Professional Documents

Culture Documents

FEA Basics Very Imp

Uploaded by

Manivannan Jeeva100%(1)100% found this document useful (1 vote)

61 views26 pagesgood

Original Title

FEA Basics Very Imp Ppt

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

61 views26 pagesFEA Basics Very Imp

Uploaded by

Manivannan Jeevagood

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 26

1

Finite Element Analysis

Introduction to

2

What This Presentation Covers

Introduction to Different Numerical Method

Introduction to FEM - Concept & Philosophy

Practical Application of FEA

Need & Advantages of Finite Element Analysis

Different Professional FEA Tools/Software

Steps involved in any Finite Element Analysis Best Practices Approach

Types of Analysis

Introduction to Finite Element Analysis

3

Objective of this Session

By the End of this session, You will be able to :

Understand and apply the Concept of FEM / FEA on Actual practical

day-to-day / complex problems

Understand Different Type of Analysis covered in FEA

Prepare a suitable FE model for a given problem

Know the Behavior of different type of FE Elements used , Concept of FE

Mesh , Loads and Boundary Condition

Step by Step approach followed in any Finite Element Analysis

Introduction to Finite Element Analysis

4

Introduction to FEA

Methods to Solve Any Engineering Problem

Analytical Method Numerical Method Experimental Method

Classical Approach

100% Accurate Results

Applicable only for Simple problems like

Cantilever , simply supported beams and

Cylinders etc..

Complete in itself

Mathematical Approach

Approximate, Assumptions Made

Applicable to real life complicated problems

Results can not be believed blindly and

must be verified by experimental methods

and Hand Calculations.

Actual Measurement

Time Consuming , Needs expensive setup

Applicable only if physical prototype is

available

Results can not be believed blindly and

Minimum 2 or more prototypes must be

tested.

Although applicable to simple shaped

geometries only , Analytical methods are

considered as Closed form solutions i.e.

100% Accurate

Finite Element Method: Linear , Nonlinear ,

Buckling , Thermal, Dynamics & Fatigue

analysis

Boundary Element Method: Acoustics /

NVH analysis

Finite Volume Method: CFD

(Computational Fluid Dynamics) &

Computational Electromagnetic

Finite Difference Method: Thermal & Fluid

Flow analysis (in combination with FVM)

-Strain Gauge

- Photo elasticity

- Vibration measurement (accelerometers)

- Sensors for Temp & pressure etc

- Fatigue test

Introduction to Finite Element Analysis

5

Different Numerical Methods

Finite Element Method (FEM) :

Very Popular Method based upon discretization of component into Finite number of blocks (elements)

Applications : Linear, Nonlinear, Thermal, Dynamics , Buckling and Fatigue Analysis

Boundary Element Method (BEM) :

Its a very powerful and efficient technique to solve acoustics and NVH problems

Just like Finite Element Method, it also requires Nodes and Elements but as the name suggest, it considers only

the outer boundary of the domain

Finite Volume Method (FVM) :

All Computational Fluid Dynamics (CFD) soft wares are based upon FVM.

Unit Volume is considered in Finite Volume Method (similar to Elements in Finite Element Method)

Variable properties at nodes are Pressure , Velocity , Area , Mass etc.

It is based on Navier Stoke equations ( Mass ,Momentum and Energy Conservation equations)

Finite Difference Method (FDM) :

Finite Element and Finite Difference share many common things.

In general, Finite difference Method is described as a way to solve difference equation.

It uses Taylors series to convert differential equation into algebraic equation. Higher order terms neglected.

Is it possible to use all the above listed methods (FEA ,BEM , FVM, FDM)

to solve same problem (say Cantilever problem)?

Answer : YES ! But the difference is in Accuracy achieved , programming ease and time

required to obtain the solution

Introduction to Finite Element Analysis

6

Are FEA and FEM different ?

Finite Element Analysis (FEA) and Finite Element Method (FEM) both are

one & the same.

