Professional Documents

Culture Documents

Structural Properties of P-Type Boron Doped Carbon Film From Hydrocarbon Palm Oil For Photovoltaic Heterojunction Solar Cell Device

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Properties of P-Type Boron Doped Carbon Film From Hydrocarbon Palm Oil For Photovoltaic Heterojunction Solar Cell Device

Copyright:

Available Formats

I nternational J ournal of Engineering I nventions

e-ISSN: 2278-7461, p-ISSN: 2319-6491

Volume 3, Issue 9 (April 2014) PP: 35-41

www.ijeijournal.com Page | 35

Structural Properties Of P-Type Boron Doped Carbon Film

From Hydrocarbon Palm Oil For Photovoltaic Heterojunction

Solar Cell Device

A. Ishak

1,

M. Rusop

2,

1

NANO - ElecTronic Centre (NET), Faculty of Electrical Engineering, Universiti Teknologi MARA (UiTM),

Shah Alam, Selangor, Malaysia

2

Faculty of Electrical Engineering, UiTM Sarawak, Campus Kota Samarahan, Jalan Meranek Sarawak

Abstract: The complex-structured boron doped amorphous carbon were prepared from natural hydrocarbon

palm oil precursor deposited by negative bias substrate voltage of 0 V and -20 V are presented. Field-emission

scanning electron microscopy (FESEM) revealed the carbon films were very complex-structured. The open

circuit voltage (Voc), current density (Jsc), fill factor (FF) and efficiency () of Au/a-C:B/n-Si/Au heterojunction

solar cell device at 0 V were approximately 254 mV, 0.2324 mA/cm

2

, 0.241, and 0.0141%, respectively.

Meanwhile, the V

oc

, J

sc

, FF and of Au/a-C:B/n-Si/Au heterojunction solar cell device at -20 V were 426 mV,

5.351mA/cm

2

, 0.243, and 0.553%, respectively. The results showed the precursor palm oil and negative

substrate DC bias of -20 V can be used as an alternative precursor and technique for fabricated heterojunction

solar cell device.

Keywords: Amorphous carbon, palm-oil, negative bias, boron, pyrolysis- CVD, solar cell.

I. INTRODUCTION

Many types of carbon precursors have been discovered from renewable precursors [1-3] and non-

renewable sources for producing allotrope carbon such as carbon nano tubes (CNT), graphene, amorphous

carbon, etc. using various method of depositions [1-3]. Beside of those precursors, palm oil the other abundantly

promising green source was successfully synthesized the vertically aligned carbon nanotubes (VACNTs). Palm

oil is scientifically known as hexaeconoic acid which was derived from fibrous exocorp and mesacarp of the

fruits of palm tree. The palm oil is contained carbon (67), hydrogen (127) and oxygen (8) to form the chemical

binding of C

67

H

127

O

8

(3). This compound has the highest carbon content among the known precursors. The

synthesizing of a-C on the other hand, required less energy compared with other allotropes carbon for instant, the

VACNTs need deposition temperature above 700

o

C [1,2]. Nevertheless, the a-C films are weak p-type in nature

and they possess complex structure and high density of defects, thereby restricting their doping capacity; this low

doping efficiency is the main obstacle for their application in various electronic devices. Amorphous carbon (a-C)

films have gained considerable attention because of their controllable optical gap, which allows for its wide

application in the manufacture of semiconductors. In order to solve that problem, it was suggested the control of

doping could reduce the existing of defect and at the same time modified the electronic properties [4-6].

Among deposition parameters, negative bias voltage applied to the substrates could significantly change

film properties due to enhancement of adatom mobility and the effects of ion bombardment. The ion

bombardment during coating deposition would play an important role in affecting the morphology, structure,

composition and mechanical properties of coatings [7-9]. Many attempts were studied by others on the effect of

negative bias for instant through the use of pure lubricant coatings (MoS

2

) composite film. It was reported that,

the increase of bias caused preferential re-sputtering of S resulting in a reduced S/Mo ratio, which can affect

different properties of the film. A reported study on pure MoS

x

films deposited by bipolar pulsed DC showed that

even an S/Mo ratio of 0.8 was able to provide good lubricious property due to the strong basal plane orientation

and application of a bias voltage was found to reduce the coefficient of friction [8-10]. Therefore, an

understanding of substrate bias effects is necessary to improve the physical and mechanical properties of MoS

2

-

based coatings but also important for structural, electrical as well as electronic properties of any semiconductor

film.

