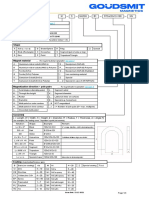

Professional Documents

Culture Documents

Drying of Supported Catalysts: A Comparison of Model Predictions and Experimental Measurements of Metal Profiles

Uploaded by

vazzoleralex6884Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying of Supported Catalysts: A Comparison of Model Predictions and Experimental Measurements of Metal Profiles

Uploaded by

vazzoleralex6884Copyright:

Available Formats

Drying of Supported Catalysts: A Comparison of Model Predictions and

Experimental Measurements of Metal Proles

Xue Liu,

Johannes G. Khinast,

and Benjamin J. Glasser*

,

Department of Chemical and Biochemical Engineering, Rutgers UniVersity, 98 Brett Road, Piscataway,

New Jersey 08854, and Institute for Process Engineering, Graz UniVersity of Technology, Inffeldg. 21A,

A-8010 Graz, Austria

Supported metal catalysts are used in many industrial applications. Experiments have shown that drying may

signicantly impact the metal distribution within the support. Therefore we need to have a fundamental

understanding of drying. In this work, a theoretical model is established to predict the drying process, and the

model predictions are compared with experimental measurements of a nickel/alumina system. It is found that

egg-shell proles can be enhanced by increasing the drying temperature or the initial metal concentration if

the metal loading is low. For high metal loadings, nearly uniform proles are observed after drying. We have

also investigated how breakage of the liquid lm inside the pores of the support can affect the metal distribution

during drying. It was found that lm-breakage has a signicant impact on the metal distribution, and it is

important to correctly capture lm-breakage in the model in order to get good experimental agreement.

1. Introduction

Supported catalysts are used in a variety of industrial

processes, ranging from catalytic converters and the production

of petroleum to the production of new drugs. These catalysts

consist of a porous support, one or more active catalytic

materials deposited on the support, and in some cases a

modier.

1

With respect to the distribution of the active

component in the support, four main categories of metal proles

can be distinguished, that is, uniform, egg-yolk, egg-shell, and

egg-white proles.

2,3

The choice of the desired metal prole is

determined by the required activity and selectivity, and can be

tailored for specic reactions and/or processes. Although the

development and preparation of supported catalysts have been

investigated for many years, many aspects of the various catalyst

manufacturing steps are still not fully understood, and in industry

the design of catalysts is predominated by trial and error

experiments, which are expensive and time-consuming, and do

not always offer assurances on the nal manufacturing results.

The preparation of supported catalysts usually involves three

steps: impregnation, drying, and reduction and calcination.

Experimental work has shown that the metal distribution within

the support is mainly determined by the impregnation and drying

steps.

4-9

Therefore, to achieve an optimum metal prole a

fundamental understanding of both impregnation and drying is

crucial. However, most studies on controlling the metal proles

in catalysts have focused on the impact of the impregnation

step. There are still many questions regarding the impact of

drying that remain unanswered.

The effect of drying on the metal distribution and catalyst

properties has been studied experimentally by Wu et al.

10,11

who

investigated the impact of various preparation procedures on

the mechanical strength of solid catalysts and showed that drying

has a signicant effect on the catalysts mechanical properties.

Santhanam et al.

12

examined the nature of the Pd precursors

and the adsorption of Pd complexes during and after drying

with different adsorption strengths. They showed that for strong

adsorption there is no migration of the metal through the pellets

during drying, while for weak adsorption migration does occur,

leading to a modied nal prole. Li et al.

9

studied the Ni

distribution during the preparation of Ni/alumina catalyst pellets

and compared the experiments with simulations. They showed

that the simulation tted the experimental data well, if the metal

redistribution during drying was considered. Other work has

focused on the characterizations of the physicochemical pro-

cesses that occur during the preparation of supported catalysts

using nuclear magnetic resonance,

13-17

and spatially resolved

Raman and UV-visible-NIR spectroscopy.

18-20

Computer simulations have also been used to predict the

impregnation and drying of supported catalysts. Theoretical

models describing the impregnation step have been reported in

a number of papers.

6,7,21-23

Because of the complexity of the

drying step, only a few theoretical models have been reported

for drying. However, experiments and simulations have shown

that the drying procedure can signicantly affect the metal

prole established during impregnation, if adsorption of the

metal component on the support surface is weak or mode-

rate.

12,24-27

Neimark et al.

5,28

were among the rst to theoreti-

cally study the metal redistribution during drying. They used a

dimensionless number to characterize slow drying and fast

drying regimes, and their theory is in agreement with the

experiments of Komiyama et al.,

8

who showed that a very high

drying rate can result in a uniform prole, while a relatively

low drying rate favors an egg-shell prole. More detailed drying

models were formulated by Uemura et al.,

29

Lee and Aris,

6

and

Lekhal et al.

24-26

They considered the effects of the capillary

ow and metal diffusion and simulated the metal migration

during drying. Recently, the sensitivity of the metal distribution

during impregnation and drying with respect to the physical

and processing parameters was examined by Liu et al.

27

They

also considered the effect of crystallization in their model, and

showed that metal crystallization has a signicant effect on the

generation of egg-shell proles for relatively high metal

concentrations.

It is of particular interest to compare simulation results and

experimental measurements to validate the theory and determine

the key parameters used to predict the metal distribution during

the preparation of supported catalysts. Most previous studies

* To whom correspondence should be addressed. Tel.: 732- 445-

4243. Fax: 732-445-2581. E-mail: bglasser@ rutgers.edu.

Rutgers University.

Graz University of Technology.

Ind. Eng. Chem. Res. 2010, 49, 26492657 2649

10.1021/ie9014606 2010 American Chemical Society

Published on Web 02/15/2010

only focused on a comparison of theory and experiments for

the impregnation step. A systematic comparison for the drying

step has not been reported as of yet. Thus, the objective of this

paper is to predict the metal distribution during drying and to

compare the simulation results with experimental measurements.

Furthermore, it is of interest to investigate the fundamental

mechanisms occurring during drying, and to study the impact

of the processing parameters and material properties on the nal

metal distribution.

2. Model and Experiment Setup

2.1. Model Equations. In the present work, we studied the

drying of a Ni/alumina system, which is widely used in

processes like hydrogenation, hydrodesulfurization, and steam

reforming of hydrocarbons.

30,31

During the drying process,

several phenomena are taking place simultaneously: heat transfer

from the hot gas to the wet support, solvent evaporation near

the external surface, solvent convective ow toward the external

surface, and metal diffusion and adsorption inside the support.

An accurate drying model must include all these phenomena.

In this work, we extend the model proposed by Lekhal et

al.

24

by considering a cylindrical geometry and the impact of

breakage of the liquid lm inside the pores of the support (lm-

breakage). In our model the following parameters have an

impact on the drying process: the metal diffusion coefcient,

the equilibrium constant of adsorption and desorption, the

intrinsic permeability, the initial metal concentration in the

solvent, the drying temperature, the humidity of the drying air,

and the lm-breakage parameters. It is important to note that

although the results presented are chosen for a Ni/alumina

system, the methodology is entirely general. It is not limited to

specic active components and supports.

There are two main assumptions in our model: (1) During

drying the metal concentration in the solution is below its

solubility; therefore, crystallization is not considered. (2) The

equilibrium adsorption constant can be assumed to be a constant

during the drying process. These assumptions have been made

in order to arrive at a model that can simply yet accurately

describe the important physical processes taking place during

drying. Our model can capture convective ow in the gas and

liquid phases, metal convection, diffusion, and adsorption on

the porous support as well as heat transport.

The following equations describe the drying process:

Equations 1 and 2 represent the mass balances of the drying

medium (air) and the solvent (water). Equations 3 and 4

represent the mass balances of the metal dissolved in the liquid

and deposited on the support. Equation 5 is the energy balance.

g

and

l

are the volume fractions of the gas and liquid phases,

C

g,a

(mol/m

3

) and C

l,s

(mol/m

3

) are the concentrations of the

drying air and the liquid solvent, respectively. C

l,i

(mol/m

3

) and

C

s,i

(mol/kg) are the concentrations of the metal dissolved in

the solvent and adsorbed on the support. N

g,a

(mol/(m

2

s)) and

N

g,v

(mol/(m

2

s)) are the uxes of the air and solvent vapor.

N

l,s

(mol/(m

2

s)) and N

l,i

(mol/(m

2

s)) are the uxes of the

solvent and the dissolved metal. F

s

(kg/m

3

) is the apparent

density of the porous support. R

i

(mol/kg/s) represents the rate

of metal adsorption, which is described using a Langmuir

model.

