Professional Documents

Culture Documents

Pad Foundation With Two Columns Example

Uploaded by

akankwasa0 ratings0% found this document useful (0 votes)

300 views10 pagespad foundation design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpad foundation design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

300 views10 pagesPad Foundation With Two Columns Example

Uploaded by

akankwasapad foundation design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

1

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

FOUNDATION ANALYSIS (EN1997-1: 2004)

In accordance wi t h EN1997-1: 2004 i ncorporat i ng Corri gendum dat ed February 2009 and t he UK Nat i onal Annex

i ncorporat i ng Corri gendum No.1

TEDDS calculation version 3.2.02

Pad f oundat i on det ai l s

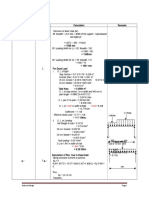

Length of foundation; Lx =3500 mm

Width of foundation; Ly =2500 mm

Foundation area; A =Lx Ly = 8.750 m

2

Depth of foundation; h = 400 mm

Depth of soil over foundation; hsoil = 600 mm

Level of water; hwater =0 mm

Density of water; water = 9.8 kN/m

3

Density of concrete; conc = 24.5 kN/m

3

1

2

63.8 kN/m

2

93.4 kN/m

2

84.9 kN/m

2

114.6 kN/m

2

x

y

Col umn no.1 detai l s

Length of column; lx1 =300 mm

Width of column; ly1 =300 mm

position in x-axis; x1 = 750 mm

position in y-axis; y1 = 1750 mm

Col umn no.2 detai l s

Length of column; lx2 =300 mm

Width of column; ly2 =300 mm

position in x-axis; x2 = 2750 mm

position in y-axis; y2 = 750 mm

Soi l propert i es

Density of soil; soil =18.0 kN/m

3

Characteristic cohesion; c'k = 0 kN/m

2

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

2

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

Characteristic effective shear resistance angle; |'k = 30 deg

Characteristic friction angle; ok = 20 deg

Foundat i on l oads

Self weight; Fswt = h conc =9.8 kN/m

2

Soil weight; Fsoil = hsoil soil =10.8 kN/m

2

Col umn no.1 l oads

Permanent load in x; FGx1 = 20.0 kN

Permanent load in y; FGy1 = 20.0 kN

Permanent load in z; FGz1 = 200.0 kN

Variable load in x; FQx1 = 10.0 kN

Variable load in y; FQy1 = 10.0 kN

Variable load in z; FQz1 = 100.0 kN

Permanent moment in x; MGx1 = 10.0 kNm

Permanent moment in y; MGy1 = 10.0 kNm

Variable moment in x; MQx1 = 5.0 kNm

Variable moment in y; MQy1 = 5.0 kNm

Col umn no.2 l oads

Permanent load in x; FGx2 = 20.0 kN

Permanent load in y; FGy2 = 20.0 kN

Permanent load in z; FGz2 = 200.0 kN

Variable load in x; FQx2 = 10.0 kN

Variable load in y; FQy2 = 10.0 kN

Variable load in z; FQz2 = 100.0 kN

Permanent moment in x; MGx2 = 10.0 kNm

Permanent moment in y; MGy2 = 10.0 kNm

Variable moment in x; MQx2 = 5.0 kNm

Variable moment in y; MQy2 = 5.0 kNm

Beari ng resi st ance (Sect i on 6.5.2)

Forces on f oundat i on

Force in x-axis; Fdx = FGx1 + FGx2 +FQx1 +FQx2 = 60.0 kN

Force in y-axis; Fdy = FGy1 + FGy2 +FQy1 +FQy2 =60.0 kN

Force in z-axis; Fdz = A (Fswt + Fsoil) + FGz1 + FGz2 +FQz1 +FQz2 =780.3 kN

Moment s on f oundat i on

Moment in x-axis; Mdx = A (Fswt + Fsoil) Lx / 2 + FGz1 x1 +MGx1 +FGx1 h + FGz2 x2 +

MGx2 + FGx2 h + FQz1 x1 +MQx1 +FQx1 h + FQz2 x2 +MQx2 +FQx2

h = 1419.4 kNm

Moment in y-axis; Mdy = A (Fswt + Fsoil) Ly / 2 + FGz1 y1 +MGy1 +FGy1 h +FGz2 y2 +

