Professional Documents

Culture Documents

Web Based Construction

Uploaded by

jcaldanabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Web Based Construction

Uploaded by

jcaldanabCopyright:

Available Formats

Web-based construction waste estimation system for building construction projects

Yashuai Li, Xueqing Zhang

Department of Civil and Environmental Engineering, The Hong Kong University of Science and Technology, Clear Water Bay, Kowloon, Hong Kong, China

a b s t r a c t a r t i c l e i n f o

Article history:

Accepted 3 May 2013

Available online xxxx

Keywords:

Construction waste

Decision support system

Estimation

Online analytical processing

Sustainable development

This paper proposes a web-based construction waste estimation system (WCWES) for building construction

projects incorporating the concepts of work breakdown structure, material quantity takeoff, material classi-

cation, material conversion ratios, material wastage levels, and the mass balance principle. The WCWES

integrates online data input modules and online analytical modules for the quantication of different kinds

of waste generated in the construction process at the project level. It facilitates accessibility, interfacing, con-

nectivity and information sharing of users in carrying out a wide range of construction waste estimation tasks

for sustainable construction waste management. A hypothetical building construction project is used to dem-

onstrate the application and usefulness of the WCWES.

2013 Elsevier B.V. All rights reserved.

1. Introduction

Construction waste is a major source of municipal solid waste in

all the megacities around the world, frequently accounting for 10%

to 30% of the total waste landlled. For example, in Hong Kong, con-

struction waste consists of 30% to 40% of the total waste. In 2005, con-

struction waste delivered to landlls was 6556 ton/day, which was

37.08% of the total waste landlled (17,503 ton/day) [25]. In Chicago,

4,656,037 tons of construction waste was generated in 2007, ac-

counting for 60.71% of the total waste (7,669,097 tons) generated

that year [4]. The large amounts of construction waste are a big chal-

lenge to the sustainable development of many large cities in both de-

veloped and developing countries/regions.

Efcient construction waste management necessitates a systematic

approach supported by various decision making tools. One such tool is

a practical construction waste estimation system, which would be

quite useful for both the government and the construction industry in

accurately quantifying and effectively managing construction waste.

Fromthe perspective of the government, relevant authorities can estab-

lish appropriate policies, guidelines, strategies and codes of practice for

sustainable construction waste management based on informed esti-

mation of construction waste, for example, in the development of opti-

mal waste treatment facilities andinthe determinationof the right level

of waste charge. Fromthe perspective of the construction industry, con-

struction companies can take active waste prevention, reduction and

utilization plans within and across construction projects to deal with

the various kinds of estimated waste to be generated from different

projects.

A number of methods have been proposed to quantify construction

waste generation. These methods can be broadly divided into three

categories:

(1) The rst waste estimation method is to estimate the total waste

froma constructionproject as a percentage of the total amount of

construction materials consumed in this project. Through a sur-

vey of some construction projects, the average waste percentage

of the total amount of construction materials consumed in these

projects can be determined. This average percentage is then used

to estimate the total waste to be generated from other construc-

tion projects. For example, Bossink and Brouwers [1] analyzed

the total quantities of construction waste fromve housing pro-

jects from April 1993 to June 1994 and concluded that waste

from a construction project lies between 1% and 10% of the pur-

chased materials in the Netherlands.

(2) The second waste estimation method is based on some generic

project parameter/variable (e.g., the oor area of a building pro-

ject) to predict the total quantity of waste from a construction

project. In general, the total construction waste froma construc-

tion project is equal to the product of the quantity of this generic

variable and the waste per unit quantity of this generic variable.

For example, construction waste estimation models based on the

construction area of a project have been developed in Greece by

Fatta et al. [8] and Kourmpanis et al. [13], inSpain by Villoria Sez

[23] and in Thailand by Kofoworola and Gheewala [12]. Speci-

cally, in these models, the total amount of waste froma construc-

tion project is calculated by multiplying the total construction

area of this project by an estimated quantity of waste per unit

of the construction area. Besides the construction oor area, the

wastage level [14,19,21], structure type & function [9] and con-

struction stage [11] can also be utilized to estimate construction

Automation in Construction xxx (2013) xxxxxx

Corresponding author. Tel.: +852 2358 8480.

E-mail address: zhangxq@ust.hk (X. Zhang).

AUTCON-01574; No of Pages 15

0926-5805/$ see front matter 2013 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.autcon.2013.05.002

Contents lists available at SciVerse ScienceDirect

Automation in Construction

j our nal homepage: www. el sevi er . com/ l ocat e/ aut con

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

waste generation.

(3) The third waste estimation method is based on some

macro-level variables to predict the total construction waste

generated from an industry, region or country. One common

macro-level variable is the population size (Martnez Lage

2010) [16]. Other macro-level variables include construction

project permits [24] and construction material productions

[7,20]. Specically, Bruvoll and Ibenholt [3] and Ibenholt [10]

presented a multi-sectoral equilibriummodel that employs mac-

roeconomic variables such as real capital invested, labor used,

material input, energy consumption and purchase prices to fore-

cast waste generated in the Norwegian manufacturing industry.

In addition to these theoretical estimation methods, SMARTWaste

is utilized as a tool in construction waste management [2]. The

SMARTWaste system tends to improve contractors' waste manage-

ment strategy by means of dening their environmental and other

key performance indicators (EPIs and KPIs) and quantifying major

waste components' sources and management methods. This system

requires the user to input waste generation amount in order to gener-

ate the site waste management plan.

