Professional Documents

Culture Documents

Energy Efficieny Improve 2012 Dec

Uploaded by

Sharif M Mizanur Rahman0 ratings0% found this document useful (0 votes)

103 views5 pagescEP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentcEP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

103 views5 pagesEnergy Efficieny Improve 2012 Dec

Uploaded by

Sharif M Mizanur RahmancEP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

16 www.aiche.

org/cep December 2012 CEP

Energy

T

he chemical process industries (CPI) have made

great strides toward energy effciency. New, high-

yield catalysts, equipment advances, improvements

to process design procedures, process control and real-time

optimization, energy-focused maintenance programs, and

changes in corporate policies have contributed to this prog-

ress. In addition to these sophisticated strategies, simple,

often-overlooked changes and activities can yield dramatic

gains in energy effciency.

This article presents several effective and relatively

easy changes that operators and process engineers can

implement to minimize energy consumption, and provides

guidance on how to avoid some of the common pitfalls.

Unnecessary cooling of process streams

A common ineffciency in a chemical plant or refnery

is the cooling of process streams that should not be cooled.

A petrochemical facility installed an air cooler on the

feed line of a distillation column (Figure 1) to prevent the

condenser from being overloaded during certain abnor-

mal operating conditions (1). Although the air cooler was

designed for use only during abnormal conditions, it ran

continuously during normal operations. Removing heat

from the feed during normal conditions required the reboiler

to work harder, thereby increasing the boilers heat load.

Changing operating procedures to refect the original

intent of the air cooler shutting off the air cooler fan dur-

Managing the energy consumption of a process

does not need to be complicated. Here are some

examples of less-complicated strategies.

Alan P. Rossiter

Rossiter & Associates

Veerasamy Venkatesan

VGA Engineering Consultants

Easy Ways to Improve

Energy Efciency

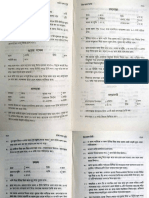

p Figure 1. A distillation column was designed with an air cooler on the feed line. Although the cooler was designed for use only during abnormal conditions, it

was run continuously, resulting in an increased reboiler heat load. Shutting off the air cooler during normal operations did not completely solve the problem, as a

signicant amount of heat was wasted due to convection in the cooler. A simple x: Install a bypass line around the air cooler (green).

Feed

Air Cooler

Condenser

Top

Product

Reboiler

Bottom

Product

After Modifications

Feed

Air Cooler

Condenser

Top

Product

Reboiler

Bottom

Product

Before Mofications

Copyright 2012 American Institute of Chemical Engineers (AIChE)

CEP December 2012 www.aiche.org/cep 17

ing normal operations reduced the reboiler duty by more

than 30% and saved the plant more than $1 million/yr, at no

cost to the facility.

Turning the air cooler off during normal operations was

a good frst step. However, a signifcant amount of heat

was still being wasted due to convection in the air cooler.

This loss was eliminated by installing a bypass around the

air cooler (Figure 1, green) a small project that saved an

additional $200,000/yr.

This example illustrates the importance of understand-

ing the purpose of all the equipment in a process. Operators

often place equipment in service inappropriately, and once

these inappropriate operating norms have been established,

they sometimes stay in place for years. Good operating

procedures combined with training, including frequent

refresher courses or continuing education, can go a long

way toward minimizing this type of equipment misuse.

Pump power

In a plastics facility (2), a large high-pressure feed

pump with a fxed-speed electric drive was operated with

spillback control (Figure 2). In this arrangement, the pump

operated at constant fow and delivery pressure, and adjust-

ments to the opening of the spillback valve accommodated

changes in the process demand. A cooler was incorporated

in the spillback line to avoid overheating.

Although the spillback control system provided opera-

tional stability and protected the pump from shut-in (a

condition that could cause damage to the equipment), it did

so at the expense of signifcant energy ineffciency. During

normal operation, the pump ran at high throughput and

relatively low head, with a large recycle fow, and thus high

power requirements (Figure 3).

Many options are available to reduce pump power

requirements. These include the use of variable-speed

drives or high-effciency pumps and motors, trimming or

replacing impellers, and adding a smaller pump for use

during periods of low throughput. For various reasons,

these options were not viable for the plastics facility in this

example. However, throttle control i.e., the addition of

a throttle valve in the line feeding the user of the pumped

fuid offers a simple alternative (Figure 2, green).

