Professional Documents

Culture Documents

PWPS For Piping-API 1104

Uploaded by

Nguyen Tien Luong100%(1)100% found this document useful (1 vote)

1K views6 pagesNoi Bai international airport terminal 2 Construction WPS No. JFE / L691 / pWPS-001 Revision No. 0 Date 20 - Nov. - 2012 Supporting PQR No.(s) to be Qualified Date GTAW Type(s) Manual, Machine, Automatic, Semi-Auto JOINTS (QW - 402) DETAILS Joints Design: All type of groove &Fillet Welds T 1-2 mm 1-3

Original Description:

Original Title

PWPS for Piping-API 1104

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNoi Bai international airport terminal 2 Construction WPS No. JFE / L691 / pWPS-001 Revision No. 0 Date 20 - Nov. - 2012 Supporting PQR No.(s) to be Qualified Date GTAW Type(s) Manual, Machine, Automatic, Semi-Auto JOINTS (QW - 402) DETAILS Joints Design: All type of groove &Fillet Welds T 1-2 mm 1-3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views6 pagesPWPS For Piping-API 1104

Uploaded by

Nguyen Tien LuongNoi Bai international airport terminal 2 Construction WPS No. JFE / L691 / pWPS-001 Revision No. 0 Date 20 - Nov. - 2012 Supporting PQR No.(s) to be Qualified Date GTAW Type(s) Manual, Machine, Automatic, Semi-Auto JOINTS (QW - 402) DETAILS Joints Design: All type of groove &Fillet Welds T 1-2 mm 1-3

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

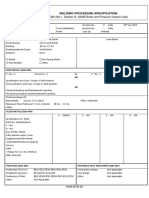

PRELIMINARY WELDING PROCEDURE SPECIFICATION (pWPS) Sheet 1 / 2

Project Name Noi Bai International Airport Terminal 2 Construction

WPS No. JFE/L691/pWPS-001 Revision No. 0 Date 20 - Nov. - 2012

Supporting PQR No.(s) To be Qualified Revision No. Date

Welding Process(es) GTAW Type(s)

Manual

(Manual, Machine, Automatic, Semi-Auto)

Applicable Code API Standard 1104 - 2007

JOINTS (QW - 402)

DETAILS

Joints Design: All type of Groove &Fillet Welds

T

1-2 mm

1-3 mm

70

0

-80

0

T

T

1-3 mm

1-3 mm

Backing (Yes) N/A (No) X

Backing Meterial (Type): No X

Refer to both backing andretainers

Metal Nonfusing Metal

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

BASE METALS (QW - 403)

P-No. 1 Group No. 1; 2 To P-No. 1 Group No. 1; 2

OR

Specification Type and Grade ASTM A53 Gr.B; A106 Gr.C OR EQUIVALENT

To Specification Type and Grade

ASTM A53 Gr.B; A106 Gr.C OR EQUIVALENT

OR

Chem. Analysis & Mech. Prop /

To Chem. Analysis & Mech. Prop /

Thickness Range:

Base Metal: Groove 1.5 mm to 7.82 mm

Fillet UNLIMITED

Diameter range

UNLIMITED

Other N/A

FILLER METALS (QW - 404)

Spec No. (SFA) SFA 5.18

AWS No. (Class) ER 70S-6

F - No. 6

A - No. 1

Size of Filler Metals: 2.4 mm

Weld Metal Thickness Range:

Groove 1.5 mm to 7.82 mm

Fillet UNLIMITED

Electrode Flux (Class) N/A

Filler Metal Trade Name Kobe TGS-51T/ Chosun TGC-50S

Hyundai ST-50.6/ Lincoln E70S6F0/

Metrode ER70S-6

Consumable Insert /

Flux Trade Name /

Other /

pWPS No.: JFE/L691/pWPS-001

Sheet 2 / 2

POSITIONS (QW - 405) POSTWELD HEAT TREATMENT (QW - 407)

Position(s) of Groove All positions

Temp. Range None

Welding Progression All positions Time Range N/A

Position(s) of Fillet All positions Heating Rate N/A

Other N/A Cooling Rate N/A

PREHEAT (QW - 406) GAS (QW - 408)

Preheat Temp. Min. Ambient Percent Composition

Interpass Temperature 250

0

C (Max.) Gas(es) (Mixture) Flow Rate

Preheat Maintenance N/A Shielding Ar 99,9% 7 -15L/min

Inter Cooling N/A Trailing N/A N/A N/A

(Continuous or special heating where applicable should be

recorded)

Backing N/A N/A N/A

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC: DC Polarity: EN (DC-)

Amps (Range): See table below Volts (Range): See table below

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a

tabular from to that shown be low)

Tungsten Electrode Size and Type: 2.4mm, EWTh-2

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW: N/A

(Spray Arc, Short Circuiting Arc, etc.)