In viewof the fact that the construction industry is project-based,

this paper proposes a web-based construction waste estimate sys-

tem (WCWES) for building construction projects. As a supportive

platform, the WCWES integrates online data input modules and on-

line analytical modules for the quantication of different kinds of

waste generated in the construction process at the project level. Fur-

thermore, the WCWES facilitates accessibility, interfacing, connec-

tivity and information sharing of users in carrying out a wide range

of construction waste estimation tasks for sustainable construction

waste management.

2. Overall methodology of building project waste estimation

Zhang and Li [27] developed a quantitative construction waste

estimation model for building construction projects. The overall

methodology of this project-based waste estimation model is

shown in Fig. 1. Specically, this model integrates the following

concepts: work breakdown structure (WBS), material quantity

takeoff, material classication, material conversion ratios, material

wastage levels in each terminal work package and the mass balance

principle. The project-based waste estimation model is able to pre-

dict the various kinds of waste generated in each work package of a

building construction project. Details of this project-based con-

struction waste estimation model are discussed in the following

sections.

3. Construction waste estimation according to work packages

3.1. Construction waste from terminal work packages

Work packages at the lowest practical level of the WBS of a build-

ing project are referred to as terminal work packages. The quantity of

construction waste of a particular kind of material from a terminal

work package is a function of the quantity of this material used in

this terminal work package and the wastage level of this material

in this terminal work package. The wastage level is the percentage

of the quantity of a material used in a terminal work package that be-

comes waste. Basic procedures to estimate construction waste froma

terminal work package are discussed in the following:

Step 1: Develop the WBS of a building construction project

A building construction project can be broken down into

four hierarchical levels [26]: system, component, element

and sub-element. The sub-element is the terminal work package.

Specically,

(1) A systems of a building is denoted as W

s

, where s = 1, 2, , S,

and S is the total number of systems in this building.

(2) A component c in system s is denoted as W

c

s

, where c = 1, 2,

, C

s,

and C

s

is the total number of components in system s

of a building.

Fig. 1. A quantitative construction waste estimation model.

2 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

(3) An element e in component c of system s is denoted as W

e

sc

,

where e = 1, 2, , E

sc

, and E

sc

is the total number of elements

in component c of system s of a building.

(4) A sub-element d in element e of component c of system s is

denoted as W

d

sce

, where d = 1, 2, , D

sce

, and D

sce

is the

total number of sub-elements in element e of component c

of system s of a building.

Step 2: Conduct material quantity takeoff for each terminal work

package

Materials involved in the delivery of a work package can be

generally classied into four categories: construction

materials, packaging materials, extracted materials, and tar-

get building elements. Construction materials are those ma-

terials that are used to form the target building elements.

Packaging materials refer to those that package construction

materials. Extracted materials mainly mean soil excavated

in the construction process. Target building elements mean

the designed elements of a building to be built.

Without loss of generality, it is assumed that there are I kinds of

construction materials, G kinds of packaging materials, J kinds

of extracted materials and K kinds of target building elements

in the delivery of a terminal work package. The quantities of

Fig. 2. Architecture of the web-based construction waste estimation system.

Fig. 3. Registration.

3 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

the i-th construction material, g-th packaging material, j-th

extracted material and k-th target building element in terminal

work package W

d

sce

are denoted asQ

MU

iW

sce

d

, Q

PU

gW

sce

d

, Q

EU

jW

sce

d

andQ

TU

kW

sce

d

respectively. In the superscript of Q

MU

iW

sce

d

, the rst letter Mmeans

construction materials (i.e., M will be changed to P for pack-

aging materials, to E for extracted materials, or to T for target

building elements); the second letter U indicates the unit of

measurement (i.e., U will be changed to V if the material is

measured in volume or to W if the material is measured by

weight). Taking the concrete used in the terminal work package

wall foundation as an example, it is assumed that the quantity

of concrete used in the work package is 665.8 m

3

.

Step 3: Convert the units of different materials to a common one

In the construction practice, the quantities of different

materials are measured in different units. For the conve-

nience of comparison and analysis, different measurements

may be converted to a common unit using conversion ra-

tios. In this paper, weight in kilogram is used as the com-

mon measurement unit. Thus, the weight of the x-th

material in terminal work package Wd

sce

is

Q

XW

xW

sce

d

Q

XU

xW

sce

d

C

XW

x

; X M; P; E; T f g

x

1; ; I if X M

1; ; G if X P

1; ; J if X E

1; ; K if X T

8

>

>

<

>

>

:

1

where X = the material category, withX = M, P, E and T mean-

ing construction material, packaging material, extracted

Fig. 4. Account management.

Fig. 5. Functions of the web-based construction waste estimation system.

4 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

material and target building element respectively; Q

MW

iW

sce

d

= the

weight of the i-th construction material in Wd

sce

, Q

PW

gW

sce

d

= the

weight of the g-th packaging material in Wd

sce

, Q

EW

jW

sce

d

= the

weight of the j-th extracted material in Wd

sce

, Q

PW

kW

sce

d

= the

weight of the k-th building element in Wd

sce

; Cx

XW

= the conver-

sion ratio of the x-th material of category X, that is, Ci

MW

, Cg

PW

,

Cj

EW

and Ck

TW

are the conversion ratios of the i-th construction

material, g-th packaging material, j-th extracted material and

k-th target building element from a particular measurement

unit to weight. For instance, given that the conversion ratio of

concrete fromcubic meter to weight is 2300, the weight of con-

crete used in wall foundation is 1,531,340 kg.