FEA is a method/process based upon FEM

Term FEA is more popular in industries while FEM at Education

centers

Introduction to Finite Element Analysis

7

Why Finite Element Method ?

FEA is the most widely applied computer simulation method in Engineering.

It is very closely integrated with CAD/CAM applications.

It is very well proven , tested and validated method for simulating any complex

practical scenario in the area of Structural ,Thermal ,Vibration etc..

Introduction to Finite Element Analysis

8

Application of FEM in Engineering

Mechanical / Aerospace / Civil Engineering / Automobile Engineering

Structural Analysis ( Static / Dynamic , Linear / Non-Linear )

Thermal Analysis ( Steady State / Transient )

Electromagnetic Analysis

Geomechanics

Biomechanics

etc.

Introduction to Finite Element Analysis

9

Practical Applications of FEA

Aerospace Domain

Automotive Domain

Introduction to Finite Element Analysis

10

Practical Applications of FEA

Hi-Tech /Electronics

Medical Devices

Introduction to Finite Element Analysis

11

and many more .

Practical Applications of FEA

Introduction to Finite Element Analysis

12

Advantages of FEA

Cost

Design Cycle time

No. of Prototypes

Testing

Design Optimization

Introduction to Finite Element Analysis

13

Available Commercial FEA Tools/Software Packages

Introduction to Finite Element Analysis

14

Analysis Types

Introduction to Finite Element Analysis

Structural Analysis

Static Analysis

Linear

Non-Linear

Dynamic Analysis

Modal

Analysis

Harmonic

Analysis

Random

Analysis

15

Steps involved in FEA

Understanding the Problem (Thermal , Structural, Dynamic etc)

Element Selection (Solid , Shell , Beams etc)

Deciding the Boundary Conditions (Constraints , Connections etc..)

Load Application (Point , Surface , Body loads etc..)

Solution (Solver , Sub step / Time step , Nonlinearity etc)

In-Depth study & interpretation of Analysis Results (Sanity Checks)

Post processing of Results (Deflection , Stress , Strain etc..)

Report Preparation

Observation and Conclusion from the Analysis (MoS Calcs, Design ok)

Suggestion and Recommendation for Design Changes, if required.

Pre

Processing

Solution

Post

Processing

Introduction to Finite Element Analysis

16

FEM Philosophy in layman terms

The Philosophy of FEA can be explained with a small example such as

Measuring the Perimeter of a Circle

If one need to evaluate the perimeter of a circle without using the conventional

formula (2*pi*r), FEA approach is analogous to Dividing the circle into a number of

segments and joining the points using Straight lines

Since it is very easy to measure the length of straight line. Measure the length of

one line and multiply it by No. of lines to get the perimeter.

Approximate results.isnt it ?

What if we want to achieve more

accurate result?

Introduction to Finite Element Analysis

17

Concept of Discretization (Meshing)

Physical System

FE Model

Introduction to Finite Element Analysis

18

Concept of Discretization (Meshing)

Concept of FEM is all about Discretization (Meshing) i.e. Dividing a

big structure/component into small discrete Blocks (Nodes and

Element concept)

But why do we do this Meshing ???

No. of Points =

DoF per point = 6

Total No of Equations to be solved

= * 6 =

No. of Points = 8

DoF per point = 6

Total No of Equations to be solved

= 8 * 6 = 48

From Infinite to FiniteHence the

Term Finite Element Method

Introduction to Finite Element Analysis

19

Concept of Discretization (Meshing)

Introduction to Finite Element Analysis

20

Concept of Discretization (Meshing)

Parameters deciding the Quality of Mesh :

Aspect ratio

Skew / Warpage

Element internal Angles

and more

Bad Quality FEA

Good Quality FEA

Better the Mesh Quality , Better the Accuracy

Introduction to Finite Element Analysis

21

Different Type of Elements

Linear - 1

st

Order

Element

Quadratic 2

nd

Order Element

Hexahedral

Element

Quadrilateral

Element

Triangular

Element

2D

3D

Introduction to Finite Element Analysis

22

Types of Contacts used in FEA

Introduction to Finite Element Analysis

Bonded Contact

This is the default configuration and applies to all contact regions( surfaces, solids, faces, edges). If contact

Regions are bonded, then no sliding or separation between faces or edges is allowed. This type of contact

Allows for a linear solution since the contact length/area will not change during the application of the load.

