Professional Documents

Culture Documents

Europa Myths of Underground Cables

Uploaded by

student_ujjwol3163Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Europa Myths of Underground Cables

Uploaded by

student_ujjwol3163Copyright:

Available Formats

UNDERGROUNDI NG

WORKS!

MYTHS AND REALITIES

of Partial Undergrounding of 380 kV Electricity Powerlines

2 Concept of Partial Undergrounding

Introducing the Europacable Concept

of Partial Undergrounding

Europes electricity grids need to be upgraded and

extended, notably to allow the integration of renewable

energy power sources. The key question however is how

and where new power lines are to be introduced, while at

the same time respecting the quality of life for the people

living close to such lines or the environment surrounding it.

Seeking to offer an innovative solution to this challenge,

the European wire and cable manufacturers, represented

by Europacable, have developed the Concept of Partial

Undergrounding:

This concept proposes to underground extra high

voltage power lines in sensitive areas comple-

menting overhead lines where their deployment

is restricted by public concerns or environmental

limitations.

The Concept of Partial Undergrounding can be applied

at any voltage level. However, we believe that today the

largest potential to facilitate grid extensions lies with

380kV extra high voltage (EHV) cross linked polyethylene

(XLPE) alternating current (AC) cables.

There are many myths about what EHV XLPE AC cables

can and cannot do. With this brochure we would like to

address those myths, present the facts and offer our

view on the most important issues.

The technical information we provide here is based on

the Joint Paper Europacable prepared with ENTSO-E

under the guidance of the European Commission DG

Energy. The paper is available at www.europacable.com

8 MYTHS AND REALITIES OF

PARTIAL UNDERGROUNDING

CONCEPT OF PARTIAL UNDER-

GROUNDING: NEW FLEXIBILITY

FOR FUTURE ELECTRICITY GRIDS

> Alternative, possibly shorter routes

> Faster realisation due to higher public acceptance

> Limited visual impact, as line can be adapted individually

to surrounding landscape

> Reduction of cost multiples as higher expenditure for

undergrounding is limited to only sections

> Pilot projects allow European manufacturers to further

demonstrate their technology expertise, thus securing

Europes leadership in this sector

MYTH NUMBER 1

Partial undergrounding is not an option.

EHV XLPE cables are not State of the

Art. It is too complex to integrate them

into the existing transmission systems.

In Europe, and around the world, EHV XLPE cables are

increasingly used as a component in electricity transmis-

sion projects. Whether or not they meet legal denitions

of state of the art depends on the local terminology.

Fact is, EHV XLPE cables are available, well established

and operate safely in accordance with relevant standards.

Integrating a partially undergrounded section into a

meshed AC overhead line system is a highly complex un-

dertaking which requires thorough analysis on a case by

case basis. But: it is entirely feasible.

EUROPACABLE VIEW:

PARTIAL UNDERGROUNDING:

THE TECHNOLOGY IS AVAILABLE

FACTS

> EHV XLPE cables are proven and

established components for partial

undergrounding

> Over 200 km of 400 kV XLPE cables

installed in Europe since 1996 many

more in other parts of the world

> Integrating underground sections

into the grid is complex and needs to

be analysed on a case-by-case

basis, but is entirely feasible

4 The technology is available

MYTH NUMBER 2

EHV XLPE cables are not reliable

notably joint bays are a weakness. Like

in Berlin, they can explode and if they do

it takes forever to repair, putting energy

supply at a risk.

XLPE cables systems are a reliable transmission technol-

ogy that performs well based on established international

standards. This said, any manmade technology can fail

as did a joint bay in Berlin in December 2009.

In the case of failure, 3 aspects are critical:

>Secure power supplies: The n-1 criterion guarantees that

the 2nd cable system will carry the full load to secure power.

> Shorten repair times: XLPE cables are custom made

per project and spare cable is recommended to be

kept in stock.

> Use current technology: Europacable members

constantly drive R&D forward. The technology used

in Berlin is no longer available on the market.

