Professional Documents

Culture Documents

Farrowing House Design

Uploaded by

Adrian FranzingisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Farrowing House Design

Uploaded by

Adrian FranzingisCopyright:

Available Formats

Farrowing House Design

(313) The control of piglet diseases is dependent upon the design of the house and the way it is

managed. Key features of a good farrowing house:

The design should enable an all-in all-out management system to be operated with complete cleaning,

disinfection and drying of pens between groups. This prevents the build up of infection and reduces the

exposure to viruses, bacteria and parasites.

To achieve an efficient all-in all-out system the farrowing houses should be of a size appropriate to the

number of the sows in the herd and the number of farrowings planned for each week. Thus, ideally, in a

family farm of 300-500 sows farrowing houses should contain about 10 crates and in smaller herds about 6.

In large herds of 1000 or more sows it is useful to have farrowing houses of two or more different sizes, say,

10 to 12 crates and 20 to 24 crates. If rooms are bigger than this the farrowing spread becomes too large to

operate an efficient all-in all-out system.

The floor and work surfaces should be made of non-porous easily cleaned materials that dry quickly.

The floors should be well constructed and drained so that no pools of liquid occur and they should be free

from cracks and fissures that harbour infections.

The rooms should be adequately insulated and the ventilation system should maintain even temperatures

with no draughts around the sows or piglets. In temperate and colder climates the system should be

mechanically operated.

There should be passages in front of the farrowing pens as well as behind them for easy access to the

piglets, without climbing from one pen to another. This is particularly important when outbreaks of piglet

diarrhoea occur.

Examples of farrowing house layouts are given in Fig.8-22.

(Fig.8-22)

Farrowing crate and pen design are important in the management of the sow and litter. Pig producers are nothing if

not resourceful and ingenious and it is not surprising that over the 25 to 30 years of the development of the modern

industry a variety of pen and crate designs have been developed, some good, some not so good, none perfect.

Numerous pens have been designed that avoid total confinement of the sow in a crate or which confine the sow for

the first few days of lactation and then allow her free movement (e.g. multi suckling systems) but they have all been

found wanting and some have

been disastrous. There is, as

yet, no system more

productive and welfare

friendly to the piglets as well

as the sow and safe for the

attendant, than full

confinement in a farrowing

crate for most or preferably all

of lactation, provided weaning

is at less than 41/2 weeks.

An example of a

satisfactory farrowing pen

layout is shown in Fig.8-23.

The pen area is a minimum of 1.8m wide by 2.4m with the crate offset to one side with a side creep to the

larger side close to the front passage. Provided the management is good there seems to be little

difference in piglet mortality whether the creep is in front of the sow (as in the Camborough crate), to one

side of the head of the sow (as in Fig.8-23) or further back, level with the udder. The position of the creep

in Fig.8-23 gives the piglet contact to the sows head, fostering a maternal bond. It encourages the piglets

to remain at the head of the sow rather than at the udder where they may be laid on. In hot climates a

heated front creep may prevent the sow cooling herself and drip cooling procedures become necessary.

Crate designs vary widely and serve several purposes.

Safety for the stockperson.

Ease of management for such procedures as clipping teeth and tailing, examining the piglets and

the sows udder.

Treating the piglets or the sow, feeding, changing creep feed and general hygiene.

Provision of a simple safe creep close to the sow for the piglets.

Reducing piglet mortality from crushing and disease.

Economy of space in the farrowing room.

One guide to the efficiency of the design is the level of mortality achieved but other factors should also be

assessed, such as the comfort and contentment of the sow, whether the crates are big enough for the

biggest sows and the availability of both rows of teats to the piglets. To facilitate this ( and to reduce

crushing against the bottom bar) "fingers" are incorporated as in Fig.8-23 instead of a low bottom bar.

Various gadgets have been developed to reduce crushing when the sow lies down:

Adjustable bottom rails for different size sows.

A hinged bottom bar that drops inwards when the sow stands up making it difficult for her just to drop down

when lying again.

Bottom bars that operate on an hydraulic ram (the proctor crate) so that the sides swing in when the sow

stands and will only swing out slowly again when the sow starts to lie down. Such crates are expensive and

elaborate but they do help to reduce mortality.

