States, however, early concepts of ID were

distinctly different and the trend is best evidenced in 1930s.

By the 1970s, however, European design had strongly

influenced American ID..

By 2000, industrial design became widely practiced in the

United States by professionals in many diverse settings ranging

from small design consulting firms to in-house design offices

within large manufacturing companies.

The Industrial Designers Society of America (IDSA) defines

industrial design as the professional service of creating and

developing concepts and specifications that optimize the

function, value, and appearance of products and systems for the

mutual benefit of both user and manufacturer.

What is Industrial Design

Dreyfuss (1967) lists five critical goals that industrial designers

can help a team to achieve when developing new products:

Utility

Products human interfaces should be safe, easy to use, and

intuitive.

Each feature should be shaped so that it communicates its

function to the user.

Appearance

Form, line, shape, and color are used to integrate the product

into a pleasing whole.

Ease of maintenance

Products must also be designed to communicate how they

are to be maintained and repaired.

What is Industrial Design

Low costs

Form and features have a large impact on tooling and

production costs, so these must be considered jointly by the

team.

Communication

Product designs should communicate the corporate design

philosophy and mission through visual qualities of the

products.

What is Industrial Design

Industrial designers are typically educated in four-year

university programs where they study sculpture and form;

develop drawing, presentation, and model-making skills; and

gain a basic understanding of materials, manufacturing

techniques & finishes.

In industrial practice, designers receive additional exposure to

basic engineering, advanced manufacturing/fabrication

processes, and common marketing practices.

Ability to express ideas visually can facilitate the process of

concept development for the team.

Industrial designers may create most of the concept sketches,

models, and renderings used by the team throughout the

development process, even though the ideas come from the

entire team.

What is Industrial Design

Assessing the need for ID

Expenditures for Industrial Design

For products with relatively little user interaction such as some

types of industrial equipment, the cost of ID is only in the tens

of thousands of dollars.

On the other hand, the development of an intensely visual and

interactive product such as an automobile requires millions of

dollars of ID effort.

For a technically sophisticated product, such as a new aircraft,

the ID cost can be insignificant relative to the engineering and

other development expenditures.

Certainly the success of a new automobile design is highly

dependent on its aesthetic appeal and the quality of the user

interfaces, two dimensions largely determined by ID.

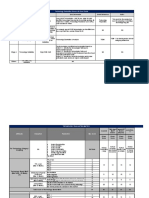

Total expenditures on ID and the percentage of the product development budget invested on ID for

some consumer and industrial products spanning various industries.

Statistics give design teams a rough idea of how much ID investment is required for a new product.

How important is Industrial Design to a Product?

Most products on the market can be improved in some way or

another by good ID.

All products that are used, operated, or seen by people depend

critically on ID for commercial success.

A convenient means for assessing the importance of ID to a

particular product is to characterize importance along two

dimensions: Ergonomics and Aesthetics.

The more important each dimension is to products success, the

more dependent the product is on ID.

Assessing the need for ID

Ergonomics Needs

How important is ease of use?

Important both for frequently used products and for in

frequently sued products.

Challenging if the product has multiple features and modes

of operation which may frustrate the user.

Industrial designers need to ensure that the features of the

product effectively communicate their function.

How important is ease of maintenance?

If the product need to be serviced or repaired frequently,

then ease of maintenance is crucial.

For example, a user should be able to clear a paper jam in a

printer or photocopier easily.

Assessing the need for ID

How many user interactions are required?

In general, the more interactions users have with the product,

the more the product will depend on ID.

For example, a doorknob typically requires only one

interaction, whereas a laptop computer may require a dozen

or more, all of which the industrial designer must understand.

How novel are the user interaction needs?

A user interface requiring incremental improvements to an

existing design will be relatively straightforward to design,

such as the buttons on a new desktop computer mouse.

What are the safety issues?

All products have safety considerations.

For example, the safety concerns in the design of a childs toy.

Assessing the need for ID

Aesthetic Needs

Is visual differentiation required?

Products with stable markets and technology are highly

dependent upon ID to create aesthetic appeal and, hence,

visual differentiation.

In contrast, a product such as a computers internal disk

drive, which is differentiated by its technological

performance, is less dependent on ID.

How important are pride of ownership, image and fashion?

A customers perception of a product is in part based upon

its aesthetic appeal.