Electrode Wire Feed Speed Range: N/A

TECHNIQUE (QW - 410)

String or Weave Bead: String and weave

Orifice or Gas Cup Size: No. 4, 5, 6 and 10

Initial and Interpass Cleaning: Brushing, Chipping and Grinding

Method of Backing Gouging: None

Contact Tube to Work Distance: /

Multiple or Single Pass (per side): Multiple

Multiple or Single Electrodes: Single

Travel Speed Range: See table below

Peening: /

Weld

Layer(s) Process

Filler Metal Current Volts

Range

(V)

Travel

Speed

(mm /min)

Remark

Class Dia.(mm) Polarity Amp (A)

Root pass

Hot pass

Fill pass

Cap pass

GTAW ER70S-6 2.4 DCEN 60 - 150 12 - 18 50 - 130 /

Prepared by: LILAMA 69-1 Checked by: JFE Approved by: TVJV Approved by: Owner

Name: Name: Name: Name:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

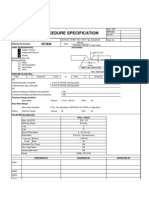

PRELIMINARY WELDING PROCEDURE SPECIFICATION (pWPS) Sheet 1 / 2

Project Name Noi Bai International Airport Terminal 2 Construction

WPS No. JFE/L691/pWPS-002 Revision No. Date 20 - Nov. - 2012

Supporting PQR No.(s) To be Qualified Revision No. Date

Welding Process(es) GTAW Type(s)

Manual

(Manual, Machine, Automatic, Semi-Auto)

Applicable Code API Standard 1104 - 2007

JOINTS (QW - 402)

DETAILS

Joints Design: All type of Groove &Fillet Welds

Backing (Yes) N/A (No) X

T

1-2 mm

1-3 mm

70

0

-80

0

T

T

1-3 mm

1-3 mm

Backing Meterial (Type): No X

Refer to both backing andretainers

Metal Nonfusing Metal

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be specified.

BASE METALS (QW - 403)

P-No. 8 Group No. 1 To P-No. 8 Group No. 1

OR

Specification Type and Grade ASTM A312 TP304 OR EQUIVALENT

To Specification Type and Grade ASTM A312 TP304 OR EQUIVALENT

OR

Chem. Analysis & Mech. Prop /

To Chem. Analysis & Mech. Prop /

Thickness Range:

Base Metal: Groove 1.5 mm to 11.08 mm

Fillet UNLIMITED

Diameter range

UNLIMITED

Other N/A

FILLER METALS (QW - 404)

Spec No. (SFA) SFA 5.9

AWS No. (Class) ER 308L

F - No. 6

A - No. 8

Size of Filler Metals: 2.4 mm

Weld Metal Thickness Range:

Groove 1.5 mm to 11.08 mm

Fillet UNLIMITED

Electrode Flux (Class) N/A

Filler Metal Trade Name Kobe TGS-308L/ Chosun TGC-308L/ Hyundai ST-308L/

ESAB OK Tigrod 308L/ Kiswel T-308L/

Kuangtai KTS-308L/ Metrode 308S92

Consumable Insert /

Flux Trade Name /

Other /

pWPS No.: JFE/L691/pWPS-002

Sheet 2 / 2

POSITIONS (QW - 405) POSTWELD HEAT TREATMENT (QW - 407)

Position(s) of Groove All positions

Temp. Range None

Welding Progression All positions Time Range N/A

Position(s) of Fillet All positions Heating Rate N/A

Other N/A Cooling Rate N/A

PREHEAT (QW - 406) GAS (QW - 408)

Preheat Temp. Min. Ambient Percent Composition

Interpass Temperature 150

0

C (Max.) Gas(es) (Mixture) Flow Rate

Preheat Maintenance N/A Shielding Ar 99,9% 7 -15L/min

Inter Cooling N/A Trailing N/A N/A N/A

(Continuous or special heating where applicable should be

recorded)

Backing Ar 99,9% 10 -20L/min

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC: DC Polarity: EN (DC-)

Amps (Range): See table below Volts (Range): See table below

(Amps and volts range should be recorded for each electrode

size, position, and thickness, etc. This information may be listed

in a tabular from to that shown be low)

Tungsten Electrode Size and Type: 2.4mm, EWTh-2

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW: N/A

(Spray Arc, Short Circuiting Arc, etc.)