MGy2 + FGy2 h + FQz1 y1 +MQy1 +FQy1 h +FQz2 y2 + MQy2 + FQy2

h = 1029.3 kNm

Eccent ri ci t y of base react i on

Eccentricity of base reaction in x-axis; ex =Mdx / Fdz - Lx / 2 =69 mm

Eccentricity of base reaction in y-axis; ey =Mdy / Fdz - Ly / 2 =69 mm

Pad base pressures

q1 =Fdz (1 - 6 ex / Lx - 6 ey / Ly) / (Lx Ly) =63.8 kN/m

2

q2 =Fdz (1 - 6 ex / Lx +6 ey / Ly) / (Lx Ly) =93.4 kN/m

2

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

3

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

q3 =Fdz (1 + 6 ex / Lx - 6 ey / Ly) / (Lx Ly) =84.9 kN/m

2

q4 =Fdz (1 + 6 ex / Lx +6 ey / Ly) / (Lx Ly) = 114.6 kN/m

2

Minimum base pressure; qmin =min(q1, q2, q3, q4) = 63.8 kN/m

2

Maximum base pressure; qmax = max(q1, q2, q3, q4) =114.6 kN/m

2

Presumed beari ng capaci t y

Presumed bearing capacity; Pbearing = 200.0 kN/m

2

PASS - Presumed beari ng capaci t y exceeds desi gn base pressure

Part i al f act ors on act i ons - Combi nat i on1

Permanent unfavourable action - Table A.3; G =1.35

Permanent favourable action - Table A.3; Gf = 1.00

Variable unfavourable action - Table A.3; Q =1.50

Variable favourable action - Table A.3; Qf = 0.00

Part i al f act ors f or spread f oundat i ons - Combi nat i on1

Bearing - Table A.5; R.v =1.00

Sliding - Table A.5; R.h =1.00

Forces on f oundat i on

Force in x-axis; Fdx = G (FGx1 + FGx2) +Q (FQx1 +FQx2) =84.0 kN

Force in y-axis; Fdy = G (FGy1 + FGy2) +Q (FQy1 +FQy2) = 84.0 kN

Force in z-axis; Fdz = G (A (Fswt + Fsoil) + FGz1 + FGz2) +Q (FQz1 +FQz2) = 1083.3

kN

Moment s on f oundat i on

Moment in x-axis; Mdx = G (A (Fswt + Fsoil) Lx / 2 + FGz1 x1 +FGz2 x2) + G (MGx1 +

MGx2) +Q (FQz1 x1 +FQz2 x2) +Q (MQx1 +MQx2) + (G (FGx1 +

FGx2) +Q (FQx1 +FQx2)) h =1971.4 kNm

Moment in y-axis; Mdy = G (A (Fswt + Fsoil) Ly / 2 + FGz1 y1 + FGz2 y2) + G (MGy1 +

MGy2) +Q (FQz1 y1 +FQz2 y2) +Q (MQy1 +MQy2) + (G (FGy1 +

FGy2) +Q (FQy1 +FQy2)) h =1429.8 kNm

Eccent ri ci t y of base react i on

Eccentricity of base reaction in x-axis; ex =Mdx / Fdz - Lx / 2 =70 mm

Eccentricity of base reaction in y-axis; ey =Mdy / Fdz - Ly / 2 =70 mm

Ef f ect i ve area of base

Effective length; L'x = Lx - 2 ex = 3360 mm

Effective width; L'y = Ly - 2 ey = 2360 mm

Effective area; A' =L'x L'y =7.932 m

2

Pad base pressure

Design base pressure; fdz =Fdz / A' = 136.6 kN/m

2

Sl i di ng resi st ance (Sect i on 6.5.3)

Forces on f oundat i on

Force in x-axis; Fdx = G (FGx1 + FGx2) +Q (FQx1 +FQx2) =84.0 kN

Force in y-axis; Fdy = G (FGy1 + FGy2) +Q (FQy1 +FQy2) = 84.0 kN

Force in z-axis; Fdz = Gf (A (Fswt +Fsoil) +FGz1 +FGz2) +Qf (FQz1 + FQz2) =580.3

kN

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

4

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

Sl i di ng resi st ance veri f i cat i on (Sect i on 6.5.3)

Horizontal force on foundation; H =[Fdx

2

+Fdy

2

]

0.5

= 118.8 kN

Sliding resistance (exp.6.3b); RH.d =Fdz tan(ok) / R.h = 211.2 kN

PASS - Foundat i on i s not subj ect t o f ai l ure by sl i di ng

Part i al f act ors on act i ons - Combi nat i on2

Permanent unfavourable action - Table A.3; G =1.00

Permanent favourable action - Table A.3; Gf = 1.00

Variable unfavourable action - Table A.3; Q =1.30

Variable favourable action - Table A.3; Qf = 0.00

Part i al f act ors f or spread f oundat i ons - Combi nat i on2

Bearing - Table A.5; R.v =1.00

Sliding - Table A.5; R.h =1.00

Forces on f oundat i on

Force in x-axis; Fdx = G (FGx1 + FGx2) +Q (FQx1 +FQx2) =66.0 kN

Force in y-axis; Fdy = G (FGy1 + FGy2) +Q (FQy1 +FQy2) = 66.0 kN

Force in z-axis; Fdz = G (A (Fswt + Fsoil) + FGz1 + FGz2) +Q (FQz1 +FQz2) = 840.3 kN

Moment s on f oundat i on

Moment in x-axis; Mdx = G (A (Fswt + Fsoil) Lx / 2 + FGz1 x1 +FGz2 x2) + G (MGx1 +

MGx2) +Q (FQz1 x1 +FQz2 x2) +Q (MQx1 +MQx2) + (G (FGx1 +

FGx2) +Q (FQx1 +FQx2)) h =1529.8 kNm

Moment in y-axis; Mdy = G (A (Fswt + Fsoil) Ly / 2 + FGz1 y1 + FGz2 y2) + G (MGy1 +

MGy2) +Q (FQz1 y1 +FQz2 y2) +Q (MQy1 +MQy2) + (G (FGy1 +

FGy2) +Q (FQy1 +FQy2)) h =1109.7 kNm

Eccent ri ci t y of base react i on

Eccentricity of base reaction in x-axis; ex =Mdx / Fdz - Lx / 2 =71 mm

Eccentricity of base reaction in y-axis; ey =Mdy / Fdz - Ly / 2 =71 mm

Ef f ect i ve area of base

Effective length; L'x = Lx - 2 ex = 3359 mm

Effective width; L'y = Ly - 2 ey = 2359 mm

Effective area; A' =L'x L'y =7.922 m

2

Pad base pressure

Design base pressure; fdz =Fdz / A' = 106.1 kN/m

2

Sl i di ng resi st ance (Sect i on 6.5.3)