EUROPACABLE VIEW:

EHV XLPE CABLE SYSTEMS:

RELIABLE ENERGY TRANSMISSION

FACTS

> EHV XLPE cables are reliable. Once in the ground,

they are well protected against external impacts

> EHV XLPE cables undergo double testing:

after production and after installation

> Joining EHV cables is a delicate task which needs

to be executed by trained experts with utmost care

> Todays joint bay technology is highly reliable

> According to CIGRE Technical Brochure 379 more

than 1/3 of cable faults were repaired and the

cable system was re-energized within 1 week

and more than 75% within 1 month

6 Reliable energy transmission

MYTH NUMBER 3

EHV XLPE cables have a signicant

impact on the environment, they dry out

the soil and wide trenches are required.

Any EHV installation impacts the environment. This said,

vegetation on top of the cable will be normally reinstated

after 1- 2 years. There is no restriction on cultivation

apart from deeply rooted trees.

The width of the cable trench depends mainly on the

desired transmission capacity. For an indicative example

of a 400kV XLPE cable system (3.600 A per circuit, 4

trenches) 20 25 meters will be required. Under normal

load operations, the cable temperature will not lead to

a drying of the surrounding soil. Studies show that only

under long-term full load conditions the soil may heat up

by approximately 2C.

EUROPACABLE VIEW:

EHV XLPE CABLE SYSTEMS:

LIMITED ENVIRONMENTAL IMPACT

FACTS

> Trenches for 4 cable systems will be up

to 25 meters

> Installation works required for the cables are

a temporary impact on the environment

> After completion, vegetation will be reinstated

after 1-2 years

> Apart from deeply rooted trees, there are no

limitations to cultivation on top of the cable

trench, including agricultural farming

> No drying of the soil under normal load

conditions

8 Limited environmental impact

EU Recommendation

1999/519/EC

100 T

50 T

25 T

75 T

MYTH NUMBER 4

Electromagnetic elds of electricity

transmission lines, and particularly

of underground cables, are a signicant

risk to human health.

Many modern technologies create electromagnetic elds

(EMFs). EU Recommendation 1999/519/EC indicates a

maximum level of 100 T for public exposure based on

values established by the International Commission on

Non-Ionising Radiation (ICNIRP).

A typical transmission project, whether overhead line or

partially undergrounded carrying 400 kV, will show a

magnetic eld exposure in the range of 65 to 75 T.

These values will vary with the clearance to ground for

the overhead line and the depth of the underground ca-

ble as well as additional specic congurations. In any

case they will not exceed the maximum references as

set by the EU Recommendation.

EUROPACABLE VIEW:

SAFE ELECTRICITY TRANSMISSION:

NO RISKS TO HUMAN HEALTH

FACTS

> Exposure to magnetic elds under a typical

overhead line or above an underground cable

system carrying 400 kV does not exceed the

reference level of 100T based on EU Recom-

mendation 199/519/EC

> As the underground cable is shielded, there is

no exposure to an electric eld above ground

> The EMF from a cable dissipates quicker than

from an overhead line as you move away

from the line

10 No risks to human health

MYTH NUMBER 5

Rather than building an AC line,

lets fully underground a long distance line

by using HVDC technology particularly

when linking off shore wind farms to

centres of electricity consumption which

are much further inland.

Historically, Europe has a meshed Alternating Current

(AC) grid network which has come of age and requires

short term upgrading. In addition, Europe is setting out to

create an additional Direct Current (DC) grid structure for

the future. Both are needed.

HVDC underground cables can safely transport high power

loads over long distances with minimal losses. In addi-

tion to this transport efciency, fewer cables are required

to carry the required capacity, hence allowing narrower

trenches. HVDC underground cables are compatible with

HVDC overhead technology and can be combined in sen-

sitive areas.

Switchgear technology is under nal development and

while the cost for the HVDC cable is only 2 3 times

compared to HVDC overhead technology, signicant

investments are required for the converter stations. This

today still limits HVDC deployment.

EUROPACABLE VIEW:

EUROPE NEEDS BOTH:

AC UPGRADING AND DC OVERLAY NET

FACTS

> Two discussions must not be confused:

todays need to refurbish and upgrade existing

AC networks and the future perspective to

build an additional DC backbone structure

> HVAC and HVDC cables are available

> The cost of conversion and the nal develop-

ment of switchgear technology today still limits

DC deployment and experience to

date is limted

12 AC upgrading and DC overlay net

MYTH NUMBER 6

EHV XLPE cables are 15 to 20 times

more expensive and therefore not

economically viable.

