Professional Documents

Culture Documents

01 Bypass Principle

Uploaded by

Imam Yudho0 ratings0% found this document useful (0 votes)

144 views1 pageThe kiln bypass removes volatile elements like chlorine and sulfur from clinker production to control coating and clogging. A bypass extracts hot kiln gases with high volatile concentrations before they condense. Quenching cools the gases, causing volatiles to condense on collected bypass dust. Insufficient bypass rates or low volatile withdrawal can cause clogging or kiln shutdowns, while proper hot meal analysis and bypass adjustment prevents issues.

Original Description:

by pass principle

Original Title

01 Bypass principle.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe kiln bypass removes volatile elements like chlorine and sulfur from clinker production to control coating and clogging. A bypass extracts hot kiln gases with high volatile concentrations before they condense. Quenching cools the gases, causing volatiles to condense on collected bypass dust. Insufficient bypass rates or low volatile withdrawal can cause clogging or kiln shutdowns, while proper hot meal analysis and bypass adjustment prevents issues.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

144 views1 page01 Bypass Principle

Uploaded by

Imam YudhoThe kiln bypass removes volatile elements like chlorine and sulfur from clinker production to control coating and clogging. A bypass extracts hot kiln gases with high volatile concentrations before they condense. Quenching cools the gases, causing volatiles to condense on collected bypass dust. Insufficient bypass rates or low volatile withdrawal can cause clogging or kiln shutdowns, while proper hot meal analysis and bypass adjustment prevents issues.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

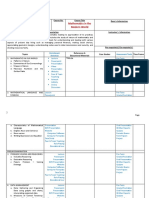

HGRS MASTER

Operation Area: Clinker Production

Category : Equipment

Module: Kiln Bypass

Unit: Bypass Principle 01 o 0!

"ersion: 1#0 $%&0'&0(

Bypass Principle

Purpose: A )ypass creates a *al*e or circulating elements in t+e kiln and remo*es elements suc+ as Cl,

sulur and alkalis until t+e coating-clogging situation in t+e pre+eater-kiln )ecomes controlla)le

.it+ t+e +elp o cleaning#

A )ypass is used or t+e remo*al o alkalis in case lo.&alkali cement is )eing produced

Function/

Description:

/+e kiln gases containing t+e *olatili0ed elements 1see unit circulation p+enomena2 are e3tracted

at t+eir point o +ig+est concentration, i#e# t+e kiln inlet# /+is pre*ents t+em rom condensing in

t+e pre+eater to.er and creating cyclone )lockages t+ere#

4t can roug+ly )e stated t+at or eac+ 100g-t cli o c+lorine o total input, 15 o )ypass rate is

necessary#

6ue to t+e )ypass t+e +eat consumption o t+e kiln system is roug+ly increased )y 10 k7-kg cli

or precalciner kilns and $0 k7-kg cli or pre+eater kilns per percent o )ypass rate#

/+e eiciency o )ypass installations is most eicient or Cl and muc+ less or 8 and alkalis#

/+ereore Cl )ypass rates are muc+ smaller t+an ot+er )ypass rates#

Ater t+e )ypass t+e +ot kiln gases are quenc+ed in a mi3ing c+am)er .it+ t+e +elp o quenc+ing

air alone or .it+ quenc+ing air and .ater in9ection# /+is quenc+ing +as t.o main reasons:

6ue to t+e cooling do.n o t+e gases t+e gaseous *olatile elements solidiy and

condense on t+e kiln dust and is e3tracted as )ypass dust# /+is dust can )e separated

rom t+e gas stream and remo*ed rom t+e kiln system#

/+e +ot kiln gases 1ca# 11:0;C2 are cooled do.n to 1:0&(:0;C 1according to t+e ilter

type used2 in order not to damage t+e ilter 1e#g# )ag ilters2 and-or in order to impro*e

t+e eiciency o t+e ilter 1e#g# Electrostatic precipitators2

/+e quenc+ed gases are introduced into a ilter .+ere t+e )ypass dust is separated rom t+e

gas# /+e gas is lead to t+e main or a separate )ypass stack or is reintroduced into t+e kiln

system 1cooler, pre+eater, ra. mill, etc#2#/+e potential or t+e e3traction o *olatiles .it+ a )ypass

is gi*en )y:

*olatile e3traction potential < dust quantity = *olatile&concentration

/+e collected )ypass dust is used or instance in cement as a iller or t+e *olatile elements can

