Professional Documents

Culture Documents

Carbon Fiber Deicer: Senior Engineering Design Project

Uploaded by

andreww1212Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Carbon Fiber Deicer: Senior Engineering Design Project

Uploaded by

andreww1212Copyright:

ENS 491/ENS 492

Carbon Fiber Deicer

Senior Engineering Design Project

Andrew Wosciechowski

5/27/2013

1

Table of Contents

Abstract ..................................................................................................................................................... 3

Object/ Introduction - Apparatus/Materials ............................................................................................. 4

Theory .................................................................................................................................................... 5-6

Design ................................................................................................................................................... 7-11

Simulation .......................................................................................................................................... 12-15

Experimental Setup/Procedure ......................................................................................................... 16-21

Discussion/Conclusion ....................................................................................................................... 22-27

Appendix .....................................................................................................................................................

2

Table of Figures

Figure 1: The front panel of the simulation ............................................................................................ 12

Figure 2: Block diagram of the simulation .............................................................................................. 13

Figure 3: Graph of the simulated results ................................................................................................ 14

Figure 4: Circuit diagram in Multisim ...................................................................................................... 15

Figure 5: Pin configuration of the DS18B20 ............................................................................................ 17

Figure 6: Testing the carbon-fiber strip in the lab .................................................................................. 20

Figure 7: Graph of the experimental results ........................................................................................... 20

Figure 8: Block diagram for the system .................................................................................................. 21

Figure 9: Fritzing model of the system .................................................................................................... 21

Figure 10: Concept image of the final system......................................................................................... 23

3

Abstract:

The goal was to design a system capable of melting snow/ice with the use of joule heating by

applying voltage/current to a conductor in order to generate heat. The material chosen was carbon

fiber. This was due to its rigidity, durability, conductive properties and its light weight. Weve opted to

control the system based on temperature. Once the ambient (environmental) temperature went below

a certain level, chosen to be the freezing point (32F) then the system would trigger thus melting the ice.

If the ambient temperature goes above this certain level then the system would turn off.

To control the system weve used the Arduino microcontroller coupled with two temperature

sensors, an N-Channel MOSFET, a power supply and the heating element (carbon-fiber). The Arduino

was to provide control and feedback for the system. The two temperature sensors are to read the

ambient temperature and the temperature of the heating element. The MOSFET was chosen to act as a

switch even though it has many uses in electronics. The Arduino will control the MOSFET when the

temperature reaches below/above the programmed threshold. Connected to the MOSFET is also our

carbon-fiber heating element which is also connected to the power supply. Current is constantly flowing

through the heating element from the power supply thus causing it to increase in temperature. When

the temperature goes below a certain programmed level this current will be allowed to flow through the

element and MOSFET. When the temperature is above this programmed threshold then the MOSFET

will prevent the current from flowing through the heating element thus causing the system to cool

down.

Before doing the programming and connecting the system we have tested the carbon strip with

certain amounts of voltage/current and to see what temperatures are produced. We went from 0V to

10V and recorded the temperatures accordingly. At 5V/0.20A weve generated a temperature of

approximately 90F. At the maximum of 10V/0.45A weve achieved a temperature of 137F. We felt that

at the maximum temperature this was a bit of a waste of electricity for the system so weve opted to

use around 5-7V DC.

After testing the strip weve done the necessary programming and tested it in steps to ensure

everything was working. First we programmed the LCD to display text and the information such as the

ambient and system temperatures. Once weve seen that was working we then implemented the

control structure to regulate the MOSFET as a switch. Once the ambient temperature goes below the

threshold then the current from the power supply would be allowed to pass through the heating

element. When the ambient temperature goes above the threshold then the MOSFET is closed and

the current is not allowed to pass, allowing the system to return back to room temperature.

Upon completing the program weve connected everything and observed the working design.

From here we were able to add a second strip to create a baseline for scalability. Two strips were placed

approximately 10cm apart. This value was chosen because its a simple even number. Also if the strips

are too close then the system would be inefficient, too far apart then the heat generated would not be

concentrated enough to melt ice. Using the sizes of the carbon strips and the spacing along with the

rating (60V/30A) for the MOSFET we could find that the maximum amount of area to be covered with

our prototype was 9.660m

2

using 130 strips of carbon fiber.

By scaling up the prototype we were able to determine how many strips, how many MOSFETs

and how large of a power supply is needed to cover the area. As an example we chose a driveway of

approximately 35m

2

and have found that a 600W power supply along with 4 MOSFETs and 437 strips

were needed to generate the necessary temperature of 95F as done in the prototype. Upon scaling up

we have also attributed the cost to be around $3214.00 for the materials.

4

Objective/Introduction:

The project stemmed from the problem of trying to prevent snow/ice accumulation on surfaces

outdoors when the environment is cold. The idea was to have a portable system to properly melt snow

and ice that anyone could use. Currently there are systems implemented in large office buildings,

hospitals and up-scale residential neighborhoods. This system is not portable, requires a lot of effort to

install and can be quite expensive to operate and install. We were looking to create the total opposite of

this system. Good portability, minimal effort to implement at any location and ease of use. Weve set to

design the system based on these factors.

Instead of a system that is permanently installed underneath concrete and asphalt like some

existing systems weve chose to create an aboveground system. This would provide for easier

maintenance and better usability since it can be taken anywhere. Such a system would require less

installation than an in-ground system. Current in-ground systems require extensive construction such as

ripping up of concrete/asphalt, lying of the heating element, the wiring and repaving the ground. This

can be quite costly and time consuming. Also such a system can only be marketed toward large

companies and the well-to-do. This system design was targeted toward an average person with

average/slightly above average income.

Apparatus/Materials:

1. (1) Arduino Mega 2560 R3 Microcontroller.

2. (1) Mini breadboard.

3. Wire jumpers.

4. (1)DFRobot LCD Keypad Shield.

5. (2) One-Wire Digital Temperature Sensor DS18B20.

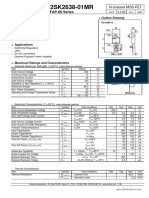

6. (1) Fairchild Semiconductor N-Channel MOSFET (60V 30A).

7. (1) Clear Blue 5mm LED.

8. (1) Labvolt Variable Power Supply.

9. (10) Banana plug to alligator leads.

10. (1) Carbon-Fiber Strip (67cm x 1cm x 0.2cm).

5

Theory:

The premise of this project was to generate heat electrically through a heating element in order

to the melt ice. This process is referred to as Joule heating. Joule heating can be commonly seen in

soldering irons, electric stoves and toaster ovens. We pass an electrical current through a highly

conductive material and the conductor releases heat. Joule heating is dependent on the type of current

used whether AC or DC. For the sake of the experiment we will be using DC.

For DC current we know that total power is represented by the equation:

=

Where:

P = Power measured in Watts (W)

V = Voltage measured in Volts (V)

I = Current measured in Amps (A)

This equation is used to determine the power across our heating element. The heating element

(conductor) has an electrical resistance. Electrical resistance is the blocking of electrical current and is

given by the equation:

=

Where:

R = Resistance measured in Ohms ()

V = Voltage measured in Volts(V)

I = Current measured in Amps(A)

This equation is referred to as Ohms Law and can be written also as:

=

=

By using these simple equations we can determine the voltage by having the value for the current and

resistance or we can determine the voltage by knowing the value for the voltage and resistance. These

will be very helpful in the design.

Joule heating is based upon Joules First Law

1

:

2

Where:

Q = Heat measured in Joules (J).

I = Current measured in Amps(A).

R = Resistance measured in Ohms ().

1

http://en.wikipedia.org/wiki/Joule_heating

6

The heat is proportional to the amount of current (squared) multiplied by the resistance of the heating

element.

From the aforementioned equations we can see how current/voltage, combined with the

resistance of a heating element can produce heat. This is the main premise behind many electrical

heating systems used residentially and commercially. Therefore, by applying the voltage and current

through the heating element (resistor) we can generate heat. The heat will then be used to melt ice and

prevent snow accumulation in cold environments.

Referring to heat (Q) brings up another important part of the system. We have said that applied

voltage/current (power) to a resistive heating element generates heat. Once the heat is generated it will

eventually be emitted to the environment. This process is known as Convection. This is given by the

equation

2

:

= (

)

Where:

Q

c

= The thermal energy in Joules (J).

h = Heat transfer coefficient (W/m

2

K).

