Professional Documents

Culture Documents

Introduction To Drilling Technology

Uploaded by

Krupal PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Drilling Technology

Uploaded by

Krupal PatelCopyright:

Available Formats

ONGC a Wealth Creator

Types of Drilling

Exploratory Drilling-

To establish commercially viable oil & gas reserves.

Development Drilling-

To exploit already proven reserves.

ONGC a Wealth Creator

Steps Involved in Drilling a Well

Selection of drilling location based on geological/

seismic survey data

Preparation of drill-site/survey of sea-bed for moving

rig

Rig-move/Rig building

Spudding a well

Drilling the well upto TD and lowering of production

casing / Liner

Hermetical testing of Production Casing.

Well Planning

Collection of Geo-prognosticated data and analysis.

Study of offset well histories and complication if any.

Selection of Casing Seats.

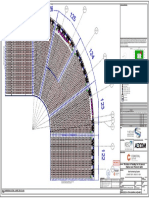

Planning of directional profile incase of directional

well.

Casing Design

Drill string design

Drill bit selection

Hydraulics

Selection of well head /BOP and other Well control

equipments

Drilling fluid Policy

Cementing Policy

Classification of Rig

ONGC a Wealth Creator

6

A semi-submersible rig is a special type of oil rig designed for drilling

in ultradeep water. Essentially, it is a giant floating platform that can

take on water to sink lower; this is why it is called a semi-submersible

rig. Because there is no way to anchor these rigs securely, they use

engines to remain in one place.

7

The Drillship shown is capable of operating at a water depth up to

12,000ft (3,650m) and having capacity of drilling wells upto 40,000ft

(12,200m).

8

The drilling barges are smaller, more mobile and less technically

demanding than the other units

9

Conventionally, drilling tenders are only deployable next to fixed

platforms. Presently it has been enhanced to provide drilling contractors

and operators the flexibility to operate even in deep waters.

10

11

Jack Up Type Rig

12

A Submersible Rig

LAND RIG

ONGC a Wealth Creator

LAND RIG

#2 E&P Company in the world

LAND RIG

TRAILOR RIG

RIGS IN ONGC as on March 2013

ONSHORE

E-3000

E-2000

E-1400

E-760

ARMCO

BI-2000

BI-1500

F-6100

F-4900

IPS-700-M

IR-900

ONSHORE RIG (OWN) = 68

OFFSHORE RIG (OWN)= 09

OFFSHORE

Jack ups

Sagar Pragati

Sagar Gaurav

Sagar Jyoti

Sagar Kiran

Sagar Shakti

Sagar Uday

Sagar Ratna

Drill ships

Sagar Vijay

Sagar Bhushan

HIRED OFFSHORE RIG = 31

TOTAL FLEET OF RIGS = 121

HIRED ONSHORE RIG = 13

Wells Drilled in 2012-13

RIG CLASSIFICATION

BY DRAWWORKS POWER

1000HP (E-760)

1500HP (BI-1500, E-1400)

2000HP (BI-2000, E-2000, National1320)

3000HP (E-3000, National 1625)

Divided Into Following Categories:

Hoisting Equipment

Rotary Equipment

Circulating Equipment

21

Major Drilling Rig Equipment

Draw Works Front

View

22

Hoisting Equipment

Draw Works Rear view

23

Hoisting Equipment

Crown Block

24

Crown Block

Mounted on beams at the top of the derrick

Most crown blocks have from 4 to 7 sheaves

which may be as large as 5 ft in diameter

The sheaves of this block have restraints to

keep the line from jumping the sheave in case of

slackness occurs.

Equipped with extra sheaves to accommodate a

sand line and a cat line.

25

Travelling Block

26

Travelling Block

Moves up and down in derrick

Is attached to a hook.

Consists of several sheaves made of high

quality steel mounted on large dia anti friction

bearing

Drilling lines reeved in pulleys

27

28

Hook

Hook

Is large joining device suspended from

traveling block

Supports drill string during drilling

Supports drill string during tripping using

elevator links and elevators

Rotates on bearings in its support housing

Has strong and big spring inside to cushion

the weight of drill pipe so that tool joint

threads are not damaged in making up and

breaking out drill pipe.