32-34

where k

ads

(m

3

/mol/s) and k

des

(s

-1

) are the adsorption and

desorption constants of the metal component. C

sat

(mol/kg)

denotes the metal saturation concentration. In this model we

assume adsorption is not the limiting step. Consequently, the

adsorbed metal is in equilibrium with its dissolved precursor,

and the equilibrium adsorption constant can be calculated as

K

eq

) k

ads

/k

des

. Although the value of the equilibrium adsorption

constant may change during drying,

26

in this work we assume

it to be a constant. h

g,i

(J/mol) represents the enthalpy of the air

or solvent vapor. h

l

(J/mol) and h

s

(J/kg) denote the enthalpy of

the liquid and solid. (J/(m s K)) is the effective thermal

conductivity.

Film-breakage is an important phenomenon during drying.

At the beginning of drying, the water phase is continuously

distributed in the support. As evaporation proceeds, isolated

domains are gradually formed in the liquid phase. Finally, the

liquid is only found in the isolated domains. To consider

the effect of lm-breakage in our model, a factor R is added to

the ux terms in eqs 2, 3, and 5. Neimark et al.

5

showed that

lm-breakage is related to the support pore structure and the

water content in the support. Therefore, for a given solid carrier,

we assume that the lm-breakage factor, R, is a function of the

water volume fraction.

where R

1

represents the water volume fraction when lm-

breakage starts, and R

2

represents the water volume fraction

when the solvent only exists in the isolated domains and the

water ux completely stops. We assume that when the value of

the water volume fraction is between R

1

and R

2

, R linearly

decreases with a decrease in the water volume fraction indicating

that the ux in the liquid phase linearly decreases with a decrease

in the water content.

The gas-phase uxes N

g,a

and N

g,v

are assumed to follow the

dusty gas model (DGM),

35

which considers the effect of

molecular diffusion, Knudsen diffusion, and viscous ow.

In eq 8 P

g

(Pa) is the total gas pressure, R (8.314 J/(mol K))

is the gas constant, T (K) is the temperature, x

g,i

represents the

t

(

g

C

g,a

) ) -

1

r

r

(rN

g,a

) (1)

t

(

l

C

l,s

) ) -

1

r

r

(RrN

l,s

+ rN

g,v

) (2)

t

(

l

C

l,i

) ) -

1

r

r

(RrN

l,i

) - F

s

R

i

(3)

t

(C

s,i

) ) R

i

, i ) metal component (4)

t

(

i)1

2

g

C

g,i

h

g,i

+

l

C

l,s

h

l

+ F

s

h

s

) )

-

1

r

r

(

i)1

2

rN

g,i

h

g,i

+ RrN

l,s

h

l

- r

T

r

)

(5)

R

i

) k

ads

C

l,i

(C

sat

- C

s,i

) - k

des

C

s,i

, i ) metal component

(6)

R ) 1 when

f

g R

1

R )

(R

1

-

f

)

(R

1

- R

2

)

when R

1

>

f

> R

2

R ) 0 when

f

e R

2

(7)

-

P

g

RT

x

g,i

-

x

g,i

RT

(

1 -

KK

g,eff

P

g

g

D

Knud

)

P

g

)

j)1

j*i

2

x

g,j

N

g,i

- x

g,i

N

g,j

D

g,ij

+

N

g,i

D

Knud

(8)

2650 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

vapor or air mole fraction in the gas phase, D

g,ij

(m

2

/s) and D

Knud

(m

2

/s) are the effective binary and Knudsen diffusion coefcients

estimated from the kinetic gas theory,

36

and K

g,eff

is the intrinsic

permeability of the gas phase, which has the form

Jones

37

has shown that eq 9 can describe experimental data

very well. In this work, the water vapor pressure is calculated

using the Antoine equation

38

and the Hailwood-Horrobin

equation

39

with parameters tted by Simpson.

40

We assume that

the convective ow in the liquid phase follows Darcys law,

41

where K

l,eff

is the relative permeability of the liquid phase,

l

(Pa s) is the viscosity of the liquid phase, K (m

2

) represents

the intrinsic permeability, and P

l

(Pa) is the liquid phase

pressure, which is equal to the local gas pressure less the

capillary pressure P

c

(Pa).

41

In the present work P

c

is described

using the form proposed by Perre et al.,

42

where (N/m) represents the surface tension, and M

l,s

is the

molecular weight of the liquid solvent. The ux of the dissolved

metal is described by the Nernst-Planck equation,

43

which takes

into account the effect of convective ow of the solvent

(capillary ow), diffusion due to the metal concentration

gradient, and migration caused by electrical charges. It takes

the form

where D

l,i

(m

2

/s) is the effective diffusion coefcient of the

dissolved metal, Z

i

is the charge of the metal component, F

(96500 C/mol) is the Faraday constant, and (V) represents

the electrostatic potential. In this work we assume there is no

external current and the electroneutrality condition is satised

in the support. The gradient of the electrostatic potential, which

is a function of the number of charges and the concentration

gradient of the charged components, is determined by the no-

current equation:

44

where n is the total number of ionic species in the liquid phase.

The constitutive relations proposed by Jones

37

are adopted for

the relative permeability K

l,eff

.

The boundary conditions are the zero-ux conditions at the

support center and the Neumann conditions at the support

surface.

24,25

The resulting system of nonlinear partial differential

equations is spatially discretized by a nite volume method.

45

Then the resulting set of ordinary differential equations is solved

by LIMEX, which is efcient for solving highly stiff differential-

algebraic equations.

46

2.2. Experiment Setup and Parameter Measurement. The

system studied in this work is a nickel/alumina system. Nickel

nitrate powders (Sigma-Aldrich) were used as metal precursors

and cylindrical -alumina pellets provided by Saint-Gobain were

used as solid carriers. The pellets are 3 mm in diameter and

around 10 mm in length with a void volume fraction of 0.3

cm

3

/g and a surface area of 200.7 m

2

/g. The basic experimental

protocol includes the following steps: (1) The solid support is

preheated in an oven at 120 C for 12 h. (2) The dry alumina

supports are immersed in nickel nitrate solutions for impregna-

tion. The pH of the solutions is adjusted by adding nitric acid

or NH

4

OH. To investigate the effect of the metal concentration,

we changed the concentration of the nickel nitrate solutions from

0.01 to 4 M. Usually we hold the impregnation time sufciently

long such that a uniform prole can be obtained after impregna-

tion, representing an equilibrium state. (3) The catalyst samples

are dried in an oven at a constant temperature. The drying

temperature is varied between 22 and 180 C. (4) Calcination

is carried out at 500 C for 2 h. During impregnation and drying,

nickel nitrate gives the catalyst a green color. During calcination,

nickel nitrate becomes nickel oxide, and thus, the catalyst color

changes. The gray or black color of the samples after calcination

is most likely due to some deviation from ideal 1:1 stoichiometry

of the NiO.

47

The nickel concentration in the solution is measured using a

UV-visible spectrophotometer at a wavelength of 190 nm. To

obtain the standard curve, seven samples were prepared with

the Ni(NO

3

)

2

concentration equaling 0.001, 0.005, 0.01, 0.025,

0.05, 0.075, and 0.1 M. Then the absorbance value of each

sample was measured by the UV-visible apparatus. From

experiments we found that there is a linear relation between

the nickel concentration, C

Ni

and the absorbance value, A

uv

.

Using a linear regression, we can obtain the equation:

This equation can be used to calculate the nickel concentration

in the solution during impregnation. To investigate the metal

proles after drying or calcination, we cut the catalyst samples

in half in the radial direction and measured the radial nickel

prole using micro-X-ray uorescence spectroscopy (micro-

XRF).

To solve our drying model, we need to measure several

parameters.

9,32

In our work, a Langmuir equation is used to

describe the adsorption and desorption processes (see eq 6).

Under equilibrium conditions, the rate of the metal adsorption

is equal to the rate of the metal desorption (R

M

) 0). Therefore,

eq 6 can be rewritten as

From eq 16 it can be seen that a straight line is obtained

when plotting 1/C

eq

versus 1/C

s

. Then the values of C

sat

and

K

eq

can be calculated from the line intercept and the slope. Six

samples with Ni(NO

3

)

2

concentration equal to 0.01 M, 0.02 M,

0.04 M, 0.06 M, 0.08 M, and 0.1 M were prepared. Each sample

contained 100 mL of Ni(NO

3

)

2

solution and 1 g of alumina

support with the pH equal to 6.5. The value of C

s

can be

calculated based on the Ni mass balance in the system, since

the amount of the metal in the solution before impregnation

minus the amount of the metal in the solution after impregnation

equals the amount of the metal adsorbed on the support. From

Figure 1, it can be seen that the amount of metal deposited on

the supports increases rapidly at the beginning of impregnation.