A = Surface area (m

2

).

T

b

= Temperature of the surface area.

T

f

= Temperature of the environment.

This equation is known as Newtons Law of Cooling.

As the current/voltage is applied to the heating element (resistor) this will generate heat. The surface

area of the heating element matters along with the environmental temperature and temperature of the

resistor.

2

Fundamentals of Engineering Thermodynamics, Moran, Shapiro, Boettner, Baily, 2011, p. 57

7

Design:

We have identified the properties of the design as:

1. Simple installation by the user.

2. Portable.

3. Durable.

4. Economical compared to current systems.

With these properties we were able to make proper decisions of what materials to use and how they

will be implemented. However before proceeding with these ideas we must take into account the

constraints:

1. Economic consideration.

2. Environmental consideration.

3. Social considerations.

4. Manufacturability considerations.

5. Sustainability.

6. Ethical considerations.

7. Health and Safety.

8. Political consideration.

Economical Consideration:

As we have examined preliminarily in the report most systems currently being used arent very

economically feasible. Existing systems require the establishment to do demolition of the ground to lay

in the heating element. Then after the heating element is laid in reconstruction of the ground must be

done. This process alone can be very expensive due to the amount of labor and equipment is needed to

complete the job. Along with these factors comes the cost of the system itself. Our system hopes to

alleviate these extravagant costs to something more possible. At this point the current systems being

used are more of a luxury item that not many establishments can have.

According to the parts list we have gathered the approximate cost of building this prototype is:

1. (1) Arduino Mega 2560 R3 Microcontroller $35.00

2. (1) Mini breadboard. $5.00

3. Wire jumpers. $5.00

4. (1)DFRobot LCD Keypad Shield. $11.00

5. (2) One-Wire Digital Temperature Sensor DS18B20. $9.90

6. (1) Fairchild Semiconductor N-Channel MOSFET (60V 30A). $1.95

7. (1) Clear Blue 5mm LED. $0.05

8. (1) Labvolt Variable Power Supply. $100.00

9. (10) Banana plug to alligator leads. $15.00

10. (4) Carbon-Fiber Strips (67cm x 1cm x 0.2cm). $19.80

Estimated Total: $202.70

8

So far the system being build is more economically feasible than most available systems. Since

this is only a prototype, weve had to buy the parts at retail cost. If the parts were to be purchased in

mass quantities (i.e. bulk) then we would certainly be able to build a lot more of these devices at a

cheaper price. In order to bring the price down to a respectable level; we would most likely have to

charge customers by the area (sq. ft.) of which they are trying to de-ice.

Certainly if the system were to be mass-produced and sold at reasonable prices I think there

would be a fair number of customers to purchase this product. The low price and easy-implementation

is a viable selling point compared to other systems currently on the market. Of course the right exposure

of the product is also necessary. Television ads, displays in popular stores and online marketing would

certainly be of great benefit. Current systems are so esoteric that they really arent advertised on a large

scale. This could be due to the fact that they are very expensive and very difficult to implement.

Environmental Consideration:

The system is being used outdoors so therefore there will be a large interaction with the

outdoor surroundings. As we have discussed, the system, when triggered heats up to a certain level and

proceed to melt the snow and ice. Therefore we see a possible risk of fire when using this device. For

example, there could be some dry, leaves/grass near the system and they could possibly catch fire on a

day where its dry but cold. We would have to keep the heating element of the system enclosed in a

thermally conductive but fireproof material.

There is also a risk of electricity shock. We are applying 120V

RMS

into

the DC power supply that provides the voltage/current to our system. If

there is a voltage/current running through the carbon then when exposed

the carbon could pose an electrical shock. Once again we would need to seal

the heating element and wiring off from the outside as much as possible.

We could definitely manufacture the system with these safety

precautions. In the product documentation, as well as on the product itself

we will note that there is a possible risk of burn and electrical shock if the

device is opened or used improperly.

Social Consideration:

Upon examination there are really no social impacts of the device. It does use electricity as its

main source of operation so some religions and lifestyles that forbid the use of electricity may be

affected.

9

Manufacturability Considerations:

The proposed system can certainly be manufactured using existing technology. Weve selected

the components to be as durable and effective as possible while still being reasonably simple to

manufacture and produce in large quantities. If the system were to be manufactured in large quantities

then the price per unit would certainly decrease.

For manufacturing we could buy raw carbon fiber in bulk and cut it down to the proper sizes

needed for each unit. Raw carbon fiber is certainly cheaper than the treated, polished versions out on

the market. Each of the microcontrollers could be bought and pre-programmed by the manufacturer

and implemented into the package. As far as service there would be a warranty.

The prototype is fairly reliable and straight forward. Scaling the prototype up would simply require using

larger components. The quality of the components however would still remain the same. If something

were to go wrong with a unit we could offer a warranty which would cover the parts and labor.

Future Improvement:

A few considerations to make the system more useable:

1. A moisture sensor to detect when snow/ice forms on the system thus turning the system on

based on temperature and moisture.

2. Manual access to turn the system on and off with wireless capability. For example turning the

system on with any wireless device such as a cellphone or laptop.

3. Display how long the system has been on over a certain period of time (hours, days, weeks).

4. How much power the system has consumed over an amount of time (kWh).

5. Recording this data for future reference.

Sustainability:

The proposed system can certainly meet the needs of the consumer in the short term as well as

the long term. Our system is meant to be used during the winter months in the temperate environments

and longer in the colder climates. In the short term the system certainly meets the needs of the

consumers. If we were to include the above improvements to the prototype then it would certainly

provide more than what is needed by the consumer in the short term with a lot of functionality. The

proposed improvements would make the system more useable thus has greater sustainability without

making it too complicated.

The proposed system is flexible enough to meet the changing needs of the environmental,

economic and social considerations. From these three it seems that the environmental factors are the

most crucial since we are designing a system for outdoor use. Therefore we must manufacture the

device to withstand the elements outdoors. Granted the system in portable and can be taken in during

the warmer months however it must be able to endure cold temperatures when it is used.

Upon reviewing the overall design so far we see the system being able to meet the changing

needs of consumers for the foreseeable future. After all weve designed it around these principles. We

wanted a system thats easy to use, easy to implement and relatively economical to acquire and

operate.

10

Ethical Considerations:

We will certainly note the proper operating conditions for the system as well as the inherit

health risks to the system. All data shown in this report will be available in the final products manual. All

of the data shall not be altered.

Health and Safety:

As we have discussed the possible risks to the public include electrical shock and burn hazards.

We must display warning labels and explain that these factors can be very dangerous if the system is

used improperly or mistreated. To protect the consumer from these risks we have to design the system

to be safe while being just as effective. All electrical components must be sealed off along with the

heating element. The heating element will be warm and also have electrical power running through it.

This is the most crucial item that cannot be exposed to the public.

In order for the system to be operated safely one must not have any exposed electrical wires or

components. Therefore the system shall not be opened under any circumstances. This includes the

heating element (carbon fiber), the power supply and the wires conducting the electricity to the system.

Possible injuries include electrical shock.

While the system is on the heating element can be a possible burn risk. Therefore while in

operation the heating element shall not be touched with bare skin. In order for safe operation the

heating element shall be left in the thermally conductive material that prevents accidental exposure.

If the system must be serviced then be sure that all electronic components are unplugged from

the source and the system has been unplugged for quite some time. If the system was hot and recently

unplugged then it could still provide a possible burn risk.

Political Consideration:

There doesnt seem to be any political considerations to be observed at this time.

11

We have designed the system using the aforementioned constraints. We would like it to be as

safe, reliable, economic and user-friendly as possible. With these constraints in mind we have made the

following choices for the system.

Carbon-Fiber:

This is our heating element or thermally conductive material. When voltage/current (power) is

applied then the material will heat up. Weve opted for this specific material over others because it is

extremely light in weight, rigid, durable and in large quantities relatively cheap. Obviously its not the

most economically feasible material but the attributes mentioned make up for the price. If this material

is implemented in a lot more systems today then it will be more economically feasible. In fact, its

already starting to be more feasible. Ten to twenty years ago such a material would have been a lot

more expensive. Today we were able to build a prototype that was relatively inexpensive.