)e .as+ed out and remo*ed, t+e rest o t+e dust )eing reused as ra. material#

Impact if not

correctly

functionin

Clogging in t+e pre+eater to.er or ring ormation in t+e kiln

E*entually kiln s+ut do.n

Cement quality pro)lems in case o lo.&alkali cement production

!auses of

malfunctions

4nadequate )ypass rate 1too lo.2

/oo lo. alkali *olatili0ation and .it+dra.al 1lack o c+lorine added2

Erroneous +ot meal analysis o *olatile elements

Pre"enti"e

actions

Correct +ot meal analysis o *olatile elements at least once per s+it

Ad9ustment o t+e )ypass rate according to t+e +ot meal analysis

See site specific unit for a##itional information$ respecti"e correcti"e

actions an# applica%le safety instructions&

'M( #enotes maintenance issue

AD)*+,&#sf / -ma ./&+&*.

0uenc1 air

fan

0uenc1

c1am%er

clin2er

intro#uction

into t1e cement

%a filter

coolin to3er

%ypass

%a filter

%ypass fan

You might also like

- KilnOpBasics - ManufProcess OverviewDocument31 pagesKilnOpBasics - ManufProcess OverviewmustafNo ratings yet

- Flowsheet& Theoretical HeatDocument35 pagesFlowsheet& Theoretical HeatRamachandrarao MaddaliNo ratings yet

- Project:: 2800TPD Burning System CalculationDocument7 pagesProject:: 2800TPD Burning System CalculationOUSSAMA LAKHILINo ratings yet

- RCA - IV Cyclone Blockage 11.12.14Document6 pagesRCA - IV Cyclone Blockage 11.12.14Visnu SankarNo ratings yet

- How To Control The Hot MealDocument4 pagesHow To Control The Hot MealGiequat100% (2)

- How To Line The Burner Pipe PDFDocument19 pagesHow To Line The Burner Pipe PDFMustafa Ramadan100% (2)

- Heat Consumption Mastery Standard: CementDocument16 pagesHeat Consumption Mastery Standard: CementJunaid Mazhar100% (3)

- Alkali CyclesDocument14 pagesAlkali CyclesElwathig BakhietNo ratings yet

- Firing: Vii - CombustionDocument207 pagesFiring: Vii - CombustionMustafa RamadanNo ratings yet

- Cement Division Technical Training Tools: 090519 Technicaltrainingtools DescriptionDocument6 pagesCement Division Technical Training Tools: 090519 Technicaltrainingtools Descriptionrupesh soniNo ratings yet

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguNo ratings yet

- Cooler Air Distribution: Job AidDocument2 pagesCooler Air Distribution: Job Aidrupesh soniNo ratings yet

- 05 Measurement Gas FlowDocument68 pages05 Measurement Gas FlowYhaneNo ratings yet

- Kiln Control UnicemfinalDocument26 pagesKiln Control UnicemfinalOUSSAMA LAKHILI100% (1)

- Mod 7Document47 pagesMod 7mkpq100% (1)

- Coating, Rings and BallsDocument8 pagesCoating, Rings and BallsHazem Diab100% (1)

- Calculation of Flame MomentumDocument1 pageCalculation of Flame MomentumAnoop TiwariNo ratings yet

- Kiln Control and OperationDocument56 pagesKiln Control and OperationLe Hoang100% (1)

- VDZ-Onlinecourse 7 3 enDocument20 pagesVDZ-Onlinecourse 7 3 enAnonymous iI88LtNo ratings yet

- ROTAFLAM Burner AdjustmentDocument5 pagesROTAFLAM Burner AdjustmentMuhammad Zaghloul100% (2)

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBmkpqNo ratings yet

- MillOpBasics OperationDocument36 pagesMillOpBasics OperationIrshad HussainNo ratings yet

- Raw Material Preparation: Raw Meal Homogenization and Kiln Dust Management Pe Latam 2012Document26 pagesRaw Material Preparation: Raw Meal Homogenization and Kiln Dust Management Pe Latam 2012Pedro PastenNo ratings yet

- 10 081222 CroDocument1 page10 081222 Crorupesh soniNo ratings yet

- Impact of Alkali, Sulphur and Chlorine in The KilnDocument3 pagesImpact of Alkali, Sulphur and Chlorine in The KilnJa Phe Ti100% (1)

