Professional Documents

Culture Documents

ASM Material Data Sheet (Aluminium Beam)

Uploaded by

Mohammed Adnan0 ratings0% found this document useful (0 votes)

80 views2 pagesThis document provides material data on aluminum alloy 6061-T6 and 6061-T651, including its typical composition, physical and mechanical properties, thermal properties, and common applications. Key points include:

- The alloy is composed primarily of aluminum (95.8-98.6%), along with magnesium, silicon, and copper.

- It has good workability, strength, and corrosion resistance, making it widely used for aircraft fittings, bike frames, and other applications.

- Typical properties include a density of 0.0975 lb/in3, ultimate tensile strength of 45,000 psi, elongation at break of 12%, and thermal conductivity of 1160 BTU-in/hr-

Original Description:

Material Data

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides material data on aluminum alloy 6061-T6 and 6061-T651, including its typical composition, physical and mechanical properties, thermal properties, and common applications. Key points include:

- The alloy is composed primarily of aluminum (95.8-98.6%), along with magnesium, silicon, and copper.

- It has good workability, strength, and corrosion resistance, making it widely used for aircraft fittings, bike frames, and other applications.

- Typical properties include a density of 0.0975 lb/in3, ultimate tensile strength of 45,000 psi, elongation at break of 12%, and thermal conductivity of 1160 BTU-in/hr-

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

80 views2 pagesASM Material Data Sheet (Aluminium Beam)

Uploaded by

Mohammed AdnanThis document provides material data on aluminum alloy 6061-T6 and 6061-T651, including its typical composition, physical and mechanical properties, thermal properties, and common applications. Key points include:

- The alloy is composed primarily of aluminum (95.8-98.6%), along with magnesium, silicon, and copper.

- It has good workability, strength, and corrosion resistance, making it widely used for aircraft fittings, bike frames, and other applications.

- Typical properties include a density of 0.0975 lb/in3, ultimate tensile strength of 45,000 psi, elongation at break of 12%, and thermal conductivity of 1160 BTU-in/hr-

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

NOLNNLNO ^ pj =j ~~=a ~~=p

NLO ~ K ~ K L~Lpj ~~K~\ ~ Zj ^ SMSNS

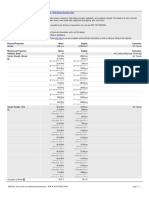

Aluminum 6061-T6; 6061-T651

Subcategory: 6000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal

Close Analogs:

Composition Notes:

Aluminum content reported is calculated as remainder.

Composition information provided by the Aluminum Association and is not for design.

Key Words: al6061, UNS A96061; ISO AlMg1SiCu; Aluminium 6061-T6, AD-33 (Russia); AA6061-T6;

6061T6, UNS A96061; ISO AlMg1SiCu; Aluminium 6061-T651, AD-33 (Russia); AA6061-T651

Component Wt. %

Al 95.8 - 98.6

Cr 0.04 - 0.35

Cu 0.15 - 0.4

Fe Max 0.7

Component Wt. %

Mg 0.8 - 1.2

Mn Max 0.15

Other, each Max 0.05

Other, total Max 0.15

Component Wt. %

Si 0.4 - 0.8

Ti Max 0.15

Zn Max 0.25

Material Notes:

Information provided by Alcoa, Starmet and the references. General 6061 characteristics and uses: Excellent joining

characteristics, good acceptance of applied coatings. Combines relatively high strength, good workability, and high resistance to

corrosion; widely available. The T8 and T9 tempers offer better chipping characteristics over the T6 temper.