An attractive product may be associated with high fashion

and image and will likely create a strong sense of pride

among its owners.

Assessing the need for ID

Will an aesthetic product motivate the team?

A product that is aesthetically appealing can generate a

sense of team pride among the design and manufacturing

staff.

Team pride helps motivate and unify everyone associated

with the project.

To demonstrate this method, we can use the above questions to

assess the importance of ID in the development of the Motorola

RAZR phone.

Assessing the need for ID

Assessing the Ergonomics importance of ID for Motorolas RAZR mobile phone.

Assessing the Aesthetics importance of ID for Motorolas RAZR mobile phone.

The Impact of ID

Is Industrial Design worth the Investment?

Managers will often know, for a specific product or for a

business operation in general, how much effort should be

invested in ID.

The costs of ID include:

Direct Cost

Cost of the ID services.

Determined by the number and type of designers used,

duration of the project, and number of models required,

plus material costs and other related expenses.

Additional charges include costs for models, photos, and

other expenses.

Manufacturing Cost

Expense incurred to implement the product details

created through ID.

Surface finishes, stylized shapes, rich colors, and many

other design details can increase tooling cost and

production cost.

In facts, some ID inputs can actually reduce

manufacturing costs-particularly when the industrial

designer works closely with the manufacturing engineers.

Time Cost

Penalty associated with extended lead time.

As industrial designers attempt to refine the ergonomics

and aesthetics of a product, multiple design iterations and

prototypes will be necessary.

The Impact of ID

Benefits of using ID include increased product appeal and

greater customer satisfaction through additional or better

features, strong brand identity, and product differentiation.

More recent studies have assessed ID effectiveness and

integration of ID into the product development process and

found positive correlations between these ID measures and

corporate financial performance.

For a specific project decision, performing simple calculations

and sensitivity analyses can help quantify the likely economic

returns from ID.

The rough estimates of these benefits can be compared to the

expected cost of the ID effort.

Spreadsheet models are commonly used for this kind of

financial decision making.

The Impact of ID

How does ID establish a Corporate identity?

Corporate identity is derived from the visual style of an

organization, a factor that affects the firms positioning in the

market.

Advertising, logos, signage, uniforms, buildings, packaging,

and product designs all contribute to creating corporate

identity.

ID determines a products style, which is directly related to the

public perception of the firm.

When a companys products maintain a consistent and

recognizable appearance, visual equity is established.

A consistent look and feel may be associated with the products

color, form, style, or even its features.

The Impact of ID

Some companies that have used ID to establish visual equity

and corporate identity through their product lines include:

Apple Computer, Inc

More recent Apple designs have striking lines and

innovative styling in silver, black, and white finishes.

Rolex Watch Co.

Maintains a classic look and solid feel that signifies

quality and prestige.

Braun GmbH

Kitchen appliances and shavers have clean lines and

basic colors.

The Impact of ID

Bang & Olufsen a/s

High-fidelity consumer electronics systems are designed

to have sleek lines and impressive visual displays,

providing an image of technological innovation.

BMW AG

Automobiles, known for luxury features and driver-

oriented performance, display exterior styling features

that have evolved slowly, retaining the equity associated

with the brand.

Motorola, Inc.

Mobile phones were recognized as Motorolas leading-

edge flip-phone innovations and also uses a folding

clamshell concept in a much thinner from factor.

The Impact of ID

The Industrial Design Process

Large companies have internal industrial design departments.

Small companies tend to use contract ID services provided by

consulting firms.

Most industrial designers follow a process for designing the

aesthetics and ergonomics of a product.

ID process consists of following phases:

Investigation of customer needs.

Conceptualization.

Preliminary refinement.

Further refinement and final concept selection.

Control drawings or models.

Coordination with engineering, manufacturing, and external

vendors.

Investigation of Customer Needs

Since, industrial designers are skilled at recognizing issues

involving user interactions, ID involvement is crucial in the

needs process.

For example, in researching customers needs for a new medical

instrument, the team would study an operating room, interview

physicians, and conduct focus groups.

ID allows the industrial designer to gain an intimate

understanding of the interactions between the user and the

product.

The team used extensive input form Motorola employees to

understand the evolution of user needs.

Motorolas research on consumer perceptions of quality in

mobile phones revealed that while light weight was desirable,

the phones density was also critical.

