Professional Documents

Culture Documents

Hydraulic Structures - Designing Baffled Apron Drops

Uploaded by

raghurmiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Structures - Designing Baffled Apron Drops

Uploaded by

raghurmiCopyright:

Available Formats

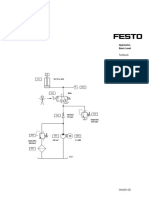

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

1

Baffled Apron Drops

Reference: United States Dept. of the Interior Bureau of Reclamation, Design of Small Canal

Structures, United States Government Printing Office, Denver, 1974. Pages 299-308. Available in the

college library and the course website.

Design Considerations

Capacity

The capacity of the baffled apron drop is a function of the allowable flow rate, q, per foot of width. See

Table 6-1.

Inlet

The inlet should be the same width as baffled apron and should provide a velocity of approach slower

than the critical velocity V

c

where splashing must be minimized, the entrance velocity should not exceed

about 2

c

V where

3

c

V gq =

1. Sill control:

The inlet length should be at least

1

2d , as shown in Figure 6-2. The required height of the sill

above the inlet floor may be determined from the energy balance between the inlet and upstream

channel. Thus

1

1

c

c

s s i s

s s s i

E E h h

h E E h

= + +

=

where

s

h is the sill height,

1 1

1 s v

E d h = + in the upstream channel,

c c

s c v

E d h = + in the control section at the sill.

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

2

( )

1

2 2

1

0.5

0.5 0.5

2 2

i

c

i v

c

v v

h h

V V

h h

g g

= A

| |

= =

|

\ .

Max R=9 ft. A R=6 ft is frequently used.

The sill has a 6 wide slot to provide drainage of the upstream pool.

Baffled Apron Dimensions

1. Set the longitudinal slope of the chute floor and side-walls at 2 to 1 ( tan 0.5 | = ).

2. Approximate width of structure (B) should be

Q

B

q

=

where

B= width,

Q= Maximum total flow rate, and

q= allowable flow rate per foot of width.

3. Baffle block height, h

b

, should be about 0.9d

c

to nearest inch.

4. Baffle block widths and spaces should be equal, and not less than h

b

but not more than

1

2

1

b

h . Partial blocks, having a width not less than

1

3 b

h and not more than

2

3 b

h should be

placed against the sidewalls in rows 1, 3, 5, 7, etc. Alternate rows of baffle blocks should

be staggered so that each block is downstream from a space in the adjacent row.

5. The slope distance, S, between rows of baffle blocks, as shown in Figure 6-5 should be at

least 2h

b

but not greater than 6 ft.

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

3

6. A minimum of four rows of baffle blocks should be used. The baffled apron should be

extended so that the top of at least one row of baffle blocks will be below the bed of the

outlet channel. The apron should be extended beyond the last row of blocks a distance

equal to the clear space between block rows.

7. Upstream faces of baffle blocks are normal to the chute floor. The longitudinal thickness,

T, of the baffle blocks at the top should be at least 8 inches, but not more than 10 inches.

8. Suggested height of the walls to provide adequate free board is three times the baffle block

height measured normal to the chute floor.

Uplift stability

The net forces causing floatation of the structure should be considered, assuming a sudden

cessation of flow in the channel. The net floatation force is equal to the weight of the empty

structure minus the hydrostatic force remaining in the soil around the structure.

Sliding Stability

Major forces, F

S

, tending to induce sliding along the horizontal plane, during maximum flow

in the channel are

1 2 3 4 S

F F F F F = + + +

where

F

1

= Hydrostatic force on the upstream face of the upstream cutoff walls.

F

2

= Hydrostatic force on the vertical face of the sill.

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

4

F

3

= Horizontal component of hydrostatic force on the upstream face of the baffle

blocks.

F

4

= Force of saturated earth load on the upstream face of the downstream cutoff

walls.

Resisting Forces (F

R

)

Frictional resistance for ( )

1 2

L L + as the sloping portion can move horizontal. Frictional

resistance is a function of structure weight reduced by uplift.