We are only going to be designing the system with one carbon-fiber strip for simplicity. We want

to investigate how well it responds to our simulation and experimental results. If the results are

successful then we will consider it in the final system. We would just have to scale the number of strips

and power consumption up based on our results.

Electronic Components:

The main electronics components we have selected are the Arduino Mega 2560 R3, (2) One-

Wire Digital Temperature Sensor DS18B20, (1) Fairchild Semiconductor N-Channel MOSFET (60V

30A), (1)DFRobot LCD Keypad Shield, (1) 5mm clear blue LED and all of the necessary components to

connect these together.

The Arduino microcontroller is a versatile microcontroller with large exposure over many

people/countries. Since it has a large following there is a large selection of components for it at cheap

prices. Weve chosen an LCD shield to go with the microcontroller. A shield is simply a module that plugs

directly into the Arduino board to make it more useable. The LCD shield will be activated through

programming and will display the ambient temperature and system temperature.

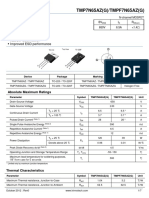

The temperature sensors we have chosen were seemed to be of high quality for our needs. They

have an operating temperature of (-55C to +125C) and the resolution (accuracy of each temperature

measurement) can be selected from 9-bits to 12-bits with the correct programming. More information

on these sensors can be found in the appendix.

Most importantly we have opted for an N-Channel Enhancement Mode MOSFET. This is another

critical portion in the design. It serves as a switch to our system to turn it on when the ambient

temperature reaches below a certain level (threshold) and to turn it off when the ambient temperature

reaches above a certain level. The MOSFET was chosen because it was much cheaper than other

solutions such as a relay (actual switch) and there are no moving parts to it. This means theres less

chance of failure than that of a relay which has moving parts.

12

Simulation:

Weve opted to use National Instruments LabVIEW as a simulation program. We have needed to

simulate temperature with respect to current and resistance in the heating element. In order to do this

we need to examine the equation as stated in the theory portion of this experiment.

2

t

The amount of heat is proportional to the current squared times the resistance of the heating

element. We wanted to model this in the program and see how the system would respond to certain

amounts of current at a fixed resistance. We are currently testing the system with only one carbon-fiber

strip. Before we can start the simulation we must take a preliminary measurement of the resistance of

the carbon strip to simulate in LabVIEW. We have measured the resistance of the strip to be

approximately 22. We record this value and note it for use in the simulation.

We want to simulate the voltage/current running through the resistive heating material.

Therefore we want to see how various values for the power correspond to temperature of the carbon

fiber. We start by creating a front panel in the LabVIEW program to accommodate our needs. The front

panel serves to control our values and display the information needed. 4 numeric indicators are placed

onto the front panel. These will display our Voltage (V), Current (I), Heat (Q) and Temperature (F). We

place a numeric control knob onto the front panel which will serve as our voltage control. The final front

panel can be seen in figure 1.

Please note that the values shown

are the default values at the start

of the simulation and does not

reflect the actual results that we

have obtained.

The front panel is just one

of two portions of the LabVIEW

simulation. We must also create a

block diagram to compute the

data for the given input on the

voltage control.

Figure 1 - The front panel of the simulation.

13

Please note a larger version of the block diagram can be found in the appendix.

Starting from left to right of the block diagram we have the voltage control input at point 1 as

noted. That voltage is displayed onto the numeric indicator at point 2. We know that current is

equivalent to the voltage divided by the resistance. Therefore voltage is divided by the resistance at

point 3 to obtain the current. The current is displayed on the numeric indicator at point 4.

We have stated that the heat(Q) is proportional to the amount of current squared multiplied by

the resistance. Therefore at point 5 we take the current and square it and multiply it by the resistance at

point 6. Heat is also a function of time so we add in time at point 7. We take the time and multiply it by

the current squared and resistance at point 8. The result is the amount of heat (Q) at point 9.

The next step is to convert the heat (Q) to temperature. We multiply the heat by a constant of

600 at point 10. We then take this value and divide it by 1.0x10

11

at point 11 to obtain proper values for

the Celsius temperature. At points 12, 13 and 14 we use the formula:

=

9

5

+32

This is to convert our Celsius temperature to Fahrenheit. At point 15 we display the Fahrenheit

temperature. We also display the temperature (F) on a visual thermometer at point 16.

Now that we have created a function block diagram we can begin to run the simulation and take note of

values for the voltage/current and temperature. For simplicity we will increase the voltage in 0.5 step

increments and record the value for the temperature, current and voltage.

Figure 2 - Block diagram of the simulation.

14

Upon running the simulation we record the following data:

Voltage

(V)

Current

(A)

Temperature

(F)

0.5 0.022 37.59

1 0.045 43.59

1.5 0.068 48.78

2 0.090 54.38

2.5 0.114 59.98

3 0.136 65.57

3.5 0.159 71.17

4 0.182 76.76

4.5 0.205 82.36

5 0.227 87.96

5.5 0.250 93.56

6 0.273 99.15

6.5 0.295 104.75

7 0.318 110.36

7.5 0.341 115.96

8 0.364 121.56

8.5 0.386 127.16

9 0.409 132.76

9.5 0.432 138.36

10 0.455 143.96

Figure 3 - Graph of the simulated results. Temperature (F) vs. Current(A)

15

From the graphical results in figure 3 we can see that as current increases then temperature

increases linearly. From the simulated results we note that a desirable temperature for the system (to

melt ice/snow) would be above 100F. Therefore we take note of this value and find that the minimum

voltage/current needed is around 6.5V/0.295A 7V/0.318A. This will produce a system temperature

around 104.75F 110.36F.

Another part of the simulation is to create the proposed circuit using circuit simulation software. The

program were accustomed to using is National Instruments Multisim.

We want to control the current running through the carbon fiber strip. When the ambient

temperature reaches below the threshold we want to allow the current to flow through the carbon-

strip. When the ambient temperature is above the threshold we want to block the current from flowing

through the resistor. This is where the use of the N-Channel MOSFET comes in. We technically want to

use it as a switch.

The MOSFET will be controlled via the Arduino. The Arduino gives off 5V from each pin and the

portion of the MOSFET that allows us control is the gate. We connect an Arduino pin to the gate of the

MOSFET. This is represented by the 5V on the circuit diagram. We also connect a 10k resistor in series.

The use of this resistor is referred to as a pull-down resistor. It keeps the gate in an off or low state

when the Arduino doesnt send a signal. The gate of the MOSFET can be thought of as a door.

The drain of the MOSFET is connected to one end of our carbon-fiber strip, represented with the

22 resistor, R2 in figure 4. The other end of the carbon-fiber strip is connected in series to our main DC

power supply.

The source of the MOSFET is connected to the ground and to the negative of the DC power

supply. From the diagram we can see how current can freely flow through the N-Channel MOSFET when

activated which means the temperature will increase in the carbon-strip. However when non-activated

the current loop is blocked and there will be no voltage/current running through the carbon strip,

meaning there will be no temperature.

When the Arduino pin is activated the current will be allowed to flow through the carbon-fiber

thus heating it up. When the Arduino pin is deactivated then the current is blocked allowing the carbon-

fiber to cool down. In order to accomplish this task we must program the Arduino controller during the

experiment.

Figure 4 - Circuit diagram in Multisim.

16

Experimental Setup/Procedure:

Now that we have our components and what is to be done we can start the experiment. We

begin by connecting the components to the microcontroller and writing a program. Please note that the

full program written can be found in the appendix. First we visualize what we want the LCD to display to

us. We make a decision that the current ambient temperature and system temperature are an ideal

approach. The ambient temperature will give us information on what threshold temperature to

program. The system temperature will help us compare our simulated results and see how well carbon

fiber strip heats up.

An example of the format for the LCD is as follows:

Amb.Temp: 81.60F

Sys.Temp: 104.43F

We will read from both temperature sensors. One sensor will be the ambient temperature and

the other will be the system temperature. Now that we have the format we will begin trying to

implement it onto the microcontroller by programming it. Before we setup the temperature sensors we

begin with writing the basics for the program. Therefore we start with the basic structure of an Arduino

program. We use the blink program from the Arduino site to get ourselves acclimated with the

structure. The basic structure of an Arduino program or sketch as they refer to it

3

and the test

program can be found in the appendix (1-1). This example program is taken directly from the Arduino

website. Its usually to give individuals of how the overall structure of an Arduino sketch works.