Step 4: Estimate construction waste from each terminal work package

Construction waste from the x-th material is expressed as

R

XW

xW

sce

d

Q

XW

xW

sce

d

L

X

xW

sce

d

2

where R

XW

xW

sce

d

= the weight of waste of the x-th material of cat-

egory X from terminal work package Wd

sce

and L

X

xW

sce

d

= the

wastage level of the x-th material of category X in terminal

work package Wd

sce

. For example, if the wastage level of con-

crete in the terminal work package wall foundation is 1.5%,

the quantity of concrete waste from the work package is the

multiplication of the weight of concrete (1,531,340 kg) by the

wastage level (1.5%), that is, 2297 kg.

Step 5: Estimate the total construction waste from each terminal work

package

The total construction waste from terminal work package Wd

sce

is equal to the summation of the waste of construction mate-

rials, packaging materials, extracted materials and target build-

ing elements from this package, that is

R

AW

W

sce

d

X

I

i1

R

MW

iW

sce

d

X

G

g1

R

PW

gW

sce

d

X

J

j1

R

EW

jW

sce

d

X

K

k1

R

TW

kW

sce

d

3

whereR

AW

W

sce

d

= the total construction waste fromterminal work

package Wd

sce

.

3.2. Construction waste from higher levels of work packages

Once construction waste of the four material categories (i.e., con-

struction materials, packaging materials, extracted materials and

target building elements) from each terminal work package is esti-

mated, construction waste from a higher level work package can be

determined by rolling up the quantities of the corresponding kind

of waste from the work packages immediately below the higher

level package.

Construction waste froman element W

e

sc

(i.e., element e of compo-

nent c of system s of a project) can be expressed as

R

XW

xW

sc

e

X

D

sce

d1

R

XW

xW

sce

d

4

Table 1

Work packages of the substructure system of ABC Building.

Code Work package name Work package type

W

1

Substructure System

W

1

1

Foundation Component

W

1

11

Standard foundation Element

W

1

111

Wall foundation Sub-element

W

2

111

Column foundation & pile caps Sub-element

W

3

111

Perimeter drainage & insulation Sub-element

W

2

11

Special foundation Element

W

1

112

Pile foundation Sub-element

W

2

112

Grade beam Sub-element

W

3

11

Slab on grade Element

W

1

113

Standard slab on grade Sub-element

W

2

1

Basement construction Component

W

1

12

Basement excavation Element

W

1

121

Excavation for basement Sub-element

W

2

121

Structural back ll & compacting Sub-element

W

2

12

Basement walls Element

W

1

122

Basement wall construction Sub-element

Table 2

Material quantities in sub-elements.

Code Construction material Packaging

material

Extracted material Target building element

Concrete

(m

3

)

Steel

(t)

Formwork

(m

2

)

Sand

(t)

SBS

a

(m

2

)

PP

b

(unit)

Brown

paper

(unit)

Soil

(m

3

)

Wall foundation

(m

3

)

Column

(RC)

(m

3

)

Insulation

(m

2

)

Pile

(RC)

(m

3

)

Beam

(RC)

(m

3

)

Slab

(RC)

(m

3

)

Basement

cave

(unit)

Basement

wall (RC)

(m

3

)

W

1

111

665.8 26.3 457 30 660

W

2

111

215 83.6 1290 80 216

W

3

111

69.41 223.59 651 66 520

W

1

112

666 632 666

W

2

112

404 133.3 2870 180 403

W

1

113

491 80.38 4100 250 495

W

1

121

4810 1

W

2

121

962

W

1

122

70 34.8 478 30 73

Note:

a

Styrene butadiene styrene (SBS) waterproof membrane.

b

Polypropylene (PP) bag.

Table 3

Conversion ratios of various materials.

Material name Measurement Weight ratio (kg) Volume ratio (m

3

)

Concrete/pile m

3

2300 1

Steel t 1000 0.128

Formwork m

2

23.4 0.018

Sand m

3

1500 1

SBS

a

m

2

3.5 0.005

Soil m

3

1800 1

Polypropylene (PP) bag unit 1.15 0.002

Brown paper bag Unit 0.314 0.015

Note:

a

Styrene butadiene styrene (SBS) waterproof membrane.

5 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

where R

XW

iW

sc

e

= the quantity of waste of the i-th material of category X

from element e of component c of system s of a project. For example,

the concrete waste from the component standard foundation di-

rectly above the sub-element wall foundation includes the concrete

waste generated from the sub-element wall foundation.

The total quantity of waste fromelement e of component c of system

s of a project is

R

AW

W

sc

e

X

I

i1

R

MW

iW

sc

e

X

G

g1

R

PW

gW

sc

e

X

J

j1

R

EW

jW

sc

e

X

K

k1

R

TW

kW

sc

e

5

where R

AW

W

sc

e

= the total quantity of waste of construction materials,

packaging materials, extracted materials and target building elements

from element e of component c of system s of a project.

Construction waste from a component W

c

s

, a system W

s

and a pro-

ject W can be expressed as

R

XW

xW

s

c

X

E

sc

e1

R

XW

xW

sc

e

6

R

XW

xW

s

X

C

s

c1

R

XW

xW

s

c

R

XW

xW

X

S

s1

R

XW

xW

s

whereR

XW

xW

s

c

, R

XW

xW

s

and R

xW

XW

= the quantity of waste of the x-th material

of category X from component c, system s and a project respectively.

The total construction waste froma component, systemor project is

expressed as

R

AW

W

s

c

X

I

i1

R

MW

iW

s

c

X

G

g1

R

PW

gW

s

c

X

J

j1

R

EW

jW

s

c

X

K

k1

R

TW

kW

s

c

R

AW

W

s

X

I

i1

R

MW

iW

s

X

G

g1

R

PW

gW

s

X

J

j1

R

EW

jW

s

X

K

k1

R

TW

kW

s

R

AW

W

X

I

i1

R

MW

iW

X

G

g1

R

PW

gW

X

J

j1

R

EW

jW

X

K

k1

R

TW

kW

7

where R

AW

W

s

c

, R

AW

W

s

and R

W

AW

= the total quantity of waste of construction

materials, packaging materials, extracted materials and target building

elements from component c, system s and a project respectively.