Eg: Welding, Glued connection, Bolted connection.

No Separation Contact

This contact setting is similar to the bonded case. It only applies to regions of faces(for 3D solids) or edges

(for 2D plates). Separation of the geometries in this contact is not allowed, but small amount of frictionless

Sliding can occur along contact geometries.

Frictionless Contact

This contact setting models standard unilateral contact, that is normal pressure equals to zero if separation

occurs. Thus gaps can form in the model between bodies depending on the loading. This solution is non linear

because the area of contact may change as the load is applied. A zero coefficient of friction is assumed,

thus allowing free sliding. The model should be well constrained when using this contact setting.

Frictional Contact

In this contact setting, the two contacting geometries can carry shear stresses upto a certain magnitude across their interface before

they start sliding relative to each other. This state is known as sticking. The model defines an equivalent shear stress at which sliding

on the geometry begins as a fraction of contact pressure. Once the shear stress exceeded, the two geometries will slide relative to

each other.

23

Types of Boundary Conditions, Loads & Results

Boundary Conditions :

Fixed Boundary Conditions (U , ROT etc.. = 0)

Prescribed Displacements (U , ROT , Temp etc.. 0)

Loads:

Point /Concentrated Load (Force)

Surface Load (Pressure , Flux etc..)

Body Load (Temp , Inertia g etc..)

Results:

Displacement

Reaction Forces

Stresses /Strains (Equivalent Von Mises , Directional & Principal )

Temperature etc..

Introduction to Finite Element Analysis

24

Finite Element Analysis At a Glance

Best Practice Approach

Introduction to Finite Element Analysis

25

Best Practices Approach

Plan your analysis

Analysis type (Static/Dynamic, Linear/Non-Linear etc..)

Material Details (isotropic/orthotropic , Constant/Temp dependent)

Choice of Elements and Meshing (2D/3D , Hex / Tet)

Results Evaluation (Detailed Post processing)

Verification (Sanity Checks , Test data match)

Introduction to Finite Element Analysis

26

Thanks !

You might also like

- Industrial Engineering 2009 by S K Mondal PDFDocument217 pagesIndustrial Engineering 2009 by S K Mondal PDFAshok DargarNo ratings yet

- Spur Gear Terminalogy Force AnalysisPresentation-OnDocument18 pagesSpur Gear Terminalogy Force AnalysisPresentation-OnManivannan JeevaNo ratings yet

- MechDocument1 pageMechManivannan JeevaNo ratings yet

- EeeDocument1 pageEeeManivannan JeevaNo ratings yet

- HTTP WWW - Google.co - in Url Q HTTP Nptel - Iitm.ac - in Courses IIT-MADRAS Machine Design II PDF 2 7Document15 pagesHTTP WWW - Google.co - in Url Q HTTP Nptel - Iitm.ac - in Courses IIT-MADRAS Machine Design II PDF 2 7fiemsabyasachiNo ratings yet

- EceDocument2 pagesEceManivannan JeevaNo ratings yet

- Mechanics of Materials I:: Fundamentals of Stress & Strain and Axial LoadingDocument5 pagesMechanics of Materials I:: Fundamentals of Stress & Strain and Axial LoadingManivannan JeevaNo ratings yet

- In-Plane Chirals Revised CleanDocument23 pagesIn-Plane Chirals Revised CleanManivannan JeevaNo ratings yet

- Paper8 ChiralCompB PDFDocument15 pagesPaper8 ChiralCompB PDFManivannan JeevaNo ratings yet

