Professional Documents

Culture Documents

Severity, Occurrence, and Detection Criteria For Design FMEA

Uploaded by

tejashraj93Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Severity, Occurrence, and Detection Criteria For Design FMEA

Uploaded by

tejashraj93Copyright:

Available Formats

Severity, Occurrence, and Detection Criteria for Design FMEA

Absolute

Uncertainty

Very Remote

Remote

Very Low

Low

Moderate

Moderately

High

High

Very High

Almost

Certain

10

9

8

7

6

5

4

3

2

1

Design Control will not and/or cannot detect a potential cause/

mechanism and subsequent failure mode; or there is no

Design Control.

Very Remote chance the Design Control will detect a potential

cause/mechanism and subsequent failure mode.

Remote chance the Design Control will detect a potential cause/

mechanism and subsequent failure mode.

Very Low chance the Design Control will detect a potential

cause/mechanism and subsequent failure mode.

Low chance the Design Control will detect a potential cause/mechanism

and subsequent failure mode.

Moderate chance the Design Control will detect a potential cause/

mechanism and subsequent failure mode.

Moderately High chance the Design Control will detect a potential

cause/mechanism and subsequent failure mode.

Very High chance the Design Control will detect a potential cause/

mechanism and subsequent failure mode.

High chance the Design Control will detect a potential cause/

mechanism and subsequent failure mode.

Design Controls will almost certainly detect a potential cause/

mechanism and subsequent failure mode.

DETECTION

SUGGESTED DETECTION EVALUATION CRITERIA

CRITERIA RNK.

Hazardous-

with

warning

Very High

High

Very high severity ranking when a potential failure mode affects safe

vehicle operation and/or involves noncompliance with government

regulation without warning

Low

Very Low

Minor

Very Minor

None

Very high severity ranking when a potential failure mode affects safe

vehicle operation and/or involves noncompliance with government

regulation with warning

Vehicle/item inoperable (loss of primary function).

Vehicle/item operable but at a reduced level of performance.

Customer very dissatisfied.

Vehicle/item operable but Comfort/Convenience item(s) inoperable.

Customer dissatisfied.

Vehicle/item operable but Comfort/Convenience item(s) operable at a

reduced level of performance. Customer somewhat dissatisfied.

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed by

most customers (greater than 75%).

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed by

50% of customers.

Fit & Finish/Squeak & Rattle item does not conform. Defect noticed by

discriminating customers (less than 25%).

No discernable effect.

10

8

7

6

3

2

1

Hazardous-

without

warning

Moderate

4

5

EFFECT CRITERIA: Severity of Effect RNK.

SEVERITY EVALUATION CRITERIA

9

*Note: Zero (0) rankings for Severity, Occurrence or Detection are not allowed

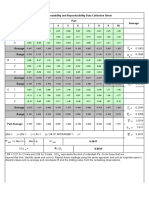

Probability of Likely Failure Rates Over Design Life Ranking

Failure

SUGGESTED OCCURRENCE EVALUATION CRITERIA

Very High: Persistent failures

High: Frequent failures

Moderate: Occasional failures

Low: Relatively few failures

Remote: Failure is unlikely

100 per thousand vehicles/items

50 per thousand vehicles/items

20 per thousand vehicles/items

10 per thousand vehicles/items

5 per thousand vehicles/items

2 per thousand vehicles/items

1 per thousand vehicles/items

0.5 per thousand vehicles/items

0.1 per thousand vehicles/items

0.01 per thousand vehicles/items

10

9

8

7

6

5

4

3

2

1

(313) 565 - 6266

US (888) FOR - FMEA

CDN (877) 609-0999

AUS 011 61 (03) 9585 - 6423

www.quality-one.com

There is no threshold value for RPNs. In other words, there is

no value above which it is mandatory to take a

Recommended Action or below which the team is automatically

excused from an action.

RPN THRESHOLD

Critical & Significant

Characteristics Action Guidelines

S

e

v

e

r

i

t

y

10

9

8

7

6

5

4

3

2

1

Occurrence

1 2 3 4 5 6 7 8 9 10

ANNOYANCE

ZONE

2.) Confirmed Significant

Characteristic; Action

Required

1.) Confirmed Critical Characteristic

3.) RPN-Top

20% by pareto

US (888) FOR-FMEA

US (313) 565 - 6266

CDN (877) 609 0999

AUS 011 61 (03) 9585 - 6423

www.quality-one.com

FMEA EXPRESS

CompleteFMEAs morequickly

Address high-risk potential

failuremodes first

Usea cross-functional FMEA

teamapproach

TM

Potential

Failure Mode and Effects Analysis

(Design FMEA)

System

Sub System

Component:

Model Year/Vehicle (s):

Core Team:

Design Responsibility:

Key Date: Engineering Rel. 2/3/98

FMEA Number:

Page 1 of 1

Prepared by:

FMEA Date (orig.):

Item

Function

Potential

Failure

Mode

Potential

Effect(s) of

Failure

S

e

v

C

l

a

s

s

Potential

Cause(s)/

Mechanism(s)

Failure

O

c

c

u

r

Current

Design

Controls

D

e

t

e

c

R.