4. Web-based construction waste estimation system

4.1. General architecture of the system

To facilitate the application in the construction industry, the con-

struction waste estimation system is computerized and web-enabled.

Users can access to this systemthrough a web browser, for example, in-

ternet explorer. Fig. 2 shows the general architecture of this web-based

construction waste estimation system (WCWES) and the data ow

among the three major components of the WCWES (i.e., web browser,

web server and application logic, and database server).

4.2. Web browser

A web browser is a software application for retrieving, presenting

and traversing information resources on the world wide web through

the http protocol. The web browser displays user interfaces in the

form of active server pages (ASP). By manipulating ASP web pages,

http requests are sent to the web server through the web browser.

Then, these requests are handled and corresponding responses are

sent back. Users can input data and retrieve analytical results through

relevant interfaces.

4.3. Web server and application logic

Once receiving an http request from the web browser, the web

server deals with this request and then propagates back a response

to the web browser. The continuous interactions between users and

the WCWES necessitate effective management of the application

logic and its various modules. In this regard, the organized application

logic integrates account modules, data input modules and analytical

modules. Through account modules, users can register, set and change

password, and update the user prole. Data input modules include

modules for material management, project management, WBS man-

agement and material quantity takeoff. These modules allowusers to

input/modify/delete material, project, WBS and material quantity

takeoff information in the database. Analytical modules enable on-

line analytical processing (OLAP) of various construction waste

data and provide analytical results from various perspectives, for ex-

ample, according to work packages, waste streams and waste origin

categories.

4.4. Database

The database stores the input data and the results of various analy-

ses for each project using a relational database management system.

Table 4

Wastage levels of materials in each terminal work package.

Code Construction material Packaging material Extracted material Target building element

Concrete Steel Formwork Sand SBS

a

PP

b

Brown paper Soil Wall foundation Column Insulation Pile Beam Slab Basement cave Basement wall

W

1

111

1.5%

c

0.8%

d

33.3% 100%

c

0%

W

2

111

4.5%

c

0.8%

d

33.3% 100%

c

0%

W

3

111

1.5%

c

2%

c

20%

c

100%

c

0%

W

1

112

1%

c

100%

c

5%

W

2

112

4.5%

c

0.8%

d

33.3% 100%

c

0%

W

1

113

1.5%

c

0.8%

d

33.3% 100%

c

0%

W

1

121

80%

c

W

2

121

1%

c

W

1

122

1.5%

c

0.8%

d

33.3% 100%

c

0%

Note:

a

Styrene butadiene styrene (SBS) waterproof membrane.

b

Polypropylene (PP) bag.

c

Obtained through personal interviews.

d

The wastage level is extracted from Poon et al. [19].

6 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

Adopting Microsoft SQL Server 2008, the database contains a number of

tables, views, functions, and stored procedures.

4.5. Security system and rewall

The WCWES also incorporates a security system and rewall in

order to protect the WCWES and user information. The security system

denes user access rights and levels of authorities. Fig. 3 shows a

screenshot of the registration interface. A user can access the WCWES

through the registered username and password. As shown in Fig. 4 of

the account management interface, a registered user can manage his/

her account by changing password, updating prole, applying a role,

tracking application process, downloading the systemmanual, and log-

ging out. Changing password and updating prole allow a user to

change the corresponding user information. Three roles are dened in

the WCWES, that is, administrator, VIP user, and common user. A user

can track its application status through the tracking application pro-

cess function. The system manual provides step-by-step procedures

on how to use the WCWES.

5. Input functions of the WCWES

5.1. Hypothetical project for WCWES demonstration

Fig. 5 is a screenshot of the overall interface of the WCWES once

a user logs into the system. This interface displays the various func-

tions of the WCWES. The major input functions include material

management, project management, WBS management and

a) Add a material

b) Update material information

Fig. 6. Material management.

7 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

material quantity management. A hypothetical construction pro-

ject, ABC Building, is used as an example to demonstrate the appli-

cation of the various functions of the WCWES. To save space, this

paper only discusses the waste estimation of one of the systems,

i.e., the substructure, in the WBS of the ABC Building. Table 1

shows the information of the various components, elements and

sub-elements of the substructure. Table 2 shows the quantities of

different materials in volume (m

3

) and weight (kg) in each

sub-element. Table 3 shows the conversion ratio of various mate-

rials from different measurement units used in practice to weight

(kg) and volume (m

3

). Table 4 shows the wastage levels of various

materials in different sub-elements.

5.2. Material management

As discussed in the previous section, materials involved in the

construction process are broadly classied into four categories: con-

struction materials, packaging materials, extracted materials, and

target building elements. Users can identify the kinds of materials

involved in a project under concern and the material category to

which each kind of materials belong, and estimate the quantity of

each kind of materials through a quantity takeoff process. The infor-

mation of each kind of materials can then be input into the material

repository. General material information includes material name,

brand, specication, description, measurement unit, weight ratio,

and volume ratio. Furthermore, packaging materials come together

with construction materials and thus it is necessary to build the

relationship between packaging materials and construction mate-

rials. A screenshot of adding a material to the material repository

is shown in Fig. 6(a).