In this paper, we report the complex-structured boron doped amorphous carbon films deposited by using

deposition temperature without bias (0 V) and deposition temperature with the help of a constant negative bias (-

20 V). To the best of our knowledge, there is less report on natural bio-hydrocarbon of palm oil as a p-type of a-C

film for heterojunction solar cell using negative bias technique.

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 36

II. METHODOLOGY

The Boron doped amorphous carbon (a-C:B) were deposited by using bias-assisted pyrolysis-CVD onto

the corning glass substrates (thickness: 1mm) and n-Si (100) (thickness 325 + 25 m, resistivity 1-10 cm).

Substrates (glass and n-silicon) were together cleaned with acetone (C

5

H

6

O) followed by methanol (CH

3

OH) for

15 min in ultrasonic cleaner (power Sonic 405), respectively and the glass substrates were then rinse with

deionizer water (DI) water for 15 min.

Oil palm

Waste

power Heater

Dc volt

selector

Temperature controller

- volt

+ volt Dc volt regulator

PV

SV

SEL

C

100%

50%

0%

DC volt

display

Heat

V

a

p

o

r

i

z

e

d

o

f

o

i

l

p

a

l

m

Air from pump

Argon gas

subsystem

A

subsystem

B

subsystem

C

subsystem

D

subsystem

E

9-10

5-6

waste

3-4

5-6

7-8

Figure 1 A schematic diagram of bias assisted pyrolysis-CVD

Moreover, excess oxide layers of n-type silicon substrates were continued by the etching process with

diluted hydrofluoric acid (10%) solution for about 3 min before rinsing in DI water. Substrates were blown with

nitrogen gas. The cleaned of glass and silicon substrate was attached inside the chamber as shown in Fig. 1. The

deposition temperature was set at 325

o

C for 1h deposition. A liquid of palm oil precursor was heated in the bottle

outside the chamber at around 150

o

C by using hot platter (Stuart CB162). The vaporized of palm oil was then

pressured into the chamber using low cost aquarium air pumps (model GA8000) (not shown in Fig. 1). The

amount of vaporized palm oil, carrier gas argon used into were set to be constant at 114 mL/min, 200 mL/min,

respectively by using AALBORG flow meter. For doping process, 1g of boron was placed on the aluminium foil

above the metal plate heater. The negative bias voltage is set at 0V and -20V, respectively.

L

i

g

h

t

c

l

o

s

u

r

e

A

u

(

1

2

n

m

)

A

u

(

6

0

n

m

)

a

-

C

:

B

(

2

5

0

n

m

)

n

-

S

i

(

3

5

0

m

)

S

a

m

p

l

e

h

o

l

d

e

r

(

2

5

0

c

m

)

1 cm

1 cm

e

load

A

u

(

6

0

n

m

)

Figure 2. The technique for measure heterojunction solar cell (Au/a-C:B/n-Si/Au)

In the measurement of solar cell device, both sided of silicon (buttom and top) is deposited with

approximately 60nm and 12nm of gold, respectively. Another gold with thickness of 60 nm deposited at the top

surface of 12 nm gold for confirm the point of probe is properly contacted on the gold metal contact. The light

closure is attached at the top of the device as shown in Fig. 2 (dark color) to ensure light strike only the area of 2

cm

2

. For complete the whole circuit, the other probe is connected to the conductive metal holder. Solar simulator

(Bukuh Keiki EP200), surface profiler (Veeco Dektak 150), JASCO UV-VIS/NIR Spectrophotometer (V-670

EX) and field emission scanning electron microscopic (FESEM, ZEISS Supra 40VP) to characterize the

electronic properties, optical properties, and surface morphologly, respectively.