( ) passive earth force

R c w

F W W U = + +

where,

is the coefficient of sliding friction, generally assumed to be equal to

0.35,

W

c

is the weight of concrete in the inlet portion of the structure, and

W

w

is the weight of the water in the inlet portion of the structure.

U is the vertical uplift force as determined by Lanes weighted creep

method.

Passive earth force is the total force resulting from passive earth pressure on

the d.s. side of cutoff walls.

Factor of safety . .

R

S

F

F S

F

=

Miscellaneous Considerations

Gravel or riprap should be provided on each side of structure from the top of the slope to the d.s.

wing wall, extending laterally a distance equal to the wall height to prevent erosion from

splashing.

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

5

Design Example

Design a baffled apron drop for the data

1

1

2

1

1

120

8

4.10

58.02

2.08 /

0.07

v

Q cfs

b ft

d ft

A ft

V ft sec

h ft

=

=

=

=

=

=

1

2

2.55

0.025

0.00035

1 :1

2

6.1

b

B

R

n

S

SS

f ft

h ft

=

=

=

=

=

=

A drop of 6 feet in invert elevation is required.

Solution

1. From Table 6-1 find the recommended flow rate q for 120 cfs.

16 q cfs per foor =

120

7.5

16

Q

B ft

q

= = =

2.

3

3

32.2 16 8.0 /

c

V gq

ft sec

=

= =

16

2

8

c

c

c

q

d ft

V

= = =

Block height h

b

= 0.9 d

c

= 0.92=1.8 ft, say 1ft 10 inches

Block width and spacing = w

Min. 1.83

b

w h ft = =

Max. 1.5 1.5 1.83 2.75

b

w h ft = = =

3. Determine exact dimensions of baffle blocks and chute width

1 1

3 3

2 2

3 3

min. 1.83 0.61

max. 1.83 1.22

p b

p b

w h ft

w h ft

= = =

= = =

For simplicity try

1

2

0.915

p b

w h ft = =

B= 2 half blocks + 1 full block + 2 full spaces

Considering width of blocks and spaces equal to the block height = 1.83 ft

1

2

2 2 4

1.83

4 1.83 7.32

b

B w w w w

w h ft

B ft

= + + =

= =

= =

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

6

For simplicity use ( ) 2 1.83 and 2.75 w ft ft ft = > <

And ( ) 1 0.61 1.22

p

w ft ft ft = > <

Then 4 4 2 8 B w ft = = =

3

120

15

8

32.2 15 7.85 /

1.91

0.9 1.91 1.72

c

c

c

b

q cfs per foot

V ft sec

q

d ft

V

h ft

= =

= =

= =

= =

Use h

b

= 1 ft 9 inches = 1.75 ft

Select T=9 inches > 8 inches < 10 inches

4. Determination of inlet length,

1

L

1 1

2 2 4.1 8.2 L d ft = = =

Use

1

8 3 L ft inches =

5. Determination of inlet sill height,

s

h

8 , 15 , 1.91 , 0.96, 7.86

c

c v c

B ft q cfs d ft h V ft = = = = =

( ) ( ) ( )

( ) ( ) ( )

1 2

1 1

1

(where, inlet loss)

= 0.5

4.1 0.07 1.91 0.96 0.5 0.96 0.07

0.85 use 10 0.83

c c

s s s i i

v c v v v

s

h E E h h

d h d h h h

ft h inches ft

= =

+ +

= + +

= = =

6. Check inlet velocity to minimize splashing

Determine depth, d

1

, at inlet cutoff

1

0.83 1.91 0.96

3.70

c

s c v

d h d h

ft

= + +

= + +

=

The entrance velocity is then

1

1 1

120

4

3.7 8

Q Q

V fps

A d B

= = = =

Determine critical velocity, V

c

, over crest

1

120

7.85 2 O.K.

1.91 8

c

c

Q Q

V fps V

A d B

= = = =

Inlet velocity is approximately equal to half the critical velocity, and splashing will be minimized.