When a throttle valve is used for fow control with a

fxed-speed pump, the fow through the pump is equal to the

amount of feed required by the process user. This is signif-

cantly lower than the pump fowrate with spillback control.

Throttling also introduces a backpressure on the pump,

and this, together with the reduced fowrate, moves the

operating point on the pump curve up and to the left, which

corresponds to a reduced power requirement (Figure 3). It is

important to keep the spillback valve in the system because

of its ability to prevent the pump from being shut-in; the

spillback valve opens if the process feed requirement falls

below a predetermined minimum allowable fowrate.

Installing throttle control in this system reduced the

pump power by about 10%, which resulted in savings of

about $150,000/yr. The only expenditures required were

for the throttle valve and associated equipment, and repro-

gramming of the control system.

This example highlights a common tendency of engi-

neers and operators to accept the design of their control

systems as long as the equipment functions reliably and

safely. Safety and reliability are, of course, top priorities.

However, many control systems are designed without

regard to the energy losses they create. It is well worth

reassessing these systems and questioning the losses.

Maintenance tracking and communication

While working in a refnery, one of the authors (Rossiter)

noticed that a heat exchanger was out of service which

was not unusual, as heat exchangers often require mainte-

nance. However, the records showed that this particular heat

exchanger had been idle for more than three months after

p Figure 2. A high-pressure feed pump in a plastics facility was operated

with spillback control. This arrangement provides for operational stability, but

at the expense of energy inefciency. A throttle valve was added (green) to the

high-pressure feed pump system to allow the pump to operate during normal

conditions at a lower owrate and thus lower power requirement.

Operating with Throttle Operating without Throttle

P

o

w

e

r

H

e

a

d

Flowrate

p Figure 3. The pump curve for the pump shown in Figure 2 compares the

operating point with and without throttle control.

Pump

Feed

CW Supply

CW Return

Spillback Valve

Throttle Valve

FIC

Copyright 2012 American Institute of Chemical Engineers (AIChE)

18 www.aiche.org/cep December 2012 CEP

Energy

being taken out of service for cleaning. The work had been

completed within a few weeks, at which point the mainte-

nance supervisor notifed the shift supervisor that the heat

exchanger was ready for use. But plant personnel were occu-

pied with other activities, so the heat exchanger could not be

put back into service at that time. The shift supervisor failed

to pass the information on to the next shift, and no follow-up

action was taken until the idle equipment was pointed out.

Once the unit manager was informed of the situation,

the heat exchanger was placed back in service within

hours. The energy loss incurred during the 2.5 months

that the heat exchanger had been left idle was worth over

$100,000 (1).

Management of heat-exchanger cleaning programs has

become increasingly sophisticated, with both improved

cleaning techniques and better tools for assessing appropri-

ate cleaning intervals for the heat exchangers in the circuit.

However, the best cleaning methods and the most elegant

optimization of cleaning intervals are of little use when

communication fails.

In this example, better systems were needed for

tracking the status of maintenance jobs on the unit. A

simple electronic reminder system, for example, could

have alerted the operators of the need to bring the heat

exchanger back online.

Optimizing steam systems

Steam systems including boilers, steam distribution

lines, and power generation with steam turbines present

signifcant opportunities for improving energy effciency.

The fnal two examples illustrate this point.

Preheating deaerator feedwater. Steam systems used

for process heating in oil refneries and chemical plants

commonly employ thermal deaerators to drive off oxygen

and other dissolved gases from boiler feedwater. In prin-

ciple, only a small amount of steam is needed to do this.

However, the temperature of the incoming water is often

much lower than the saturation temperature in the deaera-

tor, so a substantial amount of additional steam is used to

preheat the water. Preheating the feedwater to a deaerator

can consume 10%, or even 15%, of the total steam gener-

ated on a site. For this reason, strategies are often devel-

oped to preheat deaerator feedwater with recovered waste

process heat.

In this example, the deaerator in a chemical plant

processed a combination of warm returned condensate and

softened makeup water that is available only at ambi-

ent temperature. Within the boiler house there were also

several water-cooled air compressors (Figure 4), one of

which was experiencing chronic maintenance problems in

its cooling tower.