Forces on f oundat i on

Force in x-axis; Fdx = G (FGx1 + FGx2) +Q (FQx1 +FQx2) =66.0 kN

Force in y-axis; Fdy = G (FGy1 + FGy2) +Q (FQy1 +FQy2) = 66.0 kN

Force in z-axis; Fdz = Gf (A (Fswt +Fsoil) +FGz1 +FGz2) +Qf (FQz1 + FQz2) =580.3

kN

Sl i di ng resi st ance veri f i cat i on (Sect i on 6.5.3)

Horizontal force on foundation; H =[Fdx

2

+Fdy

2

]

0.5

= 93.3 kN

Sliding resistance (exp.6.3b); RH.d =Fdz tan(ok) / R.h = 211.2 kN

PASS - Foundat i on i s not subj ect t o f ai l ure by sl i di ng

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

5

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

FOUNDATION DESIGN (EN1992-1-1: 2004)

In accordance wi t h EN1992-1-1: 2004 i ncorporat i ng Corri gendum dat ed January 2008 and t he UK Nat i onal Annex

i ncorporat i ng Nati onal Amendment No.1

TEDDS calculation version 3.2.02

Concret e det ai l s (Tabl e 3.1 - St rengt h and def ormat i on charact eri st i cs f or concret e)

Concrete strength class; C30/37

Characteristic compressive cylinder strength; fck =30 N/mm

2

Characteristic compressive cube strength; fck,cube = 37 N/mm

2

Mean value of compressive cylinder strength; fcm =fck + 8 N/mm

2

= 38 N/mm

2

Mean value of axial tensile strength; fctm = 0.3 N/mm

2

(fck/ 1 N/mm

2

)

2/3

= 2.9 N/mm

2

5% fractile of axial tensile strength; fctk,0.05 = 0.7 fctm = 2.0 N/mm

2

Secant modulus of elasticity of concrete; Ecm = 22 kN/mm

2

[fcm/10 N/mm

2

]

0.3

=32837 N/mm

2

Partial factor for concrete (Table 2.1N); C =1.50

Compressive strength coefficient (cl.3.1.6(1)); occ = 0.85

Design compressive concrete strength (exp.3.15); fcd =occ fck / C =17.0 N/mm

2

Tens.strength coeff.for plain concrete (cl.12.3.1(1)); oct,pl = 0.80

Des.tens.strength for plain concrete (exp.12.1); fctd,pl = oct,pl fctk,0.05 / C =1.1 N/mm

2

Maximum aggregate size; hagg =20 mm

Rei nf orcement det ai l s

Characteristic yield strength of reinforcement; fyk =500 N/mm

2

Modulus of elasticity of reinforcement; Es = 210000 N/mm

2

Partial factor for reinforcing steel (Table 2.1N); S = 1.15

Design yield strength of reinforcement; fyd =fyk / S = 435 N/mm

2

Nominal cover to reinforcement; cnom = 30 mm

Rect angul ar sect i on i n f l exure (Sect i on 6.1)

Design bending moment; MEd.x.max = 78.3 kNm

Depth to tension reinforcement; d = h - cnom - |y.bot - |x.bot / 2 = 352 mm

K =MEd.x.max / (Ly d

2

fck) =0.008

K' =0.207

K' > K - No compressi on rei nf orcement i s requi red

Lever arm; z = min((d / 2) [1 + (1 - 3.53 K)

0.5

], 0.95 d) = 334 mm

Depth of neutral axis; x =2.5 (d - z) = 44 mm

Area of tension reinforcement required; Asx.bot.req = MEd.x.max / (fyd z) =539 mm

2

Tension reinforcement provided; 12 No.12 dia.bars bottom (225 c/c)

Area of tension reinforcement provided; Asx.bot.prov =1357 mm

2

Minimum area of reinforcement (exp.9.1N); As.min =max(0.26 fctm / fyk, 0.0013) Ly d =1325 mm

2

Maximum area of reinforcement (cl.9.2.1.1(3)); As.max =0.04 Ly d =35200 mm

2

PASS - Area of rei nforcement provi ded i s greater t han area of rei nforcement requi red

Crack cont rol (Sect i on 7.3)

Limiting crack width; wmax =0.3 mm

Variable load factor (EN1990 Table A1.1); 2 = 0.3

Serviceability bending moment; Msls.x.max = 42.8 kNm

Tensile stress in reinforcement; os =Msls.x.max / (Asx.bot.prov z) =94.3 N/mm

2

Load duration factor; kt =0.4

Effective depth of concrete in tension; hc.ef =min(2.5 (h - d), (h - x) / 3, h / 2) = 119 mm

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

6

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

Effective area of concrete in tension; Ac.eff =hc.ef Ly = 296667 mm

2

Mean value of concrete tensile strength; fct.eff =fctm = 2.9 N/mm

2

Reinforcement ratio; p.eff = Asx.bot.prov / Ac.eff = 0.005

Modular ratio; oe = Es / Ecm =6.395

Bond property coefficient; k1 =0.8

Strain distribution coefficient; k2 =0.5

k3 =3.4

k4 =0.425

Maximum crack spacing (exp.7.11); sr.max =k3 (cnom + |y.bot) + k1 k2 k4 |x.bot / p.eff =589 mm

