Professional Documents

Culture Documents

RMXS-DVM SM

Uploaded by

ttkohOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMXS-DVM SM

Uploaded by

ttkohCopyright:

Available Formats

Si18 - 525B

[Applied Models]

Super Multi Plus : Cooling only

Super Multi Plus : Heat Pump

D-Series

Si18-525B

Table of Contents i

SUPER MULTI PLUS

D-Series

Cooling Only

Indoor Unit

<R-410A>

FTKS25DVM FTKS20DVMA FDKS25CVMB FFQ25B7V1B

FTKS35DVM FTKS25DVMA FDKS35CVMB FFQ35B7V1B

FTKS50BVMB FTKS35DVMA CDKS50CVMB FFQ50B7V1B

FTKS60BVMB FTKS50BVMA8 CDKS60CVMB FFQ60B7V1B

FTKS71BVMB FTKS60BVMA8 CDKS25CVMA FCQ35BVE

FTK50AZVMB FTKS71BVMA8 CDKS35CVMA FCQ50BVE

FTK60AZVMB CDKS50CVMA FCQ60BVE

FTK71AZVMB CDKS60CVMA FCQ71BVE

FBQ60BV1

FBQ71BV1

FHQ35BUV1B9

FHQ50BUV1B9

FHQ60BUV1B9

<R-22>

FTKD25DVM FTK50AVM CDKD25CVM CDKD25EAVM

FTKD35DVM FTK60AVM CDKD35CVM CDKD35EAVM

FTKD50FVM FTK71AVM CDKD50CVM

FTKD60FVM CDKD60CVM

FTKD71FVM

Outdoor Unit

<R-410A>

RMKS112DVM RMKS112DV1A BPMKS967A2 BPMKS967A2B

RMKS140DVM RMKS140DV1A BPMKS967A3 BPMKS967A3B

RMKS160DVM RMKS160DV1A

<R-22>

RMKD112DVM BPMKD967A2

RMKD140DVM BPMKD967A3

RMKD160DVM

Si18-525B

ii Table of Contents

Heat Pump

Indoor Unit

<R-410A>

FTXS20DVMA CDXS25CVMA FLXS25BVMA FFQ25B7V1B

FTXS25DVMA CDXS35CVMA FLXS35BVMA FFQ35B7V1B

FTXS35DVMA CDXS50CVMA FLXS50BVMA FFQ50B7V1B

FTXS50BVMA8 CDXS60CVMA FLXS60BVMA FFQ60B7V1B

FTXS60BVMA8 CDXS25DVMT FVXS35BVMA FCQ35BVE

FTXS71BVMA8 CDXS35DVMT FVXS50BVMA FCQ50BVE

FTXS20DVMT CDXS50DVMT FCQ60BVE

FTXS25DVMT CDXS60DVMT FCQ71BVE

FTXS35DVMT FBQ60BV1

FTXS50DVMT FBQ71BV1

FTXS60DVMT FBQ60BVL

FTXS71DVMT FBQ71BVL

FHQ35BUV1B9

FHQ50BUV1B9

FHQ60BUV1B9

Outdoor Unit

<R-410A>

RMXS112DVM RMXS112DV1A RMXS112DVLT BPMKS967A2

RMXS140DVM RMXS140DV1A RMXS140DVLT BPMKS967A3

RMXS160DVM RMXS160DV1A RMXS160DVLT

Si18-525B

Table of Contents iii

1. Introduction .......................................................................................... viii

1.1 Safety Cautions..................................................................................... viii

1.2 Used Icons ............................................................................................. xii

Part 1 List of Functions ................................................................ 1

1. List of Functions......................................................................................2

1.1 Cooling Only.............................................................................................2

1.2 Heat Pump .............................................................................................13

Part 2 Specifications .................................................................. 21

1. Specifications........................................................................................22

1.1 Cooling Only...........................................................................................22

1.2 Heat Pump .............................................................................................42

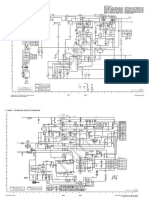

Part 3 Printed Circuit Board Connector Wiring Diagram ........... 59

1. Printed Circuit Board Connector Wiring Diagram..................................60

1.1 Outdoor Unit ...........................................................................................60

1.2 Branch Provider Unit ..............................................................................66

1.3 Wall Mounted Type ................................................................................67

1.4 Duct Connected Type.............................................................................76

1.5 Floor / Ceiling Suspended Dual Type.....................................................78

1.6 Floor Standing Type...............................................................................81

1.7 Ceiling Mounted Cassette Type (600600)............................................84

1.8 Ceiling Mounted Cassette Type (950950)............................................87

1.9 Ceiling Mounted Built-in Type ................................................................90

1.10 Ceiling Suspended Type ........................................................................92

Part 4 Refrigerant Circuit ........................................................... 95

1. Refrigerant Circuit .................................................................................96

1.1 Outdoor Units .........................................................................................96

1.2 BP Units .................................................................................................98

2. Functional Parts Layout ........................................................................99

2.1 Outdoor Units .........................................................................................99

3. Refrigerant Flow for Each Operation Mode.........................................100

3.1 Cooling Operation ................................................................................100

3.2 Heating Operation ................................................................................101

3.3 Cooling Oil Return Operation ...............................................................102

3.4 Heating Oil Return Operation & Defrost Operation ..............................103

Part 5 Function.......................................................................... 105