Applications: Aircraft fittings, camera lens mounts, couplings, marines fittings and hardware, electrical fittings and connectors,

decorative or misc. hardware, hinge pins, magneto parts, brake pistons, hydraulic pistons, appliance fittings, valves and valve

parts; bike frames.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

Physical Properties Metric English Comments

Density 2.7 g/cc 0.0975 lb/in

AA; Typical

Mechanical Properties

Hardness, Brinell 95 95

AA; Typical; 500 g load; 10 mm ball

Hardness, Knoop 120 120

Converted from Brinell Hardness Value

Hardness, Rockwell A 40 40

Converted from Brinell Hardness Value

Hardness, Rockwell B 60 60

Converted from Brinell Hardness Value

Hardness, Vickers 107 107

Converted from Brinell Hardness Value

Ultimate Tensile Strength 310 MPa 45000 psi

AA; Typical

Tensile Yield Strength 276 MPa 40000 psi

AA; Typical

Elongation at Break 12 % 12 %

AA; Typical; 1/16 in. (1.6 mm) Thickness

Elongation at Break 17 % 17 %

AA; Typical; 1/2 in. (12.7 mm) Diameter

NOLNNLNO ^ pj =j ~~=a ~~=p

OLO ~ K ~ K L~Lpj ~~K~\ ~ Zj ^ SMSNS

AA; Typical; 1/2 in. (12.7 mm) Diameter

Modulus of Elasticity 68.9 GPa 10000 ksi

AA; Typical; Average of tension and compression.

Compression modulus is about 2% greater than tensile

modulus.

Notched Tensile Strength 324 MPa 47000 psi

2.5 cm width x 0.16 cm thick side-notched specimen, K

t

=

17.

Ultimate Bearing Strength 607 MPa 88000 psi

Edge distance/pin diameter = 2.0

Bearing Yield Strength 386 MPa 56000 psi

Edge distance/pin diameter = 2.0

Poisson's Ratio 0.33 0.33

Estimated from trends in similar Al alloys.

Fatigue Strength 96.5 MPa 14000 psi

AA; 500,000,000 cycles completely reversed stress; RR

Moore machine/specimen

Fracture Toughness 29 MPa-m 26.4 ksi-in

K

IC

; TL orientation.

Machinability 50 % 50 %

0-100 Scale of Aluminum Alloys

Shear Modulus 26 GPa 3770 ksi

Estimated from similar Al alloys.

Shear Strength 207 MPa 30000 psi

AA; Typical

Electrical Properties

Electrical Resistivity 3.99e-006 ohm-cm 3.99e-006 ohm-cm

AA; Typical at 68F

Thermal Properties

CTE, linear 68F 23.6 m/m-C 13.1 in/in-F

AA; Typical; Average over 68-212F range.

CTE, linear 250C 25.2 m/m-C 14 in/in-F

Estimated from trends in similar Al alloys. 20-300C.

Specific Heat Capacity 0.896 J/g-C 0.214 BTU/lb-F

Thermal Conductivity 167 W/m-K 1160 BTU-in/hr-ft-F

AA; Typical at 77F

Melting Point 582 - 652 C 1080 - 1205 F

AA; Typical range based on typical composition for wrought

products 1/4 inch thickness or greater; Eutectic melting can

be completely eliminated by homogenization.

Solidus 582 C 1080 F

AA; Typical

Liquidus 652 C 1205 F

AA; Typical

Processing Properties

Solution Temperature 529 C 985 F

Aging Temperature 160 C 320 F

Rolled or drawn products; hold at temperature for 18 hr

Aging Temperature 177 C 350 F

Extrusions or forgings; hold at temperature for 8 hr

References for this datasheet.

Some of the val ues di spl ayed above may have been converted from thei r ori gi nal uni ts and/or rounded i n order to di spl ay the i nformati on i n a consi stant

format. Users requi ri ng more preci se data for sci enti fi c or engi neeri ng cal cul ati ons can cl i ck on the property val ue to see the ori gi nal val ue as wel l as raw

conversi ons to equi val ent uni ts. We advi se that you onl y use the ori gi nal val ue or one of i ts raw conversi ons i n your cal cul ati ons to mi ni mi ze roundi ng error. We

al so ask that you refer to MatWeb's di scl ai mer and terms of use regardi ng thi s i nformati on. MatWeb data and tool s provi ded by MatWeb, LLC.