Once the customer needs and constraints are understood, the

industrial designers help the team conceptualize the product.

Industrial designers make simple sketches, which are fast and

inexpensive medium for expressing ideas and evaluating

possibilities, known as thumbnail sketches, of each concept.

Conceptualization

Two quick thumbnail concept sketches (left) and a more detailed colored rendering (right) showing

evolution of the RAZR concept.

It is fortunate that in some companies, industrial designers

work quite independently from engineering.

ID is likely to propose concepts involving strictly from and

style, and there are usually numerous iterations when

engineering finds the concepts technically feasible.

Firms have therefore found it beneficial to tightly coordinate

the efforts of industrial designers and engineers throughout the

concept development phase so that these iterations can be

accomplished more quickly-even in sketch form.

Conceptualization

Industrial designers build models of the most promising

concepts.

Soft models are typically made in full scale using foam or

foam-core board and are the second-fastest method-only

slightly slower than sketches-used to evaluate concepts.

Although generally quite rough, these models are invaluable

because they allow the development team to express and

visualize product concepts in three dimensions.

Concepts are evaluated by industrial designers, engineers,

marketing personnel, and (at times) potential customers

through the process of touching, feeling, and modifying the

models.

Concepts that are particularly difficult to visualize require more

models than do simpler ones.

Preliminary Refinement

Preliminary Refinement

A soft model (left) and a hard model (right) used by the RAZR industrial designers

to study alternative forms.

Industrial designers often switch from soft models and sketches

to hard models and information-intensive drawings known as

renderings.

Renderings show the details of the design and often depict the

product in use.

Renderings are often used for color studies and for testing

customers reception to the proposed products features and

functionality.

The final refinement step before selecting a concept is to create

hard models, which are still technically nonfunctional yet are

close replicas of the final design with a realistic look and feel.

Hard models are made from wood, dense foam, plastic, or

metal; are painted and textured; and have some working

features such as buttons that push or sliders that move.

Further Refinement & Final Concept

Selection

For many types of products, hard models are fabricated to have

the intended size, density, weight distribution, surface finish,

and color.

Hard models can then be used by industrial designers and

engineers to further refine the final concept specifications.

Furthermore, these models can also be used to gain additional

customer feedback in focus groups, to advertise and promote

the product at trade shows, and to sell the concept to senior

management within an organization.

Further Refinement & Final Concept

Selection

Industrial designers complete their development process by

making control drawings or models of the final concept.

Control drawings or models document functionality, features,

sizes, colors, surface finishes, and key dimensions.

Although they are not detailed part drawings (known as

engineering drawings), they can be used to fabricate final

design models and other prototypes.

Control Drawings or Models

Side view of the RAZR control model defining the final RAZR shape and

dimensions.

Industrial designers must continue to work closely with

engineering and manufacturing personnel throughout the

subsequent product development process.

Some industrial design consulting firms offer quite

comprehensive product development services, including

detailed engineering design and the selection and management

of outside vendors of materials, tooling, components, and

assembly services.

Coordination with Engineering,

Manufacturing, & External Vendors

Using modern 3D CAD tools, industrial designers can

generate, display, and rapidly modify three-dimensional

designs on high-resolution computer displays.

The visual realism of 3D CAD images can enhance

communication within the product development team and

eliminate much of the inaccuracy of the manually generated

sketches provided by industrial designers.

Furthermore, 3D CAD systems may be used to generate control

models or drawings, and these data can be directly transferred

to engineering design systems, allowing the entire development

process to be more easily integrated.

Impact of Computer-Based Tools on

the ID Process

Impact of Computer-Based Tools on

the ID Process

3D CAD concept image created using Pro/ENGINEER software.

ID is typically involved in the overall product development

process during several different phases.

The timing of the ID effort depends upon the nature of the

product being designed.

Technology-driven products

Core benefit is based on its technology, or its ability to

accomplish a specific technical task.

Ex.: Hard disk for a computer is largely technology

driven.

The role of ID is often limited to packaging the core

technology which entails determining the products

external appearance and ensuring that the product

communities its technological capabilities and modes of

interaction to the user.

Management of the ID Process

User-driven products

Core benefit is derived from the functionality of its

interface and/or its aesthetic appeal.

The user interfaces must be safe, easy to use, and easy to

maintain.