1. Operation Mode ..................................................................................107

2. Basic Control .......................................................................................108

2.1 Normal Operation.................................................................................108

2.2 Compressor PI Control .........................................................................109

2.3 Electronic Expansion Valve PI Control .................................................112

2.4 Cooling Operation Fan Control.............................................................113

Si18-525B

iv Table of Contents

3. Special Control ....................................................................................114

3.1 Startup Control .....................................................................................114

3.2 Oil Return Operation ............................................................................115

3.3 Defrosting Operation ............................................................................117

3.4 Pump-down Residual Operation ..........................................................118

3.5 Restart Standby....................................................................................118

3.6 Stopping Operation ..............................................................................119

3.7 Pressure Equalization Prior to Startup .................................................119

4. Protection Control ...............................................................................120

4.1 High Pressure Protection Control .........................................................120

4.2 Low Pressure Protection Control..........................................................122

4.3 Discharge Pipe Protection Control .......................................................123

4.4 Inverter Protection Control ...................................................................124

4.5 Freeze-up Protection Control ...............................................................125

4.6 Dew Condensation Prevention Control ................................................126

5. Other Control.......................................................................................127

5.1 Demand Operation...............................................................................127

5.2 Heating Operation Prohibition ..............................................................127

6. BP Unit Control ...................................................................................128

6.1 BP Unit Command Conversion ............................................................128

6.2 BP Unit Electronic Expansion Valve Control ........................................129

6.3 SH Control in Cooling Operation..........................................................131

6.4 SC Control in Heating Operation..........................................................132

6.5 Heat Exchanger Isothermal Control in Heating Operation ...................132

7. Indoor Unit (RA Models)......................................................................133

7.1 Power-Airflow Dual Flaps, Wide Angle Louvers and Auto-Swing ........133

7.2 Fan Speed Control for Indoor Units......................................................134

7.3 Programme Dry Function .....................................................................135

7.4 Automatic Operation.............................................................................136

7.5 Thermostat Control...............................................................................137

7.6 Night Set Mode.....................................................................................138

7.7 ECONO Mode ......................................................................................139

7.8 MOLD PROOF Operation ....................................................................139

7.9 INTELLIGENT EYE..............................................................................140

7.10 HOME LEAVE Operation .....................................................................142

7.11 Inverter POWERFUL Operation...........................................................143

7.12 Other Functions....................................................................................144

8. Indoor Unit (SkyAir Models) ................................................................146

8.1 Function Outline ...................................................................................146

8.2 Electric Function Parts .........................................................................147

8.3 Function Details....................................................................................148

Part 6 Test Operation ............................................................... 159

1. Test Operation ....................................................................................160

1.1 Procedure and Outline .........................................................................160

2. Outdoor Unit PCB Layout....................................................................165

3. Field Setting ........................................................................................166

3.1 Field Setting from Outdoor Unit............................................................166

3.2 Detail of Setting Mode..........................................................................172

Si18-525B

Table of Contents v

4. Field Setting for SkyAir Indoor Unit .....................................................182

4.1 Explanation...........................................................................................182

4.2 Field Setting .........................................................................................183

4.3 Initial Setting Contents .........................................................................184

4.4 Local Setting Mode Number.................................................................185

4.5 Detailed Explanation of Setting Modes ................................................186

4.6 Centralized Group No. Setting .............................................................190

4.7 Maintenance Mode Setting...................................................................191

5. Test Operation and Field Setting for RA Indoor Unit...........................192

5.1 Test Operation from the Remote Controller .........................................192

5.2 Jumper Settings ...................................................................................193

Part 7 System Configuration..................................................... 195

1. System Configuration..........................................................................196

1.1 Operation Instructions ..........................................................................196

2. Instruction............................................................................................197

2.1 Outdoor Units .......................................................................................197

2.2 Wall Mounted, Duct, Floor/Ceiling, Floor Standing,

Wall Built-in Type .................................................................................198

2.3 Ceiling Mounted Cassette Type ...........................................................278

2.4 Ceiling Mounted Built-in Type ..............................................................289

2.5 Ceiling Suspended Type ......................................................................299

Part 8 Troubleshooting ............................................................. 311