During a project to replace this cooling tower, one of the

authors (Venkatesan) noticed that the average quantity of

softened makeup water (at ambient temperature) going to the

deaerator (115150 gpm) was almost identical to the amount

of cooling water needed for the air compressor (120 gpm).

Based on this observation, a new project was proposed to

route the makeup water through the air compressor and

isolate the cooling tower with blinds (Figure 5). The new

proposal was evaluated and accepted, and the piping modif-

cations were completed within two months.

Heat from the air compressor is now recovered by

preheating the softened water,

saving $80,000/yr in deaerator

steam usage. Implementa-

tion was very inexpensive, as

it required only local pip-

ing changes. In addition, the

project eliminated the need to

maintain or replace the cool-

ing tower, thus signifcantly

reducing costs.

This example illustrates the

benefts of preheating deaerator

feedwater. Perhaps even more

importantly, it shows how

a single project can achieve

multiple objectives in this

case, save energy and elimi-

nate a chronic maintenance

problem. It also illustrates

the importance of looking

for creative ways to redeploy

Compressed Air to Process

Air Inlet

Cooling

Tower

Third Stage

Second

Stage

First Stage

Air Compressor

After-Cooler Inter-Cooler

Inter-Cooler

Oil Cooler

p Figure 4. A deaerator in a chemical plant processes a combination of warm returned condensate and softened

makeup water at ambient temperature. Extra steam is consumed in this conguration to heat the softened makeup

water. Coincidentally, the average quantity of softened makeup water going to the deaerator was almost identical to

the amount of cooling water needed for one of the air compressors within the boiler house.

Deaerator

Softened Makeup

Water for Deaerator

6065F

115150 gpm

Returned

Condensate

Copyright 2012 American Institute of Chemical Engineers (AIChE)

CEP December 2012 www.aiche.org/cep 19

existing equipment in situ to save energy. Of course, it is

always essential to check equipment limitations and follow

appropriate management-of-change procedures when mak-

ing process modifcations. In addition, when implementing

steam-saving projects, one should consider the overall fuel

and steam balances of the plant, and not focus purely on

improving the effciency of individual equipment (3).

Adding excessive safety margins to steam consumption.

In a commodity chemical plant in Europe, two steam turbines

drove a large air compressor and an electric generator in a

single-shaft arrangement. The frst turbine, a backpressure

turbine, was used to let down high-pressure (HP), 930-psig

steam to medium-pressure (MP), 290-psig steam. The second

turbine, an extraction-condensing turbine, received MP steam,

which was extracted as low-pressure (LP), 73-psig steam (in

the extraction section) for process use, and the remaining MP

steam was expanded into a vacuum condenser (Figure 6).

In the original design, only the exhaust steam from the

backpressure turbine was used to supply MP steam to the

extraction-condensing turbine. Because the temperature of

the outlet steam from the backpressure turbine was higher

than 660F (the maximum allowable steam inlet tempera-

p Figure 5. To eliminate some of the extra steam required to heat the softened makeup water for the deaerator shown in Figure 4, the makeup water was

rerouted (green) through the air compressor, which heats the water from 6065F to 8590F.

Deaerator

Air Compressor

Softened Makeup

Water for Deaerator

6065F

115150 gpm

Compressed Air to Process

Air Inlet

After-Cooler

Cooling

Tower

Third Stage

Second

Stage

First Stage

Inter-Cooler Inter-Cooler Oil Cooler

Preheated Makeup Water

8590F

115150 gpm

Returned

Condensate

73 psig

Generator

Backpressure

Turbine

Extraction-

Condensing

Turbine

Process Gas

Compressor

Desuperheater

Vacuum

Condenser

Steam from

Waste-Heat Boiler

To Users

600F

290 psig

698F

290 psig

550F

930 psig

932F

Boiler Feedwater

Steam

Cold Water 63F

Cold Water 81F

574F

p Figure 6. At a commodity chemicals plant in Europe, two steam turbines (a backpressure turbine and an extraction-condensing turbine) drove a large air

compressor and an electric generator. A desuperheater reduced the temperature of the MP backpressure steam before it entered the extraction-condensing

turbine together with steam from a waste-heat boiler.