Maximum crack width (exp.7.8); wk = sr.max max([os kt (fct.eff / p.eff) (1 +oe p.eff)] / Es,

0.6 os / Es) = 0.159 mm

PASS - Maxi mum crack wi dt h i s l ess t han l i mi ti ng crack wi dt hRect angul ar sect i on i n f l exure (Sect i on 6.1)

Design bending moment; abs(MEd.x.min) = 71.6 kNm

Depth to tension reinforcement; d = h - cnom - |y.top - |x.top / 2 = 352 mm

K =abs(MEd.x.min) / (Ly d

2

fck) =0.008

K' =0.207

K' > K - No compressi on rei nf orcement i s requi red

Lever arm; z = min((d / 2) [1 + (1 - 3.53 K)

0.5

], 0.95 d) = 334 mm

Depth of neutral axis; x =2.5 (d - z) = 44 mm

Area of tension reinforcement required; Asx.top.req = abs(MEd.x.min) / (fyd z) = 493 mm

2

Tension reinforcement provided; 12 No.12 dia.bars top (225 c/c)

Area of tension reinforcement provided; Asx.top.prov =1357 mm

2

Minimum area of reinforcement (exp.9.1N); As.min =max(0.26 fctm / fyk, 0.0013) Ly d =1325 mm

2

Maximum area of reinforcement (cl.9.2.1.1(3)); As.max =0.04 Ly d =35200 mm

2

PASS - Area of rei nforcement provi ded i s greater t han area of rei nforcement requi red

Crack cont rol (Sect i on 7.3)

Limiting crack width; wmax =0.3 mm

Variable load factor (EN1990 Table A1.1); 2 = 0.3

Serviceability bending moment; abs(Msls.x.min) = 39.2 kNm

Tensile stress in reinforcement; os =abs(Msls.x.min) / (Asx.top.prov z) =86.5 N/mm

2

Load duration factor; kt =0.4

Effective depth of concrete in tension; hc.ef =min(2.5 (h - d), (h - x) / 3, h / 2) = 119 mm

Effective area of concrete in tension; Ac.eff =hc.ef Ly = 296667 mm

2

Mean value of concrete tensile strength; fct.eff =fctm = 2.9 N/mm

2

Reinforcement ratio; p.eff = Asx.top.prov / Ac.eff = 0.005

Modular ratio; oe = Es / Ecm =6.395

Bond property coefficient; k1 =0.8

Strain distribution coefficient; k2 =0.5

k3 =3.4

k4 =0.425

Maximum crack spacing (exp.7.11); sr.max =k3 (cnom + |y.top) + k1 k2 k4 |x.top / p.eff =589 mm

Maximum crack width (exp.7.8); wk = sr.max max([os kt (fct.eff / p.eff) (1 +oe p.eff)] / Es,

0.6 os / Es) = 0.145 mm

PASS - Maxi mum crack wi dt h i s l ess t han l i mi ti ng crack wi dt hRect angul ar sect i on i n shear (Sect i on 6.2)

Design shear force; abs(VEd.x.min) =150.2 kN

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

7

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

CRd,c = 0.18 / C =0.120

k = min(1 + \(200 mm / d), 2) = 1.754

Longitudinal reinforcement ratio; l =min(Asx.bot.prov / (Ly d), 0.02) = 0.002

vmin = 0.035 N

1/2

/mm k

3/2

fck

0.5

= 0.445 N/mm

2

Design shear resistance (exp.6.2a & 6.2b); VRd.c = max(CRd.c k (100 N

2

/mm

4

l fck)

1/3

, vmin) Ly d

VRd.c = 391.8 kN

PASS - Desi gn shear resi st ance exceeds desi gn shear f orce

Rect angul ar sect i on i n f l exure (Sect i on 6.1)

Design bending moment; MEd.y.max = 95.9 kNm

Depth to tension reinforcement; d = h - cnom - |y.bot / 2 =364 mm

K =MEd.y.max / (Lx d

2

fck) =0.007

K' =0.207

K' > K - No compressi on rei nf orcement i s requi red

Lever arm; z = min((d / 2) [1 + (1 - 3.53 K)

0.5

], 0.95 d) = 346 mm

Depth of neutral axis; x =2.5 (d - z) = 45 mm

Area of tension reinforcement required; Asy.bot.req = MEd.y.max / (fyd z) = 638 mm

2

Tension reinforcement provided; 18 No.12 dia.bars bottom (225 c/c)

Area of tension reinforcement provided; Asy.bot.prov =2036 mm

2

Minimum area of reinforcement (exp.9.1N); As.min =max(0.26 fctm / fyk, 0.0013) Lx d =1919 mm

2

Maximum area of reinforcement (cl.9.2.1.1(3)); As.max =0.04 Lx d = 50960 mm

2

PASS - Area of rei nforcement provi ded i s greater t han area of rei nforcement requi red

Crack cont rol (Sect i on 7.3)

Limiting crack width; wmax =0.3 mm

Variable load factor (EN1990 Table A1.1); 2 = 0.3

Serviceability bending moment; Msls.y.max = 52.4 kNm

Tensile stress in reinforcement; os =Msls.y.max / (Asy.bot.prov z) =74.5 N/mm

2

Load duration factor; kt =0.4

Effective depth of concrete in tension; hc.ef =min(2.5 (h - d), (h - x) / 3, h / 2) = 90 mm