1. Caution for Diagnosis.........................................................................313

1.1 Troubleshooting with Operation Lamp .................................................313

1.2 Troubleshooting with the LED on the SkyAir Indoor Unit .....................314

1.3 Troubleshooting with the LED on the Outdoor Unit..............................315

1.4 Troubleshooting with the LED on the BP Unit ......................................316

2. Service Check Function ......................................................................317

2.1 RA Indoor Unit Wireless Remote Controller.........................................317

2.2 SkyAir Indoor Unit INSPECTION/TEST Button....................................320

2.3 SkyAir Indoor Unit Wired Remote Controller........................................321

2.4 SkyAir Indoor Unit Wireless Remote Controller ...................................322

2.5 Sky Air Indoor Unit Error Codes and LED Indication............................324

2.6 Malfunction Code Indication by Outdoor Unit PCB ..............................325

3. List of Malfunction Code......................................................................327

4. Troubleshooting for RA Indoor Unit.....................................................329

4.1 Indoor Unit PCB Abnormality ...............................................................329

4.2 Freeze-up Protection Control or High Pressure Control.......................330

4.3 Fan Motor or Related Abnormality .......................................................332

4.4 Thermistor or Related Abnormality (Indoor Unit)..................................335

4.5 Shutter Drive Motor / Shutter Limit Switch Abnormality .......................336

4.6 Check ...................................................................................................337

5. Troubleshooting for SkyAir Indoor Unit ...............................................340

5.1 Indoor Unit PCB Abnormality ...............................................................340

5.2 Malfunction of Drain Water Level System (Float Type)........................341

5.3 Malfunction of Drain System................................................................343

5.4 Indoor Unit Fan Motor Lock..................................................................344

5.5 Malfunction of Indoor Unit Fan Motor ...................................................345

Si18-525B

vi Table of Contents

5.6 Swing Flap Motor Malfunction / Lock ...................................................347

5.7 Malfunction of Capacity Setting............................................................349

5.8 Malfunction of Heat Exchanger Thermistor (R2T)................................350

5.9 Malfunction of Heat Exchanger Thermistor (R3T)................................351

5.10 Malfunction of Suction Air Thermistor ..................................................352

5.11 Malfunction of Remote Controller Thermistor.......................................353

5.12 Transmission Error (between Indoor Unit and Remote Controller) ......354

5.13 Transmission Error (between Main and Sub Remote Controller).........355

5.14 Malfunction of Field Setting Switch ......................................................356

5.15 Check ...................................................................................................357

6. Troubleshooting for BP Unit ................................................................359

6.1 Malfunction of Electronic Expansion Valve ..........................................359

6.2 Faulty BP Unit PCB..............................................................................360

6.3 Faulty BP Liquid or Gas Pipe Thermistor .............................................361

6.4 Transmission Error between Indoor Unit and BP Unit..........................362

6.5 Transmission Error between Outdoor Unit and BP Unit.......................364

6.6 Check ...................................................................................................365

7. Troubleshooting for Outdoor Unit........................................................366

7.1 Faulty Outdoor Unit PCB......................................................................366

7.2 Actuation of High Pressure Switch.......................................................367

7.3 Actuation of Low Pressure Switch........................................................368

7.4 Compressor Motor Lock.......................................................................369

7.5 Malfunction of Outdoor Unit Fan Motor ................................................370

7.6 Malfunction of Moving Part of Electronic Expansion Valve ..................371

7.7 Abnormal Discharge Pipe Temperature...............................................372

7.8 Malfunction of Thermistor for Outdoor Air (R1T) ..................................373

7.9 Malfunction of Discharge Pipe Thermistor (R3T) .................................374

7.10 Malfunction of Thermistor (R2T) for Suction Pipe ................................375

7.11 Malfunction of Thermistor (R4T) for Outdoor Unit Heat Exchanger .....376

7.12 Malfunction of Receiver Gas Pipe Thermistor (R5T)............................377

7.13 Outdoor Unit: Malfunction of High Pressure Sensor ............................378

7.14 Malfunction of Low Pressure Sensor....................................................379

7.15 Malfunction of Inverter Radiating Fin Temperature Rise......................380

7.16 Inverter Compressor Abnormal ............................................................381

7.17 Inverter Current Abnormal ....................................................................382

7.18 Inverter Start up Error...........................................................................383

7.19 Malfunction of Transmission between Inverter and Control PCB.........384

7.20 Malfunction of Inverter Radiating Fin Temperature Rise Sensor .........386

7.21 Faulty Combination of Inverter and Fan Driver ....................................387

7.22 Low Pressure Drop Due to Refrigerant Shortage or

Electronic Expansion Valve Failure......................................................388

7.23 Power Supply Insufficient or Instantaneous Failure .............................389

7.24 Check Operation not Executed ............................................................391

7.25 Malfunction in other Indoor Unit or other BP Unit.................................392

7.26 Mismatching of Indoor Unit, BP Unit and Outdoor Unit ........................393

7.27 Refrigerant System not Set, Incompatible Wiring/Piping......................394

7.28 Malfunction of System, Refrigerant System Address Undefined..........395

8. Check..................................................................................................396

9. Thermistor Resistance / Temperature Characteristics........................398

10.Pressure Sensor .................................................................................400

Si18-525B

Table of Contents vii

Part 9 Removal Procedure........................................................ 401

1. Outdoor Unit........................................................................................402

1.1 Removal of Outer Panels .....................................................................402

1.2 Removal of PCB...................................................................................409

1.3 Removal of Solenoid Valve, Four Way Valve and Motorized Valve.....420

1.4 Removal of Thermistor Assembly ........................................................421

1.5 Removal of Fan Motor..........................................................................422

2. BP Unit ................................................................................................425

2.1 Removal of PCB...................................................................................425

2.2 Removal of Solenoid Valve Coil ...........................................................428

Part 10Appendix......................................................................... 431

1. Piping Diagrams..................................................................................432

1.1 Outdoor Units .......................................................................................432

1.2 BP Units ...............................................................................................433

1.3 Indoor Units..........................................................................................434

2. Wiring Diagrams..................................................................................442

2.1 Outdoor Units .......................................................................................442

2.2 BP Units ...............................................................................................445

2.3 Indoor Units..........................................................................................447

Index ............................................................................................. i

Drawings & Flow Charts .............................................................. vii

Introduction Si18-525B

viii

1. Introduction

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into Warning and Caution. The Warning

items are especially important since they can lead to death or serious injury if they are not

followed closely. The Caution items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

About the pictograms

This symbol indicates the item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates the prohibited action.

The prohibited item or action is shown in the illustration or near the symbol.

This symbol indicates the action that must be taken, or the instruction.

The instruction is shown in the illustration or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer.

1.1.1 Cautions Regarding Safety of Workers

Warning

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for repair.

Working on the equipment that is connected to the power supply may cause an

electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas is discharged during the repair work, do not touch the

discharged refrigerant gas.

The refrigerant gas may cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the

welded section, evacuate the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it may

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas may generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor may cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging the

power cable plug.

Plugging or unplugging the power cable plug to operate the equipment may

cause an electrical shock or fire.

Si18-525B Introduction

ix

Be sure to wear a safety helmet, gloves, and a safety belt when working at a

high place (more than 2m). Insufficient safety measures may cause a fall

accident.

In case of R410A refrigerant models, be sure to use pipes, flare nuts and tools

for the exclusive use of the R410A refrigerant.

The use of materials for R22 refrigerant models may cause a serious accident

such as a damage of refrigerant cycle as well as an equipment failure.

Warning

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands may cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water may cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when cleaning

the equipment.

The internal fan rotates at a high speed, and cause injury.

Be sure to conduct repair work with appropriate tools.

The use of inappropriate tools may cause injury.

Be sure to check that the refrigerating cycle section has cooled down enough

before conducting repair work.

Working on the unit when the refrigerating cycle section is hot may cause

burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room may cause oxygen deficiency.

Introduction Si18-525B

x

1.1.2 Cautions Regarding Safety of Users

Warning

Be sure to use parts listed in the service parts list of the applicable model and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools may cause an electrical shock,

excessive heat generation or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires may cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances, since it may cause an electrical shock,

excessive heat generation or fire.