Investment cost for 400 kV XLPE cables installed in Eu-

rope over the past 10 years were generally around 5

10 times higher than for overhead lines. This is due to

higher component prices as well as installation costs,

which can be upto 60% depending on soil conditions.

It is important to underline that cost conside rations

should not only reference installation costs, but should

be based on a full life cycle analysis including costs of

operation, losses of property value and costs related to

the delay of line construction.

When applying the Concept of Partial Undergrounding,

these higher costs only apply to the undergrounded sec-

tions. Therefore the cost factor for realizing the actual

projects will average around 1.2 2 times only.

EUROPACABLE VIEW:

PARTIAL UNDERGROUNDING:

MAKING SENSE OF THE ECONOMICS

FACTS

> On average, underground cabling will be 5 10 times

more expensive than overhead lines

> This said, this cost factor only applies to the under-

grounded section, not to the entire project. Here the

cost factor will be as low as 1.2 2 times

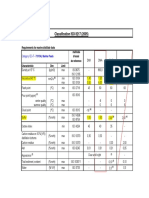

Example:

Total length of line: 100 KM

Distance to be undergrounded: 10 KM

Cost factor x10 for undergrounding

Total added cost to entire line: Factor 1.9

14 Making sense of the economics

4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4% 4%

4% 4%

4% 4%

4% 4%

4% 4%

4% 4%

4% 4%

MYTH NUMBER 7

The cost of undergrounding will

signicantly raise our electricity bills.

Consumers will not accept this

additional cost burden.

A recent study conducted for UKs National Grid shows

that in public perception the cost of electricity transmis-

sion represents 10% of the domestic electricity bill when

in fact it is only 4%.

42% believe that electricity transmission costs repre-

sent good value for money compared to 17% who do

not. National Grids own consultation showed 97% of

respondents favouring some form of undergrounding of

new lines to preserve visual amenity.

47% are prepared to pay for undergrounding all new

lines in the UK which is striking, as undergrounding

all new lines in the UK would only lead to a 6 increase

of the annual electricity bill, representing a 1% increase.

Deploying the Concept of Partial Undergrounding would

obviously cost less than this.

EUROPACABLE VIEW:

TRANSMISSION COSTS:

THE MINOR PART IN YOUR ELECTRICITY BILL

FACTS

> Electricity transmission only represents 4%

of the consumer electricity bill

> Research shows customers are willing to pay

more for undergrounding new power lines

> The additional burden on the annual

electricity bill would be minimal

16 The minor part in your electricity bill

2005 2008 2011 2011

km/p.a.

3.500

1.750

MYTH NUMBER 8

The cable industry will not be able to

deliver the amount of cables required.

Therefore cabling is not an option.

Europe needs to complete its electricity market to integrate

renewables and to secure supplies. To do so, the Euro-

pean Commission has earmarked 140bn in electricity

grid investments by 2020. In its 2010 Ten Year Network

Development Plan, ENTSO-E has identied 35,000 km

of new transmission lines and 7,000 km of existing line

upgrades by 2020.

Responding to this challenge, Europacable members

have increased production capacity by 40% since 2008.

Given the signicant investments required for EHV pro-

duction, the European wire and cable industry needs

clear regulatory frameworks enabling the use of its

components to balance the investment risks it is willing

to take.

EUROPACABLE VIEW:

EUROPEAN WIRE AND CABLE INDUSTRY:

RESPONDING TO INCREASED DEMAND

FACTS

> Europacable member companies manufacture

XLPE EHV underground cables at 22 production

facilities across Europe

> With an average capacity of 150 km of

cable per year, total production capacity

amounts to around 3,500 km of EHV p.a.

> Since 2008, production capacity of EHV

cables has increased by 40%

18 Responding to increased demand

Europacable represents approximately 85% of the Euro-

pean wire and cable manufacturers. Founded in 1991,

our member companies and national asso ciations

include global technology leaders as well SMEs highly

specialized in the production of energy-, telecommuni-

cation- and data-cables. With over 55.000 employees

across Europe and 20 billion of wire and cable con-

sumption in 2009, Europacable member companies

produce some 38 million km of cables p.a. in Europe

alone. Europacable is registered with the EU Institutions

at 453103789-92.