P.

N.

Recommended

Action(s)

Responsibility

& Target

Completion Date

Actions

Taken

Action Results

R.

P.

N.

D

e

t

O

c

c

S

e

v

Must provide an FMEA

which determines design

risk and addresses

potential significant and

critical characteristic

selection:

Measurable:

Reduced RPN

Number of significant

and critical characteristics.

Number of design

actions.

Product liability

Customer

dissatisfaction

Reduced performance

of system or

component

Potential risk of

injury

Inadequate FMEA

development

Cross functional

team not assembled

Facilitation not

used

FMEA expertise is

limited

5

Design

verification,

planning

and testing

Training

2 100 Call an FMEA

facilitator to

reduce time required

and improve quality

of the FMEA process

Design team leader

or project manager;

ASAP

FMEA performed

under the supervision

and leadership of

an expert/certified

FMEA facilitator

10 2 2 40

Verb-noun

measurable

is desirable

objective

subjective

Customer

focus/experience

end user

assembler

maker

regulatory

body

Brainstorm causes

man

material

method

machine

environment

Determine Root

cause if YC

Detect

Planned tests

Transfer to

or from DV Plan

evaluations

builds

bucks

Note: Must have

written instructions.

Prevent

Reduces Occurrence

Actions should:

eliminate failure

mode SEV=9/10

eliminate causes

on YS

reduce occurrence

improve tests

detection

reduction last

option

Brief action

result

description

Date action

taken

Recalculate RPN, after

action has been

taken

occurrence

detection

Note: severity will

likely stay the same

unless failure mode is

eliminated

See Detection

Chart on

opposite side

X

Generic Decision

98.5

M. Moore, M. Weber, D. Wojcik, L. Dawson

QAI, Inc.

Lee Dawson

Name of team

member to

carry issue.

Name of

champion

Date action

desired

completion

See Severity

Chart on

opposite side

See Occurrence

Chart on

opposite side

FMEA - Quick Reference Guide

Anti function

for functional

approach

full

partial

intermittent

excess function

FMEA not

adequately

performed; high

risk remains

10 YC

1997 (REV: 04/2002)

Mistake

Proofing

Prevent Detect

Actions are Required:

(by Priority)

1.) When this exists (initiate

Process FMEA to verify)

2.) When this exists (initiate

Process FMEA to verify)

3.) For the top 20% Failure

Modes / Causes (Pareto by

RPN)

Top 20% of Failure

Modes by RPN

R

P

N

Failure Modes

You might also like

- Effective FMEAs: Achieving Safe, Reliable, and Economical Products and Processes using Failure Mode and Effects AnalysisFrom EverandEffective FMEAs: Achieving Safe, Reliable, and Economical Products and Processes using Failure Mode and Effects AnalysisRating: 4 out of 5 stars4/5 (1)

- Advanced PFMEADocument22 pagesAdvanced PFMEAHassan KhanNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- Design Failure Mode Effect Analysis FMEADocument42 pagesDesign Failure Mode Effect Analysis FMEARahman SonowijoyoNo ratings yet

- Design FMEA of Radiator Endplate LeaksDocument5 pagesDesign FMEA of Radiator Endplate LeaksLeonardoViannaNo ratings yet

- Failure Mode and Effects Analysis (Design) : Importance in NPD ProcessDocument12 pagesFailure Mode and Effects Analysis (Design) : Importance in NPD Processsushant3240No ratings yet

- Design FMEADocument10 pagesDesign FMEAAbu AzkhaNo ratings yet

- Measurement System Analysis GuideDocument19 pagesMeasurement System Analysis Guiderollickingdeol100% (1)

- 02 FMEA Training - How To DoDocument45 pages02 FMEA Training - How To DoRamkumar PerumalNo ratings yet

- Design Fmea Sae j1739Document1 pageDesign Fmea Sae j1739Tarek SanNo ratings yet

- Week 3 Stability 5S TPMDocument66 pagesWeek 3 Stability 5S TPMQuynh Chau TranNo ratings yet