Be sure to use an exclusive power circuit for the equipment, and follow the local

technical standards related to the electrical equipment, the internal wiring

regulations, and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work may cause an

electrical shock or fire.

Be sure to use the specified cable for wiring between the indoor and outdoor

units. Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections may cause excessive heat generation or fire.

When wiring between the indoor and outdoor units, make sure that the terminal

cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section may cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable may cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable

may damage the cable.

Do not mix air or gas other than the specified refrigerant (R410A / R22) in the

refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leaking point and repair it

before charging the refrigerant. After charging refrigerant, make sure that there

is no refrigerant leak.

If the leaking point cannot be located and the repair work must be stopped, be

sure to perform pump-down and close the service valve, to prevent the

refrigerant gas from leaking into the room. The refrigerant gas itself is

harmless, but it may generate toxic gases when it contacts flames, such as fan

and other heaters, stoves and ranges.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment may fall and cause injury.

Si18-525B Introduction

xi

Check to make sure that the power cable plug is not dirty or loose, then insert

the plug into a power outlet securely.

If the plug has dust or loose connection, it may cause an electrical shock or fire.

Be sure to install the product correctly by using the provided standard

installation frame.

Incorrect use of the installation frame and improper installation may cause the

equipment to fall, resulting in injury.

For unitary type

only

Be sure to install the product securely in the installation frame mounted on the

window frame.

If the unit is not securely mounted, it may fall and cause injury.

For unitary type

only

When replacing the coin battery in the remote controller, be sure to disposed

of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Warning

Caution

Installation of a leakage breaker is necessary in some cases depending on the

conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If the combustible gas leaks and remains around the unit, it may cause a fire.

Check to see if the parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections may cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame may cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding may cause an electrical shock.

Introduction Si18-525B

xii

1.2 Used Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

icon is described in the table below:

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 M or higher.

Faulty insulation may cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage may cause the water to enter the room and wet the furniture

and floor.

Do not tilt the unit when removing it.

The water inside the unit may spill and wet the furniture and floor.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water may enter the room and

wet the furniture and floor.

For unitary type

only

Caution

Icon Type of

Information

Description

Note:

Note A note provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution A caution is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get

an unexpected result or has to restart (part of) a procedure.

Warning

Warning A warning is used when there is danger of personal injury.

Reference A reference guides the reader to other places in this binder or

in this manual, where he/she will find additional information on a

specific topic.

Si18-525B

List of Functions 1

Part 1

List of Functions

1. List of Functions......................................................................................2

1.1 Cooling Only.............................................................................................2

1.2 Heat Pump .............................................................................................13

List of Functions Si18-525B

2 List of Functions

1. List of Functions

1.1 Cooling Only

1.1.1 R-410A Models

Category Functions

R

M

K

S

1

1

2

1

4

0

1

6

0

D

V

M

Category Functions

R

M

K

S

1

1

2

1

4

0

1

6

0

D

V

M

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

5

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mold Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down)

Timer 24-Hour On/Off Timer

72-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) Night Set Mode

3-D Airflow Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

Comfort Airflow Mode Self-Diagnosis (Digital, LED) Display O

3-Step Airflow (H/P Only) Wiring-Error Check

Comfort

Control

Auto Fan Speed

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Indoor Unit Quiet Operation

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Night Quiet Mode (Automatic) O Flexible Voltage Correspondence

Outdoor Unit Quiet Operation (Manual) O High Ceiling Application

Intelligent Eye Chargeless

Quick Warming Function Either Side Drain (Right or Left)

Hot-Start Function Power-Selection

Automatic Defrosting

Remote

Control

5-Rooms Centralized Controller

(Option)

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open Contact) (Option)

Fan Only Dlll-NET Compatible (Adaptor) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Remote

Controller

Wireless

Inverter Powerful Operation Wired

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 3

Category Functions

R

M

K

S

1

1

2

1

4

0

1

6

0

D

V

1

A

Category Functions

R

M

K

S

1

1

2

1

4

0

1

6

0

D

V

1

A

Basic Function Inverter (with Inverter Power Control) O Health & Clean Air Purifying Filter

Operation Limit for Cooling (CDB)

5

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mold Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down)

Timer 24-Hour On/Off Timer

72-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) Night Set Mode

3-D Airflow Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

Comfort Airflow Mode Self-Diagnosis (Digital, LED) Display O

3-Step Airflow (H/P Only) Wiring-Error Check

Comfort

Control

Auto Fan Speed

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Indoor Unit Quiet Operation

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Night Quiet Mode (Automatic) O Flexible Voltage Correspondence

Outdoor Unit Quiet Operation (Manual) O High Ceiling Application

Intelligent Eye Chargeless

Quick Warming Function Either Side Drain (Right or Left)

Hot-Start Function Power-Selection

Automatic Defrosting

Remote

Control

5-Rooms Centralized Controller

(Option)

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open Contact) (Option)

Fan Only Dlll-NET Compatible (Adaptor) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Remote

Controller

Wireless

Inverter Powerful Operation Wired

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

4 List of Functions

Category Functions

F

T

K

S

2

5

3

5

D

V

M

F

T

K

S

5

0

-

7

1

B

V

M

B

Category Functions

F

T

K

S

2

5

3

5

D

V

M

F

T

K

S

5

0

-

7

1

B

V

M

B

Basic

Function

Inverter (with Inverter Power Control) O O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

Operation Limit for Heating (CWB) Photocatalytic Deodorizing Filter

PAM Control

Air Purifying Filter with Photocatalytic

Deodorizing Function

O

Compressor Oval Scroll Compressor

Swing Compressor

Titanium Apatite Photocatalytic

Air-Purifying Filter

O

Rotary Compressor

Reluctance DC Motor Longlife Filter (Option)