K

g,eff

) 1 - 1.11

(

)

(9)

N

l,s

) -C

l,s

KK

l,eff

l

P

l

(10)

P

c

) 1.364 10

5

l

c

l,s

M

l,s

F

s

)

-0.63

(11)

N

l,i

) -C

l,i

KK

l,eff

l

P -

l

D

l,i

c

l,i

-

l

C

l,i

Z

i

D

l,i

F

RT

l

,

i ) metal component (12)

i)1

n

z

i

N

l,i

) 0 (13)

K

l,eff

)

(

)

3

(14)

C

Ni

) 0.0878A

uv

(15)

1

C

eq

)

1

C

sat

K

eq

1

C

s

+

1

C

sat

(16)

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2651

Then, the adsorption rate decreases due to the increase in the

surface coverage of the active sites. After approximately 3 days

a plateau is reached indicating an equilibrium state, from which

we can obtain the equilibrium metal concentration in the solution

C

eq

and the corresponding metal load on the support C

s

. Using

eq 16, we obtained C

sat

) 0.3 mol/kg and K

eq

) 0.2 m

3

/mol

when plotting 1/C

eq

versus 1/C

s

.

At the beginning of impregnation, the effect of desorption

can be neglected. Thus, the decrease in the metal concentration

in the solution is mainly due to the accumulation of the metal

adsorbed on the support. Therefore,

where C

0

represents the initial metal concentration in the

solution.

9,32

When plotting dC

0

/dt versus C

0

, a straight line can

be obtained and the value of the kinetic adsorption constant

k

ads

can be calculated from the slope. To obtain k

ads

, we prepared

ve samples with Ni(NO

3

)

2

concentrations equal to 0.01, 0.02,

0.03, 0.04 and 0.05 M, at a pH equal to 6.5. To reduce diffusion

effects during impregnation we ground the pellet supports into

powders. The particle size was between 150 and 250 m. We

used a sieve to remove large particles, and then used water to

wash out ne particles. The powder supports were dried in the

oven at 120 C for 12 h before being used. For each sample,

the value of the Ni concentration was measured at 10 min

intervals after impregnation started. Then the value of dC

0

/dt

was calculated. By plotting dC

0

/dt versus C

0

, we obtained k

ads

) 6.5 10

-5

m

3

/(mol/s).

The diffusion coefcient of nickel nitrate in water was taken

from the work of Takahashi et al.

48

as D ) 6 10

-10

m

2

/s.

The permeability is based on the support pore size distribution.

The pore size distribution was measured by Saint-Gobain using

a mercury volume test. The porosity of the support is around

0.67 with 80% small pores (average 7 nm) and 20% large pores

(average 500 nm). Then the permeability of the support can be

calculated using the modied Ergun equation.

49

Using eq 18, we obtained a permeability of K ) 5 10

-16

m

2

.

In general, the base case conditions used in our simulations

are pH ) 6.5, C

sat

) 0.3 mol/kg, K

eq

) 0.2 m

3

/mol, k

ads

) 6.5

10

-5

m

3

/(mol/s), D ) 6 10

-10

m

2

/s, K ) 5 10

-16

m

2

,

and 30% relative humidity. The initial metal concentration in

the solution C

0

was varied from 0.04 to 4 M, and the drying

temperature T

bulk

was varied from 22 to 180 C. A uniform initial

metal distribution was utilized indicating that impregnation

reached an equilibrium state.

3. Results and Discussion

3.1. Experimental Results. Typical experimental drying

results are shown in Figure 2 for T

bulk

) 60 C. In Figure 2a

the water volume fraction can be seen to decrease with time

until a plateau is reached. In Figure 2b the drying rate is equal

to the weight of the water evaporated from the support per

kilogram dry support per minute. At the beginning of the process

the drying rate is constant. After about 40 min the drying rate

decreases and nally the water content in the support is reduced

to 1% after 75 min (see Figure 2a) indicating the end point of

drying. Similar results have been reported in previous studies.

25

During drying the metal concentration in the liquid phase

increases due to evaporation of water. This may greatly affect

the solution properties, the drying rate, and the metal distribu-

tion. Figure 3 shows experimental measurements of the evolu-

tion of the drying rate for different initial metal concentrations

at a drying temperature of 60 C. The lines here are included

as a guide for the eye. By comparing the curves for C

0

) 0 M

(water only) and C

0

) 0.1 M, we nd that for a low initial

Figure 1. The variation of the concentration of the metal deposited on the

support with the impregnation time.

dC

0

dt

) -k

ads

FC

sat

C

0

(17)

K )

i

3

i

d

ci

2

200

(18)

Figure 2. Variation of (a) the water volume fraction and (b) drying rate

with the drying time at T

bulk

) 60 C and C

0

) 100 mol/m

3

.

Figure 3. Effect of the initial metal concentration on the drying rate at

T

bulk

) 60 C for (a) catalyst samples and (b) solution samples. The lines

here are included as a guide for the eye.

2652 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

metal concentration (C

0

< 0.1 M), the effect of the metal

concentration on the drying rate is not signicant (see Figure

3a). For C

0

> 2 M, however, the drying rate is signicantly

reduced. In Figure 3a, the drying time for C

0

) 0.1 M is around

50 min. In contrast, the drying time required for C

0

) 4 M is

more than 75 min. We believe that this is due to the decrease

in the vapor pressure and the increase in the solvent viscosity

with an increase in the metal concentration.

50

Therefore, drying

is much slower for high metal concentrations, and the drying

time required for high metal concentrations is much longer than

for low metal concentrations. To eliminate the effect of the

support pore size distribution and pore network on the drying

rate and only focus on the contribution of the initial metal

concentration, 1 mL of solution (no support) with a certain

amount of Ni(NO

3

)

2

was dried in the oven at 60 C. In Figure

3b, we show results for ve samples with Ni(NO

3

)

2

concentra-

tion equal to 0 M (only water), 0.1, 0.5, 2, and 4 M. It is clear

that for a low initial metal concentration (C

0

< 0.1 M), after an

initial increase the drying rate reaches a plateau and then reduces

rapidly at the end of drying. For a high initial metal concentra-

tion (C

0

> 2 M), however, the drying rate is much lower and

the drying rate evolution becomes quite different. The plateau

region observed in the low initial metal concentration conditions

disappears and the drying rate gradually reduces with time. This

is because for high metal concentration conditions, the amount

of the metal precursor is comparable to the amount of water so

the increase in the molar ratio of the metal precursor in the

liquid phase during drying becomes signicant leading to a

gradual decrease in the water vapor pressure.

50

In contrast, for

low metal concentration conditions the amount of water is much

higher than the amount of the metal precursor. Therefore,

although the molar ratio of the metal precursor keeps increasing

during drying its effect on the change of the water vapor pressure

is negligible. If we compare the drying rate evolution curves

shown in Figure 3 panels a and b, we nd that the curve shapes

and the extent of the decrease in the drying rate with the initial

metal concentration look quite similar for the two cases. This

indicates that the effect of the initial metal concentration on

the drying procedure during preparation of supported catalysts

is important. For moderate or high metal loading, an accurate

drying model must be capable of capturing the change of the

solvent properties due to the increase in the metal precursor

concentration during drying.

After impregnation, the metal inside the support has two

forms: metal dissolved in the solvent or metal adsorbed on the

support. From past studies we know that drying can change the

distribution of the metal dissolved in the solvent, while its effect

on the metal already adsorbed on the support is much smaller.

12

After impregnation, the ratio of the amount of the metal

dissolved in the solvent to that adsorbed on the support is

determined by the adsorption strength and the initial metal

concentration in the solvent. The effect of adsorption strength

on the metal proles during drying has been reported in previous

work.

25,27

It was found that drying can modify the metal proles

only for weak adsorption, while its effect is not signicant for

strong adsorption.

The impact of the initial metal concentration on the nal metal

distribution after drying is shown in Figure 4a-c. Clearly, the

total metal left in the support after drying increases with an

increase in the initial metal concentration. From Figure 4a,b,

we can see that for a uniform initial condition, an egg-shell

prole is obtained if the metal load in the system is low or

moderate. This is due to the effect of convection which drives

the metal to move toward the support surface. If the initial metal

concentration is sufciently high (C

0

> 3 M), nearly uniform

proles can be observed after drying (see Figure 4c). This may

be related to three mechanisms. (1) For C

0

> 3 M, the drying

rate is greatly reduced (see Figure 3a), which favors a nal

uniform distribution. (2) If the metal concentration is sufciently

high, during drying the support pores can be blocked by the

accumulation of metal crystals due to adsorption and crystal-

lization. This pore-blockage mechanism can greatly reduce the

water transport and the metal redistribution during drying.