Ex.: An office chair is largely user driven.

The role of engineering may still be important to

determine any technical features of the product; however,

since the technology is often already established, the

development team focuses on the user aspects of the

product.

Management of the ID Process

Rarely does a product belong at one of the two extremes.

Instead, most products fall somewhere along the continuum.

Management of the ID Process

Classification of some common products on the continuum from technology-driven

product to user-driven product.

The technical nature of the problems that confront engineers in

their design activities typically demands substantially more

development effort than do the issues considered by ID.

Timing of ID Involvement

Relative timing of the industrial design process for two types of products.

The role of industrial design according to product type.

Five categories for evaluating a product.

1. Quality of the User Interface - Rating of how easy the

product is to use. Interface quality is related to the products

appearance, feel, and modes of interaction.

Examples of product-specific questions include: Is the grip

comfortable, Is the power switch easy to locate, Does the

control knob turn easily and smoothly, Is the display easy to

read and understand.

Do the features of the product effectively communicate their

operation to the user?

Is the products use intuitive?

Are all features safe?

Have all potential users and uses of the product been

considered?

Assessing the Quality of ID

2. Emotional Appeal - Rating of the overall consumer appeal of

the product. Appeal is achieved in part through appearance,

feel, sound, and smell.

Examples of product-specific questions include: How does the

car door sound when slammed, Does the hand tool feel solid

and sturdy, Does the appliance look good on the kitchen

counter.

Is the product attractive? Is it exciting?

Does the product express quality?

What images come to mind when viewing it?

Does the product inspire pride of ownership?

Does the product evoke feelings of pride among the

development team and sales staff?

Assessing the Quality of ID

3. Ability to Maintain and Repair the Product - Rating of the

ease of product maintenance and repair. Maintenance and

repair should be considered along with the other user

interactions.

Examples of product-specific questions include: How easy and

obvious is it to clear a paper jam in the printer, How difficult is

it to disassemble and clean the food processor, How long does

it take to change the batteries in the remote controller.

Is the maintenance of the product obvious? Is it easy?

Do product features effectively communicate disassembly

and assembly procedures?

Assessing the Quality of ID

4. Appropriate Use of Resources Rating of how well resources

were used in satisfying the customer needs. Resources typically

refer to the dollar expenditures on ID and other functions.

Category asks whether these investments were well spent.

How well were resources used to satisfy the customer

requirements?

Is the material selection appropriate (in terms of cost and

quality)?

Is the product over-or underdesigned (does it have features

that are unnecessary or neglected)?

Were environment/ecological factors considered?

Assessing the Quality of ID

5. Product Differentiation Rating of a products uniqueness

and consistence with the corporate identity. Differentiation

predominantly from appearance.

Will a customer who sees the product in a store be able to

identify it because of its appearance?

Will it be remembered by a consumer who has seen it in an

advertisement?

Will it be recognized when seen on the street?

Does the product fit with or enhance the corporate identity?

Assessing the Quality of ID

Assessment of industrial designs role in the RAZR development project.

You might also like

- Report On 3 D PrintingDocument37 pagesReport On 3 D Printingawanish singhNo ratings yet

- SKF Ball Bearing Units - UC Range 200 and 300 SeriesDocument40 pagesSKF Ball Bearing Units - UC Range 200 and 300 Seriesg1763970No ratings yet

- Design and Fabrication of Multi-Spindle MachineDocument6 pagesDesign and Fabrication of Multi-Spindle MachineIJIRSTNo ratings yet

- Preparing For The Solid Edge Professional Certification ExamDocument29 pagesPreparing For The Solid Edge Professional Certification ExamAnderson PereiraNo ratings yet

- Solar Car Lift Jack: SynopsisDocument3 pagesSolar Car Lift Jack: SynopsisPradeepNo ratings yet

- Cad Assignment 1Document14 pagesCad Assignment 1Gursewak SinghNo ratings yet

- Welcome to Diagonal CADD PLM ConceptsDocument21 pagesWelcome to Diagonal CADD PLM ConceptsjoyalNo ratings yet

- 3D Printing OverviewDocument4 pages3D Printing OverviewAziz Ul Hassan MohsanNo ratings yet

- A Design of 360 Degree Flexible Drilling MachineDocument26 pagesA Design of 360 Degree Flexible Drilling MachineSai RamNo ratings yet