Has safety latch for swivel

Has locking arms or link ears at both sides for

elevator links

29

Swivel

30

Rotating

Equipment

Swivel

31

Functions of swivel

Suspend the drill stem

Permit free rotation

Passage to drilling fluid

32

Rotary table

Functions:

To impart rotation to bit through string

To support weight of drilling/casing string

whenever required

33

Classification:

by max. opening: 17-1/2, 20-1/2, 27-1/2, 37-

1/2 & 49-1/2, 60 etc.

By dead load rating: 250 t, 450t, 500t, 650t etc.

34

Kelly Bushing, Master Bushing and Rotary Table

Top Drive System

Suspended in the derrick

Performs several rotary drilling functions at a time

a. It rotates the drill stem

b. Serves as a passage for Drilling mud

c. Supports the drill stem in the hole

Rig uses top drive in place of Swivel, Kelly, Kelly

bushing and Rotary Table.

35

The rotary table and muster bushing are retained

as a place for floor hands and to set the slips to

suspend the drill stem in the hole.

Stands are used in place of singles

String can be rotated during POOH which is not

possible with rotary table

Top drive

36

37

Top drive

38

Top drive

TOP DRIVE

40

Circulating System

MUD CIRCULATION SYSTEM

Mud Pump

42

3 pistons and liners

Fluid displaced on forward stroke only.

Compact size, less weight.

Functions of Mud Pump

To circulate drilling fluid through the well

Displacement of cement

Pressure testing of casing

Mud Pump

43

Mud Tanks and Pump

44

RIG MOVE/RIG BUILDING

Rig is dismantled into smaller components

The components are loaded on trucks and

trailers by cranes

With movement of components to next location

rig-building is started

On-shore

RAISING OF RIG MAST

SPUDDING A WELL

ONSHORE

False conductor pipe is grouted in the cellar pit

After curing time, well is spudded with drill bit and

Kelly and required no. of drill-collars/drill-pipes.

SPUDDING OF WELL

The well is spudded and drilled upto TD as per plan.

Production casing/liner is lowered according to the

objective of the well.

After casing has been lowered , CBL - VDL is

conducted and thereafter , integrity of casing is tested

Integrity is tested by subjecting the casing to pressure

testing known as hermetical testing

It is conducted by displacing Drilling fluid inside the

casing with water gradually in several steps then

casing is pressurized to the required pressure as per

plan.

MILLED

TOOTH BIT

INSERT BIT

PDC BIT

Bit

Various Major Items for Performing Drilling

DRILL STEM:

ALL MEMBERS IN DRILLING

ASSEMBLY FROM KELLY

TO BIT

BOTTOM HOLE ASSEMBLY

(BHA):

DRILL COLLARS,H.W.D/P

STABILIZERS, JARS,

REAMERS, SHOCK SUBS,

X-OVERS, BIT SUB ETC.

Drill Pipe

Drill Pipe

Steel pipe, approximately 30-foot (9 meter) long,

screwed together to form a continuous pipe

extending from the surface to the drilling bit at the

bottom of the hole.

Rotation of the drill pipe and bit causes the bit to

drill through the rock.

Is used to transmit torque and hydraulic horse power

at the bit.

Drill Pipe Sizes

Available in various Sizes

Outside Diameters (OD) Ranges from 2-3/8 to 6-5/8.