Similar results have been observed in previous work. Sietsma

et al.

47

investigated the preparation of Ni/SiO

2

catalysts via the

impregnation and drying method. They found that with 4.2 M

initial metal concentration, the average crystal size after drying

was 9 nm which was around the same size as the mesopore

Figure 4. Effect of the metal concentration on the metal proles after drying at T

bulk

) 60 C: (a) low metal concentrations; (b) moderate metal concentrations;

(c) high metal concentrations. Effect of the metal concentration on the metal proles after calcination: (d) low metal concentrations; (e) moderate metal

concentrations; (f) high metal concentrations.

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2653

diameter of the SBA-15 support they used. (3) Since the melting

point of Ni(NO

3

)

2

is 56 C, part of the nickel nitrate could be

melted when the samples were dried at 60 C. For high metal

loading conditions (C

0

> 3 M), the liquid Ni(NO

3

)

2

may lead to

the liquid phase remaining continuous during drying, and thus

lm-breakage would not occur. This will favor a nal uniform

distribution. The effect of lm-breakage on the metal distribution

during drying will be further discussed in the following section.

For practical use of the catalyst it is of interest to study the

effect of calcination on the distribution of the metal in the

support. Figure 4 panels d-f show the metal distribution after

calcination with the variation of the metal concentration from

0.05 to 4 M. It is clear that for all cases studied in this work

the metal distribution after drying and after calcination is similar,

indicating that the effect of calcination on the metal redistribu-

tion is not signicant. Therefore, it is reasonable to assume that

for our specic systems the metal prole obtained after drying

can be used to predict the nal metal distribution of the catalysts.

3.2. Comparison of Experiments and Simulations. In this

section we focus on low metal loads where the initial metal

concentration is less than or equal to 0.1 M. For these cases,

the effect of the metal ions on the solvent properties during

drying is small, and pore-blockage and crystallization are

negligible. Therefore, the nal metal distribution is determined

by the initial metal concentration (C

0

), adsorption strength (K

eq

,

k

ads

, C

sat

), drying conditions (T

bulk

), transport properties (D

l,i

, K)

and lm-breakage conditions (R

1

, R

2

). Given a specic

metal-support system, the parameters for adsorption, transport,

and lm-breakage are xed and cannot be adjusted in a

straightforward manner. Thus, the nal metal prole can be

controlled mainly by changing the initial metal concentration

and the drying temperature.

The variation of the water volume fraction in the support

during drying for different drying temperatures is shown in

Figure 5, where the symbols represent the experimental data

and the lines represent the simulation results. To investigate

the effect of lm-breakage, two sets of simulation results are

presentedsone including and one excluding the effects of lm

breakage. In the simulations with lm-breakage, we assume R

1

) 0.53 representing the situation where lm-breakage starts as

the water evaporation transits from the large pores to the small

pores (R

1

)voidage volume fraction x percentage of small pores

in the void ) 0.67 0.8), and R

2

) 0.013 below which the

liquid phase is completely discontinuous (solvent ux ) 0). The

value of R

2

was chosen on the basis of the regression of

experimental data for C

0

) 0.04 M, and thereafter we held this

value a constant for other cases. R

2

) 0.013 corresponds to the

mass ratio of water in the support equal to 2%. In general the

value of R

2

is related to the hydrophilic or hydrophobic

properties of the solvent on the support, the size of the small

pores, and the pore network in the support.

51

The structure of

the pore network has a signicant effect on the transport of the

solvent during drying. Neimark et al. proposed that the point

where the liquid phase becomes completely discontinuous (i.e.,

R

2

) can be calculated on the basis of a coordination number for

the support if the porous space can be represented as a system

of intersecting channels and the coordination number is the

average number of channels meeting at a lattice site.

28

In Figure 5, it is clear that drying is much faster at higher

drying temperatures. When drying is carried out at room

temperature (T

bulk

) 22 C), drying is very slow and an

unacceptable amount of water remains in the support at the end.

When the drying temperature is above 60 C, the mass fraction

of the water in the support can be reduced to 1% within a

reasonable amount of time. From Figure 5 it can be seen that

for low to moderate drying rates (T

bulk

< 60 C), the effect of

lm-breakage on the change in the water content inside the

support during drying is small. When the drying temperature is

high, the drying rate decreases slightly when lm-breakage is

taken into account. This effect is observed since for fast drying

rates lm-breakage occurs at the support surface fairly early in

the drying process. For all three cases shown in Figure 5, the

comparison between the experiments and simulations is gener-

ally good, and the effect of lm-breakage is rather small.

Corresponding to the data in Figure 5, Figure 6 shows

experimental data and simulation results for the drying rate. The

simulation results in the gure include the effect of lm-

breakage. Simulations without lm-breakage have also been

carried out (not shown) and they are very similar to the

simulation results in Figure 6. As before, the drying temperature

is 22, 60, and 115 C, respectively. The variation of the

Figure 5. Effect of the drying temperature on the water volume fraction

for C

0

) 100 mol/m

3

, R

1

) 0.53, and R

2

) 0.013.

Figure 6. Effect of the drying temperature on the drying rate for C

0

) 100

mol/m

3

, R

1

) 0.53 and R

2

) 0.013: (a) T

bulk

) 22 C; (b) T

bulk

) 60 C; (c)

T

bulk

) 115 C.

2654 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

temperature in the support during drying was also examined in

this work (not shown). For a low drying temperature, initially

the temperature in the particle decreases due to evaporation,

reaches a plateau, and then increases (T

bulk

) 22 C). Corre-

sponding to the change of the particle temperature, the drying

rate shows three stages (see Figure 6a), i.e., a decrease in the

rate, a plateau stage, and a second decrease in the rate. The

sharp drop in the drying rate in the rst stage is due to the sharp

drop in the particle temperature at the beginning of drying. The

third stage occurs when the drying front starts to move from

the support surface to the center due to the loss of water in the

support. For a moderate drying temperature (T

bulk

) 60 C),

the particle temperature only changes slightly before reaching

a plateau. Thus, only two stages can be observed in Figure 6b.

For a high drying temperature (T

bulk

) 115 C), initially the

temperature in the particle increases, reaches a plateau, and then

increases again. Therefore, we observe a preheating period,

followed by a constant-rate period, and a falling-rate period (see

Figure 6c). Similar results have been reported in previous

work.

25

In general, the simulation results match the experimental

measurements fairly well.

The nal metal proles for different drying temperatures are

shown in Figure 7 when the initial metal concentration is 0.04

M. Clearly, more metal is accumulated near the surface with

an increase in the drying temperature. This is due to the

competition between convection and diffusion. For low drying

temperatures, diffusion dominates the drying procedure, which

leads to a uniform proles (see Figure 7a). For relatively high

drying temperatures, convection dominates the drying process

at the early stages of drying, which transports the water and

metal ions toward the external surface, leading to pronounced

egg-shell proles. Although at the late stages of drying, diffusion

may control the drying process, causing the metal to move

toward the support center and the metal distribution to atten,

the nal metal distribution still remains egg-shell (see the

experimental data in Figure 7b,c). One can see from Figure 7

that lm-breakage is very crucial to capture the egg-shell proles

observed in the experiments. If the effect of lm-breakage is

not considered, egg-white proles are predicted for relatively

high drying temperatures (see Figure 7b,c). When the effect of

lm-breakage is taken into account, egg-shell proles can be

obtained for relatively high drying temperatures (see Figure

7b,c). In all the cases studied in Figure 7, the egg-shell proles

are greatly enhanced and the simulations show a good agreement

with the experiments if the effect of lm-breakage is considered.

This is due to the effect of lm-breakage on convection and

diffusion. If lm breakage occurs at the early stage of drying,

it will reduce the liquid ux and thus reduce the effect of

convection. At the late stages of drying, diffusion may dominate

the drying process, and its effect is also reduced by lm-

breakage. Therefore, we believe lm-breakage suppresses the

egg-shell distribution at the early stages of drying and favors

the egg-shell distribution at the late stages of drying. In Figure

7, our simulations show that the egg-shell distribution is

enhanced by lm-breakage, indicating that under the drying

conditions used in Figure 7 lm-breakage does not start at the

very early stage of drying so its main contribution is to reduce

the effect of diffusion. On the other hand, if the drying rate is

sufciently high and lm-breakage occurs at the surface nearly

immediately, the effect of convection should be reduced and

the extent of the egg-shell distribution should be reduced.