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 37

III. RESULT AND DISCUSSION

(a) (b)

Figure 3 FESEM images of boron doped amorphous carbon with magnification of 900 at (a) 0 V and (b) -20 V

Fig. 3 (a) and (b) show the FESEM images of complex-structured a-C:B films. The images were taken

with magnification of 900 and voltage of 5.0 kV. The images in Fig. 3 (a) shows the irregular pattern of structure

synthesized from pure hydrocarbon precursor of palm oil with the micro-structured size. As can be observed

from FESEM images, the miro-structured a-C:B film consists of irregularly scattered micro flower-like of

agglomerated particles. In contrast, the complex-structured a-C:B film has more finer and denser. As bias

voltage of -20 V, the flower-like particles becomes denser and finer. This difference in the surface morphology

film can be attributed to the ion bombardment during the growth of the films which is controlled by the applied

of negative bias onto the substrate. More specifically, during the deposition of a-C:B film with applied of -20 V,

an intense positive-ion bombardment on the growing film surface is occurred. The flux and the energy of these

species affect the mechanisms that govern the incorporation of boron in the a-C network and the formation of a-

C:B bonding groups [10-12]. The negative bias of -20 V increases the energy of the bombarding ions, enhancing

the chemical reactions between different species and their mobility at the growing film surface. As a result, the

high-energy gas ions dissociate the deposition carbon clusters affecting the boron distribution, and the bonding

structure of the a-C:B film. Accordingly, without bias voltage (0 V) applied to substrate, the ions energy is too

weak to penetrate into the growing surface and most of the ions are only trapped on the growing surface,

resulting in the formation of the loose cross-linking [13-15] resulting to the irregularly scattered micro flower-

like of agglomerated particles.

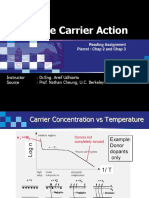

Figure 4 Optical band gaps of boron doped amorphous carbon at 0V and -20V

The optical properties of thin films are investigated by UV-visible spectroscopy measuremets on glass

substrates in the range of 350-900 nm wavelength, to derive the Tauc estimated optical band gap (E

g

) for

amorphous semiconductors [16,17]. The E

g

of the thin films is obtained from the extrapolation of the linear part

of the curve at the =0, using the Tauc relation, (hv)

1/2

=B

2

(E

g

-hv),where B

2

is the Tauc parameter [13,14].The

estimated E

g

of a-C:B at 0 V and -20 V are approximately 2.1 and 2.0 eV, respectively as shown in Fig. 4 (a)

10 m

10 m

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 38

and (b). The optical band gap is decreased as the applied of negative bias voltage of -20 V. The extra energy by

negative bias of -20V attributed to more interstitial doping boron (B) into a-C films which modify a-C:B bonding

that related with E

g

. Similar phenomena causing decreasing of E

g

were also reported by using other parameters

such as the percentage of dopants, (nitrogen and phosphorous), and deposition temperature [16-18]. The values of

these E

g

were a good agreement why the surface morphology at -20 V has finer and denser than 0 V.

Figure 5 The current-voltage characteristics of Au/a-C:B/n-Si/Au heterojunction solar cell under dark

measurement

The current densityvoltage (JV) characteristics of Au/a-C:B/n-Si/Au heterojunction solar cell device

with and without applied Dc bias susbstrate in dark environment are shown in Fig. 5 (a) and (b). The Au/a-C:B/n-

Si/Au heterojunction solar cells display rectifying curves, which indicate the formation of heterojunction between

the a-C:B film and silicon. The a-C:B layers acted as a p-type semiconductor with respect to n-type silicon, thus

forming the rectifying curve. The reverse saturation current, which is low as compared with the forward current,

gradually increases with reverse bias (photocurrent increases). These behaviors can be attributed to the generation

of minority carriers within the depletion region. At forward bias, the current increases exponetially, indicating a

good quality of pn junction. The ideality factor is approximatelty 2, indicating the dominance of the

recombination current rather than the diffusion current. Many deviations from the ideal pn characteristics are

observed, which can be due to the high low doping efficiency and posses complex structure and high density of

defects [19-21].

The IV characteristics of Au/a-C:B/n-Si/Au devices under illumination at 100 mW/cm

2

are illustrated in

Fig. 6 (a) and (b). A dissimilar trends in the form of curves are observed for micro-structured film for Au/a-

C:B/n-Si/Au heterojunction solar cells. The obtained curve of Au/a-C:B/n-Si/Au solar cell at 0 V is less broad

and small area as compared with the obtained curve of Au/a-C:B/n-Si/Au solar cell at -20 V. A slightly broad

curve indicates reduced area (fill factor, FF) or maximum output power, and thus, the overall conversion

efficiency is minimized. This phenomenon is attributed to series and shunt resistances, which are caused by metal

contact and material defect, respectively. The open circuit voltage (V

oc

), current density (J

sc

), fill factor (FF) and

efficiency () of Au/a-C:B/n-Si/Au at 0 V were 254 mV, 234 mA/cm

2

, 0.241, and 0.0141 %, respectively.