Effective area of concrete in tension; Ac.eff =hc.ef Lx = 315000 mm

2

Mean value of concrete tensile strength; fct.eff =fctm = 2.9 N/mm

2

Reinforcement ratio; p.eff = Asy.bot.prov / Ac.eff = 0.006

Modular ratio; oe = Es / Ecm =6.395

Bond property coefficient; k1 =0.8

Strain distribution coefficient; k2 =0.5

k3 =3.4

k4 =0.425

Maximum crack spacing (exp.7.11); sr.max =k3 cnom +k1 k2 k4 |y.bot / p.eff = 418 mm

Maximum crack width (exp.7.8); wk = sr.max max([os kt (fct.eff / p.eff) (1 +oe p.eff)] / Es,

0.6 os / Es) = 0.089 mm

PASS - Maxi mum crack wi dt h i s l ess t han l i mi ti ng crack wi dt hRect angul ar sect i on i n f l exure (Sect i on 6.1)

Design bending moment; abs(MEd.y.min) = 1.2 kNm

Depth to tension reinforcement; d = h - cnom - |y.top / 2 =364 mm

K =abs(MEd.y.min) / (Lx d

2

fck) =0.000

K' =0.207

K' > K - No compressi on rei nf orcement i s requi red

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

8

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

Lever arm; z = min((d / 2) [1 + (1 - 3.53 K)

0.5

], 0.95 d) = 346 mm

Depth of neutral axis; x =2.5 (d - z) = 45 mm

Area of tension reinforcement required; Asy.top.req = abs(MEd.y.min) / (fyd z) = 8 mm

2

Tension reinforcement provided; 18 No.12 dia.bars top (225 c/c)

Area of tension reinforcement provided; Asy.top.prov =2036 mm

2

Minimum area of reinforcement (exp.9.1N); As.min =max(0.26 fctm / fyk, 0.0013) Lx d =1919 mm

2

Maximum area of reinforcement (cl.9.2.1.1(3)); As.max =0.04 Lx d = 50960 mm

2

PASS - Area of rei nforcement provi ded i s greater t han area of rei nforcement requi red

Crack cont rol (Sect i on 7.3)

Limiting crack width; wmax =0.3 mm

Variable load factor (EN1990 Table A1.1); 2 = 0.3

Serviceability bending moment; abs(Msls.y.min) = 0.8 kNm

Tensile stress in reinforcement; os =abs(Msls.y.min) / (Asy.top.prov z) =1.2 N/mm

2

Load duration factor; kt =0.4

Effective depth of concrete in tension; hc.ef =min(2.5 (h - d), (h - x) / 3, h / 2) = 90 mm

Effective area of concrete in tension; Ac.eff =hc.ef Lx = 315000 mm

2

Mean value of concrete tensile strength; fct.eff =fctm = 2.9 N/mm

2

Reinforcement ratio; p.eff = Asy.top.prov / Ac.eff = 0.006

Modular ratio; oe = Es / Ecm =6.395

Bond property coefficient; k1 =0.8

Strain distribution coefficient; k2 =0.5

k3 =3.4

k4 =0.425

Maximum crack spacing (exp.7.11); sr.max =k3 cnom +k1 k2 k4 |y.top / p.eff = 418 mm

Maximum crack width (exp.7.8); wk = sr.max max([os kt (fct.eff / p.eff) (1 +oe p.eff)] / Es,

0.6 os / Es) = 0.001 mm

PASS - Maxi mum crack wi dt h i s l ess t han l i mi ti ng crack wi dt hRect angul ar sect i on i n shear (Sect i on 6.2)

Design shear force; abs(VEd.y.min) = 33.8 kN

CRd,c = 0.18 / C =0.120

k = min(1 + \(200 mm / d), 2) = 1.741

Longitudinal reinforcement ratio; l =min(Asy.bot.prov / (Lx d), 0.02) = 0.002

vmin = 0.035 N

1/2

/mm k

3/2

fck

0.5

= 0.440 N/mm

2

Design shear resistance (exp.6.2a & 6.2b); VRd.c = max(CRd.c k (100 N

2

/mm

4

l fck)

1/3

, vmin) Lx d

VRd.c = 561.2 kN

PASS - Desi gn shear resi st ance exceeds desi gn shear f orce

Punchi ng shear (Sect i on 6.4)

Strength reduction factor (exp 6.6N); v = 0.6 [1 - fck / 250 N/mm

2

] =0.528

Average depth to reinforcement; d = 358 mm

Maximum punching shear resistance (cl.6.4.5(3)); vRd.max = 0.5 v fcd = 4.488 N/mm

2

k = min(1 + \(200 mm / d), 2) = 1.747

Longitudinal reinforcement ratio (cl.6.4.4(1)); lx = Asx.bot.prov / (Ly d) = 0.002

ly =Asy.bot.prov / (Lx d) = 0.002

l =min(\(lx ly), 0.02) =0.002

vmin = 0.035 N

1/2

/mm k

3/2

fck

0.5

= 0.443 N/mm

2

Design punching shear resistance (exp.6.47); vRd.c = max(CRd.c k (100 N

2

/mm

4

l fck)