- Open Learning Book CadDocument348 pagesOpen Learning Book CadLoughton BtyNo ratings yet

- Presented By, Nikhil Vijay Nitheesh Kurian Paul Joy: WWW - Final-Yearprojects - Co.ccDocument27 pagesPresented By, Nikhil Vijay Nitheesh Kurian Paul Joy: WWW - Final-Yearprojects - Co.ccTintin Estrada PinedaNo ratings yet

- K.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1Document18 pagesK.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1kshitijNo ratings yet

- Automatic Poor QualityDocument5 pagesAutomatic Poor Qualityqwerty187190No ratings yet

- Catia: Internship TrainingDocument15 pagesCatia: Internship TrainingMithilesh GuruNo ratings yet

- Surface Grinder ManualDocument98 pagesSurface Grinder ManualMohamed Shaban100% (1)

- Hypersonic Air Intake Design For High Performance and StartingDocument40 pagesHypersonic Air Intake Design For High Performance and StartingRavi ShankarNo ratings yet

- Forge IICDocument44 pagesForge IICYash KalaNo ratings yet

- Cost and Breakeven AnalysisDocument42 pagesCost and Breakeven Analysistoyota952No ratings yet

- Tabletop CNC Wire Bender Machine Using DXF by Generating CNC CodesDocument4 pagesTabletop CNC Wire Bender Machine Using DXF by Generating CNC CodesPrasanna RahmaniacNo ratings yet

- Six Eyes of A DesignerDocument45 pagesSix Eyes of A DesignerSriram100% (3)

- Boosting Engineering Collaboration with CATIA V5 & ENOVIA VPLMDocument6 pagesBoosting Engineering Collaboration with CATIA V5 & ENOVIA VPLMelectronicssucksNo ratings yet

- MCAD ManualDocument38 pagesMCAD ManualsureshrnalNo ratings yet

- Product Design Project Report On Device To Aid Outdoor CleaningDocument23 pagesProduct Design Project Report On Device To Aid Outdoor CleaningNajiNo ratings yet

- Fire Fighter Robot With Night Vision CameraDocument7 pagesFire Fighter Robot With Night Vision CameraKrish KalyanNo ratings yet

- Drill Jig Assembly - Example For ClassDocument1 pageDrill Jig Assembly - Example For ClassSrikanth ReddyNo ratings yet

- Computer Integrated Manufacturing (PLTW) SyllabusDocument4 pagesComputer Integrated Manufacturing (PLTW) SyllabusmailmelakaNo ratings yet

- 43 - Drill Head Assembly FinalDocument1 page43 - Drill Head Assembly Finaladmam jonesNo ratings yet

- UNIT-II Oil Hydraulic System and Its Components Marks-14Document32 pagesUNIT-II Oil Hydraulic System and Its Components Marks-14Chaitanya Yenge100% (1)

- HOW To DO Capsmill Cycle Time Reduction CadcamDocument23 pagesHOW To DO Capsmill Cycle Time Reduction CadcamrajualagNo ratings yet

- Dynamic Speed GovernorDocument1 pageDynamic Speed GovernorBijil BajiNo ratings yet

- Fabrication of Pneumatic Drill JigDocument2 pagesFabrication of Pneumatic Drill JigvikasysNo ratings yet

- Hydro Drive Seminar ReportDocument18 pagesHydro Drive Seminar ReportChethan Pinto100% (2)

- Gearless Transmission Using Elbow MechanismDocument32 pagesGearless Transmission Using Elbow Mechanismsanoop joseNo ratings yet

- Additive Manufacturing: Case Study: Generative Design of A Bracket, Part 1Document35 pagesAdditive Manufacturing: Case Study: Generative Design of A Bracket, Part 1Ali Raza JuttNo ratings yet

- Solar Parabolic Water Heaters Project ReportDocument37 pagesSolar Parabolic Water Heaters Project Reportthreephasefault100% (2)

- Under Wind MillDocument32 pagesUnder Wind MillArjun DasNo ratings yet

- Acetylene Powered Engine Report GTUDocument31 pagesAcetylene Powered Engine Report GTUAshish VadhavaniNo ratings yet

- Pneumatic Sheet Cutting Machine: A Project Report OnDocument14 pagesPneumatic Sheet Cutting Machine: A Project Report OnKapil SharmaNo ratings yet