To validate our hypothesis, we experimentally measured the

metal proles for different drying rates (see Figure 8). The lines

in Figure 8 are only meant as a guide for the eye. For a low

drying temperature (T

bulk

) 25 C) the effect of convection and

lm-breakage is not signicant so a nearly uniform prole is

observed. For a relatively high drying temperature (T

bulk

) 120

C) convection accumulates the metal near the surface at the

early stage of drying and lm-breakage reduces the effect of

back-diffusion at the late stage of drying so a more pronounced

egg-shell prole can be obtained. If the drying rate is sufciently

high (T

bulk

) 500 C) isolated domains occur at the surface

nearly immediately during drying and the metal has no time to

migrate from the center toward the surface so the egg-shell

prole is less pronounced. Similar results have been observed

in previous work.

8

In Figure 9, we compare the nal metal proles for experi-

ments and simulations for a higher initial metal loading of C

0

) 0.1 M. We found that for all the cases studied, lm-breakage

enhances the egg-shell proles, and simulations show good

agreement with the experiments only if the effect of lm-

breakage is considered. This is in agreement with our previous

results at lower initial metal concentrations (see Figure 7).

From Figure 7 and 9, it can be seen that for the cases we have

examined, lm-breakage must be considered if one is to capture

the metal proles observed in the experiments. Therefore, it is of

Figure 7. Effect of the drying temperature on the nal metal prole for C

0

) 40 mol/m

3

, R

1

) 0.53, and R

2

) 0.013: (a) T

bulk

) 22 C; (b) T

bulk

) 115

C; (c) T

bulk

) 180 C.

Figure 8. Experimental measurement of the nal metal distribution for C

0

) 100 mol/m

3

. The lines here are drawn to guide the eye.

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2655

interest to investigate the sensitivity of the metal distribution after

drying to the lm-breakage parameters, R

1

and R

2

. Generally, the

egg-shell prole is enhanced with an increase in R

1

(not shown).

However, when R

1

is sufciently high (R

1

> 0.53) we nd that the

metal distribution changes only slightly when further increasing

this number. This is because two mechanisms occur with the

variation of R

1

. For a high R

1

value, lm-breakage occurs at the

beginning of drying, which reduces the water ux toward

the surface, and thus suppresses the accumulation of the metal

at the surface. With continued drying, metal starts to move back

to the support center due to the gradient of the metal concentration

in the solvent. Film-breakage can reduce this back diffusion, and

this reduction effect increases with an increase in R

1

. Therefore,

for a high R

1

value lm-breakage suppresses the egg-shell prole

at the earlier stages of drying and favors the egg-shell prole at

the later stages of drying. Consequently, the effect of R

1

on the

nal metal proles is due to the compensation of these two

contributions. To enhance the egg-shell prole, an optimum R

1

is

required. The egg-shell prole can be greatly enhanced with

increasing the value of R

2

(not shown). This is because the variation

of the value of R

2

has only a slight effect on the early stage of

drying, while its effect on the nal stage of drying is signicant.

Therefore, for a high value of R

2

(R

2

)0.13), the pronounced egg-

shell prole formed in the early stage of drying may be still

observed at the end of drying.

The sensitivity analysis was also carried out for other

parameters based on our nickel/alumina system (not shown).

In general, the egg-shell proles can be enhanced by increasing

the permeability and uniform proles can be obtained by

increasing the diffusion coefcient. This is in agreement with

our previous work.

25,27

In our specic case the adsorption

process is much faster than the transport process; we found that

the metal redistribution is not sensitive to the variation of the

kinetic adsorption constant.

4. Conclusions

We established a theoretical model to predict the metal

distribution during drying and compared the simulation results

with experimental measurements for a nickel/alumina system.

The adsorption and transport parameters used in the simulations

are obtained from separate experiments/calculations.

From the experiments, several interesting phenomena were

observed. (1) We found that egg-shell proles can be enhanced

by increasing the drying temperature and the initial metal

concentrations, if the metal load in the system is low or

moderate. For high metal loadings, nearly uniform metal proles

are observed from the experiments. (2) We compared the metal

proles after drying and after calcination and showed that for

our specic situation the effect of calcination on the metal

distribution is not signicant. Thus, the metal proles obtained

after drying can be used to predict the nal metal distribution

of the catalysts. (3) By plotting the variation of the water content

and the drying rate with the drying time for different initial

metal concentrations, we found that if the initial metal concen-

tration is high the solvent properties may change dramatically

during drying because of water evaporation and high metal

concentration in the liquid phase.

We also compared the simulations with experiments to

validate our theory. Since the effect of crystallization and pore-

blockage is not considered in our model, our comparison only

focused on low metal load conditions. To investigate the effect

of lm-breakage on the metal redistribution during drying, we

assume that once lm-breakage occurs the solvent ux linearly

decreases with the decrease in the water volume faction until

the water volume fraction reaches a certain point, at which the

liquid ux completely stops and the metal is enclosed in isolated

liquid domains. We found that lm-breakage is crucial to capture

the metal proles observed in the experiments and the simula-

tions show an excellent agreement with experiments if the effect

of lm-breakage is considered.

In summary, the goal of this study is to better understand

the fundamental mechanisms during drying, and to determine

the key parameters used to generate a desired metal prole, using

theoretical simulations and experiments. We have compared

experiments and simulations for low metal concentration

conditions (C

0

< 0.1 M). For moderate and high metal

concentrations, crystallization may become important and the

change of the solvent properties during drying due to the

increase in the metal concentration in the solvent may greatly

affect the drying process. Pore-blockage may also become

important at high metal concentrations. It remains to be seen

what is the relative importance of these additional phenomena

that occur at moderate and high metal concentrations, and future

work should investigate how these phenomena interact to impact

drying.

Acknowledgment

We wish to acknowledge partial nancial support for this

work from the National Science Foundation and the Rutgers

Catalyst Manufacturing Science and Engineering Consortium.

Literature Cited

(1) Ertl, G.; Knozinger, H.; Weitkamp, J. Preparation of Solid Catalysts;

Wiley-VCH: Weinheim, Germany, 1999.

(2) Shyr, Y. S.; Ernst, W. Preparation of nonuniformly active catalysts.

J. Catal. 1980, 63, 425432.

(3) Gavrilidis, A.; Varma, A.; Morbidelli, M. Optimal distribution of

catalyst in pellets. Catal. ReV.-Sci. Eng. 1993, 35, 399456.

Figure 9. Effect of the drying temperature on the nal metal prole for C

0

) 100 mol/m

3

, R

1

) 0.53, and R

2

) 0.013: (a) T

bulk

) 22 C; (b) T

bulk

)

115 C; (c) T

bulk

) 180 C.

2656 Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010

(4) Maatman, R. W.; Prater, C. D. Adsorption and exclusion in

impregnation of porous catalytic supports. Ind. Eng. Chem. Fundam. 1957,

49, 253257.

(5) Neimark, A. V.; Kheifez, L. I.; Fenelonov, V. B. Theory of

preparation of supported catalysts. Ind. Eng. Chem. Prod. Res. DeV. 1981,

20, 439450.

(6) Lee, S.-Y.; Aris, R. The distribution of active ingredients in supported

catalysts prepared by impregnation. Catal. ReV.-Sci. Eng. 1985, 27, 207

340.

(7) Kotter, M.; Riekert, L. Impregnation type catalysts with nonuniform

distribution of the active component. Part II: Preparation and properties of

catalysts with different distribution of the active component on inert carriers.

Chem. Eng. Fundam. 1983, 2, 3138.

(8) Komiyama, M.; Merrill, R. P.; Harnsberger, H. F. Concentration

proles in impregnation of porous catalysts: nickel of alumina. J. Catal.

1980, 63, 3552.

(9) Li, W. D.; Li, Y. W.; Qin, Z. F.; Chen, S. Y. Theoretical prediction

and experimental validation of the egg-shell distribution of Ni for supported

NidAl

2

O

3

catalysts. Chem. Eng. Sci. 1994, 49, 48894895.

(10) Wu, D. F.; Zhou, J. C.; Li, Y. D. Mechanical strength of solid

catalysts: Recent developments and future prospects. AIChE J. 2007, 53,

26182629.

(11) Wu, D. F.; Li, Y. D. Effects of the impregnating and drying process

factors on the mechanical properties of a PCoMo/Al

2

O

3

hydrotreating

catalyst. Stud. Surf. Sci. Catal. 2002, 143, 101109.

(12) Santhanam, N.; Conforti, T. A.; Spieker, W. A.; Regalbuto, J. R.