With that being said, we declare our variables before the void setup() structure. Since we want to use an

LCD to display our data we must include the header file #include <LiquidCrystal.h>. The header file

allows us to easily read/write to any LCD based on the Hitatchi HD44780 (or compatible) chipset

4

. Our

LCD is based on this chip set and the information for our specific display can be found in the Appendix.

The next step is to actually define the pins that the LCD is using. These pins will be where we

control the LCDs hardware (i.e. the backlight and power), transmit data and receive data. To do this we

take note of where the LCD is plugged into the board. We also double check which pins to activate by

referring to the manufacturers website

5

. We find that the pins we need to declare are 8,9,4,5,6,7.

Therefore the code is: LiquidCrystal lcd(8, 9, 4, 5, 6, 7);

We do a bit of testing to see if the LCD is transmitting and receiving data. We write a hello

world sketch to test it out by using the above commands. This code can be found in the appendix (1-2).

We upload the above code to the board and confirm that its working. Now we can begin to get our

format for the LCD to suit our project. As stated, we would like to display ambient temperature and

system temperature. With testing and trial an error we were able to get the text into the proper area of

the display. We are finally able to get the format needed by using the code weve written

3

http://arduino.cc/en/Tutorial/blink

4

http://arduino.cc/en/Reference/LiquidCrystal

5

http://www.dfrobot.com/index.php?route=product/product&product_id=51#.UYPNQsr9dGg

17

At this point in the project, we must display the temperature from the two digital temperature

sensors. The temperature sensors are called the DS18B20, 1-Wire temperature sensor. They are

referred to as 1-Wire because it only requires on pin from the Arduino to run multiple sensors. This

means we can take two different measurements (using two sensors) all on one single pin. Before we can

begin to take measurements we must install the libraries given by the manufacturer. The libraries

contain much needed information to actually read/write information to the Arduino.

We must connect the digital temperature sensors together. We have

already connected a jumper wire from digital pin 52 to the breadboard. Pin 1 of the

temperature sensor is connected to the ground. The jumper wire going from pin 52

is connected to pin 2 of the temperature sensor. This is the information being sent

and received. Pin 3 of the temperature sensor is connected to one of the Arduinos

dedicated 5V voltage ports.

In order to connect the other temperature sensor (for the system) we run

wire from pins 1, 2 and 3 respectively. Essentially we are connecting both

temperature sensors in series. We use jumper wires and connect them to a

different point on the breadboard. An long jumper wire is connected from this

point to the temperature sensor to read the value of the temperature on the

carbon-fiber strip.

Now that the temperature sensors have been connected, we must add in

the N-Channel MOSFET. This will serve as the switch for our system. The MOSFET

is placed onto a point on the breadboard whereas not to interfere with the

temperature sensors. We first run a jumper wire from pin 53 to the breadboard.

From this point of the breadboard to the gate of the MOSFET, we connect a 10k

resistor as shown in figure 4 of the circuit diagram on page 14. We then connect a

wire from the drain and tie the source to ground and leave another wire available.

These extra wires will be connected to the carbon fiber strip later on.

As an added feature we add an LED light onto the breadboard. Pin 22 from

the Arduino to the LED is connected and a 1k resistor is used to prevent the LED

from receiving too much current and shorting out. This LED will serve as an

indicator of when the system is currently active and when the system is inactive.

When the system is active the LED will be on or HIGH and when the system is inactive the LED will be off

or LOW.

All electronic components for the Arduino have been connected. This concludes the hardware

portion of the microcontroller. Now we must program the Arduino to correspond with all of the newly

added hardware. This includes reading/writing from the temperature sensors to the LCD, activating the

MOSFET when necessary and activating the LED indicator to show us the status of the system.

Figure 5 - Pin

configuration of

the DS18B20

temperature

sensor. (From

Manufacturer

Datasheet).

18

To read/write information from the temperature sensors we will need two libraries called

DallasTemperature.h and OneWire.h. Once these libraries are properly put into the right directory of our

Arduino folder on our computer we can begin to write the program needed. For the first part of the

program we include the Liquid Crystal library as before. Now we add the OneWire library and

DallasTemperature library. After the header files we must declare which pins we are going to use for

the temperature sensors. Since these are digital temperature sensors, we select a digital port on the

Arduino Mega 2560 board. The one we choose is pin 52. Since we have chosen pin 52, we connect a

wire from pin 52 to the breadboard.

The next step is to write the program to accommodate the digital temperature sensors. We

write the code just after the header files and before the void setup() routine as shown in the appendix

(1-4). Now that we have the proper definitions for the sensors to be used on the same pin we must find

which address (location) each sensor sends/receives information from on the board. To do this an

Arduino sketch called OneWire Address Finder is used. The full program can be found in the appendix.

We run it and take note of the addresses found. We take these addresses and insert them into our

sketch and give them names amb and sys.

At this point in the program we have define all of the necessary variables to read/write the

temperatures onto the LCD display. The next step is to do some fine tuning and make sure the program

outputs what information we need. Under the void setup() routine we define the resolution of the

temperature sensors to be 12-bit. This means that they will be more accurate in each of the

measurements taken. This part of the code can be seen in the appendix (1-4).

These commands are proprietary with the use of the DallasTemperature.h library. If we didnt have the

library installed then we could not use these commands. Another command we must also include is to

initialize the sensors to start taking measurements once the board is powered on.

The original formatting for the LCD is remained in-tact under the void setup() routine as done

previously. The next step is to constantly read and write the temperatures and display them. This has to

be done under the void loop() routine. This section of the program runs over and over again. It never

stops until the board is turned off or reset. First we use the command sensors.requestTemperatures();

to activate each sensor within the loop. This retrieves the temperature measurement from the sensor.

We then position the text to be between Amb.Temp: (number value here) F.

The command sensors.getTempCByIndex(sensor) is the command to display the temperature .

The default value is in Celsius. Therefore we must use this command along with the formula for

converting from Celsius to Fahrenheit to get the proper value for the ambient temperature as shown in

appendix 1-4. The temperature is then put into the variable ftemp1 and finally we add a delay of

100ms to properly space each measurement. This is so we dont have rapidly fluctuating temperatures

being displayed on the screen and were able to read what is being displayed.

We write similar code for the system temperature sensor. The only difference is that we set the

cursor for the second line of text, change the value for the sensor to 0 in the

sensors.getTempCByIndex(sensor) command and the value is stored into ftemp2.

19

The sketch is uploaded to the board and we observe the output on the LCD. We currently read

the ambient temperature with the sensor on the breadboard and the system temperature with the

sensor thats connected to the extra-long jumper wire thats also connected to the other point on the

breadboard. We place our hand on each sensor separately and observe the temperature increasing.

Now that we can read/write values for the temperature; the program must be adjusted to regulate the

MOSFET based on temperature and turn the LED on and off. To do this we must first define the pins

weve connected the MOSFET and LED to before the void setup() in the program by defining pins 22 and

53, respectively. We initialize pins 22 and 53 and give them the names ledPin and relayPin

respectively. Despite the fact we are not using a relay we call it relayPin because of its relay-like action.

Once the pins have been declared we must make sure these two pins are set as outputs. If not

then we will not be able to use them for our purposes. Under the void setup() structure of the sketch we

place the following code while retaining the rest as shown in appendix 1-4.

The pins weve needed have been setup as outputs. The final step is to add the code to the void loop()

structure to activate the LED and MOSFET when the ambient temperature reaches a certain level which

is the goal.

If you recall the ambient temperature sensor is ftemp1. In this case we have set the threshold

temperature to be 82 degrees which was the room temperature at time of testing. If the ambient

temperature is less than 82 degrees than the ledPin (connected to the LED) is set to high indicating the

system is on. Also the relayPin (connected to the MOSFETs gate) is set to high. When this occurs the

gate opens allowing current for our DC power supple to flow through.

If the ambient temperature is above the threshold programmed (82) then the LED pin will be set

to LOW and the LED will turn off. Likewise the pin connected to the MOSFETs gate will close thus

preventing current from flowing through the loop of our system. This concludes the programming

portion of the microcontroller. The full code can be found in the appendix.