- Raw MixDocument96 pagesRaw Mixshannu826826No ratings yet

- 04 - Combustion and 10 Golden RulesDocument30 pages04 - Combustion and 10 Golden RulesAfqan B-vNo ratings yet

- 4 - False Air Profile Dry Preheater KilnDocument1 page4 - False Air Profile Dry Preheater KilnSundara SubramaniyanNo ratings yet

- Brick CaclulatorDocument7 pagesBrick CaclulatorAbul QasimNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.100% (1)

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Burning DashboardDocument3 pagesBurning DashboardMehmet C100% (1)

- Process Optimization-Pyrosection Hand BookDocument195 pagesProcess Optimization-Pyrosection Hand Bookramsumiran vishwakarma100% (1)

- VDZ-Onlinecourse 6 5 enDocument30 pagesVDZ-Onlinecourse 6 5 enSuadNo ratings yet

- Process Problem Trouble ShootingDocument13 pagesProcess Problem Trouble ShootingMin Zayar100% (2)

- B Level Audit For Ball MillDocument27 pagesB Level Audit For Ball MillTin Nguyen100% (1)

- Opening PPE Course 2008Document7 pagesOpening PPE Course 2008vikubhardwaj9224No ratings yet

- General Presentation: PILLARD, 84 Years of Reliable Service For The World S Cement ProducersDocument22 pagesGeneral Presentation: PILLARD, 84 Years of Reliable Service For The World S Cement ProducersmustafNo ratings yet

- 03.01 PR PYR P06 02 How To Start-Up & Optimize A Burner v1Document6 pages03.01 PR PYR P06 02 How To Start-Up & Optimize A Burner v1rupesh soniNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.No ratings yet

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaNo ratings yet

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- Pet Coke Fuel Experience in Rotary KilnDocument7 pagesPet Coke Fuel Experience in Rotary KilnP.S.J.Sarma100% (1)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Precalciner Systems Cement IndustryDocument22 pagesPrecalciner Systems Cement IndustryfaheemqcNo ratings yet

- Session 8 - Advancement in Refractory Used in Cement PlantDocument75 pagesSession 8 - Advancement in Refractory Used in Cement Plantmahendra sen100% (1)

- 2.02.burning Zone CoatingDocument2 pages2.02.burning Zone CoatingJCSNo ratings yet

- How To Check The Calibration of Cooling Fan Airflows: PyroprocessingDocument2 pagesHow To Check The Calibration of Cooling Fan Airflows: Pyroprocessingrupesh soniNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Ask DR. CLARK - OdtDocument50 pagesAsk DR. CLARK - Odtmauryaraj200750% (2)

- PitotDocument5 pagesPitotJohn GiannakopoulosNo ratings yet

- Hasler Process Performance Engineer at HolcimDocument10 pagesHasler Process Performance Engineer at Holcimvikubhardwaj9224No ratings yet

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- A.Ramalingam Address For Communication 19, ChidambaranagarDocument4 pagesA.Ramalingam Address For Communication 19, ChidambaranagarSubbulakshmi RamalingamNo ratings yet

- 13 - Drilling Fluid FinalDocument20 pages13 - Drilling Fluid Finalمحمد سعيد100% (1)

- Kayfun Lite User Manual en V1.0Document12 pagesKayfun Lite User Manual en V1.0billybob123321123100% (1)

- Use of Coal Fly Ash in Cement and Its Impect On Properties of CementDocument11 pagesUse of Coal Fly Ash in Cement and Its Impect On Properties of CementJamal ShahNo ratings yet

- Honda Dio ManualDocument61 pagesHonda Dio ManualElizabeth Thompson65% (23)

- HZLDocument38 pagesHZLSatyendra Pal SinghNo ratings yet

- 10 Simple SentencesDocument4 pages10 Simple SentencesImam YudhoNo ratings yet

- NounsDocument25 pagesNounsImam YudhoNo ratings yet

- Vega level-ENDocument52 pagesVega level-ENImam YudhoNo ratings yet

- Noun SuffixesDocument4 pagesNoun SuffixesGeorge ParksNo ratings yet

- Parts of Speech VerbsDocument30 pagesParts of Speech VerbsImam YudhoNo ratings yet

- Presentasi PRONOUNSDocument15 pagesPresentasi PRONOUNSImam YudhoNo ratings yet

- Presentasi PRONOUNSDocument15 pagesPresentasi PRONOUNSImam YudhoNo ratings yet

- CEMC Screw Conveyor Manual 2.20Document107 pagesCEMC Screw Conveyor Manual 2.20Angel Alvarez100% (7)