Crates with a fan that automatically turns on when the sow stands and blows cool air around her feet

(blowaways) encouraging the piglets to return to the creep.

The floors of farrowing crates are important to piglet survival and health. If solid they should be insulated,

smooth enough not to cause abrasions on the piglets legs but not too smooth and slippery to make it

difficult for the newborn piglet to get to the udder and creep area.

Floors may be fully perforated , partly perforated as in Fig.8-23 or only perforated at the back end of the sow. They

may be raised to various heights above the passage level to help in manipulation by the stockperson, to deter the

stockperson from climbing, and to raise the piglet away from draughts at floor level.

Whilst crate design is important in assisting the sow to lie down gently, nevertheless its impact on pigs laid on is low if

the management and the design of the house encourages the piglet not to lie in the danger dropping zone. The day

by day management of the pen, the bedding and good drainage of the floor are vital components for success.

Good management in the farrowing house is the key to the successful rearing of healthy pigs and low pre-

weaning mortality.

If your mortality is 9% or more then consider in detail the following outlines. If you are achieving

all of these you should reach the target of between 5 and 8%.

Preparing the Farrowing House

(314) Sows should be moved into a dry warm house about three days before the expected farrowing date.

The house should have been completely emptied, cleaned, disinfected and more importantly dried.

As farrowing approaches a second heat lamp should be placed opposite the sows udder (if it is a side creep)

to attract the piglet away from the sow.

If the farrowing crate floor is slatted and the sow is likely to farrow at night time, a lamp should be hung at

the back of the crate.

If a sow is farrowing on slats, the areas behind and to the side of her should be covered over with solid

material during the actual period of farrowing and kept dry with shavings.

Make sure there are no draughts or high air flow across the house.

Make sure all nipple drinkers are working correctly.

Check the floors for any wear or tear or any loose panels if slatted. (Failure to carry this out frequently

results in the loss of a litter in the slurry).

Preparing the Sow

(315)

Make sure that all health routines have been carried out, for example vaccinations, mange treatment and

worming.

Check the feeding of the sow.

Regularly examine the udder as farrowing approaches.

Examine the vulva of the sow twice a day for any abnormal discharges.

Make sure the faeces is removed twice a day from behind the sow until two days post-farrowing, then once

daily for eight days.

Starting a piggery is a great business that you can start in your own backyard.

For this workbook, we solicited the help of seasoned pig farmer Rolly Bautista, who

helpedEntrepreneur Philippineswith some basic know how for people who want to get into

this kind of business. Rolly, who maintains a 200-square meter pig cage in his backyard in

Apalit, Pampanga, has been in this line of business since 2000.

KEEP IT CLEAN

It is not true that pigs are filthy animals. In fact, they can easily catch diseases if their

surroundings, and even the people who take care of them or approach them, are unclean,

he said.

So for those who want to use their backyards for a small-scale piggery business, Rolly said

the first emphasis should be on the pig cage or pen. He said that a drainage system and a

septic tank are musts. Through this, every time the pigs urinate or defecates, the area can be

cleaned immediately. The pigs defecate twice a day and the cage will only become smelly if

they get mixed with the urine.

If you will immediately clean the cage, it will not smell bad and your neighbors will not

even notice that you have a piggery in your backyard because it will not emit a foul smell,

he said.

There should also be a steady source of water because the pigs need to be washed at least

once a day. They also need to drink clean water regularly. The roofing of the cage should be

high to help it have proper ventilation, because the sow will easily suffer a miscarriage if the

area gets too hot.The pen should have regular anti-bacterial sprays. Bautista said a 200-

square meter pen can accommodate up to 10 sows (inahin) and 50 fattener piglets.

You might also like

- Michael Chinery-Insects of Britain and Western Europe-Revised 2007 EditionDocument324 pagesMichael Chinery-Insects of Britain and Western Europe-Revised 2007 EditionDIPOLMEDIA100% (6)

- Mage The Awakening - Intruders - Encounters With The Abyss PDFDocument228 pagesMage The Awakening - Intruders - Encounters With The Abyss PDFJohnRichardWuethrich100% (2)

- Danish Cattle Housing RecommendationsDocument123 pagesDanish Cattle Housing RecommendationsBurhanudin Malik100% (1)