Copyright 2012 American Institute of Chemical Engineers (AIChE)

20 www.aiche.org/cep December 2012 CEP

Energy

ture specifed for the extraction-condensing turbine), before

entering the turbine, the MP steam went through a desuper-

heater to reduce its temperature. The desuperheater was

designed to produce MP steam at 600F providing for a

60F safety margin. (Note that the amount of work extracted

from a steam turbine decreases as the inlet temperature goes

down, so adding the desuperheater reduced the amount of

work generated by the extraction-condensing turbine.)

The original design was later modifed to add steam

from a waste-heat boiler to the steam from the backpressure

turbine outlet, which increased the steam fow to the extrac-

tion-condensing turbine and thus raised its power output.

The temperature of the steam from the waste-heat boiler was

550F signifcantly cooler than the exhaust steam from the

backpressure turbine. When the designers made this modif-

cation, they did not re-evaluate the use of the desuperheater.

A subsequent study of this system by one of the authors

(Venkatesan) found that the maximum temperature that can

be reached with the combined steam fow to the extraction-

condensing turbine is below 660F, and desuperheating of the

backpressure turbine exhaust steam can be safely eliminated.

Based on this fnding, a bypass line was installed around the

desuperheater, and the water supply to the desuperheater was

shut off (Figure 7, green). This change increased the amount

of electricity generated by the turbine by 500 kW, resulting in

an annual energy cost saving of $400,000.

This example illustrates the need to challenge existing

operating practices, and also to re-evaluate conditions when

process changes are made. While it is always essential to

operate within design limits, excessively large margins of

safety can result in unnecessary losses of energy effciency.

Final thoughts

No matter how sophisticated our energy management

strategies become, it is imperative that we continue to pay

attention to basic principles. We must understand the pur-

pose and limitations of the equipment in our processes. And

when changes are made to our facilities, we must consider

their impact on all processes. Key principles of human inter-

actions especially communication are also essential to

all of our activities.

ALAN P. ROSSITER, P.E., PhD, is president of Rossiter & Associates, a

consulting company based in Bellaire, TX (Email: alan@rossiters.org;

Website: www.rossiters.org/associates) that provides consulting ser-

vices on energy efciency for the oil rening and chemical industries.

He received his BA, MEng, and PhD, all in chemical engineering, from

the Univ. of Cambridge, and he has more than 30 years of experience

in process engineering and management. He is a chartered engineer in

the U.K., and a registered professional engineer in the state of Texas.

He is a past chair of the South Texas Section of AIChE.

VEN VENKATESAN, an energy expert, heads the consulting rm VGA

Engineering Consultants (Email: venkatesan@vgaec.com; Phone: (407)

399-9316). With over 33 years of experience in the energy management

eld, he has conducted energy audits for more than 120 energy-

intensive process facilities around the world, and he has been involved

in the U.S. Dept. of Energys Save Energy Now program as a steam and

process heating systems specialist. He also conducts international

training programs for engineers through the United Nations Industrial

Organization (UNIDO). He received his BS and MS, both in chemical

engineering, from the Univ. of Madras, India.

Literature Cited

1. Rossiter, A. P., Back to the Basics, Hydrocarbon Engineering,

12 (9), pp. 6973 (Sept. 2007).

2. Rossiter, A. P., Simple Opportunities for Improving Energy

Effciency, AIChE Spring Meeting and 8th Global Congress on

Process Safety, Houston, TX, Paper No. 119a (April 4, 2012).

3. Tanthapanichakoon, W., Saving Energy in Multilevel Steam

Systems, Chem. Eng. Progress, 108 (1), pp. 2732 (Jan. 2012).

p Figure 7. A study showed that the desuperheater in Figure 6 was unnecessary. A bypass line (green) was installed around the desuperheater and the

desuperheating water was shut off, increasing power production by 500 kW.