Users can maintain the existing material repository through the

Edit, Delete and Drilldown functions as shown in Fig. 6(b). In

this gure, each row represents a material and a popup editor will

appear if the Edit button is clicked. For example, the Edit button

of concrete is red in Fig. 6(b). In the interface of Fig. 6(b), changing

the information and clicking Update, the material information will

be updated. A material will be deleted if its Delete button is

clicked. In addition, as packaging materials are dependent on specif-

ic construction materials, a Drilldown button appears before each

construction material. The details of packaging materials of a con-

struction material will be displayed if its Drilldown button is

clicked. For example, as shown in Fig. 6(b), polypropylene (PP)

bags are used for packaging formworks.

5.3. Project management

General project information includes project name, contract amount,

number of stories, total construction area, construction start date,

construction completion date, construction structure type, and a

brief description of the project. In the interface as shown in Fig. 5,

clicking Add a newproject, a windowas shown in Fig. 7 will appear

for the user to add a new project. When the information is input,

click Add Project and the information of the new project will be

saved to the database. To manage a project's prole, click Manage

Fig. 7. Adding a new project.

8 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

projects in the interface as shown in Fig. 5 and all projects of a user

will be displayed as shown in Fig. 8. The user can select a particular

project and manage its prole. The project information can be mod-

ied or updated through the Edit function or the project can be de-

leted by clicking the Delete button.

5.4. WBS management

WBS information includes work package name, start date, comple-

tion date, quantity of work, unit of work, and construction method.

Clicking Manage work packages in the interface as shown in Fig. 5,

an interface as shown in Fig. 9 will appear for the user to select a pro-

ject and to develop its WBS. Clicking a particular project, for example,

the ABC Building, an interface on work breakdown structure

development as illustrated in Fig. 10 will appear. In this interface,

there are three buttons for WBS development. Clicking the New but-

ton will create a new work package or a child work package for an

existing work package; clicking the Edit button, the information of

an existing work package can be modied and updated; and clicking

the Delete button will delete an existing work package.

5.5. Material quantity management

Material quantity information is associated with each terminal work

package and includes material type, material name, material quantity

and wastage level. Clicking Manage quantity takeoff in the interface

as shown in Fig. 5, an interface as shown in Fig. 9 will appear for the

user to select a project and to manage its material quantity information.

Fig. 8. Project prole management.

Fig. 9. Project selection for work package management.

9 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

Clicking a particular project, for example, the ABC Building, an interface

as illustrated in Fig. 11 will appear. This interface presents the WBS of

the ABC Building and terminal work packages are color-highlighted.

Clicking a terminal work package, the material quantity information

of this terminal work package will be shown (Fig. 11). Users can update

the information of existing materials in this terminal work package or

add new materials and the corresponding information by clicking

Add Material.

6. Online analytical processing

6.1. Multi-dimensional OLAP analysis

The OLAP function of the WCWES can response swiftly to multi-

dimensional queries as illustrated in Fig. 12, for example, from the di-

mensions of work package, waste origin category and waste stream

individually or a combination of them. OLAP results would provide a

Fig. 10. Work breakdown structure development.

Fig. 11. Material quantity takeoff. (For interpretation of the references to color in this gure, the reader is referred to the web version of this article.)

10 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

strong support for decision making in waste management, for exam-

ple, in tracking the origin of a waste stream, identifying the category

of waste, and determining the most signicant waste stream in a

work package or in a project. In this regard, details are discussed in

the Sections 6.2 to 6.4.

6.2. Tracking origins of waste streams

Clicking the OLAP in the interface as shown in Fig. 5, an interface as

shown in Fig. 13(a) will appear. In this interface, users can drag each of

the three dimensions (i.e., work package, waste origin and waste

stream) to each of the three areas (i.e., rowarea, column area and lter

area) that are shown in red rectangles in Fig. 13(a). In the screenshot of

Fig. 13(a), the three dimensions are located in the lter area. Fig. 13(a)

will change to Fig. 13(b) if the waste origin dimension and the waste

stream dimension are dragged from the lter area to the row area.

In the interface as shown in Fig. 13(a), dragging the two dimen-

sions, Waste Origin and Waste Stream, to the rowarea as indicated

by the blue arrows in Fig. 13(a), (b) will appear, in which work pack-

ages that generate a particular kind of waste will be shown. The

WCWES could also provide various kinds of outputs on the basis of

the OLAP analysis results. The document types include pdf, excel, txt,

and html and the exported document could either be saved or opened

in the web browser.

Clicking the All waste by waste stream in the interface as shown in

Fig. 5, a pie chart as shown in Fig. 14(a) will be drawn, which indicates

the distribution of different construction waste streams in the project.

Clicking a particular kind of waste in Fig. 14(a), for example, concrete,

a graphic presentation as shown in Fig. 14(b) will appear, indicating

Fig. 12. Multiple dimensions of OLAP analysis.

a) OLAP analysis panel

b) OLAP analysis by waste origincategory and waste stream

Fig. 13. OLAP analysis. (For interpretation of the references to color in this gure, the reader is referred to the web version of this article.)

11 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

all work packages that generate the waste of concrete and the amount

of concrete waste in each work package. The charts can be opened in

the web browser as shown in Fig. 14(a), printed, or saved in different

types of documents. In addition, the format and palette can also be

changed to suit different presentation purposes.

6.3. Distribution of construction waste across four categories

Clicking All waste by origin category in the interface as shown in

Fig. 5, the distribution of construction waste across the four material

categories (i.e., construction materials, packaging materials, extracted

a) Construction waste by stream (unit: kg)

b) Concrete waste by work package (unit: kg)

Fig. 14. Waste distribution by stream.