- Mathematics in The Modern World: Course No. Course Title Dean's InformationDocument5 pagesMathematics in The Modern World: Course No. Course Title Dean's InformationJayson SantelicesNo ratings yet

- Red Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Document7 pagesRed Bin Analysis PDF Notes - 10020477 - 2023 - 10 - 13 - 09 - 28Sameer SutarNo ratings yet

- Design and Simulation of A QCA 2 To 1 MultiplexerDocument5 pagesDesign and Simulation of A QCA 2 To 1 MultiplexerzubifayazNo ratings yet

- Immediate Settlement Analysis Using Finite Element Analysis Models of Fb-MultipierDocument22 pagesImmediate Settlement Analysis Using Finite Element Analysis Models of Fb-MultipierRaaf RifandiNo ratings yet

- Kahawalage TR 0061123036 Tony Ahfock ThesisDocument74 pagesKahawalage TR 0061123036 Tony Ahfock ThesisTharindu RukshanNo ratings yet

- V-RAY 2.0 Option Editor Overview (SketchUp)Document14 pagesV-RAY 2.0 Option Editor Overview (SketchUp)thonethoneNo ratings yet

- Fds 8878Document12 pagesFds 8878Rofo2015No ratings yet

- Hybrid ModelDocument9 pagesHybrid ModelanjulNo ratings yet

- GTG Centaur 50 TurbomachineryDocument86 pagesGTG Centaur 50 TurbomachineryAlfian Aditya100% (3)

- Electricity Markets PDFDocument2 pagesElectricity Markets PDFAhmed KhairiNo ratings yet

- Machine Translation: A Presentation By: Julie Conlonova, Rob Chase, and Eric PomerleauDocument31 pagesMachine Translation: A Presentation By: Julie Conlonova, Rob Chase, and Eric PomerleauemailmynameNo ratings yet

- Catamaran AnalysisDocument83 pagesCatamaran AnalysisbhukthaNo ratings yet

- Production of Hard Grade Bitumen For Using in High Modulus Asphalt ConcreteDocument18 pagesProduction of Hard Grade Bitumen For Using in High Modulus Asphalt ConcretePanjiNo ratings yet

- 125 Tractor: (Specifications and Design Subject To Change Without Notice)Document5 pages125 Tractor: (Specifications and Design Subject To Change Without Notice)Gary LarsonNo ratings yet

- Experiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormDocument29 pagesExperiment - 1: Aim: Create Webpage Using HTML Form To Demonstrate Student Information FormModi rutvikNo ratings yet

- S3 3 TrigonometryDocument81 pagesS3 3 TrigonometryEugene ChoongNo ratings yet

- Certificate of Analysis: Sulfate IC CRM - 1000 MG/LDocument2 pagesCertificate of Analysis: Sulfate IC CRM - 1000 MG/LasanalyticalNo ratings yet

- Physics Oly Practice Test 01Document7 pagesPhysics Oly Practice Test 01Nguyễn Trần Minh TríNo ratings yet

- AN17825ADocument8 pagesAN17825AJose M PeresNo ratings yet

- Alex H.: Penguin ProjectDocument13 pagesAlex H.: Penguin Projectapi-504550016No ratings yet

- Central Tendency, Position, and VariationDocument37 pagesCentral Tendency, Position, and VariationCeline Joy PolicarpioNo ratings yet

- LAN Cabling: Straight ThroughDocument3 pagesLAN Cabling: Straight ThroughGemma Quiocho-CardenasNo ratings yet

- Remove BatDocument1 pageRemove BatUdaya Pratap SinghNo ratings yet

- Contoh SRSDocument46 pagesContoh SRSFatur RachmanNo ratings yet

- Craig Pirrong-Commodity Price Dynamics - A Structural Approach-Cambridge University Press (2011) PDFDocument239 pagesCraig Pirrong-Commodity Price Dynamics - A Structural Approach-Cambridge University Press (2011) PDFchengadNo ratings yet

- Calibar Plate3Document10 pagesCalibar Plate3Gerald FernandezNo ratings yet

- Na VI GrammarDocument65 pagesNa VI GrammarDaniel RăzvanNo ratings yet

- m1100 s12 v1.1f en - Fender - DesignDocument48 pagesm1100 s12 v1.1f en - Fender - Designdzul fiqarNo ratings yet