73 psig

Generator

Backpressure

Turbine

Extraction-

Condensing

Turbine

Process Gas

Compressor

Desuperheater

Vacuum

Condenser

Cold Water 63F

Steam from

Waste-Heat Boiler

To Users

698F

290 psig

698F

290 psig

550F

930 psig

932F

622F

Boiler Feedwater

Cold Water 81F

Steam

CEP

Copyright 2012 American Institute of Chemical Engineers (AIChE)

You might also like

- Diabetic Cooking RecipesDocument43 pagesDiabetic Cooking Recipesmoro4500No ratings yet

- Chicken Grill RecipeDocument1 pageChicken Grill RecipeSharif M Mizanur RahmanNo ratings yet

- 03 Practical ApplicationDocument1 page03 Practical ApplicationSharif M Mizanur RahmanNo ratings yet

- Kyokushin Karate Complete GuideDocument129 pagesKyokushin Karate Complete Guidemalarem67% (3)

- FISHYDocument1 pageFISHYSharif M Mizanur RahmanNo ratings yet

- History of Science Fullversion PDFDocument70 pagesHistory of Science Fullversion PDFSharif M Mizanur RahmanNo ratings yet

- Lectures 1-9 History and Philosophy of Science and TechnologyDocument59 pagesLectures 1-9 History and Philosophy of Science and TechnologyZaky IbenNo ratings yet

- Meraj and ScienceDocument93 pagesMeraj and ScienceSharif M Mizanur RahmanNo ratings yet

- Black Holes: Warped Spacetime and Gravitational WavesDocument10 pagesBlack Holes: Warped Spacetime and Gravitational WavesSharif M Mizanur RahmanNo ratings yet

- Respiration HandoutDocument9 pagesRespiration HandoutSharif M Mizanur RahmanNo ratings yet

- Tanning KnowlegeDocument5 pagesTanning KnowlegeAnwar SuliantoNo ratings yet

- Kyokushin TerminologieDocument13 pagesKyokushin TerminologieSharif M Mizanur RahmanNo ratings yet

- CARFAX Vehicle History Report For This 2007 TOYOTA COROLLADocument6 pagesCARFAX Vehicle History Report For This 2007 TOYOTA COROLLASharif M Mizanur RahmanNo ratings yet

- s40550 016 0045 3Document9 pagess40550 016 0045 3Kate MaryNo ratings yet

- FISHYFRIEEDocument1 pageFISHYFRIEESharif M Mizanur RahmanNo ratings yet

- Ranna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Document48 pagesRanna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Sharif M Mizanur Rahman0% (1)

- Ethanolfromcornstarch PDFDocument44 pagesEthanolfromcornstarch PDFDerrick Scott FullerNo ratings yet

- Fakruddin Recipe BiryaniDocument1 pageFakruddin Recipe BiryaniSharif M Mizanur RahmanNo ratings yet

- Ranna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Document60 pagesRanna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Sharif M Mizanur RahmanNo ratings yet

- Development of An ASPEN PLUSDocument36 pagesDevelopment of An ASPEN PLUSkiny81No ratings yet

- Ge Strategies For Protein PurificationDocument167 pagesGe Strategies For Protein PurificationSharif M Mizanur RahmanNo ratings yet

- PRON 25 WordsDocument1 pagePRON 25 WordsSharif M Mizanur RahmanNo ratings yet

- Recipe For HealthDocument1 pageRecipe For HealthSharif M Mizanur RahmanNo ratings yet

- Ranna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Document60 pagesRanna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Sharif M Mizanur RahmanNo ratings yet

- Recipetehari PDFDocument153 pagesRecipetehari PDFSharif M Mizanur RahmanNo ratings yet

- U.S. Meat Goat Operations: Veterinary ServicesDocument4 pagesU.S. Meat Goat Operations: Veterinary ServicesSharif M Mizanur RahmanNo ratings yet

- Ranna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Document73 pagesRanna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Sharif M Mizanur RahmanNo ratings yet

- Isoa Hea OMPASS - 2016 - 2017 PDFDocument13 pagesIsoa Hea OMPASS - 2016 - 2017 PDFSharif M Mizanur RahmanNo ratings yet

- Diabetic Cooking RecipesDocument43 pagesDiabetic Cooking Recipesmoro4500No ratings yet

- Energy Guide Refrig - 2265225Document2 pagesEnergy Guide Refrig - 2265225Sharif M Mizanur RahmanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- STOKES DRAG Derivation PDFDocument4 pagesSTOKES DRAG Derivation PDFVadiraj HemadriNo ratings yet

- 3 - BC 2017-18 5.-6.3 FTC To Sketch and Find Total ChangeDocument6 pages3 - BC 2017-18 5.-6.3 FTC To Sketch and Find Total ChangeSamNo ratings yet