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- AEASM1x Progress - EdxDocument8 pagesAEASM1x Progress - EdxssvivekanandhNo ratings yet

- 7178-T6511 Property - ASM Material Data SheetDocument2 pages7178-T6511 Property - ASM Material Data SheetptrfmNo ratings yet

- NAM Cat CombinedCh1Document16 pagesNAM Cat CombinedCh1Thanh Do VanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Lifting SlingsDocument8 pagesLifting SlingsMohammed AdnanNo ratings yet

- 3 MS ScaffoldingDocument32 pages3 MS Scaffoldingpaansaeng94% (16)

- Scaffolding Safety OffshoreDocument29 pagesScaffolding Safety Offshoreshanemoneill408100% (4)

- Doka Framed Formwork Panel (Foundation)Document64 pagesDoka Framed Formwork Panel (Foundation)Mohammed AdnanNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetMadhu MithaNo ratings yet

- Aluminio 6061-T6 6061-T651Document2 pagesAluminio 6061-T6 6061-T651leroniusNo ratings yet

- Aluminum 6061 Data SheetDocument2 pagesAluminum 6061 Data SheetASHOK100% (1)

- Aluminum 6061Document3 pagesAluminum 6061Ali FahemNo ratings yet

- Aluminum 6061-O: To View All Available Suppliers For This MaterialDocument2 pagesAluminum 6061-O: To View All Available Suppliers For This MaterialAlonso ReynaNo ratings yet

- 6061 Vs 6063Document9 pages6061 Vs 6063SrRonNo ratings yet

- Al 7075 T651Document2 pagesAl 7075 T651Michael HarrellNo ratings yet

- Aluminum 6063Document2 pagesAluminum 6063Laurence SarmientoNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetrenjithaeroNo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavNo ratings yet

- Aluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg AlloyDocument3 pagesAluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg Alloyvishwanadh kNo ratings yet

- MaterialData 11240 PDFDocument1 pageMaterialData 11240 PDFPengelana KehidupanNo ratings yet

- Asm A2024-O PDFDocument2 pagesAsm A2024-O PDFjbaldenebroNo ratings yet

- AISI 8620 SteelDocument2 pagesAISI 8620 SteelVinit AhluwaliaNo ratings yet

- Aluminum 2024-T4-2024-T351Document3 pagesAluminum 2024-T4-2024-T351Raj EklureNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyBea Dri HdezNo ratings yet

- 7050Document1 page7050yasvanth_m1493No ratings yet

- Aluminum 1100 InformationDocument1 pageAluminum 1100 InformationaxatpgmeNo ratings yet

- 1018Document1 page1018Alonso ReynaNo ratings yet

- Aluminum 7075 SpecsDocument3 pagesAluminum 7075 SpecsZakaria MuhammadNo ratings yet

- Aco AISI 1020 PDFDocument1 pageAco AISI 1020 PDFIbsonhNo ratings yet

- Aluminio 2024-T3Document2 pagesAluminio 2024-T3IbsonhNo ratings yet

- Data Sheet Aluminium 6061 t6 Group (H)Document7 pagesData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNo ratings yet

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Zamak 5Document1 pageZamak 5san moedanoNo ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- Astm A228Document2 pagesAstm A228Rakesh S IndiaNo ratings yet

- A 488A 488M - 01 Welding, Qualifications of Procedures and PersonnelDocument16 pagesA 488A 488M - 01 Welding, Qualifications of Procedures and Personnelamitanshu01482100% (1)

- AISI 1038 Steel Round BarDocument1 pageAISI 1038 Steel Round BaredraelmxNo ratings yet

- Ceaca TD enDocument48 pagesCeaca TD enBenicio Joaquín Ferrero Brebes0% (1)

- Cigweld-Deposited Rates PDFDocument7 pagesCigweld-Deposited Rates PDFNam_HitechNo ratings yet

- Aluminum 5052 H38Document2 pagesAluminum 5052 H38Vishal VaishnavNo ratings yet

- Aisi E 52100 Steel: Advertise With Matweb!Document2 pagesAisi E 52100 Steel: Advertise With Matweb!ankitsarvaiyaNo ratings yet