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

7

7. Determine the sill length, L

2

Using R=6 ft and invert slope of 2 to 1

( )

26 34'

sin 0.4472

tan 0.5

2 13 17'

tan 2 0.2361

y

z

y

x

z

R

|

|

|

|

|

=

= =

= =

=

= =

0.2361 1.42

0.4472 0.63

1.26

0.5

z R ft

y z ft

y

x ft

= =

= =

= =

2

1.26 1.42 2.68 L x z ft = + = + =

and 0.83 0.63 0.2

s

e h y ft = = =

8. Determine the slope distance, S

2

b

S h = (min.) but not greater than 6 ft

( ) 2 1.75 3.5 S ft = =

Use S=6 ft for all blocks equal or less than 3 feet in height.

9. Determine minimum depth of cover, j at outlet to insure that the last row of baffle blocks will be

covered by the backfill, placed in the structure to the evaluation of the downstream grade.

( )

( )

sin 6 0.4472 2.68

cos 1.75 0.8944 1.57

4.25

y

y b

y y

S S ft

h h ft

j S h ft

|

|

= = =

= = =

= + =

10. Determine apron lengths,

3

and

s

L L for a drop, F= 6 feet.

Minimum distance,

0.2 6 4.25 10.45

y

L e F j

ft

= + +

= + + =

Minimum rows of blocks,

10.45

Rows 3.9 use 4 (min.)

2.68

y

y

L

S

= = =

Finally,

( )

4

4 6 24

s

L S

ft

=

= =

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

8

( )

( )

3

4

4 2.68 10.72

4 4 6cos 24 0.8944 21.47

y y

x

L S

ft

L S ft |

=

= =

= = = =

11. Determination of overall length of structure, L

1 2 3

8.25 2.68 21.47

32.4

L L L L

ft

= + +

= + +

=

12. Determination of wall heights

1 1

1

1 ( . ) 4.10 1 5.1

Use 5 2

h d ft F B ft

h ft inches

= + = + =

=

With a level invert and with the top of the walls level from

1 2

to h h

2 1

5 2 10

4 4

s

h h h

ft inches inches

ft inches

=

=

=

Height to chute walls

( )

3

3 3 1.75 5.25

5 3

b

h h ft

ft inches

= = =

=

13. Determine length, M

1

, of the upstream wing walls as shown in Figure 6-7. With C

1

=2.5 ft from

Figure 7-2.

( )

1 1 1

1.5

1.5 5.17 2.5 10.25

M h C

ft

= +

= + =

Use 10 ft 3 inches.

14. Determine length, M

3

, of downstream wing wall as shown in Figure 6-8.

3 3 3

3

1.5

2.5 for channel depth of 4.1 from Figure 7-2.

M h C

C ft ft

' = +

=

Hydraulic Structures Baffled Apron Drops Printed: December 18, 2010

9

( )

3

3

3

3

5.25

5.87

cos 0.8944

1.5 5.87 2.5 11.31

Use 11 4

h

h ft

M ft

M ft inches

|

' = = =

= + =

=

15. Check floatation of the structure (due to uplift forces) assuming a sudden cessation of channel

flow.

16. Check sliding stability of the structure according to that the resisting forces should be greater than

sliding forces.

17. Protection

For water depth 4.1 ft,

Inlet protection: Type 1, extending a distance d

1

upstream, and up the sloping sides to an

elevation 1 ft above the normal water surface.

Outlet protection: Type 3, extending downstream a distance 4 d

1

and up the sloping sides

to an elevation 1 ft above the assumed water table.

Slope protection: Type 1 should be provided on each side of the structure from the top of

the slope to the downstream wing wall extending laterally a distance equal

to wall height, to prevent erosion from splashing.