12 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

materials, and target building elements) will be generated, for example,

by a pie chart as shown in Fig. 15(a). In Fig. 15(a), clicking a material

category, for example, construction materials, a graphic presentation

as shown in Fig. 15(b) will appear, indicating all waste streams in the

category of construction materials and the distribution of these waste

streams.

a) Construction waste by waste origin category (unit: kg)

b) Waste streams from construction materials (unit: kg)

Fig. 15. Waste distribution by waste origin category.

13 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

6.4. Identication of the most signicant waste streams

It is useful in waste management to identify the most signicant

kinds of waste from a work package or a project. This can be done

through the interface shown in Fig. 13(a) by dragging the waste stream

dimension fromthe lter area to the rowarea. This action will generate

a table as shown in Fig. 16, which presents the weights and volumes of

various kinds of construction waste in a descending order of weight

(the sorted sign appears after the column title Waste Weight (Kilo-

gram)). Right clicking Waste volume, the sorting option will appear.

Clicking the sorting function, the various kinds of waste can be sorted

according to waste volume, for example, from the largest volume to

the smallest volume. Moreover, the sorting order can be changed by

clicking the sort order sign in Fig. 16. In this way, the most signicant

waste streams can be found automatically.

7. Discussion

7.1. Wastage levels of various materials in different construction

processes

The wastage level refers to the percentage of a material that be-

comes waste in a construction process. A variety of factors inuence

construction waste generation. Chen et al. [6] pointed out that material

management, design coordination and labors' attitude affect construc-

tion waste generation. Huang et al. [9] listed a number of factors that in-

uence construction waste generation in building projects, including

structural type, functional type, region, building above ground, height

underground and total oor area. Poon et al. [19] summarized wastage

levels of a number of materials in the public housing projects of Hong

Kong and further investigated the waste reduction potential through

prefabrication [18]. Wastage levels used in the paper are obtained

through interviews of project managers and secondary resources in-

cluding journal papers [19].

Inaddition, a number of newtechnologies andconstructionmethods

have been used to control construction waste in the construction pro-

cess, for example, bar-code [6], radio-frequency identication (RFID)

[15] and prefabricated elements [17]. These technologies and methods

tend to reduce the wastage levels of materials in specic construction

processes. For example, prefabrication could avoid the plastering

waste and signicantly reduce concreting and rebar xing waste [22].

7.2. Level of detail of the WBS

The level of detail of terminal work packages depends on the con-

tractors' knowledge on the construction process and their ability to

control these processes. Therefore, the work breakdown structures

vary signicantly due to a number of factors, including scale of pro-

ject, design of project and construction methods. The standard build-

ing classication systems provide a means to develop a practical

WBS for building projects. This paper adopts the widely accepted

standard classication system, Uniformat II, which breaks a building

project into four hierarchical levels: system, component, element

and sub-element regardless of their design specications, materials

used and/or construction method/technology applied [5]. The

WCWES supports any level of detail of the WBS and allows users to

dene their work breakdown structures.

7.3. Validation of the WCWES

In the process of developing the WCWES, experts and practitioners

from relevant government departments, construction companies, and

consulting companies have been involved for their comments and sug-

gestions on the various issues related to the WCWES and for the valida-

tion of this system. In addition, several workshops and seminars have

been given to introduce the WCWES. Comments and suggestions are

also solicited in these workshops and seminars. The WCWES has been

improved consequently taking into consideration of the comments

and suggestions collected from different occasions.

8. Conclusions

Construction waste is a major source of municipal solid waste and

the large amounts of waste have been a high pressure on the sustainable

development of many cities around the globe. There is a need to im-

prove the waste management performance in the construction industry

in order to create a sustainable built environment. In this regard, accu-

rate estimation of various kinds of waste in the construction process is

one of the key issues in effective construction waste management.

The WCWES developed in this study provides an online waste esti-

mation platform for building construction projects. With user-friendly

interfaces, the WCWES integrates data input modules and online ana-

lytical modules. Data input modules include material management,

project management, WBS management and material quantity takeoff.

The online analytical modules allowanalysis of construction waste from

three dimensions: waste origin, waste stream and work package. The

WCWES is able to track the origins of construction waste streams, iden-

tify construction waste categories, and determine the most signicant

construction waste streams. Analytical results can be presented in

both graphical and non-graphical formats for easy understanding and

effective communication.

Fig. 16. Sorting waste streams.

14 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

The WCWES facilitates accessibility, interfacing, connectivity and in-

formation sharing of users in carrying out a wide range of construction

waste estimation tasks. The application of the WCWES in a hypothetical

building constructionproject has demonstrated its workability and use-

fulness. The WCWES would facilitate both the government and the con-

struction industry in quantifying and managing construction waste.

Acknowledgments

This study is sponsored by the Environment and Conservation

Fund (Grant Number: ECF Project 16/2010) of the Government of

the Hong Kong Special Administrative Region, China.

References

[1] B.A.G. Bossink, H.J.H. Brouwers, Construction waste: quantication and source

evaluation, Journal of Construction Engineering and Management ASCE 122

(1996) 339346.

[2] British Research Establish, SMARTWaste, http://www.smartwaste.co.uk/.

[3] A. Bruvoll, K. Ibenholt, Future waste generation: forecasts on the basis of a mac-

roeconomic model, Resources, Conservation and Recycling 19 (1997) 137149.

[4] CDM, Waste Characterization Study, Department of Environment, City of Chicago,

Illinois, United States, 2010.

[5] R.P. Charette, H.E. Marshall, Uniformat II Elemental Classication for Building

Specications, Cost Estimating, and Cost Analysis, National Institute of Standards

and Technology, Gaithersburg, Maryland, United States, 1999.