- Universal Swine Ear Notching SystemDocument2 pagesUniversal Swine Ear Notching SystemJosé Luis Márquez JácomeNo ratings yet

- Animal Housing in Hot Climates PDFDocument122 pagesAnimal Housing in Hot Climates PDFIlyas FOxeérNo ratings yet

- Summary On Swine ManagementDocument6 pagesSummary On Swine ManagementJaskhem Lazo100% (1)

- The Complex SaraDocument10 pagesThe Complex SaraFlame10100% (3)

- Poultry ButcheryDocument110 pagesPoultry ButcheryBernard PalmerNo ratings yet

- The Teachings of DiogenesDocument14 pagesThe Teachings of Diogenesryanash777100% (1)

- Managing Sows and Litters for Healthy Pig GrowthDocument4 pagesManaging Sows and Litters for Healthy Pig GrowthJaycelle IsubolNo ratings yet

- Feasibility Report of Sugar Mill Cogen Power PlantDocument17 pagesFeasibility Report of Sugar Mill Cogen Power Plantknsaravana100% (1)

- H&W Farm Project For Bank LoanDocument25 pagesH&W Farm Project For Bank Loanhidayath khanNo ratings yet

- 114 Dog Breeds Ranked by Temperament PDFDocument1 page114 Dog Breeds Ranked by Temperament PDFRamona DonisaNo ratings yet

- Composting PresnttionDocument29 pagesComposting PresnttionChuah C. KenNo ratings yet

- Aluminium Brochure PDFDocument24 pagesAluminium Brochure PDFHassan Hassan100% (1)

- Making Poultry Feeds - KilomeDocument9 pagesMaking Poultry Feeds - KilomeHerman NdauNo ratings yet

- Electrical Rule of The ThumbDocument3 pagesElectrical Rule of The Thumbedalzurc100% (1)

- Managements Practices For Goat TetheringDocument5 pagesManagements Practices For Goat TetheringDr Maroof100% (1)

- Catalogue of LaboratoryDocument112 pagesCatalogue of LaboratoryMo Nah100% (1)

- HANDOUTS - Ear Notching in SwineDocument2 pagesHANDOUTS - Ear Notching in SwineMaria Hanah Marie100% (1)

- Cow Barn Design & Cow Comfort East African VersionDocument32 pagesCow Barn Design & Cow Comfort East African VersionEmma Wangari100% (1)

- National Farm Biosecurity Manual For Pork ProductionDocument48 pagesNational Farm Biosecurity Manual For Pork ProductionMuni Swamy100% (2)

- 8 Goat Diseases Basics Part 1Document1 page8 Goat Diseases Basics Part 1Ramesh BeniwalNo ratings yet

- Dragon Fruits in Malaysia - UpdatedDocument10 pagesDragon Fruits in Malaysia - UpdatedInsan BertaqwaNo ratings yet

- Farmer's Choice Pig Management Manual: Quality Meat ProductsDocument16 pagesFarmer's Choice Pig Management Manual: Quality Meat ProductsRoy Mwenda100% (1)

- Good Manufacturing Practices For Pig Abattoir: Thai Agricultural Standard TAS 9009-2006Document24 pagesGood Manufacturing Practices For Pig Abattoir: Thai Agricultural Standard TAS 9009-2006Jaime SilvaNo ratings yet

- ICP Project Development SpecificationDocument77 pagesICP Project Development SpecificationjeffmilumNo ratings yet

- Heating & Ventilation For PigsDocument20 pagesHeating & Ventilation For PigspirosNo ratings yet

- (Smart Animal Production, 2) Ilias Kyriazakis - Smart Livestock Nutrition-Springer (2023)Document337 pages(Smart Animal Production, 2) Ilias Kyriazakis - Smart Livestock Nutrition-Springer (2023)trần quốc vĩNo ratings yet

- Biogas PlantDocument8 pagesBiogas PlantAman BansalNo ratings yet

- TGM - Petrochemical Complexes - 160910 - NK PDFDocument240 pagesTGM - Petrochemical Complexes - 160910 - NK PDFVijayantSinghNo ratings yet

- Reliance Solar Plant 5 MWDocument9 pagesReliance Solar Plant 5 MWkaranbhaduNo ratings yet

- Feed Processing PlantDocument35 pagesFeed Processing Plantapi-372852169% (13)