20

Testing:

Now that microcontroller has been programmed to meet our needs and weve obtained all parts

we must connect all components and run the experiment. The power supply we will be using is an

adjustable Labvolt AC/DC power

supply. However before we connect

the microcontroller to the system we

want to see how the carbon-fiber

responds to the voltage/current

running through it. We want to

measure the temperature and note

the values at each value for the

voltage and see if they correspond to

the simulated results. We will only be

using the microcontroller at this

point the measure the temperature

of the carbon fiber strip.

Recall in the simulation that

the beginning temperature was 32F.

In the actual experiment this is not

true since we are starting at room

temperature. Therefore we will start

at 4.5V and go up to 10V to alleviate any discrepancies. Once again we have measured the resistance of

the carbon-fiber strip which was found to be approximately 22. Next, we apply voltage/current to the

strip at 4.5V and wait for approximately 1-2 minutes for it to reach maximum temperature as we

observe on the LCD display. We do this for each of the voltages in 0.5V increments and note the values

in the table below:

Voltage

(V)

Current

(A)

Temperature

(F)

4.5 0.205 85.52

5 0.227 90.47

5.5 0.250 94.42

6 0.273 98.34

6.5 0.295 101.16

7 0.318 104.89

7.5 0.341 110.13

8 0.364 115.58

8.5 0.386 121.60

9 0.409 126.74

9.5 0.432 131.21

10 0.455 136.95

Figure 6 - Testing the carbon-fiber strip in the lab.

Figure 7 - Graph of the experimental results.

21

Upon examining the data from the experiment and comparing it to the simulation, we can see

they are strikingly similar. On each measurement for the voltage there is only about a +3F difference.

From the data as well as physical contact with the system weve found any voltage above 7V to be too

hot and unstable. By unstable we mean the connectors going from the power supply to the carbon-strip

were getting too hot and would was becoming a fire hazard.

Now that we have successfully tested the carbon-fiber strip with the proper voltages we can

begin to connect the entire system together. To do that we must first visualize how everything will be

connected. We start by creating a block diagram for the system as shown in figure 7.

From this block diagram we can also create another model using a program called Fritizing. Fritzing is

used to make a visual representation of an Arduino project.

Figure 8 - Block diagram for the system.

Figure 9 - Fritzing model of the system.

22

Discussion/Conclusion:

Following these diagrams, we are able to connect the working system, test it extensively and

demonstrate it in front of the class. Further testing included taking some crushed ice and placing it onto

the carbon-fiber strip. It took approximately 3-minutes to melt the ice. Unfortunately this project was

complete around the middle of April when the snow had ceased in the region where the system was

being tested.

From testing we have successfully created what we have intended. An electric deicing system

with carbon-fiber has the heating element. Its automatically regulated based on environmental

(ambient) temperature. This is just the basic system. There is much more room for several

improvements. For example, we could add a moisture sensor to detect when snow/ice forms on the

system thus activating it. Also we thought that there could be monitoring of the system, wirelessly from

a device that is compatible, such as a cell phone or laptop.

If this device were to be used in a residential setting then provisions would have to be made in

order to make it safe to use with the public. For example the strips would have to be planted into a

material we have selected to be SBR (Styrene-Butadiene Rubber).

Some Properties of SBR

6

:

Durometer or Hardness Range

30 95 Shore A

Tensile Strength Range

500 3,000 PSI

Elongation (Range %)

450 % 600 %

Abrasion Resistance

Excellent

Adhesion to Metal

Excellent

Adhesion to Rigid Materials

Excellent

Compression Set

Good to Excellent

Flex Cracking Resistance

Good

Impact Resistance

Excellent

Resilience / Rebound

Good

Tear Resistance

Fair to Excellent

Vibration Dampening

Fair to Good

Another important factor of this rubber are the thermal properties.

6

http://www.robinsonrubber.com/pdfs/StyreneButadieneRubber.pdf

23

Thermal Properties:

Low Temperature Range: - 60 F to -

30 F

Minimum for Continuous Use (Static):

- -60 F

Brittle Point: - -80 F

High Temperature Range: + 210 F to

+ 250 F

Maximum for Continuous Use

(Static): + 225 F

From these properties we see that its an ideal material to be used for the finished product.

Another factor to consider is that the more area covered would mean more power consumed. If there is

a large area such as a driveway then the carbon strips would certainly need to be longer. That would

mean a need for a larger power supply.

Primarily, we were using 7V/0.3A for the experiment. This equates to approximately 2.1W.

Using this information we can do an analysis of the power for the system weve built:

2.1W/s for 1 min. = 126W to operate for 1 min.

2.1W/s for 1 hour = 7.560kW to operate for 1 hour.

2.1 W/s for 1 day = 18.1kW to operate for 1 day.

This is just for one strip. If we were to scale the system up and use even more strips then the average

amount of kilowatts used would dramatically increase. For one strip we are already at the equivalent

kWh usage for an electric stove.

7

That doesnt seem very efficient considering the size of the carbon-

fiber strip. Most likely such a system wouldnt be marketable even though it seems to surpass current

systems in terms of execution and feasibility.

7

http://www.efficiencyvermont.com/for_my_home/ways-to-save-and-

rebates/appliances/refrigerators/general_info/electric_usage_chart.aspx

Figure 10 - Concept image of the final system.

24

Scalability:

We are interested in seeing if the system weve built can be scaled up easily. By scaled up we

mean the total area we can cover with our prototype system. For scalability we want to use the same

size strips and see how large of an area we can cover with this unit size. We have tried expanding the

setup using two strips in parallel spaced evenly apart. From the prototype weve had the strips spaced

approximately 10cm (~3.93in.) apart. The reason for this amount of spacing is the even number, 10 can

be calculated easily with any number of strips. Also the amount of heat generated remains in a small

area allowing for greater ice dissipation. If the strips were to be farther apart (as tested) the heat will

not be concentrated enough and thus not efficient. If theyre too close then we will need a lot more

strips thus driving up the cost of the prototype and the amount of energy used.

From previous measurements we know that each strip is 0.67m x 0.01m x 0.002m. Therefore we

can calculate the total area covered by the prototype. Were using two strips spaced 10cm apart. So the

area covered is calculated to be:

=

= 0.67

= 2 (0.01) +0.1 = 0.12

= (0.67)(0.12) = 0.0804

All lengths are in meters to alleviate confusion in calculation. The total area covered from our prototype

is 0.0804m

2

. We would like to see how much more area can be covered using this prototype before we

need to expand the number of components such as the microcontroller, MOSFET, etc.

The components arent ideal as with anything applied to a realistic scenario. Theoretically we

can use single components to control an infinite number of systems. However when we actually build

the circuit, its limited. The primary component that controls the system (beside the microcontroller) is

the N-Channel MOSFET. The MOSFET is a logic gate and the number of inputs to a realistic logic gate is

limited. This is referred to as fan-out. A perfect logic gate would have infinite input impedance and

zero output impedance, allowing a gate output to drive any number of gate inputs. However, since real-

world fabrication technologies exhibit less than perfect characteristics, a limit will be reached where a

gate output cannot drive any more current into subsequent gate inputs - attempting to do so causes the

voltage to fall below the level defined for the logic level on that wire, causing errors.

8

That being said, we must find the maximum number of inputs to our N-Channel MOSFET for

scalability. We certainly cannot connect any number of strips we need to the current prototype with the

idea of fan-out. The current MOSFET were using is rated at 60V/30A which is the maximum load.

Therefore our current prototype can be scaled up to use 60V/30A using one MOSFET and the proper

number of strips.

To test the prototype with two strips weve used our own 5V/12A power supply. Two strips

were connected in parallel to the power supply and to the MOSFET as in the original design. We find

that the amount of current running through each strip is approximately 0.23A. The MOSFET is rated at

60V/30A. Therefore we take the total current that the MOSFET is rated at and divide it by the amount of

current in each strip:

30

0.23

= 130.43 130

8

https://en.wikipedia.org/wiki/Fanout

25

We calculate the number of strips supported by our MOSFET to be 130. This is the absolute

maximum number of strips we can use at this voltage before it begins to fail. To calculate the amount of

area covered by 130 strips of our size we do the same as with two strips. However we can expedite the

process by deriving an equation for the vertical height using the number of strips, number of spaces,

height of each strip and the vertical spacing of each strip:

[( ) +( 1) ()]

Where:

n = Number of strips

H = height of each strip (m)

n-1 = Number of spaces

y = vertical spacing of each strip (m)

L = Length of each strip

For our specific MOSFET we have calculated the number of strips (n) to be 130. The height of each strip

is 0.01. The number of spaces is simply 1 less than the number of strips and the vertical spacing of each

strip was selected to be 0.1m apart. So, we plug these numbers into the above function and obtain:

[(130 0.01) +(129) (0.1)] 0.67

This is equivalent to 9.66m

2

. This is the maximum amount of area that can be covered with one N-

Channel Enhancement mode MOSFET rated at 60V/30A. However the power supply used to test the

system only has a maximum current draw of 12A.