[6] Z. Chen, H. Li, C.T.C. Wong, An application of bar-code system for reducing con-

struction wastes, Automation in Construction 11 (2002) 521533.

[7] K.M. Cochran, T.G. Townsend, Estimating construction and demolition debris

generation using a materials ow analysis approach, Waste Management 30

(2010) 22472254.

[8] D. Fatta, A. Papadopoulos, E. Avramikos, E. Sgourou, K. Moustakas, F. Kourmoussis,

A. Mentzis, M. Loizidou, Generation and management of construction and demo-

lition waste in Greece an existing challenge, Resources, Conservation and

Recycling 40 (2003) 8191.

[9] R.-Y. Huang, L.-H. Yeh, H.-H. Chen, J.-D. Lin, P.-F. Chen, P.-H. Sung, J.-T. Yau, Esti-

mation of construction waste generation and management in Taiwan, Advanced

Materials Research 243249 (2011) 62926295.

[10] K. Ibenholt, Material accounting in a macroeconomic framework: forecast of

waste generated in manufacturing industries in Norway, Environmental and Re-

source Economics 26 (2003) 227248.

[11] A. Katz, H. Baum, A novel methodology to estimate the evolution of construction

waste in construction sites, Waste Management 31 (2011) 353358.

[12] O.F. Kofoworola, S.H. Gheewala, Estimation of construction waste generation and

management in Thailand, Waste Management 29 (2009) 731738.

[13] B. Kourmpanis, A. Papadopoulos, K. Moustakas, M. Stylianou, K.J. Haralambous, M.

Loizidou, Preliminary study for the management of construction and demolition

waste, Waste Management & Research 26 (2008) 267275.

[14] C. Llatas, A model for quantifying construction waste in projects according to the

European waste list, Waste Management 31 (2011) 12611276.

[15] W. Lu, G.Q. Huang, H. Li, Scenarios for applying RFID technology in construction

project management, Automation in Construction 20 (2011) 101106.

[16] I. Martnez Lage, F. Martnez Abella, C.V. Herrero, J.L.P. Ordez, Estimation of the

annual production and composition of C&D debris in Galicia (Spain), Waste Man-

agement 30 (2010) 636645.

[17] L. Jaillon, C.S. Poon, The evolution of prefabricated residential building systems in

Hong Kong: a review of the public and private sector, Automation in Construction

18 (2009) 239248.

[18] L. Jaillon, C.S. Poon, Y.H. Chiang, Quantifying the waste reduction potential of

using prefabrication in building construction in Hong Kong, Waste Management

29 (2009) 309320.

[19] C.S. Poon, A.T.W. Wu, S.W. Wong, E. Cheung, Management of construction waste

in public housing projects in Hong Kong, Construction Management and Econom-

ics 22 (2004) 675689.

[20] J. Shi, Y. Xu, Estimation and forecasting of concrete debris amount in China, Re-

sources, Conservation and Recycling 49 (2006) 147158.

[21] J. Sols-Guzmn, M. Marrero, M.V. Montes-Delgado, A. Ramrez-de-Arellano, A

Spanish model for quantication and management of construction waste,

Waste Management 29 (2009) 25422548.

[22] V.W.Y. Tam, C.M. Tam, L.Y. Shen, Comparing material wastage levels between

conventional in-situ and prefabrication construction in Hong Kong, Journal of

Harbin Institute of Technology 11 (2004) 548551.

[23] P. Villoria Sez, M. Del Ro Merino, C. Porras-Amores, Estimation of construction

and demolition waste volume generation in new residential buildings in Spain,

Waste Management & Research 30 (2012) 137146.

[24] J.Y. Wang, A. Touran, C. Christoforou, H. Fadlalla, A systems analysis tool for con-

struction and demolition waste management, Waste Management 24 (2004)

989997.

[25] S.H.L. Wong, W.C.K. Tam, A.H.L. Yim, N.H.Y. Ip, Monitoring of Solid Waste in Hong

Kong: Waste Statistics for 2005, Environmental Protection Department, Hong

Kong, China, 2006.

[26] X. Zhang, Markov-based optimization model for building facilities management,

Journal of Construction Engineering and Management ASCE 132 (2006)

12031211.

[27] X. Zhang, Y. Li, Developing a quantitative construction waste estimation model

for building construction projects, Waste Manage (2013), (submitted for

publication).

15 Y. Li, X. Zhang / Automation in Construction xxx (2013) xxxxxx

Please cite this article as: Y. Li, X. Zhang, Web-based construction waste estimation systemfor building construction projects, Automation in Con-

struction (2013), http://dx.doi.org/10.1016/j.autcon.2013.05.002

You might also like

- Environmental and Economic Impact Assessment of CDW Disposal PDFDocument9 pagesEnvironmental and Economic Impact Assessment of CDW Disposal PDFjcaldanabNo ratings yet

- Construction Waste Estimation Depending On Urban Planning Options in The Design Stage of Residential BuildingsDocument10 pagesConstruction Waste Estimation Depending On Urban Planning Options in The Design Stage of Residential BuildingsjcaldanabNo ratings yet

- Construction and Demolition Waste Indicators: Extended AbstractDocument16 pagesConstruction and Demolition Waste Indicators: Extended AbstractjcaldanabNo ratings yet

- Critical Management Practices Influecing On Site Waste Minimization in Construction ProjectsDocument10 pagesCritical Management Practices Influecing On Site Waste Minimization in Construction ProjectsjcaldanabNo ratings yet

- Resources, Conservation and RecyclingDocument15 pagesResources, Conservation and Recyclingjcaldanab100% (1)