- FMEA For DesignDocument7 pagesFMEA For DesignPavan Kumar100% (1)

- FSC Fmea Failure Mode and Effect AnalysisDocument21 pagesFSC Fmea Failure Mode and Effect AnalysisVbaluyoNo ratings yet

- Fmea Alignment Aiag and VdaDocument14 pagesFmea Alignment Aiag and Vdahaitem100% (1)

- Spec Characteristics GdlnesDocument2 pagesSpec Characteristics Gdlnessathyabalaraman0% (1)

- Error Proofing For EMSDocument48 pagesError Proofing For EMSsaleemanisaleemaniNo ratings yet

- Fmea DesignDocument29 pagesFmea DesignEmperor89100% (2)

- Sample DFMEA - Full PackageDocument7 pagesSample DFMEA - Full Packageabhisheksen.asindNo ratings yet

- Gage R&RDocument1 pageGage R&Rshobhit2310No ratings yet

- AIAG FMEA Manual The BenchmarkDocument2 pagesAIAG FMEA Manual The BenchmarkUmer Al-FaisalNo ratings yet

- Gage R&R FormDocument10 pagesGage R&R FormUttam SainiNo ratings yet

- FMEA Master PresentationDocument63 pagesFMEA Master Presentationnigeldouch100% (1)

- FMEA HandbookDocument14 pagesFMEA HandbookRakesh Tayenjam100% (2)

- MSA WorksheetDocument29 pagesMSA Worksheetmohammad wasimNo ratings yet

- DRBFM Worksheet AnalysisDocument1 pageDRBFM Worksheet AnalysisHareth MRAIDINo ratings yet

- Perform FMEA Methodology StepsDocument20 pagesPerform FMEA Methodology StepsGurwinder SinghNo ratings yet

- FMEA Process Training MaterialDocument38 pagesFMEA Process Training MaterialFrame UkirkacaNo ratings yet

- FMEA Failure Modes & Effects AnalysisDocument32 pagesFMEA Failure Modes & Effects AnalysisSherif Eltoukhi100% (7)

- Warm-Up - Day 2: Place Self Others Team Purpose AgendaDocument85 pagesWarm-Up - Day 2: Place Self Others Team Purpose AgendaSanjeev SharmaNo ratings yet

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- Over View - Cost of QualityDocument31 pagesOver View - Cost of QualityAntony IllamNo ratings yet

- Mistake Proofing ExamplesDocument33 pagesMistake Proofing ExamplesAhmad Bin Ismail KhanNo ratings yet

- Risk Assessment/Analysis PFMEADocument108 pagesRisk Assessment/Analysis PFMEAAHMAD YAGHINo ratings yet

- Six Sigma TerminologiesDocument92 pagesSix Sigma TerminologiesReshmi RajeshNo ratings yet

- Software ReliabilityDocument211 pagesSoftware Reliabilityapi-3775463100% (1)

- FMEADocument6 pagesFMEAEmeka NkwochaNo ratings yet

- R&R FormatDocument2 pagesR&R FormatM.saravanan100% (1)

- Measurement System Analysis LabDocument32 pagesMeasurement System Analysis LabAnonymous 3tOWlL6L0U100% (1)

- MSA Bias & GRRDocument2 pagesMSA Bias & GRRRamchandrarao DeshpandeNo ratings yet

- Variable MSA 4th Edition Blank TemplateDocument1 pageVariable MSA 4th Edition Blank TemplateSachin RamdurgNo ratings yet

- FMEADocument18 pagesFMEASeshagiri furt67% (3)

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- Fmea VviDocument52 pagesFmea VviBobby Edwin100% (2)

- How Are They Related ?Document39 pagesHow Are They Related ?MURALIDHRANo ratings yet

- Reliability Analysis and Robust Design - MatlabDocument18 pagesReliability Analysis and Robust Design - MatlabJean Callata Chura100% (1)

- Global 8d Problem Solving - FordDocument6 pagesGlobal 8d Problem Solving - FordTom@GGCNo ratings yet

- GR&R Training DraftDocument53 pagesGR&R Training DraftLOGANATHAN VNo ratings yet

- FMEA & Control PlanDocument78 pagesFMEA & Control Plansanqutbi75% (8)

- Pfmea Process Failure Mode and Effects AnalysisDocument34 pagesPfmea Process Failure Mode and Effects AnalysisRizky SihabNo ratings yet

- FMEADocument6 pagesFMEANavnath TamhaneNo ratings yet

- FMEA Failure Modes Effects Analysis PDFDocument32 pagesFMEA Failure Modes Effects Analysis PDFVILLANUEVA_DANIEL2064100% (1)