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument3 pagesAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- Alumínio Cold ASM Material Data SheetDocument2 pagesAlumínio Cold ASM Material Data Sheetmarcelogf74No ratings yet

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocument2 pagesFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666No ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- 5 Api 6aDocument8 pages5 Api 6arps1977100% (2)

- A488A488M Standard Practice For Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument18 pagesA488A488M Standard Practice For Steel Castings, Welding, Qualifications of Procedures and Personnelbhavin178No ratings yet

- ASTM A131 Steel, Grade DDocument1 pageASTM A131 Steel, Grade DjulianmorantesNo ratings yet

- Aluminum6061DataSheet PDFDocument2 pagesAluminum6061DataSheet PDFhardik033No ratings yet

- Special Metals NIMONIC® Alloy 90: Categories: Material NotesDocument3 pagesSpecial Metals NIMONIC® Alloy 90: Categories: Material NotesDragomirescu AlinaNo ratings yet

- Astm A572 Grade 50Document1 pageAstm A572 Grade 50Luis67% (3)

- Fusibles NHDocument4 pagesFusibles NHPaul SchaefferNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- MaterialData - Aço 1045Document2 pagesMaterialData - Aço 1045Victhor AraujoNo ratings yet

- MaterialData 11916 2Document1 pageMaterialData 11916 2Muhammad Shena GumilangNo ratings yet

- Formwork TechnologyDocument24 pagesFormwork Technologyriefsaldy100% (1)

- PASMA RequirementsDocument4 pagesPASMA RequirementsMohammed AdnanNo ratings yet

- Comp Aided Design of FRMWRKDocument18 pagesComp Aided Design of FRMWRKMohammed AdnanNo ratings yet

- Ring Lock SystemDocument16 pagesRing Lock SystemMohammed AdnanNo ratings yet

- CoP For Metal Scaffolding SafetyDocument85 pagesCoP For Metal Scaffolding SafetyChenthuran VilvarajahNo ratings yet

- Virginia University Online Eucation DocumentDocument42 pagesVirginia University Online Eucation Documentapi-253004596No ratings yet

- ScaffoldDocument0 pagesScaffoldRn Srtn100% (1)

- Slab Shoring SupportDocument18 pagesSlab Shoring SupportMohammed AdnanNo ratings yet

- T5.3 - Gnida - Formworks (PERI) PDFDocument63 pagesT5.3 - Gnida - Formworks (PERI) PDFMohammed AdnanNo ratings yet

- RingLock Brocure 110812Document17 pagesRingLock Brocure 110812Mohammed AdnanNo ratings yet

- Opti 222 W18Document5 pagesOpti 222 W18shufniNo ratings yet

- Acrow Bridge FormworkDocument26 pagesAcrow Bridge FormworkMohammed Adnan100% (1)

- Alt CityDocument1 pageAlt Citymallik99No ratings yet

- Canadian PlyformDocument1 pageCanadian PlyformMohammed AdnanNo ratings yet

- Doka Top50Document148 pagesDoka Top50Mohammed Adnan100% (2)

- 2012 - 03 - Online Doka Formwork Engineering DesignDocument148 pages2012 - 03 - Online Doka Formwork Engineering Designmma87No ratings yet

- Bridge Piers FormworkDocument14 pagesBridge Piers FormworkMohammed AdnanNo ratings yet

- Section 3: Nonlinear Analysis: Autodesk Simulation WorkshopDocument16 pagesSection 3: Nonlinear Analysis: Autodesk Simulation Workshopalex albNo ratings yet

- Embrittlement of Nylon in Arid EnvironmentsDocument78 pagesEmbrittlement of Nylon in Arid EnvironmentsSteven_Bolwing100% (1)

- Unit 4 Semiconductor Physics-Edited PDFDocument57 pagesUnit 4 Semiconductor Physics-Edited PDFMUSICAL MASTI RINGTONENo ratings yet

- Inconel 713 C PDFDocument33 pagesInconel 713 C PDF孙俊磊No ratings yet

- Diagarama de Fase de Los CupratosDocument97 pagesDiagarama de Fase de Los CupratosjamesNo ratings yet