Comfortable

Airflow

Power-Airflow Flap Mold Proof Air Filter O O

Power-Airflow Dual Flaps O O Wipe-clean Flat Panel O O

Power-Airflow Diffuser Washable Grille

Wide-Angle Louvers O O Filter Cleaning Indicator

Vertical Auto-Swing (Up and Down) O O Mold Proof Operation O

Horizontal Auto-Swing (Right and Left) O Heating Dry Operation

3-D Airflow O Good-Sleep Cooling Operation

Comfort Airflow Mode Timer 24-Hour On/Off Timer O O

3-Step Airflow (H/P Only) 72-Hour On/Off Timer

Comfort

Control

Auto Fan Speed O O Night Set Mode O O

Indoor Unit Quiet Operation O O Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O

Night Quiet Mode (Automatic) Self-Diagnosis (Digital, LED) Display O O

Outdoor Unit Quiet Operation (Manual) Wiring Error Check

Intelligent Eye O O

Anticorrosion Treatment of Outdoor

Heat Exchanger

Quick Warming Function

Hot-Start Function

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O O

Automatic Defrosting Flexible Voltage Correspondence O O

Operation Automatic Operation High Ceiling Application

Programme Dry Function O O Chargeless

Fan Only O O Either Side Drain (Right or Left) O O

Lifestyle

Convenience

New Powerful Operation (Non-Inverter) Power Selection

Inverter Powerful Operation O O Remote

Control

5-Rooms Centralized Controller (Option) O O

Priority-Room Setting

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O O

Cooling / Heating Mode Lock

Home Leave Operation O

Remote Control Adaptor

(Normal Open Contact) (Option)

O O

ECONO Mode O

Indoor Unit On/Off Switch O O DIII-NET Compatible (Adaptor) (Option) O O

Signal Reception Indicator O O Remote

Controller

Wireless O O

Temperature Display Wired

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 5

Category Functions

F

T

K

5

0

-

7

1

A

Z

V

M

B

Category Functions

F

T

K

5

0

-

7

1

A

Z

V

M

B

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter O

Operation Limit for Cooling (CDB)

Operation Limit for Heating (CWB) Photocatalytic Deodorizing Filter O

PAM Control

Air Purifying Filter with Photocatalytic

Deodorizing Function

Compressor Oval Scroll Compressor

Swing Compressor

Titanium Apatite Photocatalytic

Air-Purifying Filter

Rotary Compressor

Reluctance DC Motor Longlife Filter (Option)

Comfortable

Airflow

Power-Airflow Flap O Mold Proof Air Filter O

Power-Airflow Dual Flaps Wipe-clean Flat Panel

Power-Airflow Diffuser O Washable Grille O

Wide-Angle Louvers O Filter Cleaning Indicator

Vertical Auto-Swing (Up and Down) O Mold Proof Operation

Horizontal Auto-Swing (Right and Left) O Heating Dry Operation

3-D Airflow O Good-Sleep Cooling Operation

Comfort Airflow Mode Timer 24-Hour On/Off Timer O

3-Step Airflow (H/P Only) 72-Hour On/Off Timer

Comfort

Control

Auto Fan Speed O Night Set Mode O

Indoor Unit Quiet Operation O Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O

Night Quiet Mode (Automatic) Self-Diagnosis (Digital, LED) Display O

Outdoor Unit Quiet Operation (Manual) Wiring-Error Check

Intelligent Eye

Anticorrosion Treatment of Outdoor

Heat Exchanger

Quick Warming Function

Hot-Start Function

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O

Automatic Defrosting Flexible Voltage Correspondence O

Operation Automatic Operation High Ceiling Application

Programme Dry Function O Chargeless

Fan Only O Either Side Drain (Right or Left) O

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Power-Selection

Inverter Powerful Operation O Remote

Control

5-Rooms Centralized Controller (Option) O

Priority-Room Setting

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O

Cooling / Heating Mode Lock

Remote Control Adaptor

(Normal Open Contact) (Option)

O

Home Leave Operation O Dlll-NET Compatible (Adaptor) (Option) O

ECONO Mode Remote

Controller

Wireless O

Indoor Unit On/Off Switch O Wired

Signal Reception Indicator O

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

6 List of Functions

Category Functions

F

T

K

S

2

0

-

3

5

D

V

M

A

F

T

K

S

5

0

-

7

1

B

V

M

A

8

Category Functions

F

T

K

S

2

0

-

3

5

D

V

M

A

F

T

K

S

5

0

-

7

1

B

V

M

A

8

Basic Function Inverter (with Inverter Power Control) O O Health & Clean Air Purifying Filter

Operation Limit for Cooling (CDB) Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

O

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

O

Compressor Oval Scroll Compressor Longlife Filter (Option)

Swing Compressor Mold Proof Air Filter O O

Rotary Compressor Wipe-clean Flat Panel O O

Reluctance DC Motor Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps O O Mold Proof Operation O

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers O O Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) O O

Timer 24-Hour On/Off Timer O O

72-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) O Night Set Mode O O

3-D Airflow O Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O

Comfort Airflow Mode Self-Diagnosis (Digital, LED) Display O O

3-Step Airflow (H/P Only) Wiring-Error Check

Comfort

Control

Auto Fan Speed O O

Anticorrosion Treatment of Outdoor

Heat Exchanger

Indoor Unit Quiet Operation O O

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O O

Night Quiet Mode (Automatic) Flexible Voltage Correspondence O O

Outdoor Unit Quiet Operation (Manual) High Ceiling Application

Intelligent Eye O O Chargeless

Quick Warming Function Either Side Drain (Right or Left) O O

Hot-Start Function Power-Selection

Automatic Defrosting

Remote

Control

5-Rooms Centralized Controller

(Option)

O O

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O O

Programme Dry Function O O

Remote Control Adaptor

(Normal Open Contact) (Option)