You might also like

- GVF Model Question Solved PDFDocument34 pagesGVF Model Question Solved PDFJeewan75% (4)

- LoadingDocument6 pagesLoadingMaika Mae GalindezNo ratings yet

- Final Exam Hydraulic Jan2012Document9 pagesFinal Exam Hydraulic Jan2012Anni SuhanaNo ratings yet

- Design of Cut throat FlumesDocument20 pagesDesign of Cut throat FlumesSunita ChaurasiaNo ratings yet

- Liquefaction AnalysisDocument75 pagesLiquefaction AnalysisRyanYuNo ratings yet

- Chapter+1+-+main+hydrological+concepts+ EditedDocument11 pagesChapter+1+-+main+hydrological+concepts+ EditedMARVINNo ratings yet

- Bore Log TestDocument1 pageBore Log TesthansyusofNo ratings yet

- Open Channel Labsheet PDFDocument6 pagesOpen Channel Labsheet PDFSulaksha WimalasenaNo ratings yet

- NUS Past Year PaperDocument8 pagesNUS Past Year PaperSteven KuaNo ratings yet

- Stage (M) Storage (M) Discharge (M /S) Stage (M) Storage (M) Dischargec (M /S)Document37 pagesStage (M) Storage (M) Discharge (M /S) Stage (M) Storage (M) Dischargec (M /S)kpop is moodNo ratings yet

- Civil Engineering Lecture on Transportation EngineeringDocument144 pagesCivil Engineering Lecture on Transportation EngineeringMeenu TomsonNo ratings yet

- The Deflection of A Uniform Beam Subject To A Linearly Increasing Distributed Load Can Be Computed AsDocument15 pagesThe Deflection of A Uniform Beam Subject To A Linearly Increasing Distributed Load Can Be Computed AsAlodia Lulu SmileNo ratings yet

- Chapter 1:types of Flow in Open ChannelDocument61 pagesChapter 1:types of Flow in Open ChannelHani BarjokNo ratings yet

- Chapter-1: Introduction To Dynamics Mechanics As The Origin of DynamicsDocument92 pagesChapter-1: Introduction To Dynamics Mechanics As The Origin of DynamicsRoutine Of Nepal BandaNo ratings yet

- Taking Off SewerageDocument4 pagesTaking Off SewerageMrJanji JohnyNo ratings yet

- Core Test PDFDocument8 pagesCore Test PDFprince aNo ratings yet

- Counter Weight On Soft ClayDocument19 pagesCounter Weight On Soft ClaysantosoNo ratings yet

- Geotechnical Engineering - Course OutlineDocument10 pagesGeotechnical Engineering - Course OutlineJoshua John JulioNo ratings yet

- Design of AqueductDocument5 pagesDesign of Aqueducthari_shresthaNo ratings yet

- Advanced Soil Mechanics OverviewDocument5 pagesAdvanced Soil Mechanics OverviewZack FengNo ratings yet

- Allowable Bearing CapacityDocument13 pagesAllowable Bearing CapacitylfpachecoNo ratings yet

- Standard Method For Gradually Varied FlowDocument5 pagesStandard Method For Gradually Varied Flowj0bgimhanNo ratings yet

- Pad Strip Foundation Analysis - ADocument14 pagesPad Strip Foundation Analysis - AAshadi HamdanNo ratings yet

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- ASD Specification (Volumn 1 Corrigendum)Document0 pagesASD Specification (Volumn 1 Corrigendum)Agnon FungNo ratings yet

- SEEPAGEDocument28 pagesSEEPAGEkhazman76No ratings yet

- Infravera Engineering Software.: Drain+ Manual TrainingDocument19 pagesInfravera Engineering Software.: Drain+ Manual TrainingshafiqNo ratings yet

- Analysis of Theoretical Versus Actual HDD Pulling LoadsDocument7 pagesAnalysis of Theoretical Versus Actual HDD Pulling Loadsjua666nNo ratings yet

- Permeability & SeepageDocument40 pagesPermeability & SeepageShekh Muhsen Uddin Ahmed100% (1)

- Surge Tank Functions and Water Surface OscillationsDocument27 pagesSurge Tank Functions and Water Surface OscillationsArup K HazraNo ratings yet