=

1

1

22

1

=

1

1

22

50

1

0.44

=

=

5

0.44

11.36

With the 5V/12A power supply we would only be able to use approximately 50 strips. 50 strips would

only cover an area of 3.618m

2

using the above equation for area. Therefore we would need a bigger

power supply rated at 30A or above to cover the area of 9.66m

2

with 130 strips. We would like to get

the maximum use out of each component as possible.

26

Scalability Example:

We would like to cover a driveway of approximately 34.82m

2

. Obviously we cannot use the

same exact prototype that we have built. We must add more to it to accommodate this larger size. We

have calculated the maximum area to be 9.66m

2

using the prototype system coupled with a 5V/30A (or

more amperage) power supply. Therefore we will need nearly 4 times as much from the prototype to

cover this driveway.

To figure out exactly what is needed the proper calculations using the above equation must be

done:

A (Area to be covered) (m

2

) = 34.82.

H = height of each strip (m) = 0.01

y = vertical spacing of each strip (m) = 0.1

L = length of each strip (m) = 0.67

34.82 = [( 0.01) +( 1) (0.1)] 0.67

34.82 = 0.0737( 0.909091)

Upon solving for n:

n = 437.365 437 strips.

So, for this size of area we would be approximately 437 strips. From the prototype we know that the

maximum number of strips supported by one MOSFET is 132. The amount of MOSFETS we need for the

driveway is:

437

132

= 3.31 4

The microcontroller and its 52 digital ports are certainly capable of switching 4 N-Channel MOSFETS.

Also the increased number of MOSFETs is not a problem seeing as how theyre only $0.95 each at the

consumer level. However the number of carbon-strips can be quite costly. The strips purchased for the

prototype are $4.95 each. 437 strips at $4.95 equates to $2163.15. This already is an extravagant price

for the average homeowner looking for a deicing solution to a small area.

Aside from the amount of strips needed to cover the area we must consider the power

consumption to cover the driveway. For the prototype we only used 5V/0.4A which is equivalent to

2.0W. For the driveway we have 437 strips (22) in parallel so we must calculate the total resistance to

find the amount of amperage needed. To find this, we use the formula:

=

1

1

22

1

=

1

1

22

437

1

0.050

Where n is the number of strips.

Then we take the number for the resistance and input it into Ohms Law combined with the power

supply voltage:

27

=

=

5

0.050

= 100

Therefore we have a requirement of a 5V/100A power supply. To generate this amount of power is not a

problem. There are many power supplies currently available to deliver this much voltage and current

and even more if needed.

9

The average computer power supply is around 400-600W. So in terms of

power usage this system could be seen as the equivalent to a desktop computer.

However we would like be smart about using all of this power. Having the system on all of the

time would be a complete waste. Also, what if certain areas have ice/snow and others did not? Keep in

mind for the driveway we are using 4 MOSFETs each being regulated by one microcontroller. That

means the total system for the driveway is broken up into four parts. Each of these parts can have a

moisture sensor. Now granted our original prototype did not have this however this can be noted under

the improvements. If there is moisture (snow/ice) in one section then the system can be triggered thus

causing the snow/ice to melt while leaving the others sections alone. This seems more sensible instead

of regulating the system as a whole based on temperature. Breaking up the entire system into sections

and having each regulated by moisture and

Based on the cost of the electronics, carbon-strips and power usage the prototype scaled up doesnt

seem that cost-effective. To build this drive way prototype we would nearly have to spend in excess of

$3,000. Approximating the costs:

1. $2,200.00 437 Carbon strips

2. $200.00 5V/100A Power Supply

3. $700.00 SBR Rubber.

4. $4.00 4 N-Channel MOSFET

5. $50.00 Arduino Microcontroller

6. $20.00 Wire

7. $40.00 Miscellaneous electronic parts

Total: $3214.00.

This amount of money combined with the electrical usage and complexity doesnt really seem

economically feasible for the average citizen when compared to shoveling snow manually. However it

depends solely on the individual and their financial situation. At this price range the system can be seen

as a luxury device such as a big screen 3D television or a hot tub. Both are complex, cost a lot to operate

and have initially high purchase prices. We think that the target market would be residents of upscale

neighborhoods rather than an average income neighborhood.

Since there are more average income users than above-average income users in many places we

dont think it would be ideal to build such a device. For such an expensive/extravagant system there

doesnt seem to be a large enough target market to defray the cost of manufacturing. That being said I

would personally not recommend building such a system.

9

http://www.ebay.com/sch/i.html?_trksid=p4069.m570.l1313.TR0.TRC0&_nkw=5V%2F120A+power+supply&_saca

t=0&_from=R40

APPENDIX

1

1-1

/ /

Bl i nk

Tur ns on an LED on f or one second, t hen of f f or one second, r epeat edl y.

Thi s exampl e code i s i n t he publ i c domai n.

/ /

/ / Pi n 13 has an LED connect ed on most Ar dui no boar ds.

/ / gi ve i t a name:

i nt l ed = 13;

/ / t he set up r out i ne r uns once when you pr ess r eset :

voi d set up( ) {

/ / i ni t i al i ze t he di gi t al pi n as an out put .

pi nMode( l ed, OUTPUT) ;

}

/ / t he l oop r out i ne r uns over and over agai n f or ever :

voi d l oop( ) {

di gi t al Wr i t e( l ed, HI GH) ; / / t ur n t he LED on ( HI GH i s t he vol t age l evel )

del ay( 1000) ; / / wai t f or a second

di gi t al Wr i t e( l ed, LOW) ; / / t ur n t he LED of f by maki ng t he vol t age LOW

del ay( 1000) ; / / wai t f or a second

}

1-2

#i ncl ude <Li qui dCr yst al . h>

Li qui dCr yst al l cd( 8, 9, 4, 5, 6, 7)

voi d set up( )

{

Lcd. begi n( 16, 2) ; / / posi t i on of LCD t ext i n t he pr oper ar ea

l cd. pr i nt ( Hel l o Wor l d) ; / / pr i nt t ext t o t he LCD

}

voi d l oop( )

{

/ / not hi ng goes her e yet

}

1-3

#i ncl ude <Li qui dCr yst al . h> / / i ncl ude t he LCD Li br ar y

Li qui dCr yst al l cd( 8, 9, 4, 5, 6, 7)

voi d set up( )

{

l cd. begi n( 16, 2) ; / / Posi t i on of LCD t ext i n t he pr oper ar ea

l cd. pr i nt ( " Amb. Temp: " ) ; / / Pr i nt t he f i r st measur ement ' s desi gnat i on

l cd. set Cur sor ( 14, 0) ; / / Posi t i on t he cur sor

l cd. pr i nt ( " F" ) ; / / Temper at ur e uni t desi gnat i on

l cd. set Cur sor ( 0, 1) ; / / Posi t i on t he second l i ne of t ext

l cd. pr i nt ( " Sys. Temp: " ) ; / / Pr i nt t he second measur ement ' s desi gnat i on

l cd. set Cur sor ( 14, 1) ; / / Posi t i on t he cur sor

l cd. pr i nt ( " F" ) ; / / Temper ar t ur e uni t desi gnat i on

}

voi d l oop( )

{

/ / not hi ng goes her e yet

}

2

1-4

#i ncl ude <OneWi r e. h> / / The Temper at ur e Sensor Li br ar y

#i ncl ude <Dal l asTemper at ur e. h> / / The Temper at ur e Sensor Li bar y ( Fr omManuf act ur er )

#i ncl ude <Li qui dCr yst al . h> / / The Li qui d Cr yst al Li br ar y

/ / I ni t i al i zat i ons

#def i ne ONE_WI RE_BUS 52 / / Set s t he t emp sensor s t o r ead f r ompi n 52

Li qui dCr yst al l cd( 8, 9, 4, 5, 6, 7) ;