O O

Fan Only O O Dlll-NET Compatible (Adaptor) (Option) O O

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Remote

Controller

Wireless O O

Inverter Powerful Operation O O Wired

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation O

ECONO Mode O

Indoor Unit On/Off Switch O O

Signal Reception Indicator O O

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 7

Category Functions

F

D

K

S

2

5

3

5

C

V

M

B

C

D

K

S

5

0

6

0

C

V

M

B

Category Functions

F

D

K

S

2

5

3

5

C

V

M

B

C

D

K

S

5

0

6

0

C

V

M

B

Basic

Function

Inverter (with Inverter Power Control) O O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

Operation Limit for Heating (CWB) Photocatalytic Deodorizing Filter

PAM Control

Air Purifying Filter with Photocatalytic

Deodorizing Function

Compressor Oval Scroll Compressor

Swing Compressor

Titanium Apatite Photocatalytic

Air-Purifying Filter

Rotary Compressor

Reluctance DC Motor Longlife Filter (Option)

Comfortable

Airflow

Power-Airflow Flap Mold Proof Air Filter O O

Power-Airflow Dual Flaps Wipe-clean Flat Panel

Power-Airflow Diffuser Washable Grille

Wide-Angle Louvers Filter Cleaning Indicator

Vertical Auto-Swing (Up and Down) Mold Proof Operation

Horizontal Auto-Swing (Right and Left) Heating Dry Operation

3-D Airflow Good-Sleep Cooling Operation

Comfort Airflow Mode Timer 24-Hour On/Off Timer O O

3-Step Airflow (H/P Only) 72-Hour On/Off Timer

Comfort

Control

Auto Fan Speed O O Night Set Mode O O

Indoor Unit Quiet Operation O O Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O

Night Quiet Mode (Automatic) Self-Diagnosis (Digital, LED) Display O O

Outdoor Unit Quiet Operation (Manual) Wiring-Error Check

Intelligent Eye

Anticorrosion Treatment of Outdoor

Heat Exchanger

Quick Warming Function

Hot-Start Function

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O

Automatic Defrosting Flexible Voltage Correspondence O O

Operation Automatic Operation High Ceiling Application

Programme Dry Function O O Chargeless

Fan Only O O Either Side Drain (Right or Left)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Power-Selection

Inverter Powerful Operation O O Remote

Control

5-Rooms Centralized Controller (Option) O O

Priority-Room Setting

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O O

Cooling / Heating Mode Lock

Remote Control Adaptor

(Normal Open Contact) (Option)

O O

Home Leave Operation O O Dlll-NET Compatible (Adaptor) (Option) O O

ECONO Mode Remote

Controller

Wireless O O

Indoor Unit On/Off Switch O O Wired

Signal Reception Indicator O O

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

8 List of Functions

Category Functions

C

D

K

S

2

5

-

6

0

C

V

M

A

F

F

Q

2

5

-

6

0

B

7

V

1

B

Category Functions

C

D

K

S

2

5

-

6

0

C

V

M

A

F

F

Q

2

5

-

6

0

B

7

V

1

B

Basic Function Inverter (with Inverter Power Control) O O Health & Clean Air Purifying Filter

Operation Limit for Cooling (CDB) Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor Longlife Filter (Option) O

Swing Compressor Mold Proof Air Filter O O

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor Washable Grille O

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator O

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) O

Timer 24-Hour On/Off Timer O

72-Hour On/Off Timer O

Horizontal Auto-Swing (Right and Left) Night Set Mode O

3-D Airflow Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O

Comfort Airflow Mode Self-Diagnosis (Digital, LED) Display O O

3-Step Airflow (H/P Only) Wiring-Error Check

Comfort

Control

Auto Fan Speed O

Anticorrosion Treatment of Outdoor

Heat Exchanger

Indoor Unit Quiet Operation O

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O

Night Quiet Mode (Automatic) Flexible Voltage Correspondence O

Outdoor Unit Quiet Operation (Manual) High Ceiling Application

Intelligent Eye Chargeless

Quick Warming Function Either Side Drain (Right or Left)

Hot-Start Function Power-Selection

Automatic Defrosting

Remote

Control

5-Rooms Centralized Controller

(Option)

O

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O

Programme Dry Function O O

Remote Control Adaptor

(Normal Open Contact) (Option)

O

Fan Only O O Dlll-NET Compatible (Adaptor) (Option) O O

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Remote

Controller

Wireless O O

Inverter Powerful Operation O Wired O

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation O

ECONO Mode

Indoor Unit On/Off Switch O

Signal Reception Indicator O

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 9

Category Functions

F

C

Q

3

5

-

7

1

B

V

E

F

B

Q

6

0

7

1

B

V

1

F

H

Q

3

5

-

6

0

B

U

V

1

B

9

Category Functions

F

C

Q

3

5

-

7

1

B

V

E

F

B

Q

6

0

7

1

B

V

1

F

H

Q

3

5

-

6

0

B

U

V

1

B

9

Basic Function Inverter (with Inverter Power Control) O O O Health & Clean Air Purifying Filter

Operation Limit for Cooling (CDB) Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor Longlife Filter (Option) O O O

Swing Compressor Mold Proof Air Filter O O O

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor Washable Grille O O

Comfortable

Airflow

Power-Airflow Flap

Filter Cleaning Indicator O O O

Mold Proof Operation

Power-Airflow Dual Flaps Heating Dry Operation

Power-Airflow Diffuser Good-Sleep Cooling Operation

Wide-Angle Louvers Timer 24-Hour On/Off Timer

Vertical Auto-Swing (Up and Down) O O

72-Hour On/Off Timer O O O

Night Set Mode

Horizontal Auto-Swing (Right and Left) Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O O

3-D Airflow Self-Diagnosis (Digital, LED) Display O O O

Comfort Airflow Mode Wiring-Error Check

3-Step Airflow (H/P Only)

Anticorrosion Treatment of Outdoor

Heat Exchanger

Comfort

Control

Auto Fan Speed

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O O O

Indoor Unit Quiet Operation Flexible Voltage Correspondence

Night Quiet Mode (Automatic) High Ceiling Application O O O

Outdoor Unit Quiet Operation (Manual) Chargeless

Intelligent Eye Either Side Drain (Right or Left)