1/3

, vmin) = 0.443 N/mm

2

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

9

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

Col umn No.1 - Punchi ng shear peri met er at col umn face

Punching shear perimeter; u0 =1200 mm

Area within punching shear perimeter; A0 = 0.090 m

2

Maximum punching shear force; VEd.max =410.2 kN

Punching shear stress factor (fig 6.21N); | = 1.500

Maximum punching shear stress (exp 6.38); vEd.max =| VEd.max / (u0 d) =1.432 N/mm

2

PASS - Maxi mum punchi ng shear resi st ance exceeds maxi mum punchi ng shear st ress

Col umn No.1 - Punchi ng shear peri met er at 2d from col umn face

Punching shear perimeter; u2 =3446 mm

Area within punching shear perimeter; A2 = 2.367 m

2

Design punching shear force; VEd.2 = 186.4 kN

Punching shear stress factor (fig 6.21N); | = 1.500

Design punching shear stress (exp 6.38); vEd.2 = | VEd.2 / (u2 d) =0.227 N/mm

2

PASS - Desi gn punchi ng shear resi st ance exceeds desi gn punchi ng shear st ress

Col umn No.2 - Punchi ng shear peri met er at col umn face

Punching shear perimeter; u0 =1200 mm

Area within punching shear perimeter; A0 = 0.090 m

2

Maximum punching shear force; VEd.max =410.2 kN

Punching shear stress factor (fig 6.21N); | = 1.500

Maximum punching shear stress (exp 6.38); vEd.max =| VEd.max / (u0 d) =1.432 N/mm

2

PASS - Maxi mum punchi ng shear resi st ance exceeds maxi mum punchi ng shear st ress

Col umn No.2 - Punchi ng shear peri met er at 2d from col umn face

Punching shear perimeter; u2 =3446 mm

Area within punching shear perimeter; A2 = 2.367 m

2

Design punching shear force; VEd.2 = 186.4 kN

Punching shear stress factor (fig 6.21N); | = 1.500

Design punching shear stress (exp 6.38); vEd.2 = | VEd.2 / (u2 d) =0.227 N/mm

2

PASS - Desi gn punchi ng shear resi st ance exceeds desi gn punchi ng shear st ress

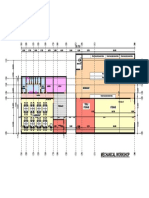

1

2

12 No.12 dia.bars bottom (225 c/c)

12 No.12 dia.bars top (225 c/c)

18 No.12 dia.bars bottom (225 c/c)

18 No.12 dia.bars top (225 c/c)

CSCE LTD.

P.O BOX 21030, KAMPALA.

Project J ob no.

Calcs for Start page no./Revision

10

Calcs by

W

Calcs date

6/25/2014

Checked by Checked date Approved by Approved date

You might also like

- Pad Footing Analysis and Design (Bs8110-1:1997)Document6 pagesPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79No ratings yet

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Rectangular Spread Footing DesignDocument42 pagesRectangular Spread Footing DesignJedidiah MelakuNo ratings yet

- Design of Isolated Footing with Moment CalculationsDocument28 pagesDesign of Isolated Footing with Moment CalculationsmeenuNo ratings yet

- ACI318-08 Circular Column Design AnalysisDocument6 pagesACI318-08 Circular Column Design Analysisazamislam726537No ratings yet

- Nib CalculationDocument1 pageNib CalculationKen LuuNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- Structural Design and Analysis Proposed Three Storey Commercial ResidenceDocument79 pagesStructural Design and Analysis Proposed Three Storey Commercial ResidenceGEREMY SANTIAGONo ratings yet

- RCC Beams: Doubly Reinforced BeamDocument2 pagesRCC Beams: Doubly Reinforced BeamSandeep ChavanNo ratings yet

- RCFootingDesignWebDocument3 pagesRCFootingDesignWebjudeNo ratings yet

- Crack Width Calculation for ColumnDocument3 pagesCrack Width Calculation for ColumnAnil kumar RNo ratings yet

- RCC14 Crack WidthDocument1 pageRCC14 Crack WidthKha Phuc100% (1)

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Document10 pages1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNo ratings yet

- ACI Moment Coefficient Design AID PDFDocument13 pagesACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Pages From PCA Notes On ACI318-08Document4 pagesPages From PCA Notes On ACI318-08Jorge Rubén TorresNo ratings yet

- RV Design of Column Base PlateDocument2 pagesRV Design of Column Base Plateapi-190618655No ratings yet

- Design of Pile Caps - Mahila Samakya BuildingsDocument8 pagesDesign of Pile Caps - Mahila Samakya BuildingsD.V.Srinivasa RaoNo ratings yet

- Calculation NoteDocument10 pagesCalculation NoteJay EvansNo ratings yet

- Circular Column Design - MPA-ECDocument1 pageCircular Column Design - MPA-ECmayphyoNo ratings yet

- Strip Footing Analysis and Design PDFDocument3 pagesStrip Footing Analysis and Design PDFcleophasNo ratings yet

- Flitch Plate BeamDocument1 pageFlitch Plate Beamdnl_vicarsNo ratings yet

- Circular Tube End Plate Calculation PDFDocument4 pagesCircular Tube End Plate Calculation PDFALPHYL BALASABASNo ratings yet

- Daniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Document2 pagesDaniel Tian Li: Plain Concrete Footing Design Based On ACI 318-05Wintun73No ratings yet

- JassimDocument29 pagesJassimZain Communication0% (1)