Nature of metal catalyst precursors adsorbed onto oxide supports. Catal.

Today 1994, 21, 141156.

(13) Bergweff, J. A.; Lysova, A. A.; Alonso, L. E.; Koptyug, I. V.;

Weckhuysen, B. M. Probing the transport of paramagnetic complexes inside

catalyst bodies in a quantitative manner by magnetic resonance imaging.

Angew. Chem., Int. Ed. 2007, 46, 72247227.

(14) Bergweff, J. A.; Lysova, A. A.; Alonso, L. E.; Koptyug, I. V.;

Weckhuysen, B. M. Monitoring transport phenomena of paramagnetic metal-

ion complexes inside catalyst bodies with magnetic resonance imaging.

Chem.sEur. J. 2008, 14, 23632374.

(15) Lysova, A. A.; Koptyug, I. V.; Sagdeev, R. Z.; Parmon, V. N.;

Bergwerff, J. A.; Weckhuysen, B. M. Noninvasive in situ visualization of

supported catalyst preparations using multinuclear magnetic resonance

imaging. J. Am. Chem. Soc. 2005, 127, 1191611917.

(16) Koptyug, I. V.; Fenelonov, V. B.; Khitrina, L.; Sagdeev, R. Z.;

Parmon, V. N. In situ NMR imaging studies of the drying kinetics of porous

catalyst support pellets. J. Phys. Chem. B 1998, 102, 30903098.

(17) Koptyug, I. V.; Kabanikhin, S. I.; Iskakov, K. T.; Fenelonov, V. B.;

Khitrina, L.; Sagdeev, R. Z.; Parmon, V. N. A quantitative NMR imaging

study of mass transport in porous solids during drying. Chem. Eng. Sci.

2000, 55, 15591571.

(18) Bergweff, J. A.; van de Water, L. G. A.; Visser, T.; de Peinder, P.;

Leliveld, B. R. G.; de; Jong, K. P.; Weckhuysen, B. M. Spatially resolved

Raman and UV-visible-NIR spectroscopy on the preparation of supported

catalyst bodies: controlling the formation of H

2

PMo

11

CoO

40

5-

inside Al

2

O

3

pellets during impregnation. Chem.sEur. J. 2005, 11, 45914601.

(19) van de Water, L. G. A.; Bezemer, G. L.; Bergweff, J. A.; Helder,

M. V.; Weckhuysen, B. M.; de Jong, K. P. Spatially resolved UV-vis

microspectroscopy on the preparation of alumina-supported Co Fischer-

Trospch catalysts: Linking activity to Co distribution and speciation. J. Catal.

2006, 242, 287298.

(20) van de Water, L. G. A.; Bergweff, J. A.; Leliveld, B. R. G.;

Weckhuysen, B. M.; de Jong, K. P. Insights into the preparation of supported

catalysts: A spatially resolved Raman and UV-vis spectroscopic study iinto

the drying process of CoMo/-Al

2

O

3

catalyst bodies. J. Phys. Chem. B 2005,

109, 1451314522.

(21) Assaf, E. M.; Jesus, L. C.; Assaf, J. M. The active phase distribution

in Ni/Al

2

O

3

catalysts and mathematical modeling of the impregnation

process. Chem. Eng. J. 2003, 94, 9398.

(22) Galarraga, C.; Peluso, E.; Lasa, H. Eggshell catalysts for Fischer-

Tropsch synthesis modeling catalyst impregnation. Chem. Eng. J. 2001,

82, 1320.

(23) Komiyama, M. Design and preparation of impregnated catalysts.

Catal. ReV.-Sci. Eng. 1985, 27, 341372.

(24) Lekhal, A.; Khinast, J. G.; Glasser, B. J. Predicting the effect of

drying on supported co-impregnation catalysts. Ind. Eng. Chem. Res. 2001,

40, 39893999.

(25) Lekhal, A.; Glasser, B. J.; Khinast, J. G. Impact of drying on the

catalyst prole in supported impregnation catalysts. Chem. Eng. Sci. 2001,

56, 44734487.

(26) Lekhal, A.; Glasser, B. J.; Khinast, J. G. Inuence of pH and ionic

strength on the metal prole of impregnation catalysts. Chem. Eng. Sci.

2004, 59, 10631077.

(27) Liu, X.; Khinast, J. G.; Glasser, B. J. A parametric investigation

of impregnation and drying of supported catalysts. Chem. Eng. Sci. 2008,

63, 45174530.

(28) Neimark, A. V.; Fenelonov, V. B.; Kheifets, L. I. Analysis of the

drying stage in the technology of supported catalysts. React. Kinet. Catal.

Lett. 1976, 5, 6772.

(29) Uemura, Y.; Hatate, Y.; Ikari, A. Formation of nickel concentration

prole in nickel/alumina catalyst during post-impregnation. J. Chem. Eng.

Jpn. 1973, 6, 117123.

(30) Reinhoudt, H. R.; Troost, R.; Langeveld, A. D. v.; van, J. A. R.;

Veen, S. T. S.; Moulijn, J. A. The Nature of the Active Phase in Sulded

NiW/-Al

2

O

3

in Relation to Its Catalytic Performance in Hydrodesulfur-

ization Reactions. J. Catal. 2001, 203, 509515.

(31) Santos, R. M.; Lisboa, J. S.; Passos, F. B.; Noronha, F. B.

Characterization of Steam-Reforming Catalysts. Braz. J. Chem. Eng. 2004,

21, 203209.

(32) Papageorgiou, P.; Price, D. M.; Gavriilidis, A.; Varma, A. Prepara-

tion of Pt/-Al

2

O

3

pellets with internal step-distribution of catalyst:

experiments and theory. J. Catal. 1996, 158, 439451.

(33) Melo, F.; Cervello, J.; Hermana, E. Impregnation of porous sup-

ports-I Theoretical study of the impregnation of one or two active species.

Chem. Eng. Sci. 1980, 35, 21652174.

(34) Sceiza, O. A.; Castro, A. A.; Ardlles, D. R.; Parera, J. M. Modeling

of the impregnation step to prepare supported Pt/Al

2

O

3

catalysts. Ind. Eng.

Chem. Res. 1986, 25, 8488.

(35) Krishna, R. A simplied procedure for the solution of the dusty

gas model equations for steady state transport in non-reacting systems.

Chem. Eng. J. 1987, 35, 7581.

(36) Wesselingh, J. A.; Krishna, R. Mass Transfer, 2nd ed.; Chichester,

U.K.: Ellis Horwood: Chichester, England, 1998.

(37) Jones, P. J. Petroleum Production; Reinhold: New York, 1946.

(38) Gomis, V.; Font, A.; Saquete, M. D. Vapour-liquid-liquid and

vapour-liquid equilibrium of the system water + ethanol + heptane at

101.3 kPa. Fluid Phase Equilib. 2006, 248, 206210.

(39) Hailwood, A. J.; Horrobin, S. Absorption of water by polymers:

Analysis in terms of a simple model. Trans. Faraday Soc. 1946, 42B, 84

92.

(40) Simpson, W. T. Predicting equilibrium moisture content of wood

by mathematical models. Wood Fiber 1973, 5, 4149.

(41) Dullien, F. A. L. Porous Media: Fluid Transport and Pore

Structure, 2nd ed.; Academic Press: San Diego, CA, 1992.

(42) Perre, P.; Moser, M.; Martin, M. Advances in transport phenomena

during convective drying with superheated steam and moist air. Int. J. Heat

Mass Transfer 1993, 36, 27252746.

(43) Newman, J. Electrochemical Systems, 2nd ed.; Prentice-Hall:

Englewood Cliffs, NJ, 1991.

(44) Krishna, R. A simplifed procedure for the solution of the dusty

gas model equations for steady state transport in nonreacting systems. Chem.

Eng. J. 1987, 35, 7581.

(45) Patankar, S. V. Numerical Heat Transfer and Fluid Flow; McGraw-

Hill: New York, 1980.

(46) Deuhard, P.; Hairer, E.; Zugck, J. One-step and extrapolation

methods for differential-algebraic systems. Numer. Math. 1987, 51, 501

516.

(47) Sietsma, J. R. A.; Meeldijk, J. D.; Versljijs-Helder, M.; Broersma,

A.; van Dillen, A. J.; de Jongh, P. E.; de Jong, K. P. Ordered mesoporous

silica to study the preparation of Ni/SiO

2

ex nitrate catalysts: Impregnation,

drying, and thermal treatments. Chem. Mater. 2008, 20, 29212931.