Most Commonly used : 5 OD DP

Rig Floor and Power Tongs

56

Drill Pipe Slips

57

Drill Collars

58

CASING

Casing

While drilling wells for oil & gas, it is necessary to

secure a borehole with steel pipe which is called

casing. Mainly it is essential for isolating one pore

pressure regime from the other and sometimes to

isolate loss/caving prone zones

Purpose of drilling a well is to evaluate one or more

prospective producing zones and provide a means of

producing hydrocarbons that may be found in those

horizons. Casing is that most important means which

provides the facility of production of hydrocarbon

from various reservoirs

Well Schematics

Casing Pipe

Casing Pipe Pin

End Threads

Float Shoe

Casing Float collar

Casing Slip

65

Casing Side Door Elevator

66

Casing Power Tong

67

68

Thank you

You might also like

- MWD LWDDocument45 pagesMWD LWDMuhammad Inam Ul Haq100% (1)

- Introduction To Onshore DrillingDocument41 pagesIntroduction To Onshore DrillingSu Chong Guang50% (4)

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDocument8 pagesDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinNo ratings yet

- Drilling 1Document37 pagesDrilling 1Samarth Patel100% (1)

- Atlas World Map For PracticeDocument1 pageAtlas World Map For PracticeRahul KatrawatNo ratings yet

- Fishing and Stuck Pipe PreventionDocument13 pagesFishing and Stuck Pipe PreventionairaghidarioNo ratings yet

- Evolution of Directional Drilling Since 1900Document7 pagesEvolution of Directional Drilling Since 1900Rafique ArisarNo ratings yet

- Well Drilling DesignDocument26 pagesWell Drilling DesignMajedur Rahman100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Well Planning, Engineering & Construction EssentialsDocument540 pagesWell Planning, Engineering & Construction Essentialskrishnsgk100% (2)

- Drilling MonitoringDocument66 pagesDrilling MonitoringgqzxmNo ratings yet

- Drilling Optimization PDFDocument22 pagesDrilling Optimization PDFRoyNo ratings yet

- Drilling Through SaltDocument12 pagesDrilling Through SaltzapspazNo ratings yet

- Directional DrillingDocument39 pagesDirectional DrillingsrikantaLee100% (1)

- Basic Drilling EngineeringDocument26 pagesBasic Drilling EngineeringbhuvanchaudhariNo ratings yet

- Geothermal Drilling Problems and SolutionsDocument38 pagesGeothermal Drilling Problems and Solutionskrishnsgk100% (1)

- Basic Course of Drilling ProcedureDocument4 pagesBasic Course of Drilling ProcedureAli Samani100% (2)

- DPT1-01-Rig Sizing and Selection (New)Document65 pagesDPT1-01-Rig Sizing and Selection (New)Brahim LetaiefNo ratings yet

- Drilling OperationDocument25 pagesDrilling OperationMohammed Mushtaq Abu OmarNo ratings yet

- Well PlanningDocument55 pagesWell Planningmts1234100% (1)

- Drilling application evaluate design bit hydraulicsDocument1 pageDrilling application evaluate design bit hydraulicsstevebeardsleyNo ratings yet

- Drill String Design 4.11Document23 pagesDrill String Design 4.11Ryan Tan Ping YiNo ratings yet

- Introduction To Petroleum Engineering - Lecture 7Document37 pagesIntroduction To Petroleum Engineering - Lecture 7shanecarlNo ratings yet

- Well Control Leak-Off Test & Kick Circulation MethodsDocument45 pagesWell Control Leak-Off Test & Kick Circulation MethodsLaxmi Kant PrasadNo ratings yet

- Formulas and Calculations For Drilling Operations by Robello Samuel - Discount FlyerDocument1 pageFormulas and Calculations For Drilling Operations by Robello Samuel - Discount Flyerarzafar0% (1)

- Casing Design PreliminaryDocument29 pagesCasing Design Preliminaryalizareiforoush100% (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersDocument9 pagesWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsNo ratings yet

- Hoisting SystemDocument42 pagesHoisting SystemBadut Sarkas100% (3)

- Well Problems GoodDocument27 pagesWell Problems Gooddeyaa Sadoon100% (1)

- Drilling an Extended Reach Well: Key ConsiderationsDocument33 pagesDrilling an Extended Reach Well: Key ConsiderationsKutz100% (2)

- 2 - Directional Well DrillingDocument105 pages2 - Directional Well DrillingAli AbdullahNo ratings yet