Meanwhile, the V

oc

, J

sc

, FF and of Au/a-C:B/n-Si/Au at -20 V were 426 mV, 5.351 mA/cm

2

, 0.243, and 0.553

%, respectively. It was observed that complex-strcutured a-C:B film deposited by -20 V use as the p-type in

heterojunction solar cell give higher convension efficiency than complex-strcutured a-C:B film deposited without

applied DC bias substrate ( 0 V).

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 39

Figure 6 The current-voltage characteristics of Au/a-C:B/n-Si/Au heterojunction solar cell device under

illumination

The series resistance results in voltage drop, thus preventing full photovoltaic voltage across the external

load; likewise, series resistance affects open circuit voltage (V

OC

) [8,11,15]. By contrast, internal resistance of

material (shunt resistance) is due to the device edges and grain boundaries. Shunt resistance significantly

contributes to the reduction of solar cell performance. In shunt resistance, a fraction of photo-generated carries are

diverted away from the external load, thereby reducing current density (J

SC

). Series resistance can be minimized

by introducing metal contact based on grid metal arrangement in commercialized silicon solar cells. Although

metal contact arrangement in the solar cell configuration in the present study is attributed to high series resistance,

which reduces the overall solar cell efficiency, our objective is to prove the complex-structured a-C:B film from

hydrocarbon source of natural palm oil can be applied in the fabrication of heterojunction solar cells.

The electronic properties of Au/a-C/n-Si/Au solar cell, including its open V

oc

, J

sc

, FF, and efficiency are

presented in Fig. 6 (b). Low V

oc

and Jsc are found for complex-strcutured a-C:B film, which diretly indicate low

FF and conversion efficiency. The low V

oc

and Jsc values are attributed to the low built-in voltage, which are

caused by the high amount of defect in the micro-strcutured a-C film. The electronic properties of Au/a-C:B/n-

Si/Au solar cells is remarakbly improved by the applied of DC bias substrate at -20 V. The Au/a-C:B/n-Si/Au

solar cells fabricated through the deposition at -20 V shows the highest conversion efficiency. The improvement

of convension efficiency can be attributed to the successful boron incorporation, which increases the number of

excess carriers in the nano-strcutured a-C:B film. The bombardment of ions produced by -20 V is important in

minimizing defects. The reduction of defects increases the built-in voltage, thereby prolonging the lifetime of

excess carriers and providing wide difussion. Although the energy-conversion efficiencies of the fabricated solar

cell devices are considerably low, the present study presents a viable alternative through the use of natural palm

oil precursor in developing solar cells. Moreover, the energy-conversion efficiency achieved in this study

(deposition at -20 V applied bias) is higher than that reported by Tian. ( = 0.3 %) [21] and Hayashi, ( =0.04 %)

[22].

The current-voltage characteristics of both Au/a-C:B/n-Si/Au devices, under illumination are shown in

Fig. 5 (a) and (b) and their electronic properties are summarized in Table 1. The open circuit voltage (V

oc

),

current density (J

SC

), fill factor (FF) and efficiency (%) of Au/a-C:B/n-Si/Au at 0V were approximately 0.254 V,

0.234 mA/cm

2

, 0.241, and 0.0141%, respectively. Meanwhile, the open circuit voltage (V

OC

), current density

(J

SC

), fill factor and efficiency of Au/a-C:B/n-Si/Au at -20 V were 0.426 V, 5.351 mA/cm2, 0.243, and 0.553%,

respectively. It was observed, convension efficiency of Au/a-C:B/n-Si/Au deposited using low negative bias

voltage of -20V is higher than 0 V.The improvement of convension efficiency might be resulted from the number

of boron incorporated with a-C to reduce the dangling bond in complex structured of films. The improvement on

electronic properties showed negative bias voltage plays an important rule to reconfigure the structure of a-C and

boron atoms to a more graphitic semiconductor.