- Reliability MINITABDocument5 pagesReliability MINITABbhavin shahNo ratings yet

- Training in MSA PQ Systems Training Material PDFDocument109 pagesTraining in MSA PQ Systems Training Material PDFsaby aroraNo ratings yet

- LEAN Execution OEEDocument11 pagesLEAN Execution OEEVergence Business Associates100% (7)

- Statistical Process ControlDocument79 pagesStatistical Process ControlKrunal PandyaNo ratings yet

- Fmea - Training ManualDocument57 pagesFmea - Training Manualsemi2542100% (2)

- Understanding OEEDocument5 pagesUnderstanding OEECristian Ramirez AmayaNo ratings yet

- Presented By:: ASQ Section 0700 ASQ Section 0701Document35 pagesPresented By:: ASQ Section 0700 ASQ Section 0701fennyNo ratings yet

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNo ratings yet

- Precis Writings LET BEDocument20 pagesPrecis Writings LET BEMuhammad Naseem Ishaq /ME Lab Engineer100% (1)

- G.B. Pant Engineering College: NoticeDocument1 pageG.B. Pant Engineering College: Noticetejashraj93No ratings yet

- Guru Gobind Singh Indraprastha University: Programme: B. Tech (CSE, ECE, EE, ICE, IT, MAE, PE, EEE, ENE, CE, TE)Document4 pagesGuru Gobind Singh Indraprastha University: Programme: B. Tech (CSE, ECE, EE, ICE, IT, MAE, PE, EEE, ENE, CE, TE)tejashraj93No ratings yet

- Puzzles PDFDocument8 pagesPuzzles PDFtejashraj93No ratings yet

- NT 1632060815Document1 pageNT 1632060815tejashraj93No ratings yet

- IES Mechanical Engineering Question PaperDocument17 pagesIES Mechanical Engineering Question PaperSimran SinghNo ratings yet

- GGSIPU Final Year Special Supplementary Exam Admit Card NoticeDocument1 pageGGSIPU Final Year Special Supplementary Exam Admit Card Noticetejashraj93No ratings yet

- O 31Document10 pagesO 31tejashraj93No ratings yet

- Or Dinan C 11020815Document13 pagesOr Dinan C 11020815tejashraj93No ratings yet

- GGSIPU B.Tech Practical Exam Schedule Sept 2015Document1 pageGGSIPU B.Tech Practical Exam Schedule Sept 2015tejashraj93No ratings yet

- Sla PC Data SheetDocument2 pagesSla PC Data Sheettejashraj93No ratings yet

- RRBDocument13 pagesRRBJeshiNo ratings yet

- GK Obj With AnsDocument9 pagesGK Obj With AnsPabitra Kumar SuraNo ratings yet

- Business Communication IDocument37 pagesBusiness Communication IRUDRAPRADEEPTAKNo ratings yet

- New-SAEINDIA STUDENT MEMBERSHIP APPLICATION 2015 PDFDocument1 pageNew-SAEINDIA STUDENT MEMBERSHIP APPLICATION 2015 PDFtejashraj93No ratings yet

- 2331 1096 Placement Paper of DrdoDocument1 page2331 1096 Placement Paper of DrdoanilfkNo ratings yet

- New-SAEINDIA STUDENT MEMBERSHIP APPLICATION 2015 PDFDocument1 pageNew-SAEINDIA STUDENT MEMBERSHIP APPLICATION 2015 PDFtejashraj93No ratings yet

- DRDO Question Paper ECE 2008Document12 pagesDRDO Question Paper ECE 2008nagaNo ratings yet

- Catia TrainingDocument8 pagesCatia Trainingtejashraj93No ratings yet

- TompkinsDocument2 pagesTompkinstejashraj93No ratings yet

- Air Suspension Axle Specifications for Trailers and Commercial VehiclesDocument8 pagesAir Suspension Axle Specifications for Trailers and Commercial Vehiclestejashraj93No ratings yet

- 137278Document47 pages137278tejashraj93No ratings yet

- Principles of MetrologyDocument7 pagesPrinciples of MetrologysptbalaNo ratings yet

- Trailing ArmDocument3 pagesTrailing Armtejashraj93No ratings yet

- Glossary ToyotaDocument6 pagesGlossary Toyotaalbin thomasNo ratings yet

- Transportation and Transhipment ProblemsDocument4 pagesTransportation and Transhipment Problemstejashraj93No ratings yet

- Safety Factor: Subject: Author: Prepared For: Date CommentsDocument1 pageSafety Factor: Subject: Author: Prepared For: Date Commentstejashraj93No ratings yet