- Formation Fluid Prediction Through Gas While Drilling AnalysisDocument89 pagesFormation Fluid Prediction Through Gas While Drilling AnalysisIcan100% (1)

- Petroleum Engineering Lesson Covers Drilling Systems, Rigs, ProcessDocument50 pagesPetroleum Engineering Lesson Covers Drilling Systems, Rigs, Processfrganga100% (1)

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- On Land Drilling Rig Operations GuideDocument37 pagesOn Land Drilling Rig Operations GuideAman Sinha50% (2)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- How To Drill An Extended Reach Well GuideDocument18 pagesHow To Drill An Extended Reach Well GuideKutzNo ratings yet

- Introduction To Drilling OperationsDocument36 pagesIntroduction To Drilling Operationsomer dafallahNo ratings yet

- Directional DrillingDocument32 pagesDirectional DrillingDante SchneiderNo ratings yet

- Tubular Mechanics in Oil-Gas WellsDocument79 pagesTubular Mechanics in Oil-Gas WellsSherif Fathy100% (1)

- 2009 - 02 - Drilling - A Guide To Successful BackreamingDocument24 pages2009 - 02 - Drilling - A Guide To Successful BackreamingThettin Oo100% (1)

- Essential Tips For Well Control Success: Aberdeen Drilling SchoolsDocument4 pagesEssential Tips For Well Control Success: Aberdeen Drilling SchoolsCerón Niño SantiagoNo ratings yet

- Overview of Drilling Operations MAY 2011 SEMDocument48 pagesOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- Drilling Problems N Drilling OptimizationDocument68 pagesDrilling Problems N Drilling Optimizationngecus50% (2)

- Bit Hydraulics Optimization for Maximum Drilling PerformanceDocument23 pagesBit Hydraulics Optimization for Maximum Drilling PerformanceShakerMahmood100% (1)

- Conceptual Design Deliverables Latest Rev2Document14 pagesConceptual Design Deliverables Latest Rev2dhanu_lagwankarNo ratings yet

- Real Time Drilling OptimizationDocument3 pagesReal Time Drilling OptimizationSergio RamirezNo ratings yet

- DirectionalDocument113 pagesDirectionalNanthini Palanisamy100% (1)

- Petroleum Engineering - Well ControlDocument43 pagesPetroleum Engineering - Well ControlJeffrey100% (1)

- Bit Balling DJENANE YOUCEFDocument13 pagesBit Balling DJENANE YOUCEFMohamed Kouchache100% (1)

- Tubing Selection Factors for Optimizing Well ProductionDocument51 pagesTubing Selection Factors for Optimizing Well ProductionImam Zulkifli SNo ratings yet

- Drilling Operations Hole Cleaning DynamicsDocument38 pagesDrilling Operations Hole Cleaning DynamicsSAKNo ratings yet

- Perf - Presentation AiymDocument32 pagesPerf - Presentation AiymNaief Javaheri100% (1)

- MCQ in Services MarketingDocument83 pagesMCQ in Services Marketingbatuerem0% (1)

- Determine Hole Cleaning Requirement in Deviated WellsDocument22 pagesDetermine Hole Cleaning Requirement in Deviated WellsCut Fanni Ayutaya100% (1)

- Mwd-Manual PDFDocument151 pagesMwd-Manual PDFmanu pratap singhNo ratings yet

- 010 Wireline LoggingDocument23 pages010 Wireline LoggingKami Oey100% (1)

- Blowouts: "Blowouts Continue To Occur at About A Constant Rate... "Document18 pagesBlowouts: "Blowouts Continue To Occur at About A Constant Rate... "Muhammad ShahrukhNo ratings yet

- Pre-Spud Checklist # 4Document2 pagesPre-Spud Checklist # 4Yougchu LuanNo ratings yet

- Introduction To Coiled TubingDocument8 pagesIntroduction To Coiled TubingFauzan Rahman HaqNo ratings yet