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 40

Table I

The Electronic Properties of Au/a-C:B/n-Si/Au Solar cell Fabricated at 0 V and -20 V

Negative

bias (V)

Open-circuit

voltage (VOC)

Current

density

(mA/cm

2

)

Fill factor

(FF)

Conversion

efficiency

(%)

0 0.254 0.234 0.241 0.0141

-20 0.426 5.351 0.243 0.553

Fig. 7 shows spectral response of Au/a-C:B/n-Si//Au at applied DC bias voltage of 0 V and -20 V. The

Au/a-C:B/n-Si/Au at -20 V shows higher spectral response as compared with the Au/a-C:B/n-Si/Au at 0 V.

Spectral responses (0 V and -20 V) indicate two broad bands at the peak wavelength approximately 550 nm and

900 nm of wavelengths. It was reported that the wavelength above 700 nm is negligible since the photocurrent is

mostly generated due to the silicon substrate [11,21,22]. In the region below 700 nm, boron doped layers act as

carbon photon absorber, and quantum efficiency has a peak in short wavelength region. The photo current peak at

approximately 550 nm are the good agreement with the optical band gap (Fig. 4 (a) and (b)) measurement and

conversion effciecnt.

Fig. 7. Spectral response of heterojunction solar cell (Au/a-C:B/n-Si/Au) at different bias voltage

IV. CONCLUSION

The complex-structured of a-C:B films using novel precursor of palm oil for heterojunction solar cell

applications was presented. FESEM revealed films deposited with negative bias of -20 V had finer and denser of

flower-like particle. Negative DC bias improved the structural properties of a-C:B films and showed the

significant increment of energy conversion efficiency by the ion bombardment effect of the negative bias (-20 V).

Solar simulator analysis results showed an open circuit voltage (V

oc

), current density (J

SC

), fill factor (FF) and

efficiency (%) of Au/a-C:B/n-Si/Au at 0V were approximately 254 mV, 0.234 mA/cm

2

, 0.241, and 0.0141%,

respectively. Meanwhile, the open circuit voltage (V

OC

), current density (J

SC

), fill factor and efficiency of Au/a-

C:B/n-Si/Au at -20 V were 426 mV, 5.351 mA/cm

2

, 0.243, and 0.553%, respectively The conversion efficiency

was increased as constant negative bias of -20 V applied for doping boron into a-C film. Although the conversion

efficiency of heterojunction solar cells are considerably low, it shows a good prospect of using palm oil as the

carbon source with the help of negative bias substrate for fabricated a-C:B film as a p-type on n-silicon substrate

in heterojunction solar cell device for the improvement of the energy conversion efficiency by optimizing the

deposition conditions.

ACKNOWLEDGEMENTS

The authors thank to Ministry of Higher Education (MOHE) Malaysia for the scholarship, and Research

Management Institute (RMI) Universiti Teknologi MARA (UiTM) for the facilities and the financial support.

Structural Properties of P-type Boron Doped Carbon Film from Hydrocarbon Palm Oil for.

www.ijeijournal.com Page | 41

REFERENCES

[1] Suriani, A.B; Azira, A.A; Nik Roslan, S.F; Rusop, M. Synthesis of vertically aligned carbon nanotubes using natural palm oil as

carbon precursor. Material Letters, 2009, vol. 63, pp. 2704-2706.

[2] Paul, S; Samdarshi, S.K. A green precursor for carbon nanotube syhthesis. New Carbon Materials, 2011, vol. 26, pp. 85-88.

[3] Ishak, A; Amirul, M; M. Rusop. AFM images of undoped amorphous carbon thin films deposited by bias-assisted thermal-CVD.

10

th

International Conference on Semiconductor Electronics (ICSE2012), 2012.

[4] Ishak, A; K. Dayana, and M. Rusop, Effect of nitrogen concentration on electrical properties of amorphous carbon thin film by

using palm oil precursor. 10

th

Regional Symposium on Micro and Nano Electronics (RSM2013), 2013.

[5] Rusop, M; Tian, X. M; Mominuzzaman, S.M; Soga, T; Jimbo, T; Umeno, M. Photoelectrical properties of pulsedlaser deposited

boron doped p-carbon/n-silicon and phosphorous doped n-carbon/p-silicon heterojunction solar cells. Solar Energy, 2005, vol.

78, pp. 406-415.

[6] Mallikarjuna Reddy, A; Sivasangkar Reddy, A; Sreedhara Reddy, P. Effect of substrate bias voltage on the physical properties of

dc reactive magnetron sputtered NiO thin films. J. Material Chemistry and Physics, 2011, vol. 125, pp. 434-439.