Quick Warming Function Power-Selection

Hot-Start Function

Remote

Control

5-Rooms Centralized Controller

(Option)

Automatic Defrosting

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open Contact) (Option)

Programme Dry Function O O O Dlll-NET Compatible (Adaptor) (Option) O O O

Fan Only O O O Remote

Controller

Wireless O O

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Wired O O O

Inverter Powerful Operation

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

10 List of Functions

1.1.2 R-22 Models

Category Functions

R

M

K

D

1

1

2

1

4

0

1

6

0

D

V

M

Category Functions

R

M

K

D

1

1

2

1

4

0

1

6

0

D

V

M

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

21

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mold Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down)

Timer 24-Hour On/Off Timer

72-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) Night Set Mode

3-D Airflow Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

Comfort Airflow Mode Self-Diagnosis (Digital, LED) Display O

3-Step Airflow (H/P Only) Wiring-Error Check

Comfort

Control

Auto Fan Speed

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Indoor Unit Quiet Operation

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Night Quiet Mode (Automatic) O Flexible Voltage Correspondence

Outdoor Unit Quiet Operation (Manual) O High Ceiling Application

Intelligent Eye Chargeless

Quick Warming Function Either Side Drain (Right or Left)

Hot-Start Function Power-Selection

Automatic Defrosting

Remote

Control

5-Rooms Centralized Controller

(Option)

Operation

Automatic Operation

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open Contact) (Option)

Fan Only Dlll-NET Compatible (Adaptor) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Remote

Controller

Wireless

Inverter Powerful Operation Wired

Priority-Room Setting

Cooling / Heating Mode Lock

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 11

Category Functions

F

T

K

D

2

5

3

5

D

V

M

F

T

K

D

5

0

-

7

1

F

V

M

Category Functions

F

T

K

D

2

5

3

5

D

V

M

F

T

K

D

5

0

-

7

1

F

V

M

Basic

Function

Inverter (with Inverter Power Control) O O Health &

Clean

Air Purifying Filter O

Operation Limit for Cooling (CDB) Photocatalytic Deodorizing Filter O

Operation Limit for Heating (CWB)

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

O

Compressor Oval Scroll Compressor Longlife Filter (Option)

Swing Compressor Mold Proof Air Filter O O

Rotary Compressor Wipe-clean Flat Panel O O

Reluctance DC Motor Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps O O Mold Proof Operation O

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers O O Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) O O Timer 24-Hour On/Off Timer O O

Horizontal Auto-Swing (Right and Left) O 72-Hour On/Off Timer

3-D Airflow O Night Set Mode O O

Comfort Airflow Mode Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O

3-Step Airflow (H/P Only) Self-Diagnosis (Digital, LED) Display O O

Comfort

Control

Auto Fan Speed O O Wiring-Error Check

Indoor Unit Quiet Operation O O

Anticorrosion Treatment of Outdoor

Heat Exchanger

Night Quiet Mode (Automatic)

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

O O

Outdoor Unit Quiet Operation (Manual) Flexible Voltage Correspondence O O

Intelligent Eye O O High Ceiling Application

Quick Warming Function Chargeless

Hot-Start Function Either Side Drain (Right or Left) O O

Automatic Defrosting Power-Selection

Operation

Automatic Operation

Remote

Control

5-Rooms Centralized Controller

(Option)

O O

Programme Dry Function O O

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O O

Fan Only O O

Remote Control Adaptor

(Normal Open Contact) (Option)

O O

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Dlll-NET Compatible (Adaptor) (Option) O O

Inverter Powerful Operation O O Remote

Controller

Wireless O O

Priority-Room Setting Wired

Cooling / Heating Mode Lock

Home Leave Operation O

ECONO Mode O

Indoor Unit On/Off Switch O O

Signal Reception Indicator O O

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

12 List of Functions

Category Functions

F

T

K

5

0

-

7

1

A

V

M

C

D

K

D

2

5

-

6

0

C

V

M

C

D

K

D

2

5

/

3

5

E

A

V

M

Category Functions

F

T

K

5

0

-

7

1

A

V

M

C

D

K

D

2

5

-

6

0

C

V

M

C

D

K

D

2

5

/

3

5

E

A

V

M

Basic

Function

Inverter (with Inverter Power Control) O O O Health &

Clean

Air Purifying Filter O

Operation Limit for Cooling (CDB)

Operation Limit for Heating (CWB) Photocatalytic Deodorizing Filter O

PAM Control

Air Purifying Filter with Photocatalytic

Deodorizing Function

Compressor

Oval Scroll Compressor

Titanium Apatite Photocatalytic

Air-Purifying Filter

Swing Compressor Longlife Filter (Option)

Rotary Compressor Mold Proof Air Filter O

Reluctance DC Motor Wipe-clean Flat Panel

Comfortable

Airflow

Power-Airflow Flap O Washable Grille O

Power-Airflow Dual Flaps Filter Cleaning Indicator

Power-Airflow Diffuser O Mold Proof Operation

Wide-Angle Louvers O Heating Dry Operation

Vertical Auto-Swing (Up and Down) O Good-Sleep Cooling Operation

Horizontal Auto-Swing (Right and Left) O Timer 24-Hour On/Off Timer O O O

3-D Airflow O 72-Hour On/Off Timer

Comfort Airflow Mode Night Set Mode O O O

3-Step Airflow (H/P Only) Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure) O O O

Comfort

Control

Auto Fan Speed O O O Self-Diagnosis (Digital, LED) Display O O O

Indoor Unit Quiet Operation O O O Wiring Error Check

Night Quiet Mode (Automatic)

Anticorrosion Treatment of Outdoor

Heat Exchanger

Outdoor Unit Quiet Operation (Manual)