- Determine Splitting Tensile StrengthDocument5 pagesDetermine Splitting Tensile StrengthsuryakantameNo ratings yet

- Lab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightDocument6 pagesLab Manual 2.3 - LEVEL 0 - Determination of Metacentric HeightMuhamad IzzanNo ratings yet

- Design of Flexible Pavement (JKR Method)Document10 pagesDesign of Flexible Pavement (JKR Method)B.A HNo ratings yet

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Project Report Topic: Analysis of Statically Determinate BeamDocument22 pagesProject Report Topic: Analysis of Statically Determinate BeamMARVINNo ratings yet

- GVF 1Document9 pagesGVF 1Abhijeeth NagarajNo ratings yet

- Civil Works Site Preparation EstimateDocument1 pageCivil Works Site Preparation EstimateBest AcaiNo ratings yet

- Hydraulic JumpDocument5 pagesHydraulic JumpKafeel Bichu0% (1)

- UDSM - Swelling Rock Model (2014)Document23 pagesUDSM - Swelling Rock Model (2014)JinChongNo ratings yet

- Tute 2 Flow Nets AnswersDocument5 pagesTute 2 Flow Nets Answerslawan100% (1)

- Hidrologi Teknik Chapter 8 Storage OutflowDocument24 pagesHidrologi Teknik Chapter 8 Storage Outflowkpop is moodNo ratings yet

- MSMADocument4 pagesMSMAMatthew WeeNo ratings yet

- Chapter 4 Non Uniform Flow in Open ChannelsDocument57 pagesChapter 4 Non Uniform Flow in Open ChannelsDianne M. DepositarioNo ratings yet

- Baffled OutletsDocument28 pagesBaffled OutletsAhmed AmediNo ratings yet

- Steel Section Table ConciseDocument36 pagesSteel Section Table ConciseVance KangNo ratings yet

- Sheet Pile Vibratory Hammer Test Program SupplementDocument7 pagesSheet Pile Vibratory Hammer Test Program SupplementDotsOyenugaNo ratings yet

- Ahe QBDocument20 pagesAhe QBNivedhitha CNo ratings yet

- Report Project EsteemDocument5 pagesReport Project EsteemKavi MaranNo ratings yet

- Guidance Note On The Design of Thrust BlocksDocument1 pageGuidance Note On The Design of Thrust BlocksLi Tsz ChunNo ratings yet

- Assignment I Field Exploration & Soil TestingDocument12 pagesAssignment I Field Exploration & Soil TestingEphrem Bizuneh100% (1)

- Design of Non Erodible ChannelsDocument2 pagesDesign of Non Erodible Channelsveena sandheepNo ratings yet

- Canal DesignDocument12 pagesCanal DesignUsman ShehryarNo ratings yet

- Head and Cross RegulatorsDocument14 pagesHead and Cross RegulatorsSaphal Lamichhane75% (8)

- Stilling Basin Design GuideDocument10 pagesStilling Basin Design GuideAbhishek Shah100% (1)

- ECK Rainage Esign: B D A - O 2006Document20 pagesECK Rainage Esign: B D A - O 2006HundeejireenyaNo ratings yet

- Head and Cross RegulatorsDocument19 pagesHead and Cross RegulatorsEng Shakir H100% (1)

- Design of Chute Spillway ComponentsDocument6 pagesDesign of Chute Spillway ComponentsPk Pk100% (1)

- Design of Sarda FallDocument77 pagesDesign of Sarda FallRamaraj Ramakrishnan100% (1)

- Design of FootingsDocument102 pagesDesign of FootingsTBCACCOUNTs100% (1)

- Muro de Contencion en CantiliverDocument20 pagesMuro de Contencion en CantiliverJosé Alberto Garcia CordovaNo ratings yet

- AutoCAD ManualDocument70 pagesAutoCAD ManualraghurmiNo ratings yet

- Hydro Lab Manual - RaghuDocument22 pagesHydro Lab Manual - RaghuraghurmiNo ratings yet