CONTACT US

for further information at

contact@europacable.com

or visit our website at

www.europacable.com

The Europacable Concept of

Partial Undergrounding proposes to

underground extra high voltage power

lines in sensitive areas complementing

overhead lines where their deployment

is restricted by public concerns or

environmental limitations.

ABOUT EUROPACABLE

20 Concept of Partial Undergrounding

europacable 80, Boulevard A. Reyers B-1030 Brussels www.europacable.com EU Transparency Register ID 4543103789-92 europacable 2011

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Syllabus 466Document6 pagesSyllabus 466student_ujjwol3163No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Potential Transformer Catalog ABBDocument4 pagesPotential Transformer Catalog ABBstudent_ujjwol3163No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Potential Transformer Catalog ABBDocument4 pagesPotential Transformer Catalog ABBstudent_ujjwol3163No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 00486181Document7 pages00486181student_ujjwol3163No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ABCD Matrix-A Unique Tool For Linear Two-Wire Transmission Line ModellingDocument10 pagesABCD Matrix-A Unique Tool For Linear Two-Wire Transmission Line Modellingstudent_ujjwol3163No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Preparation of A Formatted Technical Work For An IEEE Power & Energy Society Transactions PublicationDocument3 pagesPreparation of A Formatted Technical Work For An IEEE Power & Energy Society Transactions PublicationHitarth BuchNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- User Manual For UltrascopeDocument56 pagesUser Manual For Ultrascopestudent_ujjwol3163No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 480 Volt Corner Grounded Delta Friend or FoeDocument8 pages480 Volt Corner Grounded Delta Friend or Foestudent_ujjwol3163No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Saber TutorialDocument14 pagesSaber Tutorialstudent_ujjwol3163No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Voltage Control Scheme Using Fuzzy LogicDocument6 pagesVoltage Control Scheme Using Fuzzy Logicstudent_ujjwol3163No ratings yet

- GW Type 7 Controller ManualDocument53 pagesGW Type 7 Controller Manualstudent_ujjwol3163100% (1)

- DC DC BoostDocument21 pagesDC DC BoosttrshaaaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- MathType Shortcuts PDFDocument4 pagesMathType Shortcuts PDFEdmond Dantes100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Low Frequency Steady State Converter AnalysisDocument1 pageLow Frequency Steady State Converter Analysisstudent_ujjwol3163No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Facts Flexible AC Transmission System: Presented By: DR Ahmed MassoudDocument67 pagesFacts Flexible AC Transmission System: Presented By: DR Ahmed Massoudstudent_ujjwol3163No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Skydive Hastings MI - Tandem & Student PricesDocument3 pagesSkydive Hastings MI - Tandem & Student Pricesstudent_ujjwol31630% (1)

- All Power System StabiltyDocument78 pagesAll Power System StabiltyShafeek GhreebNo ratings yet

- Reactive Power1Document8 pagesReactive Power1Tulika BhattacharjeeNo ratings yet

- HEV ToyotaDocument23 pagesHEV ToyotaDeependra MagardeNo ratings yet

- VSC Based HVDC Power Transmission Systems An OverviewDocument11 pagesVSC Based HVDC Power Transmission Systems An Overviewstudent_ujjwol3163No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture 7Document14 pagesLecture 7student_ujjwol3163No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Converter Based Facts ControllersDocument11 pagesConverter Based Facts Controllersstudent_ujjwol3163No ratings yet

- Reactive Power Compensation Technologies, State-of-the-Art ReviewDocument21 pagesReactive Power Compensation Technologies, State-of-the-Art ReviewsharptrNo ratings yet

- Very Good Purdue Unib Effect of Source InductanceDocument7 pagesVery Good Purdue Unib Effect of Source Inductancestudent_ujjwol3163No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Homework 6 PDFDocument1 pageHomework 6 PDFstudent_ujjwol3163No ratings yet