- Design of Long Wall: Tank Full and No Soil PressureDocument6 pagesDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNo ratings yet

- Ultimate Limit State Design of Spread Foundations in The Case of UpliftDocument7 pagesUltimate Limit State Design of Spread Foundations in The Case of UpliftAndoNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- NSCP 2001 Allowable Stress Design Bending of I-Shaped MembersDocument1 pageNSCP 2001 Allowable Stress Design Bending of I-Shaped MembersDavid Nelson AngiwanNo ratings yet

- Cantilever FrameDocument3 pagesCantilever FrameNikki RobertsNo ratings yet

- Cantilever Retaining Wall ExampleDocument10 pagesCantilever Retaining Wall ExampleReab SimanthNo ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- TSS 35 / 205 sheet thickness & load data for aluminium & steel roofingDocument1 pageTSS 35 / 205 sheet thickness & load data for aluminium & steel roofingAkhil VNNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- RCC12 Bending and Axial ForceDocument4 pagesRCC12 Bending and Axial ForceAbdul KarimNo ratings yet

- Shear WallDocument238 pagesShear Wallri olNo ratings yet

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document18 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNo ratings yet

- Repport Steel Structure PDFDocument111 pagesRepport Steel Structure PDFAnonymous fxqnhfKNo ratings yet

- 2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaDocument20 pages2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaefackopaNo ratings yet

- BNBC 2015 Earthquake LoadingDocument2 pagesBNBC 2015 Earthquake LoadingSA023100% (1)

- Chap 7 Foundation DesignDocument36 pagesChap 7 Foundation DesignZulhasri WahapNo ratings yet

- Strip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Document3 pagesStrip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Er Saroj PaudelNo ratings yet

- Show Section PropertiesDocument3 pagesShow Section PropertiesCon Can100% (1)

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- Huong Dan MegafloorDocument11 pagesHuong Dan Megafloortrung1983No ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Load Combination and Flexural Design of Roof Deck BeamsDocument123 pagesLoad Combination and Flexural Design of Roof Deck BeamsMarkNo ratings yet

- Retaining Wall Analysis & Design (BS8002 - 1994)Document10 pagesRetaining Wall Analysis & Design (BS8002 - 1994)IKNo ratings yet

- Number and Spacing of Piles in A GroupDocument7 pagesNumber and Spacing of Piles in A GroupmadaraNo ratings yet

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Design of DomeDocument5 pagesDesign of DomeAmarjeet SinghNo ratings yet

- Engr. Mark Christian D. EsguerraDocument1 pageEngr. Mark Christian D. EsguerraMARKCHRISTMASNo ratings yet

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Geometrical Properties Material Properties: Design of Helicoidal StairDocument5 pagesGeometrical Properties Material Properties: Design of Helicoidal StairPrashant Verma100% (1)

- Dynamic Active Earth Pressure On Retaining StructuresDocument10 pagesDynamic Active Earth Pressure On Retaining StructurescristiannecivilNo ratings yet

- Foundation Calculations For 10 MTR Columns NewDocument15 pagesFoundation Calculations For 10 MTR Columns NewMariam AwadNo ratings yet

- Foundation Analysis Internal Footing EpsDocument13 pagesFoundation Analysis Internal Footing Epsbrian ochielNo ratings yet

- Foundation analysis and design (EN1997-1:2004Document12 pagesFoundation analysis and design (EN1997-1:2004Franklyn GenoveNo ratings yet

- Strip foundation analysis and design calculationsDocument9 pagesStrip foundation analysis and design calculationsbereketNo ratings yet

- Pad Strip Foundation Analysis - ADocument14 pagesPad Strip Foundation Analysis - AAshadi HamdanNo ratings yet

- Foundation Analysis 1Document13 pagesFoundation Analysis 1bereketNo ratings yet

- Brian Scheme Design Model (1) 2Document1 pageBrian Scheme Design Model (1) 2akankwasaNo ratings yet

- midas RC Beam Serviceability ReportDocument2 pagesmidas RC Beam Serviceability ReportakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- Cannot Open GSDDocument8 pagesCannot Open GSDakankwasaNo ratings yet

- 452 1Document6 pages452 1akankwasaNo ratings yet

- Midas Gen - Integrated Analysis and Design System For Building and General StructuresDocument1 pageMidas Gen - Integrated Analysis and Design System For Building and General StructuresakankwasaNo ratings yet

- 160Document6 pages160akankwasaNo ratings yet

- 470Document3 pages470akankwasaNo ratings yet

- Instrumentation workshop floor planDocument1 pageInstrumentation workshop floor planakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- 443Document2 pages443akankwasaNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- 38Document6 pages38akankwasaNo ratings yet

- 37Document8 pages37akankwasaNo ratings yet

- 39Document8 pages39akankwasaNo ratings yet

- 434Document8 pages434akankwasaNo ratings yet

- Plot 39 - Typical Lintol Sections.Document1 pagePlot 39 - Typical Lintol Sections.akankwasaNo ratings yet

- Etabs Lateral Loads.Document10 pagesEtabs Lateral Loads.akankwasaNo ratings yet

- Protastructure Analysis ResultsDocument8 pagesProtastructure Analysis ResultsakankwasaNo ratings yet

- Input Data: Notes: HistoryDocument5 pagesInput Data: Notes: HistoryakankwasaNo ratings yet