- Assessment of Non-Functioning Micro-Hydro ProjectsDocument47 pagesAssessment of Non-Functioning Micro-Hydro ProjectsraghurmiNo ratings yet

- Sample of GVFDocument2 pagesSample of GVFraghurmiNo ratings yet

- Jala Shakti Book 2070 Vol 12Document48 pagesJala Shakti Book 2070 Vol 12raghurmiNo ratings yet

- Sci TechDocument52 pagesSci TechraghurmiNo ratings yet

- Jala ShaktiDocument40 pagesJala ShaktiraghurmiNo ratings yet

- KumarDocument6 pagesKumarraghurmiNo ratings yet

- Jalashakti Vol No 13 Year 20 BS2071Document41 pagesJalashakti Vol No 13 Year 20 BS2071raghurmiNo ratings yet

- Nepal's Total Run-of-River Hydropower PotentialDocument6 pagesNepal's Total Run-of-River Hydropower PotentialraghurmiNo ratings yet

- Solution of Q.N. 3Document2 pagesSolution of Q.N. 3raghurmiNo ratings yet

- Annual Progress Report of NRREP 2012.13Document55 pagesAnnual Progress Report of NRREP 2012.13raghurmiNo ratings yet

- Assignment 2Document2 pagesAssignment 2raghurmiNo ratings yet

- GVF ExampleDocument2 pagesGVF ExampleraghurmiNo ratings yet

- Gis TutorilDocument95 pagesGis TutorilraghurmiNo ratings yet

- L2 StuDocument4 pagesL2 SturaghurmiNo ratings yet

- Gis 06Document7 pagesGis 06raghurmiNo ratings yet

- Assignment 1Document2 pagesAssignment 1raghurmiNo ratings yet

- Map Projections: Types of DistortionDocument6 pagesMap Projections: Types of DistortionraghurmiNo ratings yet

- Gis 01Document6 pagesGis 01raghurmiNo ratings yet

- ArcGIS Georeferencing An Image v10.0Document4 pagesArcGIS Georeferencing An Image v10.0Muhammad ZeeshanNo ratings yet

- Geor As TutorialDocument34 pagesGeor As TutorialOscar CcamaNo ratings yet

- Watershed and Stream Network Delineation - TutorialDocument39 pagesWatershed and Stream Network Delineation - TutorialraghurmiNo ratings yet

- Georas VelocityDocument3 pagesGeoras VelocityraghurmiNo ratings yet

- Arc Hydro Tools 1.1 - TutorialDocument109 pagesArc Hydro Tools 1.1 - TutorialHector Manuel Paredes PinedoNo ratings yet

- Global Delineation With EDNA Data - v1.0 Beta 2Document14 pagesGlobal Delineation With EDNA Data - v1.0 Beta 2raghurmiNo ratings yet

- GeohmsDocument25 pagesGeohmsraghurmiNo ratings yet

- Tutorial 2 - Exploring Map Projections and Grid Systems in Arcgis 10Document11 pagesTutorial 2 - Exploring Map Projections and Grid Systems in Arcgis 10raghurmiNo ratings yet

- Arc Hydro GP Tools 2.0 TutorialDocument252 pagesArc Hydro GP Tools 2.0 TutorialraghurmiNo ratings yet

- Arc Hydro Tools 2.0 TutorialDocument189 pagesArc Hydro Tools 2.0 TutorialraghurmiNo ratings yet

- Astm D2837.219-1Document14 pagesAstm D2837.219-1Mariano Emir Garcia OdriozolaNo ratings yet

- CLO - Fluid MechanicsDocument4 pagesCLO - Fluid Mechanicstooba IshfaqNo ratings yet

- Analysis of Forces Acting on Gravity DamsDocument27 pagesAnalysis of Forces Acting on Gravity DamsEleazar Tami-ingNo ratings yet