- Reactive Power Compensation Technologies, State-of-the-Art ReviewDocument21 pagesReactive Power Compensation Technologies, State-of-the-Art ReviewsharptrNo ratings yet

- 2012 Xlpe Users Guide - UsaDocument28 pages2012 Xlpe Users Guide - UsaPablo ArancibiaNo ratings yet

- Curriculum Vitae Yosep Kurniawan Basa SogenDocument19 pagesCurriculum Vitae Yosep Kurniawan Basa Sogenyosep kurniawanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Boundary Layer ThicknessDocument23 pagesBoundary Layer ThicknessPridhar ThiagarajanNo ratings yet

- Ccu Sem (2010-05-05) PDFDocument181 pagesCcu Sem (2010-05-05) PDFBích Đỗ DanhNo ratings yet

- GD 511a-1 Parts ManualDocument275 pagesGD 511a-1 Parts ManualMachinery Club100% (4)

- Fupact ISFL SeccionadorDocument1 pageFupact ISFL SeccionadormmNo ratings yet

- Classification ISO 8217 (2005)Document5 pagesClassification ISO 8217 (2005)Salah JallaliNo ratings yet

- 262 Controlled Switching of HVAC Circuit Breaker PDFDocument34 pages262 Controlled Switching of HVAC Circuit Breaker PDFepriNo ratings yet

- Thermal Shock Resistant Neoceram Glass-CeramicDocument2 pagesThermal Shock Resistant Neoceram Glass-CeramicAmândio PintoNo ratings yet

- VS1-2 Manual PDFDocument284 pagesVS1-2 Manual PDFJorge InostrozaNo ratings yet

- LT AB Cable GTPsDocument3 pagesLT AB Cable GTPsnishant sainiNo ratings yet

- YM80SA Abrasive Belt Polishing Machine-Operation ManualDocument7 pagesYM80SA Abrasive Belt Polishing Machine-Operation ManualAgha Ali KhanNo ratings yet

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.No ratings yet

- ST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Document21 pagesST Series Servo Motor: Beijing KND CNC Technique Co.,Ltd. 01.2012Dinos ArhNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDocument12 pagesArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajNo ratings yet

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Document5 pagesCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723No ratings yet

- Introduction to Distillation and Flash DistillationDocument19 pagesIntroduction to Distillation and Flash DistillationSalman HaniffaNo ratings yet

- Samsung 2800mah ICR18650-28ADocument17 pagesSamsung 2800mah ICR18650-28AStreet_skNo ratings yet

- The Design of A Slotted Vertical Screen Breakwater PDFDocument13 pagesThe Design of A Slotted Vertical Screen Breakwater PDFscrane@No ratings yet

- Waste Water-Sewage PumpDocument111 pagesWaste Water-Sewage Pumpcharadeg100No ratings yet

- FMC Smith Meter 01 - Mesurement Product & SystemDocument70 pagesFMC Smith Meter 01 - Mesurement Product & SystemDucVikingNo ratings yet

- Electrical Machines DC MotorDocument5 pagesElectrical Machines DC MotorKitkay NivramNo ratings yet

- DPDC MaintenanceDocument5 pagesDPDC MaintenanceArfana Akter BanogirNo ratings yet

- NVFMCZ20DC12VDocument2 pagesNVFMCZ20DC12VPatrik GasparikNo ratings yet

- Types of Supports For Vessels - Chemical Engineering WorldDocument10 pagesTypes of Supports For Vessels - Chemical Engineering WorldAdityaNo ratings yet

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosNo ratings yet

- PLF-76T Service ManualDocument40 pagesPLF-76T Service Manualapi-3711045100% (1)

- SIA Guidance Note 47Document11 pagesSIA Guidance Note 47Ali BiomyNo ratings yet

- Brakes & Clutches: Formulas and Applications for Friction DevicesDocument16 pagesBrakes & Clutches: Formulas and Applications for Friction DevicesNeil RubsNo ratings yet

- Checklist Water Audit v1Document19 pagesChecklist Water Audit v1hammad.phistreamNo ratings yet

- Indirect and Non-Calorimetric MethodsDocument44 pagesIndirect and Non-Calorimetric MethodsMadhuvanti GowriNo ratings yet