- Baja Team Zenith Test FinalDocument2 pagesBaja Team Zenith Test Finaltejashraj93No ratings yet

- I Robotricks PDFDocument2 pagesI Robotricks PDFtejashraj93No ratings yet

- ShakurbastiDocument5 pagesShakurbastiankit71989No ratings yet

- Transport Technology Center (T.T.C)Document19 pagesTransport Technology Center (T.T.C)Abubakar Lawan GogoriNo ratings yet

- RNTCP - Wikipedia, The Free EncyclopediaDocument5 pagesRNTCP - Wikipedia, The Free EncyclopediaakurilNo ratings yet

- Hvis Msds PDFDocument6 pagesHvis Msds PDFsesbasar sitohangNo ratings yet

- Central Adult and Pediatric in Tensive Care UnitDocument4 pagesCentral Adult and Pediatric in Tensive Care UnitChris T NaNo ratings yet

- Maintenance Scheduling For Electrical EquipmentDocument82 pagesMaintenance Scheduling For Electrical Equipmentduonza100% (6)

- Complete VaccinationDocument2 pagesComplete VaccinationNgoo NwosuNo ratings yet

- Prepared By: Ulfat Amin MSC Pediatric NursingDocument25 pagesPrepared By: Ulfat Amin MSC Pediatric NursingAngelic khanNo ratings yet

- Congenital LaryngomalaciaDocument8 pagesCongenital LaryngomalaciaRettha SigiroNo ratings yet

- AIIMS Bibinagar Recruitment for Faculty PostsDocument22 pagesAIIMS Bibinagar Recruitment for Faculty PostsavinashNo ratings yet

- Jordan Leavy Carter Criminal ComplaintDocument10 pagesJordan Leavy Carter Criminal ComplaintFOX 11 NewsNo ratings yet

- Full Plate Diet BookDocument164 pagesFull Plate Diet BookScarlettNyx100% (4)

- Care of A Child With Cardiovascular DysfunctionDocument71 pagesCare of A Child With Cardiovascular DysfunctionMorgan Mitchell100% (1)

- Safety Reports Series No. 13 (Radiation Protection and Safety in Industrial Radiography)Document69 pagesSafety Reports Series No. 13 (Radiation Protection and Safety in Industrial Radiography)jalsadidiNo ratings yet

- NCP - Acute Pain - FractureDocument1 pageNCP - Acute Pain - Fracturemawel73% (22)

- Process Design For 1.70 IFAS STPDocument18 pagesProcess Design For 1.70 IFAS STPGenesis International0% (1)

- Hahnemann Advance MethodDocument2 pagesHahnemann Advance MethodRehan AnisNo ratings yet

- Syringe CompatibilityDocument1 pageSyringe CompatibilityRaju NiraulaNo ratings yet

- Reviews of Two Works by Dr. Amy Baker.Document9 pagesReviews of Two Works by Dr. Amy Baker.Talia SchwartzNo ratings yet

- The Helping Art Clinical Nursing Who - Google SeaDocument1 pageThe Helping Art Clinical Nursing Who - Google Sea26sbn8d4p9No ratings yet

- Module 7 Health Insurance Types and ImportanceDocument10 pagesModule 7 Health Insurance Types and ImportanceKAH' CHISMISSNo ratings yet

- SC 2Document2 pagesSC 2Ryan DelaCourt0% (3)

- Laboratory Hygiene and SafetyDocument34 pagesLaboratory Hygiene and SafetyResmiNo ratings yet

- Function: What Is The Skeletal System?Document6 pagesFunction: What Is The Skeletal System?Mr. Christian ParabuacNo ratings yet

- Pain AssessmentDocument10 pagesPain Assessmentaashika15No ratings yet

- Cardiovascular NotesDocument18 pagesCardiovascular NotesCathy SantosNo ratings yet

- PDF Passive Leg Raise PLR Test Stroke Volume Index SviDocument3 pagesPDF Passive Leg Raise PLR Test Stroke Volume Index SviNama ManaNo ratings yet

- Nursing Assignment SampleDocument12 pagesNursing Assignment Sampleswetha swethaNo ratings yet

- Toba Tek SinghDocument4 pagesToba Tek Singhrupal aroraNo ratings yet

- Legal Medicine 2020 2021Document4 pagesLegal Medicine 2020 2021Zie DammiNo ratings yet

- Intro To Wastewater Collection and PumpingDocument84 pagesIntro To Wastewater Collection and PumpingMoh'd KhadNo ratings yet