Electrode Wire Feed Speed Range: N/A

TECHNIQUE (QW - 410)

String or Weave Bead: String and weave

Orifice or Gas Cup Size: No. 4, 5, 6 and 10

Initial and Interpass Cleaning: Brushing, Chipping and Grinding

Method of Backing Gouging: None

Contact Tube to Work Distance: /

Multiple or Single Pass (per side): Multiple

Multiple or Single Electrodes: Single

Travel Speed Range: See table below

Peening: /

Weld

Layer(s)

Process

Filler Metal Current Volts

Range

(V)

Travel Speed

(mm /min)

Remark

Class. Dia.(mm) Polarity Amp (A)

Root pass

Hot pass

Fill pass

Cap pass

GTAW ER308L 2.4 DCEN 90 - 160 12 - 18 60 - 120 /

Prepared by: LILAMA 69-1 Checked by: JFE Approved by: TVJV Approved by: Owner

Name: Name: Name: Name:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

PRELIMINARY WELDING PROCEDURE SPECIFICATION (pWPS) Sheet 1 / 2

Project Name Noi Bai International Airport Terminal 2 Construction

WPS No. JFE/L691/pWPS-003 Revision No. 0 Date 20 - Nov. - 2012

Supporting PQR No.(s) To be Qualified Revision No. Date

Welding Process(es) GTAW+SMAW Type(s)

Manual

(Manual, Machine, Automatic, Semi-Auto)

Applicable Code API Standard 1104 - 2007

JOINTS (QW - 402)

DETAILS

Joints Design: All type of Groove &Fillet Welds

T

1-2 mm

1-3 mm

70

0

-80

0

T

T

1-3 mm

1-3 mm

Backing (Yes) N/A (No) X

Backing Meterial (Type): No X

Refer to both backing andretainers

Metal Nonfusing Metal

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

BASE METALS (QW - 403)

P-No. 1 Group No. 1; 2 To P-No. 1 Group No. 1; 2

OR

Specification Type and Grade ASTM A53 Gr.B; A106 Gr.C OR EQUIVALENT

To Specification Type and Grade

ASTM A53 Gr.B; A106 Gr.C OR EQUIVALENT

OR

Chem. Analysis & Mech. Prop /

To Chem. Analysis & Mech. Prop /

Thickness Range:

Base Metal: Groove 5 mm to 21.94 mm

Fillet UNLIMITED

Diameter range

UNLIMITED

Other N/A

FILLER METALS (QW - 404)

Spec No. (SFA) SFA 5.18 SFA 5.1

AWS No. (Class) ER 70S-6 ER 7016

F - No. 6 4

A - No. 1 1

Size of Filler Metals: 2.4 mm 3.2 mm

Weld Metal Thickness Range:

Groove 1.5 mm to 8 mm 1.5 mm to 13.94 mm

Fillet UNLIMITED UNLIMITED

Electrode Flux (Class) N/A N/A

Filler Metal Trade Name

Kobe TGS-51T/ Chosun TGC-50S

Hyundai ST-50.6/ Lincoln E70S6F0/

Metrode ER70S-6

Kobe LB-52/ Chosun LC-300/

ESAB OK 53.05

Consumable Insert / /

Flux Trade Name / /

Other / /

pWPS No.: JFE/L691/pWPS-003

Sheet 2 / 2

POSITIONS (QW - 405) POSTWELD HEAT TREATMENT (QW - 407)

Position(s) of

Groove

All positions

Temp. Range None

Welding Progression All positions Time Range N/A

Position(s) of Fillet All positions Heating Rate N/A

Other N/A Cooling Rate N/A

PREHEAT (QW - 406) GAS (QW - 408)

Preheat Temp. Min. Ambient Percent Composition

Interpass Temperature 250

0

C (Max.) Gas(es) (Mixture) Flow Rate

Preheat Maintenance N/A Shielding Ar 99,9% 7 -15L/min

Inter Cooling N/A Trailing N/A N/A N/A

(Continuous or special heating where applicable should be

recorded)

Backing N/A N/A N/A

ELECTRICAL CHARACTERISTICS (QW- 409)

Current AC or DC: DC Polarity: EN (DC-) for GTAW/ EP(DC+) for SMAW

Amps (Range): See table below Volts (Range): See table below

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a

tabular from to that shown be low)

Tungsten Electrode Size and Type: 2.4mm, EWTh-2

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW: N/A

(Spray Arc, Short Circuiting Arc, etc.)

Electrode Wire Feed Speed Range: N/A

TECHNIQUE (QW - 410)

String or Weave Bead: String and weave

Orifice or Gas Cup Size: No. 4, 5, 6 and 10

Initial and Interpass Cleaning: Brushing, Chipping and Grinding

Method of Backing Gouging: None

Contact Tube to Work Distance: /

Multiple or Single Pass (per side): Multiple

Multiple or Single Electrodes: Single

Travel Speed Range: See table below

Peening: /

Weld

Layer(s) Process

Filler Metal Current Volts

Range

(V)

Travel

Speed

(mm /min)

Remark

Class Dia.(mm) Polarity Amp (A)