- Mechanics of Materials I:: Fundamentals of Stress & Strain and Axial LoadingDocument10 pagesMechanics of Materials I:: Fundamentals of Stress & Strain and Axial LoadingManivannan JeevaNo ratings yet

- DTS All Units With QhMergedDocument141 pagesDTS All Units With QhMergedManivannan JeevaNo ratings yet

- Nanotechnology: Past, Present, and FutureDocument1 pageNanotechnology: Past, Present, and FutureManivannan JeevaNo ratings yet

- Advanced Engineering Systems in Motion:: Dynamics of Three Dimensional (3D) MotionDocument5 pagesAdvanced Engineering Systems in Motion:: Dynamics of Three Dimensional (3D) MotiondbNo ratings yet

- Module 2 - 3D DynamicsDocument4 pagesModule 2 - 3D DynamicsRamón MartínezNo ratings yet

- Cam and Follower PDFDocument3 pagesCam and Follower PDFManivannan JeevaNo ratings yet

- GATE 2017 Question Paper Answer Key Gate AcademyDocument6 pagesGATE 2017 Question Paper Answer Key Gate AcademyHimanshu NarangNo ratings yet

- UCM Question Bank 2 MarksDocument22 pagesUCM Question Bank 2 MarksManivannan JeevaNo ratings yet

- Ce 8381 - Strength of Materials and Fluid Mechanics and Machinery Laboratory ManualDocument38 pagesCe 8381 - Strength of Materials and Fluid Mechanics and Machinery Laboratory ManualManivannan JeevaNo ratings yet

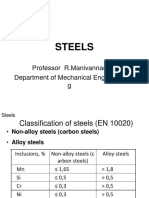

- Steels: Professor R.Manivannan Department of Mechanical Engineerin GDocument28 pagesSteels: Professor R.Manivannan Department of Mechanical Engineerin GManivannan JeevaNo ratings yet

- Hydro Static LubricationDocument24 pagesHydro Static LubricationPonangi Babu RaoNo ratings yet

- Intro RobotDocument9 pagesIntro RobotManivannan JeevaNo ratings yet

- 20 Important QuestionsDocument5 pages20 Important QuestionsManivannan JeevaNo ratings yet

- Experimental Investigation On Waste Heat Harvesting System Analysis by Thermo-Electric Generator Used Automobile Catalytic ConverterDocument3 pagesExperimental Investigation On Waste Heat Harvesting System Analysis by Thermo-Electric Generator Used Automobile Catalytic ConverterManivannan JeevaNo ratings yet

- Novel Nanostructures For SERS Biosensing: Ralph A. Tripp, Richard A. Dluhy, and Yiping ZhaoDocument7 pagesNovel Nanostructures For SERS Biosensing: Ralph A. Tripp, Richard A. Dluhy, and Yiping ZhaoManivannan JeevaNo ratings yet

- Novel Nanostructures For SERS Biosensing: Ralph A. Tripp, Richard A. Dluhy, and Yiping ZhaoDocument7 pagesNovel Nanostructures For SERS Biosensing: Ralph A. Tripp, Richard A. Dluhy, and Yiping ZhaoManivannan JeevaNo ratings yet

- Prof.R.Manivannan,: Assistant Professor/Mechanical EnggDocument2 pagesProf.R.Manivannan,: Assistant Professor/Mechanical EnggManivannan JeevaNo ratings yet

- Etd Tamu 2004C 2 AERO GuarnierDocument79 pagesEtd Tamu 2004C 2 AERO GuarnierManivannan JeevaNo ratings yet

- Name: ................................. Signature: ................................Document1 pageName: ................................. Signature: ................................Manivannan JeevaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sips 1328Document64 pagesSips 1328Jean Claude De AldánNo ratings yet

- Lesson Plan Letter SDocument4 pagesLesson Plan Letter Sapi-317303624100% (1)