- Manual PigletsDocument44 pagesManual Pigletsthanh ba matNo ratings yet

- Modern Day Poultry FarmingDocument27 pagesModern Day Poultry FarmingAkhlaqAhmad100% (1)

- Finisher Pig Buildings Design and Build: - A Blueprint For English FarmsDocument123 pagesFinisher Pig Buildings Design and Build: - A Blueprint For English FarmsNathaniel FernandesNo ratings yet

- Housing of PigsDocument17 pagesHousing of PigsAnna NdunaNo ratings yet

- RULE 99 Custody of Minors and Habeas CorpusDocument8 pagesRULE 99 Custody of Minors and Habeas CorpusAdrian FranzingisNo ratings yet

- RULE 99 Custody of Minors and Habeas CorpusDocument8 pagesRULE 99 Custody of Minors and Habeas CorpusAdrian FranzingisNo ratings yet

- RULE 99 Custody of Minors and Habeas CorpusDocument8 pagesRULE 99 Custody of Minors and Habeas CorpusAdrian FranzingisNo ratings yet

- Nutrition feed formulation guide for chick grower and layerDocument12 pagesNutrition feed formulation guide for chick grower and layerSai Pranay0% (1)

- Valve and Actuator CatalogueDocument60 pagesValve and Actuator Catalogueashfaq-matte-79930% (1)

- Bio GasDocument37 pagesBio GasSam PradhanNo ratings yet

- Fuel Source For A Renewable Future: BiogasDocument27 pagesFuel Source For A Renewable Future: BiogasAbdul LathifNo ratings yet

- Nitrogen Fixation: Jump To Navigation Jump To SearchDocument11 pagesNitrogen Fixation: Jump To Navigation Jump To SearchsakuraleeshaoranNo ratings yet

- Siemens - Pictures of The FutureDocument59 pagesSiemens - Pictures of The FuturehelderfsnNo ratings yet

- Tomato Farming Venture Using Greenhouse TechnologyDocument6 pagesTomato Farming Venture Using Greenhouse TechnologycatherineNo ratings yet

- Housing Systems of PoultryDocument7 pagesHousing Systems of PoultryferdinandNo ratings yet

- Air Intake For Pig HousesDocument12 pagesAir Intake For Pig HousesGabriel RaicaNo ratings yet

- Topic 1 - Introduction To M&E Systems PDFDocument49 pagesTopic 1 - Introduction To M&E Systems PDFSyamimi FsaNo ratings yet

- Broilers &layers Yaras MaccharlesDocument38 pagesBroilers &layers Yaras MaccharlesNyasha VincentNo ratings yet

- Poultry Production in Hot ClimatesDocument401 pagesPoultry Production in Hot ClimatesMarcos CastilloNo ratings yet

- Husk Fired Boiler Designed for SavingsDocument4 pagesHusk Fired Boiler Designed for SavingssebinNo ratings yet

- Tukau Trunkline Monitoring System OverviewDocument13 pagesTukau Trunkline Monitoring System OverviewIkhtiander IkhtianderNo ratings yet

- Control Valve Types: A Guide to Selection and OperationDocument30 pagesControl Valve Types: A Guide to Selection and Operationgad480No ratings yet

- TOTAL Calculation SheetDocument22 pagesTOTAL Calculation SheetMd. Abdulla Al MamunNo ratings yet

- Biogas Consultants ContractorsDocument8 pagesBiogas Consultants ContractorsuemaaplNo ratings yet

- Maturity Indicators of Fruits and VegetablesDocument4 pagesMaturity Indicators of Fruits and Vegetablesapi-246987133No ratings yet

- Automating GreenhousesDocument6 pagesAutomating GreenhousespabloNo ratings yet

- Covered Housing Systems: Feedlot Design and ConstructionDocument14 pagesCovered Housing Systems: Feedlot Design and ConstructionPortgas D AnneNo ratings yet

- Departmental Structure and Statistics of Chhattisgarh Fisheries DepartmentDocument33 pagesDepartmental Structure and Statistics of Chhattisgarh Fisheries DepartmentVinit Kant MajumdarNo ratings yet

- Variable Speed DrivesDocument546 pagesVariable Speed DrivescysautsNo ratings yet