- December 18, 2003 6:30 - 8:30 P.M.: Pocket-SizedDocument5 pagesDecember 18, 2003 6:30 - 8:30 P.M.: Pocket-SizedYUK LAM WONGNo ratings yet

- Am2540 - Applied Mechanics Lab Solid Mechanics Lab ReportDocument13 pagesAm2540 - Applied Mechanics Lab Solid Mechanics Lab ReportAditya KoutharapuNo ratings yet

- Doubly Reinforced Beam AnalysisDocument5 pagesDoubly Reinforced Beam AnalysisZaira Mar HajiNo ratings yet

- Okada 1992 BssaDocument23 pagesOkada 1992 BssaYehezkiel HalauwetNo ratings yet

- Handbook On The Ultrasonic Examination of Austenitic Clad Steel Componen...Document68 pagesHandbook On The Ultrasonic Examination of Austenitic Clad Steel Componen...luu cong son ndt100% (1)

- Documentation in Ultrasonics: - PublicationsDocument1 pageDocumentation in Ultrasonics: - PublicationsAnjanette ManubayNo ratings yet

- Powerplants Attachment 1 P&W Materials & Process Engineering Metallurgical Investigation Final Report Metallurgical InvestigatioDocument53 pagesPowerplants Attachment 1 P&W Materials & Process Engineering Metallurgical Investigation Final Report Metallurgical InvestigatioAntonio CorteNo ratings yet

- Shape Memory AlloysDocument25 pagesShape Memory AlloysGanesh YNo ratings yet

- Shaft DesignDocument33 pagesShaft DesignMunawwar Abbas0% (1)

- Box Girder Super Structure1Document87 pagesBox Girder Super Structure1hemantkle2u75% (4)

- A Seminar Report OnDocument7 pagesA Seminar Report OnSagar Pandit0% (1)

- Uni of Frankfurt - Thermodynamic PotentialsDocument15 pagesUni of Frankfurt - Thermodynamic PotentialstaboogaNo ratings yet

- Code Aster AnisoDocument14 pagesCode Aster AnisoAlexander NarváezNo ratings yet

- Improving weld test pass rates for stainless to mild steel jointsDocument4 pagesImproving weld test pass rates for stainless to mild steel jointscarlospalacioeNo ratings yet

- CSWIP QuizDocument12 pagesCSWIP Quizmushruff100% (1)

- Numerical Study On The Buckling of Pressurized Pipe Under Eccentric Axial CompressionDocument10 pagesNumerical Study On The Buckling of Pressurized Pipe Under Eccentric Axial CompressionHabib SusiloNo ratings yet

- Solidification Lecture 2Document32 pagesSolidification Lecture 2Shabid AshrafNo ratings yet

- Effectiveness of Bamboo Fiber As An Strength Enhancer in Con PDFDocument6 pagesEffectiveness of Bamboo Fiber As An Strength Enhancer in Con PDFwerku kosheNo ratings yet

- Pipe Flex Mar19Document5 pagesPipe Flex Mar19Joe Wong Wai Chuan100% (1)

- Understanding Heat Treatment Results Using MetallographyDocument48 pagesUnderstanding Heat Treatment Results Using Metallographydavid peralesNo ratings yet

- Example of Application of AISI 360 10 and Parallel With EC3Document5 pagesExample of Application of AISI 360 10 and Parallel With EC3Aakash KhatriNo ratings yet

- Strengthening Mechanisms QuestionsDocument106 pagesStrengthening Mechanisms Questionsellie<3No ratings yet

- Piercing Extrusion of Long Hollow Component With Subsidiary TensionDocument4 pagesPiercing Extrusion of Long Hollow Component With Subsidiary TensionDhan CNo ratings yet

- MAE1063 UTM Tall Buidling Philosophy Part6-Chapter3Document15 pagesMAE1063 UTM Tall Buidling Philosophy Part6-Chapter3Christopher SingletonNo ratings yet