- F 10 FacebookDocument6 pagesF 10 FacebookKrupal PatelNo ratings yet

- 17.11.2016 Adam Szewczyk World+steel+outlookDocument15 pages17.11.2016 Adam Szewczyk World+steel+outlookKrupal PatelNo ratings yet

- Niti PDFDocument1 pageNiti PDFKrupal PatelNo ratings yet

- The GST Effect - ZohoDocument6 pagesThe GST Effect - ZohoKrupal PatelNo ratings yet

- InternshipsDocument1 pageInternshipsKrupal PatelNo ratings yet

- 1Document8 pages1Krupal PatelNo ratings yet

- ReferencesDocument1 pageReferencesKrupal PatelNo ratings yet

- Polaroid ExhibitsDocument8 pagesPolaroid ExhibitsKrupal PatelNo ratings yet

- UST ExhibitsDocument16 pagesUST ExhibitsKrupal PatelNo ratings yet

- FRC Working Party - Oil and Gas Case Study MA Final 6feb2016Document18 pagesFRC Working Party - Oil and Gas Case Study MA Final 6feb2016Krupal PatelNo ratings yet

- RBI Internship 20/10 NITI Internship 1-10 Every Month Ministry of Finance NABARD Jan 2017Document1 pageRBI Internship 20/10 NITI Internship 1-10 Every Month Ministry of Finance NABARD Jan 2017Krupal PatelNo ratings yet

- IIM Field ActivitiesDocument4 pagesIIM Field ActivitiesKrupal PatelNo ratings yet

- Rural Immersion Program PDFDocument3 pagesRural Immersion Program PDFKrupal PatelNo ratings yet

- Rural Immersion Program PDFDocument3 pagesRural Immersion Program PDFKrupal PatelNo ratings yet

- Quiz Question1Document6 pagesQuiz Question1Krupal PatelNo ratings yet

- Rural Immersion ProgramDocument4 pagesRural Immersion ProgramKrupal PatelNo ratings yet

- Daily DemandDocument21 pagesDaily DemandKrupal PatelNo ratings yet

- First Steps To Investing A Beginners Guide Prithvi Haldea PDFDocument21 pagesFirst Steps To Investing A Beginners Guide Prithvi Haldea PDFnagaravikrishnadiviNo ratings yet

- ModuleDocument26 pagesModuleSantosh KumarNo ratings yet

- Member Zone Databank: Cover Feature New Issue Analysis (IPO) IPO Premium Corporate Inklings What's Buzzing?Document2 pagesMember Zone Databank: Cover Feature New Issue Analysis (IPO) IPO Premium Corporate Inklings What's Buzzing?Krupal PatelNo ratings yet

- 7 Amazing MathematiciansDocument2 pages7 Amazing MathematiciansKrupal PatelNo ratings yet

- Petroleum Engineering Syllabus For GATE 2016Document2 pagesPetroleum Engineering Syllabus For GATE 2016Deep JoshiNo ratings yet

- Ongc Electrical PaperDocument10 pagesOngc Electrical PaperKrupal PatelNo ratings yet

- Petroleum Engineering Syllabus For GATE 2016Document2 pagesPetroleum Engineering Syllabus For GATE 2016Deep JoshiNo ratings yet

- A Beginner's Guide To The Capital Market: July 12-17, 2010 An Initiative Under The Year Long Investor Awareness ProgrammeDocument30 pagesA Beginner's Guide To The Capital Market: July 12-17, 2010 An Initiative Under The Year Long Investor Awareness ProgrammemayanksaksNo ratings yet

- Pattern of Question Papers and Marking SchemeDocument5 pagesPattern of Question Papers and Marking SchemeKrupal PatelNo ratings yet

- Oil Industry Safety Standards and GuidelinesDocument6 pagesOil Industry Safety Standards and GuidelinesKrupal PatelNo ratings yet

- 5 Reasons Oil Prices Are DroppingDocument4 pages5 Reasons Oil Prices Are DroppingKrupal PatelNo ratings yet