[7] Hongwei Zhang, Zhanjun Zhang, Jingjian Li, Shengmin Cai. Effect of direct current bias voltages on supported bilayer lipid

membranes on a glassy carbon electrode. Electrocheministry Communications, 2007, vol. 9, pp. 605-609.

[8] Ishak, A; Rusop, M. Structural Properties of Micro and Nano-Strcutured Amorphous Carbon Films from Liquid Hydrocarbo

Precursor in Photovoltaic Heterojunction Solar Cell Applications. International Journal of Latest Reasearch in Science and

Technology, 2014, vol. 3, pp. 90-94.

[9] Bubenzer, A; Dischler, B; Brandt, G; Koids, P. rf-plasma deposited amorphous hydrogenated hard carbon films: preparation,

properties, and applications. Journal of Applied Physics, 1983, vol. 54, pp. 4590.

[10] Peng Wang, Xia Wang, Youming Chen, Guangan Zhang, Weimin Liu, Junyan Zhang The effect of applied negative bias violtage

on the structure of Ti-doped a0C:H films deposited by FCVA. Applied Surface Science, vol. 253, pp. 3722-3726, 2007.

[11] Ishak, A; Rusop, M. P-type properties of micro and nano-structured carbon films from hydrocarbon palm oil in photovoltaic

heterojunction solar cell applications. IOSR Journal of Elecetrical and Electronic Engineering, 2014, vol. 9, pp. 01-00.

[12] Liu, E; Li, L; Blainpain, B. Residual stresses of diamond and diamondlike carbon films. Journal of Applied Physics, 2005, vol.

98, pp. 073515.

[13] Stapinski, T; Swatowska, B; Kluska, S; Walasek, E. Optical and structural properties of amorphous silicon-carbon films for

optoelectronic applications. Applied Surface Science, 2004, vol. 238, pp. 367-374.

[14] Zeng, A.P; Yin, Y.B; Bilek, M; McKenzie, D. Ohmic contact to nitrogen doped amorphous carbons films. Surface Coating

Technology, 2005, vol. 198, pp. 202.

[15] Podder, J; Rusop, M; Soga, T; Jimbo, T. Boron doped amorphous carbon thin films grown by r.f. PECVD under different partial

pressure. Diamond and Related Materials, 2005, vol. 14, pp.1799-1804.

[16] Rusop, M; Mominuzzaman, S.M; Soga, T; Jimbo, T; Umeno, M. Effect of substrate temperature on growth of nitrogen

incorporated camphoric carbon films by pused laser ablation. International Journal Modern Physics B, 2002, vol. 16, pp. 866-

870.

[17] Hongwei Zhu, Jinquan Wei, Kunlin Wang, and Dehai Wu Applications of Carbon Materials In Photovoltaic Solar Cells. Solar

Energy Materials & Solar Cells, 2009, vol. 93, pp. 1461-1470.

[18] Gharbi, R; Fathallah, M; Alzaied, N; Tresso, E; A. Tagliaferro Hydrogen and nitrogen effects on optical and structural properties

of amorphous carbon. Mater. Sci. Eng. C, 2008, vol. 28, pp. 795.

[19] Kumari, L; Prasad, V; Subramanyam, S.V. Effect of iodine incorporation on the electrical properties of amorphous carbon

conducting films. Carbon, 2003, vol. 41, pp. 1841-1846.

[20] Ma, Z.Q; Liu, B.X. Boron-doped diamond-like amorphous carbon as photovoltaic films in solar cell. Solar Energy Materials,

2001, vol. 69, pp. 339-334.

[21] Tian, X.M; Rusop, M; Hayashi, Y; Soga, T; Jimbo, T; Umeno, M. A photovoltaic cell from p-type boron-doped amorphous

carbon film. Solar Energy Materials and Solar Cells, 2003, vol. 77, pp. 105-112.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Long-Wavelength Infrared Semiconductor Lasers PDFDocument406 pagesLong-Wavelength Infrared Semiconductor Lasers PDFKunchur Narayan100% (1)

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- Vagm 22Document4 pagesVagm 22AONLANo ratings yet

- Belt Conveying Vertical Curves and TransitionsDocument18 pagesBelt Conveying Vertical Curves and TransitionsFabio MiguelNo ratings yet