- Etabs 2016 16.2Document7 pagesEtabs 2016 16.2akankwasaNo ratings yet

- Plot 2683 and 2684 Mpererwe Apartments 4-BeamdesDocument13 pagesPlot 2683 and 2684 Mpererwe Apartments 4-BeamdesakankwasaNo ratings yet

- Elegu Staff Houses. Floor PlansDocument1 pageElegu Staff Houses. Floor PlansakankwasaNo ratings yet

- Wind Loads - Analysis in Etabs 2016 16.2Document420 pagesWind Loads - Analysis in Etabs 2016 16.2akankwasaNo ratings yet

- Childrens Church 1Document1 pageChildrens Church 1akankwasaNo ratings yet

- Quick Start Guide Concrete Complete-A2Document7 pagesQuick Start Guide Concrete Complete-A2akankwasaNo ratings yet

- Wall Types Library Edit Beam Wall Load Wall Types Library Building SetoutDocument3 pagesWall Types Library Edit Beam Wall Load Wall Types Library Building SetoutakankwasaNo ratings yet

- Flat Slab Training - All Columns and Shear Walls at EdgesDocument5 pagesFlat Slab Training - All Columns and Shear Walls at EdgesakankwasaNo ratings yet

- China National Machinery Imp. & Exp. Corp. DCM Pile Inspection PlanDocument6 pagesChina National Machinery Imp. & Exp. Corp. DCM Pile Inspection Plandimuthu lasinthaNo ratings yet

- Hvac Ducting FundamentalDocument56 pagesHvac Ducting Fundamentalzafarbadal100% (2)

- 55 Southey Street - WD-2 - Updated Layout - Tender Issue 2Document30 pages55 Southey Street - WD-2 - Updated Layout - Tender Issue 2RashmiNo ratings yet

- 04 Marl Chemical Park PDFDocument36 pages04 Marl Chemical Park PDFAnusha Rajagopalan100% (1)

- Material 2 2021Document94 pagesMaterial 2 2021Buildings Sub Division No. 1 MultanNo ratings yet

- 2018 Thesis - Experimental and FE Analysis of 3dprinted Fiber Reinforced Honeycomb Structured Composite MaterialsDocument67 pages2018 Thesis - Experimental and FE Analysis of 3dprinted Fiber Reinforced Honeycomb Structured Composite MaterialsMj MahzanNo ratings yet

- Isocope KROVDocument4 pagesIsocope KROVEjub ČelikovićNo ratings yet

- Planning and Design Guidelines 10-26-2021Document7 pagesPlanning and Design Guidelines 10-26-2021Aroroy RHUNo ratings yet

- Construction of Tunnels, by New Austrian Tunnelling Method (NATM) and by Tunnel Boring Machine (TBM) PDFDocument12 pagesConstruction of Tunnels, by New Austrian Tunnelling Method (NATM) and by Tunnel Boring Machine (TBM) PDFChin Thau WuiNo ratings yet

- Identifying Compressor Mechanical FailuresDocument13 pagesIdentifying Compressor Mechanical FailuresDesiderio BourdetNo ratings yet

- IC WBS With Gantt ChartDocument1 pageIC WBS With Gantt ChartWarren DiwaNo ratings yet

- Reliable Model DDX Deluge Valve, 4-6 Inches (G-G - Single - Interlocked - PreAction)Document18 pagesReliable Model DDX Deluge Valve, 4-6 Inches (G-G - Single - Interlocked - PreAction)Aqil SiddiquiNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- SB Brace Frame For Single Sided Walls Instructions For Assembly and UseDocument84 pagesSB Brace Frame For Single Sided Walls Instructions For Assembly and UseYaser IsmailNo ratings yet

- PSI Casing End Seals Installation GuideDocument10 pagesPSI Casing End Seals Installation Guideanup_sahani100% (1)

- Calculating Excavator Structural StressDocument6 pagesCalculating Excavator Structural Stressrbachalli100% (1)

- Mapping India DEFDocument74 pagesMapping India DEFAlaina LongNo ratings yet

- ( - Ekgo: TandcfrciDocument23 pages( - Ekgo: TandcfrciRajesh Arora100% (4)

- Concrete Mix Design Methods, Verification StudyDocument26 pagesConcrete Mix Design Methods, Verification StudyAhmed M AminNo ratings yet

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDocument2 pagesFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloNo ratings yet

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055No ratings yet

- Slope Stability Analysis Report PDFDocument7 pagesSlope Stability Analysis Report PDFPrakash Singh RawalNo ratings yet

- Paroc Pro Roof Slab 20 Kpa: Product DatasheetDocument2 pagesParoc Pro Roof Slab 20 Kpa: Product Datasheetcarlos martinezNo ratings yet

- Green Mark 2021 Technical Guide On Health and Well BeingDocument39 pagesGreen Mark 2021 Technical Guide On Health and Well BeingReginaNo ratings yet

- MT 25 BFB1Document74 pagesMT 25 BFB1Meritz DanNo ratings yet

- BOQ For Dubti Dam-GeotecDocument4 pagesBOQ For Dubti Dam-GeotecMehari GebremeskelNo ratings yet

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 pageStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilNo ratings yet

- Liquid Filling NozzlesDocument16 pagesLiquid Filling NozzlesFlavioNo ratings yet

- SABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteDocument26 pagesSABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteMr. Moses Imagoro100% (1)

- 18 Silbond and SilaidDocument4 pages18 Silbond and SilaidsviruindiaNo ratings yet