- 15 08 14 15 46 55 2808 Ccet0280 PDFDocument103 pages15 08 14 15 46 55 2808 Ccet0280 PDFGaurav RajputNo ratings yet

- Bell Mouth DatasheetDocument1 pageBell Mouth DatasheetwaterfrontfcNo ratings yet

- Fluid Mechanics (FM) Hand Written Notes For Class 11 JeeDocument77 pagesFluid Mechanics (FM) Hand Written Notes For Class 11 Jeesmeet mehtaNo ratings yet

- Mech 311 Fluid Mechanics Lecture NotesDocument23 pagesMech 311 Fluid Mechanics Lecture NotesMarcky ReacherNo ratings yet

- Design of Spillway Tainter GatesDocument92 pagesDesign of Spillway Tainter GatesAhmet Sahinoz100% (3)

- 1 Intro To Fluid MechanicsDocument38 pages1 Intro To Fluid MechanicsSyedShahHasnainNo ratings yet

- Hydrostatic Test Procedure Storage TankDocument15 pagesHydrostatic Test Procedure Storage TankYuwantoniAl75% (4)

- ExpansionDocument25 pagesExpansionJA K100% (1)

- Hydraulics Basic Level PDFDocument276 pagesHydraulics Basic Level PDFIwan Sb100% (1)

- NCE 3206 Problem Set3 CE 2 Group 1Document11 pagesNCE 3206 Problem Set3 CE 2 Group 1HANNAHMAE SORITANo ratings yet

- Industrial Fluid Power PDFDocument141 pagesIndustrial Fluid Power PDFchidambaram kasi33% (3)

- NOTES ON FLUID MECHANICS ContentsDocument76 pagesNOTES ON FLUID MECHANICS ContentsAhmed AptechNo ratings yet

- BS Bio - Bip16m - 23-24Document15 pagesBS Bio - Bip16m - 23-24Nix Dela TorreNo ratings yet

- 307 Basic Hydraulics Course PreviewDocument15 pages307 Basic Hydraulics Course PreviewAnonymous q9eCZHMuSNo ratings yet

- Hydrostatic Forces on SurfacesDocument12 pagesHydrostatic Forces on SurfacesPajhmanAwghanNo ratings yet

- Hydraulics PDFDocument257 pagesHydraulics PDFMuhtiarNo ratings yet

- Hydraulics 130106180852 Phpapp02Document257 pagesHydraulics 130106180852 Phpapp02hagh_mostafa2787No ratings yet

- API 650-Water SS Tank-060914Document84 pagesAPI 650-Water SS Tank-060914A.K.M Shafiq MondolNo ratings yet

- Hydrostatic Force Curved SurfacesDocument4 pagesHydrostatic Force Curved SurfacesRUSSELNo ratings yet

- General Physics Lesson 5,6 and 7Document31 pagesGeneral Physics Lesson 5,6 and 7James Sevilla GarlitNo ratings yet

- Tutorial 4 Josephine Bakewa A00224059Document7 pagesTutorial 4 Josephine Bakewa A00224059Josephine BakewaNo ratings yet

- Southern Philippines Agribusiness and Marine and Aquatic School of TechnologyDocument8 pagesSouthern Philippines Agribusiness and Marine and Aquatic School of TechnologyJoanne Louise Camonias BirondoNo ratings yet

- HS90 CoiledTubeDocs101909Document12 pagesHS90 CoiledTubeDocs101909Yongqiang LiNo ratings yet

- Hydraulics and Fluid Mechanics Questions & AnswersDocument55 pagesHydraulics and Fluid Mechanics Questions & AnswersAshfaq Ahmad100% (1)

- Fluid Mechanics NotesDocument85 pagesFluid Mechanics Notesjoz lapNo ratings yet

- HydrostaticsDocument12 pagesHydrostaticsbman0051401No ratings yet

- Applied Fluid Mechanics (MECH 2002)Document16 pagesApplied Fluid Mechanics (MECH 2002)chandan VishvakarmaNo ratings yet