Root pass

Hot pass

GTAW ER70S-6 2.4 DCEN 60 - 150 12 - 18 50 - 130 /

Fill pass

Cap pass

SMAW ER 7016 3.2 DCEP

85-130 20-28 60-100

/

Prepared by: LILAMA 69-1 Checked by: JFE Approved by: TVJV Approved by: Owner

Name: Name: Name: Name:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

You might also like

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- WPS-PQR Gmaw LtiDocument2 pagesWPS-PQR Gmaw Ltibgonzalez198150% (2)

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS 03Document2 pagesWPS 03mansoor_an100% (1)

- 653 WPS-PQR PDFDocument4 pages653 WPS-PQR PDFETSNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Concrete Slab Design Using Mathcad PDFDocument7 pagesConcrete Slab Design Using Mathcad PDFDiaconu SofiaNo ratings yet

- 3408C & 3412C Electrical System Marine Auxillary Generator SetDocument2 pages3408C & 3412C Electrical System Marine Auxillary Generator SetHamid Essarbouti100% (1)

- Katalog 920 PDFDocument707 pagesKatalog 920 PDFbubulelaman100% (4)

- 24a Fuel Injection-Motronic (1.8L)Document14 pages24a Fuel Injection-Motronic (1.8L)Sinisa Gale GacicNo ratings yet

- Ece Lab Manual - MiteDocument44 pagesEce Lab Manual - MiteSubuddhi DamodarNo ratings yet

- Yonas Thesis Final .Docx2Document87 pagesYonas Thesis Final .Docx2Noil Son100% (1)

- Itt Grinnell Pipe Hanger Design & Engineering 2008Document80 pagesItt Grinnell Pipe Hanger Design & Engineering 2008ITT GRINNELLNo ratings yet

- LEWA EcoflowTheInnovativeMeteringPumpsDocument16 pagesLEWA EcoflowTheInnovativeMeteringPumpsSrujana KandagatlaNo ratings yet

- PT Fuel System Parts ListDocument31 pagesPT Fuel System Parts Listfinanceiro engetemanNo ratings yet

- Especificaciones Rapidas P7690Document3 pagesEspecificaciones Rapidas P7690ALIB SOUNDNo ratings yet

- Natural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)Document4 pagesNatural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)jmpandolfiNo ratings yet

- Cusat Select List-TcsDocument6 pagesCusat Select List-Tcsnawazish_nehalNo ratings yet

- SHC 302 FinalDocument285 pagesSHC 302 FinalAmr HassanNo ratings yet

- Campbell Hausfeld 70 Amp Stick WelderDocument36 pagesCampbell Hausfeld 70 Amp Stick WelderJosé RamosNo ratings yet

- A Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowDocument19 pagesA Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowPeerasak ArunNo ratings yet

- A Multibody Tool For The Optimization of The SuspeDocument11 pagesA Multibody Tool For The Optimization of The SuspeMei Arief HindartoNo ratings yet

- Uniform Rotary MotionDocument26 pagesUniform Rotary MotionMark RamosNo ratings yet

- Dimensions and Other Data: Gas Engines and GensetsDocument12 pagesDimensions and Other Data: Gas Engines and Gensetsjafarinha0% (1)

- T Mech Clamp CatalogueDocument29 pagesT Mech Clamp CatalogueKABIR CHOPRANo ratings yet

- AT 402 - OM 1 DescriptionDocument17 pagesAT 402 - OM 1 DescriptionCarlos Alberto Rozo R.No ratings yet

- 5114 21 03.kitDocument3 pages5114 21 03.kitTimon2005No ratings yet

- Chapter 8 - Kinematics of GearsDocument37 pagesChapter 8 - Kinematics of GearskbashokNo ratings yet

- S.N o Committee Number Committee Name Published StandardsDocument1 pageS.N o Committee Number Committee Name Published Standardsnarendar.1No ratings yet

- Introduction To The Mathematical Nonlinear Wave MotionDocument157 pagesIntroduction To The Mathematical Nonlinear Wave Motionmehr1384No ratings yet

- d5c Clutch y Frenos 1Document4 pagesd5c Clutch y Frenos 1Pepe AlonzoNo ratings yet

- Chapter 9 Summary and ReviewDocument12 pagesChapter 9 Summary and ReviewHenry ZaleskiNo ratings yet

- Manning S CoefficientDocument9 pagesManning S CoefficientvyrgoNo ratings yet

- Omega - Installation ManualDocument25 pagesOmega - Installation ManualCreaciones VilberNo ratings yet

- Part 4 Mesin FluidaDocument23 pagesPart 4 Mesin FluidaARFAI020797No ratings yet

- WDH-SL3 Product Information SP13L002GB-04 - 1542713324933Document2 pagesWDH-SL3 Product Information SP13L002GB-04 - 1542713324933irwantino susiloNo ratings yet