- Environmental and Economic Impact Assessment of CDW DisposalDocument9 pagesEnvironmental and Economic Impact Assessment of CDW DisposaljcaldanabNo ratings yet

- Analysis of The Implementation of Effective Waste Management Practices in Construction Projects and SitesDocument13 pagesAnalysis of The Implementation of Effective Waste Management Practices in Construction Projects and Sitesjcaldanab100% (1)

- 84 - Recycled Construction and Demolition Concrete Waste As Aggregate For Structural ConcreteDocument8 pages84 - Recycled Construction and Demolition Concrete Waste As Aggregate For Structural ConcretejcaldanabNo ratings yet

- Renewable and Sustainable Energy Reviews: Hongping Yuan, Weisheng Lu, Jane Jianli HaoDocument8 pagesRenewable and Sustainable Energy Reviews: Hongping Yuan, Weisheng Lu, Jane Jianli HaoBárbara PavaniNo ratings yet

- A SWOT Analysis of Successful Construction Waste ManagementDocument8 pagesA SWOT Analysis of Successful Construction Waste ManagementJacky_LEOLEONo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Urban Identity and Iconic BuildingsDocument169 pagesUrban Identity and Iconic Buildingsimhotabdoo100% (3)

- Earthquake-Resistant Design of Open Ground Storey RC Framed BuildingsDocument8 pagesEarthquake-Resistant Design of Open Ground Storey RC Framed BuildingsHemant SonawadekarNo ratings yet

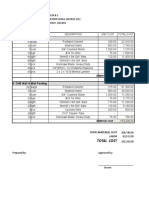

- Bill of Materials: I. Column & FootingDocument2 pagesBill of Materials: I. Column & FootingRalf Francis SaraNo ratings yet

- I H Record OfthejuryDocument6 pagesI H Record OfthejuryDelia DeliutzaNo ratings yet

- Load-Shedding Domestic GroupsDocument4 pagesLoad-Shedding Domestic GroupsTiso Blackstar Group38% (8)

- Plan Training Session CHSDocument51 pagesPlan Training Session CHSAnnabelle Reyes SucgangNo ratings yet

- Mega Everdrive-V2 User Manual EN PDFDocument15 pagesMega Everdrive-V2 User Manual EN PDFrhoads5150No ratings yet

- PXE Boot TinyCore Using CentOS - General Linux - SpiceworksDocument2 pagesPXE Boot TinyCore Using CentOS - General Linux - SpiceworksDav BarbaNo ratings yet

- LSDA Phased Evac 1990Document33 pagesLSDA Phased Evac 1990Peter GardnerNo ratings yet

- BPC Embebido PDFDocument160 pagesBPC Embebido PDFDiana Marcela Maya PatinoNo ratings yet

- Seven QC Tools For Process Quality ImprovementDocument119 pagesSeven QC Tools For Process Quality ImprovementRaajha MunibathiranNo ratings yet

- Underground Floor Ventilation Report PDFDocument23 pagesUnderground Floor Ventilation Report PDFNor Azman AmrilNo ratings yet

- Reference ArchitectureDocument15 pagesReference Architectureali_saleyNo ratings yet

- Le Corbusier and Louis Kahn (Introduction To Modernism in India)Document20 pagesLe Corbusier and Louis Kahn (Introduction To Modernism in India)AKANSHA RAWATNo ratings yet

- United Precast ConcreteDocument28 pagesUnited Precast Concretesopnanair100% (1)

- Parts List: Cybex Arc Trainer 610A Service ManualDocument10 pagesParts List: Cybex Arc Trainer 610A Service ManualJason EverittNo ratings yet

- Unit-1 HTML Common TagsDocument45 pagesUnit-1 HTML Common TagsRavi KumarNo ratings yet

- Section Details of Staff Common RoomDocument1 pageSection Details of Staff Common RoomAshok DhengeNo ratings yet

- Comet Attr EditorDocument3 pagesComet Attr EditorQAZwsx13No ratings yet

- Acsys Software (India) PVT LTD.: Web Based Fund Distributor Information SystemDocument7 pagesAcsys Software (India) PVT LTD.: Web Based Fund Distributor Information SystemRachana WagleNo ratings yet

- A PDFDocument10 pagesA PDFKimberly HerayNo ratings yet

- DataCores SANsymphonyV Part 2 Mirrored Virtual DiskDocument5 pagesDataCores SANsymphonyV Part 2 Mirrored Virtual DiskRalfRalfNo ratings yet

- Basics of Electronics and Microprocessor MCQ'sDocument16 pagesBasics of Electronics and Microprocessor MCQ'srohi8975% (4)

- Multiprotocol Label Switching (MPLS) (MPLS) : Higher Institute For Applied Sciences and TechnologyDocument31 pagesMultiprotocol Label Switching (MPLS) (MPLS) : Higher Institute For Applied Sciences and TechnologyHasan AhmadNo ratings yet

- Candy Cn65atDocument22 pagesCandy Cn65atderol12345100% (1)

- Bittorrent-Like P2P NetworkDocument41 pagesBittorrent-Like P2P NetworkNguyễn Ngọc GiàuNo ratings yet

- Good Admin Guide ExchangeDocument466 pagesGood Admin Guide Exchangejohndoe2007100% (1)

- Titan MicropilesDocument12 pagesTitan Micropilesmunain_gNo ratings yet

- Thermal Stress GlassDocument16 pagesThermal Stress GlassVinicius PetrucciNo ratings yet

- Trimoval PDFDocument6 pagesTrimoval PDFРостислав ВасилевNo ratings yet