- 1st June 2014Document25 pages1st June 2014Krupal PatelNo ratings yet

- KSB Megaflow V: Pumps For Sewage, Effuents and MisturesDocument18 pagesKSB Megaflow V: Pumps For Sewage, Effuents and MisturesKorneliusNo ratings yet

- DML Sro Karnal RMSDocument5 pagesDML Sro Karnal RMSEr Rohit MehraNo ratings yet

- Saint Louis University Baguio City Principal'S Recommendation FormDocument1 pageSaint Louis University Baguio City Principal'S Recommendation FormnidzNo ratings yet

- ESG Service Information: BackgroundDocument6 pagesESG Service Information: BackgroundAbdulSattarNo ratings yet

- OkDocument29 pagesOkgouthamlabsNo ratings yet

- NETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFDocument34 pagesNETWORK ANALYSIS Chap.8 TWO PORT NETWORK & NETWORK FUNCTIONS PDFsudarshan poojaryNo ratings yet

- Air Pak SCBA Ordering Specifications (HS 6701)Document8 pagesAir Pak SCBA Ordering Specifications (HS 6701)QHSE ManagerNo ratings yet

- AMG ActuatorsDocument12 pagesAMG ActuatorsMohan ArumugavallalNo ratings yet

- Gate Mock Test1Document17 pagesGate Mock Test1Gopinathan SudheerNo ratings yet

- VNX Power UP Down ProcedureDocument8 pagesVNX Power UP Down ProcedureShahulNo ratings yet

- Waukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsDocument6 pagesWaukesha Engine, Dresser, Inc. - Express Limited Warranty Covering Products Used in Continuous Duty ApplicationsLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Manuel Solaris Ccds1425-St Ccds1425-Dn Ccds1425-Dnx Ccds1425-Dn36en deDocument42 pagesManuel Solaris Ccds1425-St Ccds1425-Dn Ccds1425-Dnx Ccds1425-Dn36en deAllegra AmiciNo ratings yet

- Enclosed Product Catalogue 2012Document24 pagesEnclosed Product Catalogue 2012Jon BerryNo ratings yet

- 0.9PF PW 380v 3phase HF UPS10-120kvaDocument8 pages0.9PF PW 380v 3phase HF UPS10-120kvaArmandinho CaveroNo ratings yet

- SE01 SE04 SE03 SE02 E14 E13: As BuiltDocument1 pageSE01 SE04 SE03 SE02 E14 E13: As BuiltgenricNo ratings yet

- PMO ProceduresDocument21 pagesPMO ProceduresTariq JamalNo ratings yet

- Suparco+ KRL Test Ques For Electrical EngrzDocument5 pagesSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNo ratings yet

- Human Plus Machine A New Era of Automation in ManufacturingDocument8 pagesHuman Plus Machine A New Era of Automation in ManufacturingDuarte CRosaNo ratings yet

- LogDocument27 pagesLogmilli0chilliNo ratings yet

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDocument23 pagesItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNo ratings yet

- RELAY SEEDER PROTECTION GUIDE (P40 Agile CompactDocument23 pagesRELAY SEEDER PROTECTION GUIDE (P40 Agile CompactvinodlifeNo ratings yet

- I) CentrifugesDocument46 pagesI) Centrifugesiahim87No ratings yet

- PrintedElectronics ProductOverview PDFDocument2 pagesPrintedElectronics ProductOverview PDFanon_551622158No ratings yet

- 4PL Supply Chain Transformation SolutionsDocument2 pages4PL Supply Chain Transformation SolutionsGourav HegdeNo ratings yet

- Oracle Baseline Security ChecklistDocument15 pagesOracle Baseline Security ChecklistChidi OkerekeNo ratings yet

- Astral Column Pipe PricelistDocument4 pagesAstral Column Pipe PricelistVaishamNo ratings yet

- Mid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraDocument9 pagesMid Exam Odd Semester Academic Year 2021/2022 Study Program Management Faculty of Business Universitas Multimedia NusantaraaekimNo ratings yet