OneWi r e oneWi r e( ONE_WI RE_BUS) ;

Dal l asTemper at ur e sensor s( &oneWi r e) ;

doubl e f t emp1;

doubl e f t emp2;

i nt l edPi n = 22; / / I ni t i al i ze t he di gi t al por t usi ng t he LED

i nt r el ayPi n = 53; / / I ni t i al i ze t he vol t age por t

Devi ceAddr ess amb = { 0x28, 0xE3, 0xEA, 0x51, 0x04, 0x00, 0x00, 0xC0 }; / / Def i ne

Addr ess of Ambi ent Temper at ur e Sensor

Devi ceAddr ess sys = { 0x28, 0x1D, 0xF3, 0x52, 0x04, 0x00, 0x00, 0xA6 }; / / Def i ne

Addr ess of Syst emTemper at ur e Sensor

/ / Set up

voi d set up( )

{

Ser i al . begi n( 9600) ; / / St ar t t he ser i al moni t or

sensor s. set Resol ut i on( amb, 12) ; / / Ambi ent Sensor has 12- Bi t Resol ut i on

sensor s. set Resol ut i on( sys, 12) ; / / Syst emSensor has 12- Bi t Resol ut i on

/ / Temp Sensor

sensor s. begi n( ) ; / / Read f r omt he sensor l i br ar y

/ / Pi ns

pi nMode ( 22, OUTPUT) ; / / Tur ns of f 33k pul l up r esi st or

pi nMode ( 53, OUTPUT) ; / / Tur ns of f 33k pul l up r esi st or

/ / LCD Set t i ngs

l cd. begi n( 16, 2) ; / / Posi t i on of LCD t ext i n t he pr oper ar ea

l cd. pr i nt ( " Amb. Temp: " ) ; / / Pr i nt t he f i r st measur ement ' s desi gnat i on

l cd. set Cur sor ( 14, 0) ; / / Posi t i on t he cur sor

l cd. pr i nt ( " F" ) ; / / Temper at ur e uni t desi gnat i on

l cd. set Cur sor ( 0, 1) ; / / Posi t i on t he second l i ne of t ext

l cd. pr i nt ( " Sys. Temp: " ) ; / / Pr i nt t he second measur ement ' s desi gnat i on

l cd. set Cur sor ( 14, 1) ; / / Posi t i on t he cur sor

l cd. pr i nt ( " F" ) ; / / Temper ar t ur e uni t desi gnat i on

}/ / Set up Cl osur e

/ / Loop

voi d l oop( ) {

/ / Ambi ent Temp Sensor Readi ng/ Wr i t i ng

sensor s. r equest Temper at ur es( ) ; / / Send t he command t o get t emper at ur es

l cd. set Cur sor ( 10, 0) ;

f t emp1 = ( ( sensor s. get TempCByI ndex( 1) * 1. 8) + 32. 0) ; / / Conver t s t he t emp r eadi ng F

l cd. pr i nt ( f t emp1) ; / / pr i nt t he f i r st r eadi ng f r omt he f i r st sensor

del ay( 100) ;

/ / Syst emTemp Sensor Readi ng/ Wr i t i ng

sensor s. r equest Temper at ur es( ) ; / / Send t he command t o get t emper at ur es

3

l cd. set Cur sor ( 10, 1) ; / / posi t i on t he l cd t ext

f t emp2 = ( ( sensor s. get TempCByI ndex( 0) * 1. 8) + 32. 0) ; / / Conver t s t he t emp r eadi ng F

l cd. pr i nt ( f t emp2) ; / / pr i nt t he second r eadi ng f r omt he second sensor

del ay( 100) ;

/ / Cont r ol St r uct ur e - LED I ndi cat or

i f ( f t emp1 < 82) / / Tur ns t he syst emon l ess/ equal t o t hi s val ue

{

di gi t al Wr i t e( l edPi n, HI GH) ; / / set s t he LED t o 1 ( syst emon i ndi cat or )

di gi t al Wr i t e( r el ayPi n, HI GH) ; / / Set s t he V1 pi n t o hi gh

}

el se i f ( f t emp1 > 82)

{

di gi t al Wr i t e( l edPi n, LOW) ; / / Tur ns t he syst emof f i f above condi t i on i s not met

di gi t al Wr i t e( r el ayPi n, LOW) ; / / Set s V1 pi n t o l ow

}

}/ / Loop Cl osur e

You might also like

- TEC1-12706 Thermoelectric Converter - ENDocument9 pagesTEC1-12706 Thermoelectric Converter - ENtimtomtheoNo ratings yet

- Heatsink CalculationsDocument7 pagesHeatsink Calculationsram mohanNo ratings yet

- How To Read PWHTchartDocument10 pagesHow To Read PWHTchartAkhilesh Kumar100% (2)

- Literature Review of Temperature Controlled FanDocument8 pagesLiterature Review of Temperature Controlled Fanafmzslnxmqrjom100% (1)

- On-Chip Temperature Control Circuit Using Common Devices: MSEE Project ReportDocument26 pagesOn-Chip Temperature Control Circuit Using Common Devices: MSEE Project ReportWajid KhattakNo ratings yet

- Section 6: Heat Transfer: Autodesk Simulation WorkshopDocument25 pagesSection 6: Heat Transfer: Autodesk Simulation WorkshopMiguel Angel Munguia FloresNo ratings yet

- Project: Automatic Dcfan Controller Using ThermistorDocument18 pagesProject: Automatic Dcfan Controller Using ThermistorYan Mg MgNo ratings yet

- Control Systems-6511663495929481Document8 pagesControl Systems-6511663495929481Jayanth C VNo ratings yet

- Skin Effect Heat Tracing SpecDocument10 pagesSkin Effect Heat Tracing SpecSaraswatapalitNo ratings yet

- Heat Trace Fundamentals: Types, Monitoring, and Control OptionsDocument9 pagesHeat Trace Fundamentals: Types, Monitoring, and Control OptionsGanesh GanyNo ratings yet

- All About The Design of HeatsinksDocument40 pagesAll About The Design of Heatsinks조용규No ratings yet

- Centralized Alarm/Temperature Control System: Project #17Document8 pagesCentralized Alarm/Temperature Control System: Project #17Karthik VaniNo ratings yet

- 1456064976_313SDocument8 pages1456064976_313SSam SamNo ratings yet

- Tep 0013Document19 pagesTep 0013AdelChNo ratings yet

- PRJP - 1527Document7 pagesPRJP - 1527MD. Rajob AliNo ratings yet

- Air Conditioning Thesis StatementDocument7 pagesAir Conditioning Thesis Statementewdgbnief100% (2)

- 5 AbstractDocument13 pages5 AbstractIntanbyzuri ARNo ratings yet

- Elmer TutorialsDocument81 pagesElmer TutorialsPutri Nur CahyantiNo ratings yet

- Circuit DescriptionDocument6 pagesCircuit DescriptionBala MuraliNo ratings yet

- Lab Project ReportDocument18 pagesLab Project ReportDebjit SarkarNo ratings yet

- Arduino Solar Water Heater Controller: An Emergency ProjectDocument28 pagesArduino Solar Water Heater Controller: An Emergency Projectpetro2810No ratings yet

- Mathematical Modelling of Processor HeatingDocument19 pagesMathematical Modelling of Processor HeatingRaees (F-Name Khuda Baksh)No ratings yet

- Heat SensorDocument4 pagesHeat Sensorsharukh100% (1)

- Rooftop Wiring Methods and Temperature CorrectionDocument10 pagesRooftop Wiring Methods and Temperature CorrectionC GonzoNo ratings yet

- Tep 0013Document20 pagesTep 0013Ajay TiwariNo ratings yet

- Machine Overheat Detection and Control System Using ArduinoDocument37 pagesMachine Overheat Detection and Control System Using ArduinoTemmietope Horpeyemmie80% (5)

- An Automatic Temperature Monitoring and Control System For Electric Power Distribution PanelDocument5 pagesAn Automatic Temperature Monitoring and Control System For Electric Power Distribution PanelEditor IJTSRDNo ratings yet

- Project Report: Water Temperature ControllerDocument13 pagesProject Report: Water Temperature ControllerMuhammad OmerNo ratings yet