- When SIBO & IBS-Constipation Are Just Unrecognized Thiamine DeficiencyDocument3 pagesWhen SIBO & IBS-Constipation Are Just Unrecognized Thiamine Deficiencyps piasNo ratings yet

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 pagesWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNo ratings yet

- Chapter 5 IppDocument24 pagesChapter 5 IppRoseann EnriquezNo ratings yet

- Hesychasm - A Christian Path of TranscendenceDocument10 pagesHesychasm - A Christian Path of Transcendencebde_gnas100% (1)

- Level I 2018 2019 Program Changes PDFDocument2 pagesLevel I 2018 2019 Program Changes PDFMuhammad BurairNo ratings yet

- Catalogue - Central Battery SystemDocument12 pagesCatalogue - Central Battery SystemarifzakirNo ratings yet

- Big Brother Naija and Its Impact On Nigeria University Students 2 PDFDocument30 pagesBig Brother Naija and Its Impact On Nigeria University Students 2 PDFIlufoye Tunde100% (1)

- Economics - Economics - Cheat - SheetDocument1 pageEconomics - Economics - Cheat - SheetranaurNo ratings yet

- 2017LR72 - SUMMARY REPORT Final 03052020Document72 pages2017LR72 - SUMMARY REPORT Final 03052020Dung PhamNo ratings yet

- The Ethics of Peacebuilding PDFDocument201 pagesThe Ethics of Peacebuilding PDFTomas Kvedaras100% (2)

- University of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSDocument3 pagesUniversity of Ghana: This Paper Contains Two Parts (PART I and PART II) Answer All Questions From Both PARTSPhilip Pearce-PearsonNo ratings yet

- Present Perfect and Present Perfect ProgressiveDocument5 pagesPresent Perfect and Present Perfect ProgressiveKiara Fajardo matusNo ratings yet

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- Batron: 29 5 MM Character Height LCD Modules 29Document1 pageBatron: 29 5 MM Character Height LCD Modules 29Diego OliveiraNo ratings yet

- Project Analysis - M5 - MotorwayDocument6 pagesProject Analysis - M5 - MotorwayMuhammad Haroon ArshadNo ratings yet

- UserProvisioningLabKit 200330 093526Document10 pagesUserProvisioningLabKit 200330 093526Vivian BiryomumaishoNo ratings yet

- Machine Design 2021 Guidelines and MechanicsDocument2 pagesMachine Design 2021 Guidelines and Mechanicsreneil llegueNo ratings yet

- Rare Watches (Christie's) 16. 05. 2016.Document236 pagesRare Watches (Christie's) 16. 05. 2016.Simon LászlóNo ratings yet

- Dummy 13 Printable Jointed Figure Beta FilesDocument9 pagesDummy 13 Printable Jointed Figure Beta FilesArturo GuzmanNo ratings yet

- Support Vector Machine Master ThesisDocument7 pagesSupport Vector Machine Master Thesistammymajorsclarksville100% (2)

- ProjectDocument32 pagesProjectroshan jaiswalNo ratings yet

- HPSC HCS Exam 2021: Important DatesDocument6 pagesHPSC HCS Exam 2021: Important DatesTejaswi SaxenaNo ratings yet

- Rosewood Case AnalysisDocument5 pagesRosewood Case AnalysisJayant KushwahaNo ratings yet

- STW 44 3 2 Model Course Leadership and Teamwork SecretariatDocument49 pagesSTW 44 3 2 Model Course Leadership and Teamwork Secretariatwaranchai83% (6)

- Adolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaDocument20 pagesAdolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaEfosaNo ratings yet

- Prometric Questions-1 AnswersDocument45 pagesPrometric Questions-1 AnswersNina Grace Joy Marayag-Alvarez100% (1)

- The Perception of Luxury Cars MA Thesis 25 03Document60 pagesThe Perception of Luxury Cars MA Thesis 25 03Quaxi1954No ratings yet

- Furniture AnnexDocument6 pagesFurniture AnnexAlaa HusseinNo ratings yet