- A ProjectDocument14 pagesA Projectajay0% (1)

- Design and Fabrication of a Multi-Fingered Robotic GripperDocument35 pagesDesign and Fabrication of a Multi-Fingered Robotic GripperSMART_GEEKNo ratings yet

- Batch 10 v2.0 UpdatedDocument50 pagesBatch 10 v2.0 UpdatedVamshi RittuNo ratings yet

- Rane Madras Flow ChartDocument2 pagesRane Madras Flow ChartrathanNo ratings yet

- Industrial Theodolites & Total Stations Brochure en PDFDocument8 pagesIndustrial Theodolites & Total Stations Brochure en PDFGiora RozmarinNo ratings yet

- Bottle Filling and Capping Using Geneva MechanismDocument5 pagesBottle Filling and Capping Using Geneva Mechanismabubeker muhamedNo ratings yet

- Selection of Materials For Frame of DroneDocument14 pagesSelection of Materials For Frame of DroneSuresh KumarNo ratings yet

- Questions of NTTF PGDocument75 pagesQuestions of NTTF PGJayaprakash KrishnanNo ratings yet

- Process Planning & Cost Estimation Objective QuestionsDocument35 pagesProcess Planning & Cost Estimation Objective Questionsarulmurugu100% (1)

- Powder Based 3d Printer (Final)Document49 pagesPowder Based 3d Printer (Final)Sai KiruthekaNo ratings yet

- Project Report - Bottle Cleaning MachineDocument24 pagesProject Report - Bottle Cleaning MachineChetan S100% (1)

- .Design and Fabrication of Multipurpose Agriculture VehicleDocument8 pages.Design and Fabrication of Multipurpose Agriculture VehiclePriya Nanda ReddyNo ratings yet

- Vehicle Maintenance GuideDocument17 pagesVehicle Maintenance GuideRoshanNo ratings yet

- Adaptive Headlight System ReportDocument49 pagesAdaptive Headlight System ReportAkshay bypNo ratings yet

- Design and Fabrication of Modern Three Way Dumping Trolley MechanismDocument8 pagesDesign and Fabrication of Modern Three Way Dumping Trolley MechanismvenkataNo ratings yet

- Fabrication of portable hammer using crank and lever mechanismDocument14 pagesFabrication of portable hammer using crank and lever mechanismMassive Minds100% (1)

- 4 Way Traffic Light Control System With ArduinoDocument8 pages4 Way Traffic Light Control System With ArduinoJose ReyesNo ratings yet

- Canusa GTP PP II For Offshore PipelineDocument2 pagesCanusa GTP PP II For Offshore PipelineZainudinNo ratings yet

- Co Po Mapping (Example)Document2 pagesCo Po Mapping (Example)selva_raj215414No ratings yet

- PLC IN CNC MACHINESDocument37 pagesPLC IN CNC MACHINESLakshmi Kandula100% (1)

- Industrial DesignDocument5 pagesIndustrial DesignAnkit saxenaNo ratings yet

- The Ultimate Guide to Becoming an Industrial Designer: Design & Technology, #1From EverandThe Ultimate Guide to Becoming an Industrial Designer: Design & Technology, #1No ratings yet

- MA5701 Chap01 Lecture Data and StatisticsDocument31 pagesMA5701 Chap01 Lecture Data and StatisticsDattaSandeshNo ratings yet

- Criteria and ParamDocument4 pagesCriteria and ParamDattaSandeshNo ratings yet

- RADIOSS 13.0 Tutorials PDFDocument821 pagesRADIOSS 13.0 Tutorials PDFDattaSandeshNo ratings yet

- BatchMesher 11.0 User GuideDocument45 pagesBatchMesher 11.0 User GuideMarta PalenzonaNo ratings yet

- ITB Data and InformationDocument100 pagesITB Data and Informationmanjunath90No ratings yet

- Cakelicious Web App For Designing A Customised Wed PDFDocument4 pagesCakelicious Web App For Designing A Customised Wed PDFShweta PhadtareNo ratings yet

- Machine Learning As A UX Design Material: How Can We Imagine Beyond Automation, Recommenders, and Reminders?Document6 pagesMachine Learning As A UX Design Material: How Can We Imagine Beyond Automation, Recommenders, and Reminders?wcc32No ratings yet