- Chapter 7 Thermal DesignDocument28 pagesChapter 7 Thermal DesignettypasewangNo ratings yet

- Temperature Sensor ThesisDocument5 pagesTemperature Sensor Thesiss0kuzej0byn2100% (2)

- Thermocouple Measurement DeviceDocument3 pagesThermocouple Measurement DeviceylmalaverNo ratings yet

- Power Electronics Thermal Limits and How To Not Exceed ThemDocument14 pagesPower Electronics Thermal Limits and How To Not Exceed ThemRodrigo Aguilar VillasecaNo ratings yet

- Polyfuse: A Seminar Report OnDocument22 pagesPolyfuse: A Seminar Report OnVinodNo ratings yet

- Optimizing Electric Heat Tracing SystemsDocument6 pagesOptimizing Electric Heat Tracing Systemsjavad100% (1)

- Ece Polyfuse ReportDocument24 pagesEce Polyfuse ReportHarshit SinghNo ratings yet

- Hydronic Design and Installation ManualDocument68 pagesHydronic Design and Installation Manualapi-74956698No ratings yet

- Flyer Mtec Ept202foDocument6 pagesFlyer Mtec Ept202foenriqueunoNo ratings yet

- Heat Cable Installation GuideDocument20 pagesHeat Cable Installation GuidethermaltechnologiesNo ratings yet

- Thermostat Using Ic 741: A Project Report OnDocument13 pagesThermostat Using Ic 741: A Project Report OnJaiprakash GuptaNo ratings yet

- Basics of Instrumentation & ControlDocument29 pagesBasics of Instrumentation & ControlprathmeshNo ratings yet

- Mini Automated Refrigerator: Mahatma Gandhi Mission'S College of Engineering and Technology NoidaDocument25 pagesMini Automated Refrigerator: Mahatma Gandhi Mission'S College of Engineering and Technology NoidaSumit KumarNo ratings yet

- Tracking FanDocument19 pagesTracking FanVikrant Singh ChandelNo ratings yet

- Chip Design Methods Pros and ConsDocument9 pagesChip Design Methods Pros and Conslavender4994No ratings yet

- Experimental Analysis of Thermoelectric RefrigeratorDocument3 pagesExperimental Analysis of Thermoelectric RefrigeratorBrian GaskarthNo ratings yet

- Energy Transfer - ThermoelectricDocument20 pagesEnergy Transfer - ThermoelectricNarendra SinghNo ratings yet

- Ijet V2i2p12Document8 pagesIjet V2i2p12International Journal of Engineering and TechniquesNo ratings yet

- Heat Sink Seminar on Computer & Electronics CoolingDocument24 pagesHeat Sink Seminar on Computer & Electronics CoolingRohit HajareNo ratings yet

- CFD 1Document35 pagesCFD 1AdiNo ratings yet

- Thermoelectric Cooling SystemsDocument26 pagesThermoelectric Cooling SystemsPrabhat Sharma100% (2)

- Heat Trace: Types, Monitoring, and Control OptionsDocument9 pagesHeat Trace: Types, Monitoring, and Control OptionsGaurav ShrivastavaNo ratings yet

- PCB TemperaturDocument10 pagesPCB TemperaturVedic KrishnaNo ratings yet

- Miller PH35SDocument8 pagesMiller PH35Shitm357No ratings yet

- Digital Thermometer Design With Orcad Simulation and Full Report With CalculationDocument10 pagesDigital Thermometer Design With Orcad Simulation and Full Report With CalculationChabo D. WolfNo ratings yet

- Gel Electrophoresis Power SupplyDocument9 pagesGel Electrophoresis Power Supplyمحمود صالح محمود عليNo ratings yet

- Industrial Strength DesignDocument4 pagesIndustrial Strength DesignPhạm Văn TưởngNo ratings yet

- Comsats University Islamabad Wah Campus: Project ReportDocument5 pagesComsats University Islamabad Wah Campus: Project ReportNofilNo ratings yet

- Summer Internship Project ReportDocument25 pagesSummer Internship Project ReportDebjit SarkarNo ratings yet

- H A (T∞ - T) Dt = M Cpdt With M = Ρv And Change Of Variable Dt = D (T -T∞), We FindDocument9 pagesH A (T∞ - T) Dt = M Cpdt With M = Ρv And Change Of Variable Dt = D (T -T∞), We FinddxjsNo ratings yet

- Arduino Measurements in Science: Advanced Techniques and Data ProjectsFrom EverandArduino Measurements in Science: Advanced Techniques and Data ProjectsNo ratings yet

- STK 6713 BMK 4Document10 pagesSTK 6713 BMK 4KST5No ratings yet

- JMSH0804AE Rev3.4Document5 pagesJMSH0804AE Rev3.4PM1978No ratings yet

- EC6304 EC1 Questionbank RejinpaulDocument3 pagesEC6304 EC1 Questionbank RejinpaulAjay GanesanNo ratings yet

- Modified Gdi Technique - A Power Efficient Method For Digital Circuit DesignDocument23 pagesModified Gdi Technique - A Power Efficient Method For Digital Circuit DesignswathiNo ratings yet

- Dual N-Channel Enhancement Mode FET Technical DocDocument6 pagesDual N-Channel Enhancement Mode FET Technical Docdreyes3773No ratings yet

- Ds3602ac 01Document49 pagesDs3602ac 01Charles PNo ratings yet

- K2638 FujiElectricDocument2 pagesK2638 FujiElectricRoiser DelgadoNo ratings yet

- STR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETDocument28 pagesSTR-A6000 Series: Off-Line PWM Controllers With Integrated Power MOSFETAnonymous uEOZ7raPkzNo ratings yet

- Kondo History Tubes VariationDocument7 pagesKondo History Tubes VariationbilmaruthaNo ratings yet

- S8233B e NRNDDocument26 pagesS8233B e NRNDdodiyaashishNo ratings yet

- Phase Locking in High Performance Systems PDFDocument512 pagesPhase Locking in High Performance Systems PDFShahzad IslahiNo ratings yet

- TWRKV46F150 PMSM SensorlessDocument22 pagesTWRKV46F150 PMSM Sensorlessb_dupNo ratings yet

- Power MOSFET Avalanche Design GuidelinesDocument13 pagesPower MOSFET Avalanche Design Guidelinesdiogo18spNo ratings yet

- Unit-I Ic Fabrication: Part-ADocument32 pagesUnit-I Ic Fabrication: Part-Asanthosh sekarNo ratings yet

- The Frequency and ComplexityDocument10 pagesThe Frequency and ComplexitytlnrsNo ratings yet

- Jfets: T N F, P 2: HE EW Rontiers ARTDocument5 pagesJfets: T N F, P 2: HE EW Rontiers ARTzarozeNo ratings yet

- Quoc-Hoang Duong, T.Kien Nguyen and Sang-Gug LeeDocument4 pagesQuoc-Hoang Duong, T.Kien Nguyen and Sang-Gug Leeapi-19755952No ratings yet

- Technical Round Questions and AnswersDocument65 pagesTechnical Round Questions and AnswersPiyush chaurasiaNo ratings yet

- FINFETDocument11 pagesFINFETAnusha SagiNo ratings yet

- RF Mosfet BasicsDocument21 pagesRF Mosfet BasicsStephen Dunifer100% (5)

- Datasheet 520Document11 pagesDatasheet 520IvanNo ratings yet

- VHF Service PDFDocument34 pagesVHF Service PDFFabian NoguerolesNo ratings yet

- Electrical SymbolsDocument6 pagesElectrical SymbolsAnant Catalyst ShuklaNo ratings yet

- V.S.murthy Valiveti - Principles of Electronics (2022)Document226 pagesV.S.murthy Valiveti - Principles of Electronics (2022)gokcen87No ratings yet

- VTH DefinitionDocument4 pagesVTH DefinitionmerdafedidaNo ratings yet

- Multisim Users ManualDocument814 pagesMultisim Users ManualraandalNo ratings yet

- N-Channel MOSFET with 650V Breakdown and 6.5A Continuous Drain CurrentDocument7 pagesN-Channel MOSFET with 650V Breakdown and 6.5A Continuous Drain Currentjoswil21No ratings yet

- N-Channel MOSFET 600V, 2.0A, 4.5ΩDocument8 pagesN-Channel MOSFET 600V, 2.0A, 4.5ΩErroz RosadiNo ratings yet