- 2012, C, Improving The Efficiency of Power Distribution Systems Through Technical and Non-Technical Losses ReductionDocument8 pages2012, C, Improving The Efficiency of Power Distribution Systems Through Technical and Non-Technical Losses ReductionPrachitiKoreNo ratings yet

- Technical Due Diligence for Renewable Energy ProjectsDocument13 pagesTechnical Due Diligence for Renewable Energy ProjectsViorica PalcuNo ratings yet

- 2016 2017 Fisheries Aquaculture Business PlanDocument10 pages2016 2017 Fisheries Aquaculture Business PlanAtipo AmbroseNo ratings yet

- Bean SproutsDocument8 pagesBean SproutsMohd Nasha HafizulhilmiNo ratings yet

- Range Poultry Housing: Intr Intr Intr Intr Oduction Oduction Oduction OductionDocument16 pagesRange Poultry Housing: Intr Intr Intr Intr Oduction Oduction Oduction OductionMuhammad JameelNo ratings yet

- Ruminants ManagementDocument21 pagesRuminants ManagementPilo Pas KwalNo ratings yet

- Information Sheet Marilyn RosellosaDocument1 pageInformation Sheet Marilyn RosellosaAdrian FranzingisNo ratings yet

- Letter Request PRCDocument1 pageLetter Request PRCAdrian FranzingisNo ratings yet

- What is an anal fistula? Causes, Symptoms, TreatmentDocument3 pagesWhat is an anal fistula? Causes, Symptoms, TreatmentAdrian FranzingisNo ratings yet

- Affidavit of Resignation Joel ViovicenteDocument1 pageAffidavit of Resignation Joel ViovicenteAdrian FranzingisNo ratings yet

- RA 9175 Chainsaw Section 7. Penal Provisions.Document1 pageRA 9175 Chainsaw Section 7. Penal Provisions.Adrian FranzingisNo ratings yet

- What is an anal fistula? Causes, Symptoms, TreatmentDocument3 pagesWhat is an anal fistula? Causes, Symptoms, TreatmentAdrian FranzingisNo ratings yet

- Plea For Fisheries CodeDocument1 pagePlea For Fisheries CodeAdrian FranzingisNo ratings yet

- Philippines Supreme Court upholds double jeopardy protectionDocument14 pagesPhilippines Supreme Court upholds double jeopardy protectionAdrian FranzingisNo ratings yet

- What is an anal fistula? Causes, Symptoms, TreatmentDocument3 pagesWhat is an anal fistula? Causes, Symptoms, TreatmentAdrian FranzingisNo ratings yet

- Republic Act No Rental LawDocument8 pagesRepublic Act No Rental LawAdrian FranzingisNo ratings yet

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocument16 pagesBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssemblednashyachillesNo ratings yet

- CA Reverses NLRC Ruling on Seafarer's Disability ClaimDocument31 pagesCA Reverses NLRC Ruling on Seafarer's Disability ClaimAdrian FranzingisNo ratings yet

- Probation Law of The PhilippinesDocument4 pagesProbation Law of The PhilippinesLeayza Sta Maria CarreonNo ratings yet

- Affidavit of Lost ID CardsDocument1 pageAffidavit of Lost ID CardsChelissaRojasNo ratings yet

- RECIDIVISM and RPCDocument2 pagesRECIDIVISM and RPCAdrian FranzingisNo ratings yet

- ROAD To 100 KMDocument13 pagesROAD To 100 KMAdrian FranzingisNo ratings yet

- DENR Timber Possession CaseDocument47 pagesDENR Timber Possession CaseAdrian FranzingisNo ratings yet

- Wewqewqewqsadsadsaarticle 194 of The Family CodeDocument1 pageWewqewqewqsadsadsaarticle 194 of The Family CodeAdrian FranzingisNo ratings yet

- Come Here For The Set ofDocument1 pageCome Here For The Set ofAdrian FranzingisNo ratings yet

- Article 194 of The Family CodeDocument1 pageArticle 194 of The Family CodeAdrian FranzingisNo ratings yet

- Shrimp and vegetable pastaDocument1 pageShrimp and vegetable pastaAdrian FranzingisNo ratings yet

- Sadsadsaarticle 194 of The Family CodeDocument1 pageSadsadsaarticle 194 of The Family CodeAdrian FranzingisNo ratings yet