- Design Thinking Methods and Tools for InnovationDocument13 pagesDesign Thinking Methods and Tools for InnovationGaurav SinghNo ratings yet

- EY Introducing Pay As You Live Payl InsuranceDocument17 pagesEY Introducing Pay As You Live Payl InsuranceBaldeep ChowdharyNo ratings yet

- Fuzzy Micro-Agents For Interactive Narrative: Brian Magerko, Casey Fiesler, and Allan BaumerDocument6 pagesFuzzy Micro-Agents For Interactive Narrative: Brian Magerko, Casey Fiesler, and Allan BaumerLucas SantosNo ratings yet

- Automotive Styling Boot Camp - ASBC: Expertshub Industry Skill Development CenterDocument5 pagesAutomotive Styling Boot Camp - ASBC: Expertshub Industry Skill Development CentervivekNo ratings yet

- School Management System Project DocumentationDocument34 pagesSchool Management System Project DocumentationJoshua Blessing100% (3)

- Standardised Product Development For Technology Integration of Additive ManufacturingDocument8 pagesStandardised Product Development For Technology Integration of Additive ManufacturingTiago Camargo AlvesNo ratings yet

- Wind Turbine Design ProcedureDocument4 pagesWind Turbine Design ProcedureEkambaramMuniyandi100% (1)

- Tsa Catapult-Design 2023Document11 pagesTsa Catapult-Design 2023api-294653971No ratings yet

- AvioHeliTronicsInfoSystems 2Document25 pagesAvioHeliTronicsInfoSystems 2Baljinder SinghNo ratings yet

- Moodle ProposalDocument22 pagesMoodle ProposalbmishraNo ratings yet

- Smart Sajjadah For The ElderlyDocument11 pagesSmart Sajjadah For The ElderlyMas KudinNo ratings yet

- MVP Builders Guide For StartupsDocument34 pagesMVP Builders Guide For Startupsbog495100% (1)

- Ooad SDLCDocument32 pagesOoad SDLCjaswanthNo ratings yet

- Lovely Professional UniversityDocument2 pagesLovely Professional UniversityShambhav SumanNo ratings yet

- Power BI AssignmentDocument147 pagesPower BI AssignmentAditya SharmaNo ratings yet

- Management Information Systems: Managing The Digital Firm, 12e Authors: Kenneth C. Laudon and Jane P. LaudonDocument40 pagesManagement Information Systems: Managing The Digital Firm, 12e Authors: Kenneth C. Laudon and Jane P. Laudonhello everyoneNo ratings yet

- Model-Based Design For Embedded Control Systems: White PaperDocument12 pagesModel-Based Design For Embedded Control Systems: White Papersam hamNo ratings yet

- Baan CorporationDocument13 pagesBaan CorporationAbhi RicNo ratings yet

- Design Research Through Practice: From The Lab, Field, and ShowroomDocument3 pagesDesign Research Through Practice: From The Lab, Field, and ShowroomEzgiNo ratings yet

- Developing An Automated Explosives Detection Prototype PDFDocument267 pagesDeveloping An Automated Explosives Detection Prototype PDFAnonymous abOKZAa100% (1)

- Wireless Landmine Detection Robot Using GSM/GPSDocument17 pagesWireless Landmine Detection Robot Using GSM/GPSPooja GNo ratings yet

- HE21Round2Document8 pagesHE21Round2Vartika VashistaNo ratings yet

- Best Digital Prototyping Company in USA, Canada - Cuneiform Consulting PVT LTDDocument3 pagesBest Digital Prototyping Company in USA, Canada - Cuneiform Consulting PVT LTDCuneiform Consulting Private LimitedNo ratings yet

- DMU PaperDocument9 pagesDMU Papersathiyam007No ratings yet

- Design Thinking PresentationDocument21 pagesDesign Thinking PresentationAvijit DeyNo ratings yet

- Ooad 2MDocument32 pagesOoad 2MSam JosephNo ratings yet

- Decision Support Systems: Tobias Fehrer, Dominik A. Fischer, Sander J.J. Leemans, Maximilian R Oglinger, Moe T. WynnDocument12 pagesDecision Support Systems: Tobias Fehrer, Dominik A. Fischer, Sander J.J. Leemans, Maximilian R Oglinger, Moe T. Wynn胡莉沙No ratings yet