Intelligent Eye Flexibility

Multi-Split / Split Type Compatible

Indoor Unit

O

Quick Warming Function

Hot-Start Function Flexible Voltage Correspondence O O O

Automatic Defrosting High Ceiling Application

Operation Automatic Operation Chargeless

Programme Dry Function O O O Either Side Drain (Right or Left) O

Fan Only O O O Power Selection

Lifestyle

Convenience

New Powerful Operation (Non-

Inverter)

Remote

Control

5-Rooms Centralized Controller

(Option)

O O O

Inverter Powerful Operation O O O

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

O O O

Priority-Room Setting

Cooling / Heating Mode Lock

Remote Control Adaptor

(Normal Open Contact) (Option)

O O O

Home Leave Operation O O O

ECONO Mode DIII-NET Compatible (Adaptor) (Option) O O O

Indoor Unit On/Off Switch O O O Remote

Controller

Wireless O O O

Signal Reception Indicator O O O Wired

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 13

1.2 Heat Pump

1.2.1 R-410A Models

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

M

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

M

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

5

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

15

~

15.5

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mould Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) Timer 24-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) 72-Hour On/Off Timer

3-D Airflow Night Set Mode

Comfort Airflow Mode Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

3-Step Airflow (H/P Only) Self-Diagnosis (Digital, LED) Display O

Comfort

Control

Auto Fan Speed Wiring-Error Check

Indoor Unit Quiet Operation

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Night Quiet Mode (Automatic) O

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Outdoor Unit Quiet Operation (Manual) O Flexible Voltage Correspondence

Intelligent Eye High Ceiling Application

Quick Warming Function O Chargeless

Hot-Start Function Either Side Drain (Right or Left)

Automatic Defrosting O Power-Selection

Operation

Automatic Operation

Remote

Control

5-Rooms Centralized Controller

(Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Fan Only

Remote Control Adaptor

(Normal Open Contact) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Dlll-NET Compatible (Adaptor) (Option)

Inverter Powerful Operation Remote

Controller

Wireless

Priority-Room Setting Wired

Cooling / Heating Mode Lock O

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

14 List of Functions

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

1

A

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

1

A

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

5

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

15

~

15.5

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mould Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) Timer 24-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) 72-Hour On/Off Timer

3-D Airflow Night Set Mode

Comfort Airflow Mode Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

3-Step Airflow (H/P Only) Self-Diagnosis (Digital, LED) Display O

Comfort

Control

Auto Fan Speed Wiring-Error Check

Indoor Unit Quiet Operation

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Night Quiet Mode (Automatic) O

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Outdoor Unit Quiet Operation (Manual) O Flexible Voltage Correspondence

Intelligent Eye High Ceiling Application

Quick Warming Function O Chargeless

Hot-Start Function Either Side Drain (Right or Left)

Automatic Defrosting O Power-Selection

Operation

Automatic Operation

Remote

Control

5-Rooms Centralized Controller

(Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Fan Only

Remote Control Adaptor

(Normal Open Contact) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Dlll-NET Compatible (Adaptor) (Option)

Inverter Powerful Operation Remote

Controller

Wireless

Priority-Room Setting Wired

Cooling / Heating Mode Lock O

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

Si18-525B List of Functions

List of Functions 15

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

L

T

Category Functions

R

M

X

S

1

1

2

1

4

0

1

6

0

D

V

L

T

Basic

Function

Inverter (with Inverter Power Control) O Health &

Clean

Air Purifying Filter

Operation Limit for Cooling (CDB)

5

~

46

Photocatalytic Deodorizing Filter

Operation Limit for Heating (CWB)

15

~

15.5

Air Purifying Filter with Photocatalytic

Deodorizing Function

PAM Control

Titanium Apatite Photocatalytic

Air-Purifying Filter

Compressor Oval Scroll Compressor O Longlife Filter (Option)

Swing Compressor Mould Proof Air Filter

Rotary Compressor Wipe-clean Flat Panel

Reluctance DC Motor O Washable Grille

Comfortable

Airflow

Power-Airflow Flap Filter Cleaning Indicator

Power-Airflow Dual Flaps Mold Proof Operation

Power-Airflow Diffuser Heating Dry Operation

Wide-Angle Louvers Good-Sleep Cooling Operation

Vertical Auto-Swing (Up and Down) Timer 24-Hour On/Off Timer

Horizontal Auto-Swing (Right and Left) 72-Hour On/Off Timer

3-D Airflow Night Set Mode

Comfort Airflow Mode Worry Free

Reliability &

Durability

Auto-Restart (after Power Failure)

3-Step Airflow (H/P Only) Self-Diagnosis (Digital, LED) Display O

Comfort

Control

Auto Fan Speed Wiring-Error Check

Indoor Unit Quiet Operation

Anticorrosion Treatment of Outdoor

Heat Exchanger

O

Night Quiet Mode (Automatic) O

Flexibility Multi-Split / Split Type Compatible

Indoor Unit

Outdoor Unit Quiet Operation (Manual) O Flexible Voltage Correspondence

Intelligent Eye High Ceiling Application

Quick Warming Function O Chargeless

Hot-Start Function Either Side Drain (Right or Left)

Automatic Defrosting O Power-Selection

Operation

Automatic Operation

Remote

Control

5-Rooms Centralized Controller

(Option)

Programme Dry Function

Remote Control Adaptor

(Normal Open-Pulse Contact) (Option)

Fan Only

Remote Control Adaptor

(Normal Open Contact) (Option)

Lifestyle

Convenience

New Powerful Operation

(Non-Inverter)

Dlll-NET Compatible (Adaptor) (Option)

Inverter Powerful Operation Remote

Controller

Wireless

Priority-Room Setting Wired

Cooling / Heating Mode Lock O

Home Leave Operation

ECONO Mode

Indoor Unit On/Off Switch

Signal Reception Indicator

Temperature Display

Another Room Operation

Note: O : Holding Functions

: No Functions

List of Functions Si18-525B

16 List of Functions

Category Functions

F