- Demurrer Direct Assault Elements MissingDocument3 pagesDemurrer Direct Assault Elements MissingAdrian FranzingisNo ratings yet

- Shrimp and vegetable pasta with soy sauceDocument1 pageShrimp and vegetable pasta with soy sauceAdrian FranzingisNo ratings yet

- Article 194 of The Family CodeDocument1 pageArticle 194 of The Family CodeAdrian FranzingisNo ratings yet

- Article 194 of The Family CodeDocument1 pageArticle 194 of The Family CodeAdrian FranzingisNo ratings yet

- Appointment Back TemplateDocument1 pageAppointment Back TemplateAdrian FranzingisNo ratings yet

- GOMERA BSBA FM-1 Gods of EgyptDocument3 pagesGOMERA BSBA FM-1 Gods of EgyptGOMERA, ENGELONo ratings yet

- EARC Reportedecaso PDFDocument4 pagesEARC Reportedecaso PDFFed Espiritu Santo GNo ratings yet

- Advances in Understanding The Urine-Concentrating MechanismDocument26 pagesAdvances in Understanding The Urine-Concentrating MechanismKiara Lopez RelaizaNo ratings yet

- Phonetic Animals ListDocument6 pagesPhonetic Animals ListJOHN. J MESANo ratings yet

- Tumkung LangitDocument8 pagesTumkung LangitMeilin Natsume100% (1)

- Life Sciences P2 Nov 2010 EngDocument14 pagesLife Sciences P2 Nov 2010 Engbellydanceafrica9540No ratings yet

- INAPHDocument4 pagesINAPHSri VasuNo ratings yet

- Bai Darfo Registered Pet Shops As of June 30 2023Document6 pagesBai Darfo Registered Pet Shops As of June 30 2023itshardtogetauserNo ratings yet

- Hep ADocument2 pagesHep Aapi-237098034No ratings yet

- VSDDocument4 pagesVSDtikabdullahNo ratings yet

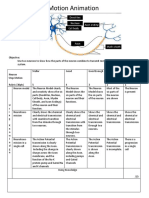

- Neurons Stop Motion AnimationDocument2 pagesNeurons Stop Motion Animationapi-495006167No ratings yet

- Microbiological Monitoring - RODACDocument2 pagesMicrobiological Monitoring - RODACdeden.drj19No ratings yet

- Sexual OffencesDocument21 pagesSexual Offencesniraj_sdNo ratings yet

- Darwin Comes To TownDocument7 pagesDarwin Comes To TownTadeoNo ratings yet

- Double Click 1 UNIT 1Document6 pagesDouble Click 1 UNIT 1matiw ledesma0% (1)

- English Grammar Cloud 8Document24 pagesEnglish Grammar Cloud 8Aismita BarNo ratings yet

- Cousins Cum 4 1Document15 pagesCousins Cum 4 1ty.mcgillNo ratings yet

- CDC Guidelines for Disinfecting HBV, HCV, HIV, TB DevicesDocument6 pagesCDC Guidelines for Disinfecting HBV, HCV, HIV, TB Devicesmr.anggaardiantoNo ratings yet

- A2.student. Parts of The BodyDocument4 pagesA2.student. Parts of The BodyLaia MartíNo ratings yet

- CH 12 Word ListDocument3 pagesCH 12 Word ListtigertiaNo ratings yet

- When Whales Walked Worksheet Part 5 1Document2 pagesWhen Whales Walked Worksheet Part 5 1api-284221392No ratings yet

- S9.1 Laboratory Work TextDocument4 pagesS9.1 Laboratory Work TextJennie Jane LobricoNo ratings yet

- NEET UG Biology Evolution PDFDocument22 pagesNEET UG Biology Evolution PDFamsaeangovanNo ratings yet

- Basics Breeding Soundness ExamsDocument1 pageBasics Breeding Soundness ExamsMaharani PutriNo ratings yet

- Name: Rihan Shufi Aditya No.: 16 Class: XRPL A. Choose The Correct Answer by Crossing A, B, C, D or E!Document9 pagesName: Rihan Shufi Aditya No.: 16 Class: XRPL A. Choose The Correct Answer by Crossing A, B, C, D or E!VICTIM No.16No ratings yet