- Losses in OfcDocument26 pagesLosses in OfcdharaniNo ratings yet

- The Ultrasound BeamDocument9 pagesThe Ultrasound BeamFrancy100% (2)

- Design and Implementaion of A Dual Tone Multi-Frequency (DTMF) Based Gsm-Controlled Car SecurityDocument7 pagesDesign and Implementaion of A Dual Tone Multi-Frequency (DTMF) Based Gsm-Controlled Car SecurityInternational Journal of Engineering Inventions (IJEI)No ratings yet

- C 0491740Document24 pagesC 0491740International Journal of Engineering Inventions (IJEI)No ratings yet

- Data Mining Impact On Business IntelligenceDocument4 pagesData Mining Impact On Business IntelligenceInternational Journal of Engineering Inventions (IJEI)No ratings yet

- G 04123844Document7 pagesG 04123844International Journal of Engineering Inventions (IJEI)No ratings yet

- B 0490716Document10 pagesB 0490716International Journal of Engineering Inventions (IJEI)No ratings yet

- Relevance of Designing and Developing An Improvised White Board Compass For Teaching Geometrical Construction Concepts in Basic TechnologyDocument6 pagesRelevance of Designing and Developing An Improvised White Board Compass For Teaching Geometrical Construction Concepts in Basic TechnologyInternational Journal of Engineering Inventions (IJEI)No ratings yet

- An Imperceptible Blind Image Watermarking Scheme For Image Authentication Using DNA Encoding and Multi-Resolution Wavelet DecompositionDocument8 pagesAn Imperceptible Blind Image Watermarking Scheme For Image Authentication Using DNA Encoding and Multi-Resolution Wavelet DecompositionInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Saturation Point of Traffic On The Channel Based On The Ship DomainDocument5 pagesSaturation Point of Traffic On The Channel Based On The Ship DomainInternational Journal of Engineering Inventions (IJEI)No ratings yet

- C 04111114Document4 pagesC 04111114International Journal of Engineering Inventions (IJEI)No ratings yet

- Improvement of Friction Testing Machine and Study On Friction TestDocument5 pagesImprovement of Friction Testing Machine and Study On Friction TestInternational Journal of Engineering Inventions (IJEI)No ratings yet

- A 0490106Document6 pagesA 0490106International Journal of Engineering Inventions (IJEI)No ratings yet

- Effect of Processing Technique On LDPE Thin Films and SheetsDocument5 pagesEffect of Processing Technique On LDPE Thin Films and SheetsInternational Journal of Engineering Inventions (IJEI)No ratings yet

- E 04112135Document15 pagesE 04112135International Journal of Engineering Inventions (IJEI)No ratings yet

- B 04110710Document4 pagesB 04110710International Journal of Engineering Inventions (IJEI)No ratings yet

- A 04110106Document6 pagesA 04110106International Journal of Engineering Inventions (IJEI)No ratings yet

- F 04103138Document8 pagesF 04103138International Journal of Engineering Inventions (IJEI)No ratings yet

- Design and Prototype Development of A Cleaning Device For Outdoor AdvertisementDocument6 pagesDesign and Prototype Development of A Cleaning Device For Outdoor AdvertisementInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Design of A Tele Medical Channel Dedicated To Telemonitoring of Cardiac Insufficiency by Correlative AnalysisDocument5 pagesDesign of A Tele Medical Channel Dedicated To Telemonitoring of Cardiac Insufficiency by Correlative AnalysisInternational Journal of Engineering Inventions (IJEI)No ratings yet

- E 04102330Document8 pagesE 04102330International Journal of Engineering Inventions (IJEI)No ratings yet

- Correlative Analysis and Determination of The Attenuation Coefficients of The Photoplethysmographic SignalDocument4 pagesCorrelative Analysis and Determination of The Attenuation Coefficients of The Photoplethysmographic SignalInternational Journal of Engineering Inventions (IJEI)No ratings yet

- I 04105358Document6 pagesI 04105358International Journal of Engineering Inventions (IJEI)No ratings yet

- G 04103948Document10 pagesG 04103948International Journal of Engineering Inventions (IJEI)No ratings yet

- Polygon Oscillating Piston Engine: Kevin Anderson, Steve Cunningham, Martin Stuart, Chris McnamaraDocument6 pagesPolygon Oscillating Piston Engine: Kevin Anderson, Steve Cunningham, Martin Stuart, Chris McnamaraInternational Journal of Engineering Inventions (IJEI)No ratings yet