(48) Takahashi, R.; Sato, S.; Sodesawa, T.; Kamomae, Y. Measurement

of the diffusion coefcient of nickel nitrate in wet silica gel using UV-vis

spectroscope equipped with a ow cell. Phys. Chem. Chem. Phys. 2000, 2,

11991204.

(49) Innocentini, M. D. M.; Salvini, V. R.; Macedo, A.; Pandolfelli,

V. C. Prediction of ceramic foams permeability using Erguns equation.

Mater. Res. 1999, 2, 283289.

(50) Smith, E. B. Basic Chemical Thermodynamics; Clarendon Press:

Oxford, UK, 1993.

(51) Regalbuto, J. R. Catalyst Preparation; CRC Press, Boca Raton,

FL, 2007.

ReceiVed for reView September 16, 2009

ReVised manuscript receiVed February 1, 2010

Accepted February 2, 2010

IE9014606

Ind. Eng. Chem. Res., Vol. 49, No. 6, 2010 2657

You might also like

- The Rate-Limiting Mechanism For The Heterogeneous Burning of Cylindrical Iron RodsDocument39 pagesThe Rate-Limiting Mechanism For The Heterogeneous Burning of Cylindrical Iron RodsTeodoraNo ratings yet

- Paper Decarburization in Spring SteelDocument7 pagesPaper Decarburization in Spring SteelMauricio RodriguezNo ratings yet

- MST Viscosity Review 2014Document11 pagesMST Viscosity Review 2014Marco PlaysNo ratings yet

- Applsci 10 05101 v2Document18 pagesApplsci 10 05101 v2Ernesto D. AguirreNo ratings yet

- Characterisation of Hot Tearing in Al Cast Alloys - Methodology and ProceduresDocument8 pagesCharacterisation of Hot Tearing in Al Cast Alloys - Methodology and ProceduresLilian Jefferson MalavaziNo ratings yet

- Basic Principles of Sulfide Smelting and Converting With Oxygen-Rich GasDocument35 pagesBasic Principles of Sulfide Smelting and Converting With Oxygen-Rich GasAnisahicNo ratings yet

- Frequency and Amplitude Dependent Behaviour of Tangled Metal Wire DampersDocument15 pagesFrequency and Amplitude Dependent Behaviour of Tangled Metal Wire DampersJoakimNo ratings yet

- Laboratory Abrasion and Electrochemical TestDocument20 pagesLaboratory Abrasion and Electrochemical TestrodrigoNo ratings yet

- Research Article: The Solubility of Two Magnetite Powders in Oxalic Acid: Applicability of Empirical ModellingDocument7 pagesResearch Article: The Solubility of Two Magnetite Powders in Oxalic Acid: Applicability of Empirical ModellingDrSrujan Kumar ReddyNo ratings yet

- 1 s2.0 S0009250910004860 MainDocument12 pages1 s2.0 S0009250910004860 MainFares EhabNo ratings yet

- Impregnation Protocols On Alumina Beads For Controlling The Preparation of Supported Metal CatalystsDocument11 pagesImpregnation Protocols On Alumina Beads For Controlling The Preparation of Supported Metal CatalystsKARTIK KUMAR GOYALNo ratings yet

- Catalyst Manufacturing Science and Engineering Consortium (CMSEC)Document11 pagesCatalyst Manufacturing Science and Engineering Consortium (CMSEC)Reza RhiNo ratings yet

- Proceedings of The 5th Canmet/ACI International Conference On Superplasticizers and Other Chemical Admixtures in ConcreteDocument20 pagesProceedings of The 5th Canmet/ACI International Conference On Superplasticizers and Other Chemical Admixtures in ConcreteAbdelaziz HasnaouiNo ratings yet

- Nanotech Catal Kung CatTod2004Document6 pagesNanotech Catal Kung CatTod2004vazzoleralex6884No ratings yet

- Selective Oxidation of Glycerol Using Heterogeneous CatalystDocument3 pagesSelective Oxidation of Glycerol Using Heterogeneous CatalystPedro lopezNo ratings yet

- Full download book High Temperature Oxidation And Corrosion Of Metals Pdf pdfDocument41 pagesFull download book High Temperature Oxidation And Corrosion Of Metals Pdf pdfvonda.ives161100% (13)

- 10 1021@acs Chemrev 5b00373Document99 pages10 1021@acs Chemrev 5b00373edupibosNo ratings yet

- Characterization of Simple Magnetorheological Fluids With Potential Application in EngineeringDocument8 pagesCharacterization of Simple Magnetorheological Fluids With Potential Application in EngineeringCésar Darío MesquidaNo ratings yet

- Duplex Stainless Steel.Document14 pagesDuplex Stainless Steel.Muhammed SulfeekNo ratings yet

- Catalyst Manufacturing Science and Engineering Consortium (CMSEC)Document11 pagesCatalyst Manufacturing Science and Engineering Consortium (CMSEC)rizkiekanandaNo ratings yet

- 4-Q1-SCOPUS-Modeling of The Carburizing and Nitriding Processes PDFDocument10 pages4-Q1-SCOPUS-Modeling of The Carburizing and Nitriding Processes PDFEnriqe PuentesNo ratings yet

- Methods For Synthesis of NanoparticlesDocument20 pagesMethods For Synthesis of NanoparticlesKurtWatleyNo ratings yet

- 1001204_Oxidation and Reduction of Copper in Steam Generator Deposits_ Under Shutdown_ Layup_ and Startup ConditionsDocument139 pages1001204_Oxidation and Reduction of Copper in Steam Generator Deposits_ Under Shutdown_ Layup_ and Startup Conditionsegyptian_scientistNo ratings yet

- Sintering of Zro Cao Sio Systems and Comparison and Determination of The Properties of Compostions Within The SystemDocument27 pagesSintering of Zro Cao Sio Systems and Comparison and Determination of The Properties of Compostions Within The Systemedwardbloomcer06No ratings yet

- Testing and Modelling of Material Behaviour and Formability in Sheet Metal - FormingDocument23 pagesTesting and Modelling of Material Behaviour and Formability in Sheet Metal - Formingnitouch3564No ratings yet

- Ilovepdf MergedDocument13 pagesIlovepdf MergedMadhu CkNo ratings yet

- Engineering Science and Technology, An International JournalDocument7 pagesEngineering Science and Technology, An International JournalGil CastilloNo ratings yet

- Synthesis-Structure-Activity Relationships in Co O Catalyzed CO OxidationDocument12 pagesSynthesis-Structure-Activity Relationships in Co O Catalyzed CO OxidationmanuelNo ratings yet

- Clean Cast Steel Technology Improves QualityDocument61 pagesClean Cast Steel Technology Improves QualitySUNDRAMNAGANo ratings yet

- Uses of Oxygen ChemistryDocument16 pagesUses of Oxygen ChemistryalifbzulNo ratings yet

- Full Text 01Document72 pagesFull Text 01AttractPointNo ratings yet

- Synthesis of Dispersed Metal Particles For Applications in Photovoltaics, Catalysis, and ElectronicsDocument51 pagesSynthesis of Dispersed Metal Particles For Applications in Photovoltaics, Catalysis, and ElectronicsKhouloud baltiNo ratings yet

- Y. A. J. J. V.: Metallurgy of Reactions ADocument76 pagesY. A. J. J. V.: Metallurgy of Reactions ASaidmurod AkramovNo ratings yet

- Review Jurnal Modul 1 & 2Document9 pagesReview Jurnal Modul 1 & 2made andraNo ratings yet

- Jurnal Evap 121 PDFDocument8 pagesJurnal Evap 121 PDFanon_628260182No ratings yet

- International Journal of Heat and Mass Transfer: Hongze Wang, Yu ZouDocument13 pagesInternational Journal of Heat and Mass Transfer: Hongze Wang, Yu ZoukishoreNo ratings yet

- Dokumen - Tips - Thermo Oxidative Ageing of Elastomers A Modelling Approach Based On A FiniteDocument29 pagesDokumen - Tips - Thermo Oxidative Ageing of Elastomers A Modelling Approach Based On A FiniteThiago BaienseNo ratings yet

- Metals 12 00165Document21 pagesMetals 12 00165anjuabrahamNo ratings yet

- Processes 07 00654 PDFDocument21 pagesProcesses 07 00654 PDFRonak PanchalNo ratings yet

- Lindegrin 2Document39 pagesLindegrin 2Babu NarayananNo ratings yet

- Effects of Hydrogen on Materials Wiki PageDocument7 pagesEffects of Hydrogen on Materials Wiki Pagelaercioudesc_No ratings yet

- The Role of Strontium in Modifying Aluminium-Silicon Alloys: Acta Materialia May 2012Document10 pagesThe Role of Strontium in Modifying Aluminium-Silicon Alloys: Acta Materialia May 2012Jagdish RanaNo ratings yet