- ORGANISASI SELULER - Struktur Dan Fungsi-2017 PDFDocument58 pagesORGANISASI SELULER - Struktur Dan Fungsi-2017 PDFMantanindah 0206No ratings yet

- Wind Loading-Base Station Antennas White Paper TP - 103194Document13 pagesWind Loading-Base Station Antennas White Paper TP - 103194nakkipatty100% (2)

- Energy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet KurbanDocument13 pagesEnergy Conversion and Management: Ümmühan Basßaran Filik, Ömer Nezih Gerek, Mehmet Kurbanakash_chandraya4200No ratings yet

- STS Lesson 2Document30 pagesSTS Lesson 2Reymond Lupoz IINo ratings yet

- Phy 101 Lecture1 (Introduction, Measurement and Estimation)Document40 pagesPhy 101 Lecture1 (Introduction, Measurement and Estimation)ChinyamaNo ratings yet

- Adjusting and Maintaining DC GeneratorsDocument10 pagesAdjusting and Maintaining DC GeneratorssandyNo ratings yet

- Identifying and Preventing Dna Contamination in A Dna Typing LaboratoryDocument3 pagesIdentifying and Preventing Dna Contamination in A Dna Typing LaboratoryDette de LaraNo ratings yet

- EEE-435 Lecture 1: Industrial SafetyDocument20 pagesEEE-435 Lecture 1: Industrial SafetyShah SyedNo ratings yet

- McKee EquationDocument2 pagesMcKee EquationKatrina Joyce Mabanes100% (1)

- EFL - ESL General Knowledge Quiz Questions PDFDocument7 pagesEFL - ESL General Knowledge Quiz Questions PDFBaloram DeyNo ratings yet

- 1 Wire Instruction ManulalDocument6 pages1 Wire Instruction ManulalhdnutzNo ratings yet

- Pokédex Eon GuardiansDocument495 pagesPokédex Eon GuardianssaacidNo ratings yet

- Quality Assurance of Computed and Digital Radiography SystemsDocument6 pagesQuality Assurance of Computed and Digital Radiography SystemsYuda FhunkshyangNo ratings yet

- Math-6 Demo-LPDocument4 pagesMath-6 Demo-LPREZANo ratings yet

- Ball and BeamDocument8 pagesBall and BeamIonel MunteanuNo ratings yet

- 2013 Shunting Effect in Resistance Spot Welding Steels - Part 2 Theoretical AnalysisDocument8 pages2013 Shunting Effect in Resistance Spot Welding Steels - Part 2 Theoretical Analysisguravshubham7777No ratings yet

- Bullivants Rigging Handbook V2Document260 pagesBullivants Rigging Handbook V2Anonymous 2QD5RVWt5100% (5)

- Lectures Matrix FieldDocument358 pagesLectures Matrix FieldLuisgarciaBerlanga100% (1)

- Chapter 1 PDFDocument43 pagesChapter 1 PDFAbdoNo ratings yet

- The Evolution of Forces PDFDocument442 pagesThe Evolution of Forces PDFTodor RadovanovicNo ratings yet

- 53 Tutorial Mouse enDocument15 pages53 Tutorial Mouse enh_eijy2743No ratings yet

- Envision - 8.3 Multiply Fractions and Whole NumbersDocument3 pagesEnvision - 8.3 Multiply Fractions and Whole NumbersMohamed A MoneimNo ratings yet

- For The Classes of Crystal: For Searching Project ReportsDocument15 pagesFor The Classes of Crystal: For Searching Project ReportsDhanapal PalNo ratings yet

- Chemistry Lab Report 4 (Chromatography)Document5 pagesChemistry Lab Report 4 (Chromatography)Daniel LohNo ratings yet

- AP Final Exam IIDocument21 pagesAP Final Exam IIRobert JonesNo ratings yet

- Mechanisms for indexing, positioning and interlockingDocument122 pagesMechanisms for indexing, positioning and interlockingRolffoTelloNo ratings yet

- Public Science Public GoodDocument6 pagesPublic Science Public GoodAbilNo ratings yet

- Zinc Alloy PlatingDocument20 pagesZinc Alloy PlatingHarish Vasishtha100% (1)