- A 04100105Document5 pagesA 04100105International Journal of Engineering Inventions (IJEI)No ratings yet

- A Solar Powered Smart Helmet With MultifeaturesDocument6 pagesA Solar Powered Smart Helmet With MultifeaturesInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Design and Prototype Development of A Cleaning Device For Outdoor AdvertisementDocument6 pagesDesign and Prototype Development of A Cleaning Device For Outdoor AdvertisementInternational Journal of Engineering Inventions (IJEI)No ratings yet

- B 0490716Document10 pagesB 0490716International Journal of Engineering Inventions (IJEI)No ratings yet

- C 0491740Document24 pagesC 0491740International Journal of Engineering Inventions (IJEI)No ratings yet

- A 0490106Document6 pagesA 0490106International Journal of Engineering Inventions (IJEI)No ratings yet

- Yasuda 1974Document15 pagesYasuda 1974Rodrigo Rodrigues de BarrosNo ratings yet

- IGCSE Physics EquationsDocument1 pageIGCSE Physics Equationsgamer eliteNo ratings yet

- Physics 2 - M3.1 ELECTRIC CHARGESDocument28 pagesPhysics 2 - M3.1 ELECTRIC CHARGESjakeNo ratings yet

- U8875 EnglishDocument1 pageU8875 Englishwelbert001No ratings yet

- B.Tech. Degree Exam Mechanics of Solids QuestionsDocument5 pagesB.Tech. Degree Exam Mechanics of Solids QuestionsArjun OrcsNo ratings yet

- LRFD Approach For Fatigue of Marine StructuresDocument6 pagesLRFD Approach For Fatigue of Marine Structuressaeed-21No ratings yet

- Mobile Carrier Action: Instructor: DR - Eng. Arief Udhiarto Source: Prof. Nathan Cheung, U.C. BerkeleyDocument23 pagesMobile Carrier Action: Instructor: DR - Eng. Arief Udhiarto Source: Prof. Nathan Cheung, U.C. BerkeleyMess YeahNo ratings yet

- Lecture Notes-Earthquakes and Seismic WavesDocument43 pagesLecture Notes-Earthquakes and Seismic WavestufdaawgNo ratings yet

- Iction Stir WeldingDocument16 pagesIction Stir WeldingNeeraj MishraNo ratings yet

- Lamco - New Instruction Manual (LA)Document18 pagesLamco - New Instruction Manual (LA)sarat sahooNo ratings yet

- Contact: ULVAC, IncDocument8 pagesContact: ULVAC, Inc黄爱明No ratings yet

- Effects of swelling and non-swelling clays on flotation performanceDocument8 pagesEffects of swelling and non-swelling clays on flotation performanceAndrea Rivera YucraNo ratings yet

- SP 01 en Power Supply PS 303 ProDocument1 pageSP 01 en Power Supply PS 303 ProRemi de CaesNo ratings yet

- Glass CalculatorDocument4 pagesGlass CalculatorSmilindNo ratings yet

- Yak Vs Newport Mats - Patent Suit - 2021Document70 pagesYak Vs Newport Mats - Patent Suit - 2021Jack deFRAUDSTERNo ratings yet

- PRACTICE QUESTIONS Unit 4, 5 and 6Document5 pagesPRACTICE QUESTIONS Unit 4, 5 and 6Samrudhi PatilNo ratings yet

- FOUNDATION DESIGN EXAMPLESDocument0 pagesFOUNDATION DESIGN EXAMPLESLaura HernandezNo ratings yet

- Answers To End-Of-Chapter Questions For Chapter 4, MoleculesDocument2 pagesAnswers To End-Of-Chapter Questions For Chapter 4, MoleculessarabNo ratings yet

- Magnetic Moment MeasurementDocument1 pageMagnetic Moment MeasurementtfurrowsNo ratings yet

- Elecs Circuit and Devices Chapter 1Document25 pagesElecs Circuit and Devices Chapter 1vhinzsanguinaryNo ratings yet

- Curved BeamsDocument2 pagesCurved Beamsivan bolañosNo ratings yet

- Flexural Strength Tests of Ceramics (SubsTech)Document3 pagesFlexural Strength Tests of Ceramics (SubsTech)mypenta2008No ratings yet