- Materials 12 01358Document22 pagesMaterials 12 01358Monish Kumar V RNo ratings yet

- Analysis of Wear Behaviour of Dual-2165Document6 pagesAnalysis of Wear Behaviour of Dual-2165Santiago Bonilla RiveraNo ratings yet

- Refinacion SecundariaDocument8 pagesRefinacion SecundariaLuis TrejoNo ratings yet

- Furnace Lining Analysis and Design by Mathematical and Physicochemical ModelingDocument16 pagesFurnace Lining Analysis and Design by Mathematical and Physicochemical ModelingAdrian BNo ratings yet

- TMP F770Document19 pagesTMP F770FrontiersNo ratings yet

- 10 21791ijems 2019 1 46Document10 pages10 21791ijems 2019 1 46John TorrezNo ratings yet

- Prediction of Microstructural Evolution During Hot Forging: January 2014Document22 pagesPrediction of Microstructural Evolution During Hot Forging: January 2014Nicole S. TeodoroNo ratings yet

- Process Corrosion Simulation PaperDocument19 pagesProcess Corrosion Simulation PaperMohammad Fouladi100% (1)

- A Generic Microstructure-Explicit Model of Creep IDocument11 pagesA Generic Microstructure-Explicit Model of Creep IVenkatesh PandianNo ratings yet

- Gasification PHD ThesisDocument8 pagesGasification PHD Thesistfwysnikd100% (2)

- Changes of Chemical Structure and Mechanical PropeDocument14 pagesChanges of Chemical Structure and Mechanical PropeFrancesca TeocoliNo ratings yet

- A Molecular Dynamics Simulation of Droplet EvaporationDocument10 pagesA Molecular Dynamics Simulation of Droplet EvaporationSayan DasNo ratings yet

- Detection of NMI in SteelDocument13 pagesDetection of NMI in SteelShahidNo ratings yet

- Hydrometallurgy: Sylvie C. Bouffard, David G. DixonDocument12 pagesHydrometallurgy: Sylvie C. Bouffard, David G. DixonAna Karoline ZillesNo ratings yet

- Materials 10 00471Document30 pagesMaterials 10 00471Hisham TariqNo ratings yet

- Catalysis: An Integrated Approach to Homogeneous, Heterogeneous and Industrial CatalysisFrom EverandCatalysis: An Integrated Approach to Homogeneous, Heterogeneous and Industrial CatalysisNo ratings yet

- Coal Science: Volume 1From EverandCoal Science: Volume 1Martin L. GorbatyNo ratings yet

- Folhas de Dados - CondensadorDocument6 pagesFolhas de Dados - Condensadorvazzoleralex6884No ratings yet

- Engineering Design DeliverablesDocument9 pagesEngineering Design Deliverablessushant_jhawer100% (5)

- PFD ConsiltatorDocument5 pagesPFD Consiltatorvazzoleralex6884No ratings yet

- Minimum Spacing Guidelines For Production Equipment - Chevron Equipment Spacing GuidelinesDocument2 pagesMinimum Spacing Guidelines For Production Equipment - Chevron Equipment Spacing Guidelinesvazzoleralex6884No ratings yet

- CEP Article - Litzen and BravoDocument8 pagesCEP Article - Litzen and BravoA MNo ratings yet

- Sigma Dados ContinuosDocument3 pagesSigma Dados Continuosvazzoleralex6884No ratings yet

- Process Design Safety ChecklistDocument8 pagesProcess Design Safety ChecklistAditya DubeyNo ratings yet

- Hydrogen technology– an overviewDocument7 pagesHydrogen technology– an overviewlili_eqNo ratings yet

- 5 Contoh Binary - DistillationDocument14 pages5 Contoh Binary - DistillationDella Intania Putri NiziNo ratings yet

- Nitric Acid PlantDocument31 pagesNitric Acid Plantejaz khanNo ratings yet

- Aylett Et Al. (1998) - Generating Operating Procedures For Chemical Process PlantsDocument32 pagesAylett Et Al. (1998) - Generating Operating Procedures For Chemical Process Plantsvazzoleralex6884No ratings yet

- Bibliography - Plant DesignDocument6 pagesBibliography - Plant DesignROBERTO JHALVER VEGA PAULINONo ratings yet

- Application of Water Pinch Analysis for Water Conservation in Indian Pulp and Paper IndustryDocument32 pagesApplication of Water Pinch Analysis for Water Conservation in Indian Pulp and Paper IndustryMihir DakwalaNo ratings yet

- Plant and Process Engineering Workflow PDFDocument43 pagesPlant and Process Engineering Workflow PDFrajkamal eshwarNo ratings yet

- Distillation Without Steam: Vapor RecompressionDocument3 pagesDistillation Without Steam: Vapor RecompressionMaria Jafar KhanNo ratings yet

- Lonakadi (2010) - Amine Contactor RevampDocument3 pagesLonakadi (2010) - Amine Contactor Revampvazzoleralex6884No ratings yet

- Experienced Based Rules of Chemical EngineeringDocument13 pagesExperienced Based Rules of Chemical Engineeringvazzoleralex6884No ratings yet

- Pre-Assembly Perks. Discover Why Modularization WorksDocument3 pagesPre-Assembly Perks. Discover Why Modularization Worksvazzoleralex6884No ratings yet

- Hansen (2000) - Engineering Design For Process SafetyDocument6 pagesHansen (2000) - Engineering Design For Process Safetyvazzoleralex6884No ratings yet

- Chlorobenzene Design 2520of 2520equipmentsDocument44 pagesChlorobenzene Design 2520of 2520equipmentsElizabeth Patrick100% (2)

- Coordination Plant LayoutDocument7 pagesCoordination Plant Layoutvazzoleralex6884No ratings yet

- Cabanyss Et Al. (2014) - Preliminary Market Analysis and Plant CapacityDocument5 pagesCabanyss Et Al. (2014) - Preliminary Market Analysis and Plant Capacityvazzoleralex6884No ratings yet

- Convert Common UnitsDocument31 pagesConvert Common Unitsintania66No ratings yet

- 4P&IDDocument8 pages4P&IDMidhun K ChandraboseNo ratings yet

- Feinberg (2002) - Toward A Theory of Process SynthesisDocument11 pagesFeinberg (2002) - Toward A Theory of Process Synthesisvazzoleralex6884No ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- A Retrospective On Design and Process Synthesis PDFDocument12 pagesA Retrospective On Design and Process Synthesis PDFMeliSNo ratings yet

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocument5 pagesChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884No ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Langdon e Hartman (2007) - FCC Gas Concentration Unit Stripper RevampDocument5 pagesLangdon e Hartman (2007) - FCC Gas Concentration Unit Stripper Revampvazzoleralex6884No ratings yet

- Guide To Resin SystemsDocument9 pagesGuide To Resin SystemsDaud Simon A100% (1)

- Catalogo Brossard ParafusosDocument0 pagesCatalogo Brossard ParafusosMarco ViniciusNo ratings yet

- Modeling of Welded Connections in Solidworks Simulation: Conference PaperDocument6 pagesModeling of Welded Connections in Solidworks Simulation: Conference PaperpatrickNX9420No ratings yet

- Useful Data On Plastic Injection MouldingDocument71 pagesUseful Data On Plastic Injection MouldingMahesh Deivasiga Mani D100% (2)

- Scribd Download - Com Pipeline Pigging Visit HTTP Piping Info Blogspot ComDocument2 pagesScribd Download - Com Pipeline Pigging Visit HTTP Piping Info Blogspot Comeng20072007No ratings yet

- Natural Convection Heat Transfer From Immersed BodiesDocument3 pagesNatural Convection Heat Transfer From Immersed BodiesJanneNo ratings yet

- Pryout Capacity of Cast-In Headed Stud AnchorsDocument62 pagesPryout Capacity of Cast-In Headed Stud Anchorsaungps_sone82No ratings yet

- LG 55uf850t, 850y-Tb 55uf851t, Y-Tc Chassis Lb53h SMDocument101 pagesLG 55uf850t, 850y-Tb 55uf851t, Y-Tc Chassis Lb53h SMLuis Fernando Calle JaramilloNo ratings yet

- Ba2487 PDFDocument19 pagesBa2487 PDFHazel Liow HYNo ratings yet

- Durability Estimation of Porous Building Stones From Pore Structure and Strength - 2004 - Engineering Geology PDFDocument15 pagesDurability Estimation of Porous Building Stones From Pore Structure and Strength - 2004 - Engineering Geology PDFJosé BritesNo ratings yet