Professional Documents

Culture Documents

Stud Rails

Uploaded by

Bruno Pilieci0 ratings0% found this document useful (0 votes)

318 views3 pagesStud rails can be used to reinforce concrete slabs against punching shear at column locations. They comprise steel studs welded to carrier rails at specific spacings. The rails ensure proper alignment and positioning of the studs within the slab. When installed, stud rails provide significantly faster reinforcement than constructing shear links on site and can accelerate concrete pouring schedules. The stud rails are designed using software from manufacturers to calculate required dimensions and layouts.

Original Description:

Concrete reinforcing in thin slabs

Original Title

Stud Rails -

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStud rails can be used to reinforce concrete slabs against punching shear at column locations. They comprise steel studs welded to carrier rails at specific spacings. The rails ensure proper alignment and positioning of the studs within the slab. When installed, stud rails provide significantly faster reinforcement than constructing shear links on site and can accelerate concrete pouring schedules. The stud rails are designed using software from manufacturers to calculate required dimensions and layouts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

318 views3 pagesStud Rails

Uploaded by

Bruno PilieciStud rails can be used to reinforce concrete slabs against punching shear at column locations. They comprise steel studs welded to carrier rails at specific spacings. The rails ensure proper alignment and positioning of the studs within the slab. When installed, stud rails provide significantly faster reinforcement than constructing shear links on site and can accelerate concrete pouring schedules. The stud rails are designed using software from manufacturers to calculate required dimensions and layouts.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

S

tud rails can be located around a column head or base

to reinforce a flat slab against punching shear. The

shear load from the slab is transferred through the studs

and into the column.

A stud rail system comprises a number of stud and rail

units, which have been factory produced to suit the spe-

cific requirements of a particular column. Each unit com-

prises double-headed studs, hot forged to three times the

diameter of the bar, welded to a flat steel carrier rail. The

rails are located around the column in the required layout.

The quantity and dimensions of both studs and rails,

the spacing and the layout are all determined by calcula-

tion. To simplify system design, stud rail manufacturers

provide free calculation software and other technical sup-

port such as faxback design sheets.

The rails perform no structural function. They simply

ensure stud alignment, spacing and vertical positioning

within the slab. Studs are manufactured in a variety of

diameters and in virtually any length to suit the load and

depth of the slab. Rails with a gap along the length allow

for the passage of concrete during pouring.

Stud rail design

A stud rail reinforcement system is designed by calculat-

ing the stress at concentric perimeters around a column,

in accordance with BS 8110

(1)

. First, the shear stress is

checked at a perimeter 1.5d (d = effective slab thick-

ness) from the face of the column (u

o

). Further checks are

carried out at successive intervals of 0.75d (u

1

, u

2

, etc)

until a perimeter is reached that does not require shear

reinforcement (u

n

).

The first stud is positioned 0.5d from the face of the

column, with the spacing between individual studs taken

as 0.75d. Rail layouts can be radial or orthogonal.

Stud rail manufacturers provide free calculation soft-

ware, which simplifies this design process.

A stud rail system can be designed for all column

shapes (rectangular, circular, L-shaped, etc) and loca-

tions (edge, corner, interior, etc). They can be installed

either top down or bottom up selection is based on

user preference. When installed top down, the studs are

installed after all other reinforcement. The rail rests on

the top layer of reinforcement and is securely tied in posi-

tion. Bottom-up installation takes place before all other

reinforcement. The rails are tied to spacers before being

located around the column and nailed to the formwork.

Comparison with shear links

Loose shear links, formed on-site from short lengths of

reinforcement bar, can be used to reinforce a slab against

CONCRETE MAY 2009 25

CONCRETE REINFORCEMENT

Stud rails: prefabricated punching

shear reinforcement

PAUL EVANS, ANCON BUILDING PRODUCTS

The loads on a concrete slab supported on a concrete column induce shear stresses

in the slab. Where additional reinforcement is not provided, this stress could result

in the column punching through the slab. Although this punching shear stress

can be relieved by localised thickening of the concrete, such as downstand beams

or enlarged column heads, the construction of a flat slab is often preferred. A

consistent head space, a reduction in overall building height and significant savings

in both time and materials are the main advantages of flat slab construction.

Figure 1 left: Ancon

Shearfix stud, welded to

a flat rail, tied to main

reinforcement.

Figure 2 below: Rails

simplify the accurate

positioning of studs in

the slab.

(

P

h

o

t

o

s

:

A

n

c

o

n

B

u

i

l

d

i

n

g

P

r

o

d

u

c

t

s

.

)

CONCRETE May 09 17-32.indd 25 21/04/2009 15:25:21

punching shear. They are hooked around the top and bot-

tom reinforcement, where calculated by the project engi-

neer. When compared to loose shear links, the use of stud

rails can accelerate both the design and the construction

process.

With reinforcement being on the critical path to com-

pleting the structural frame, time savings are the major

benefit of using stud rails. Research shows that the savings

made from the significantly reduced fixing time far out-

weigh any additional material costs. A British Cement

Association best practice guide

(2)

claims prefabricated

solutions can be up to ten times quicker to install than loose

shear links. Stud rails are supplied to site welded to rails at

the appropriate spacing, so a number of studs are installed

simultaneously unlike shear links, which are formed on-

site and installed individually.

The software provided by stud rail manufacturers not

only calculates the stud dimensions and spacing, it also

generates a DXF file of the rail layout for each column,

which is then easily inserted in to floor plans.

Although stud rails are manufactured to order, they

are available on a short lead-time. Even sizeable stud

rail systems are normally despatched one working week

from receipt of order. To enhance installation times fur-

ther, pallets can be packed in priority order, eg, by pour

number, and each rail is labelled with the particular col-

umn reference and product code. Codes normally com-

prise: stud diameter, number of studs on rail, stud length

and rail length, and correspond directly with the layout

drawing.

Kings Dock Mill, Liverpool

A significantly reduced fixing time when compared to

shear links is the main reason Ancon Shearfix stud rails

are currently being installed by Adana Construction on

the Kings Dock Mill Development in Liverpools Baltic

Triangle.

The site manager for Adana says, Our priority is the

project schedule. The Shearfix rails took just two people

one day to place and secure on this whole floor. If we had

used loose shear links they would have taken a team of

people a week to install. Site conditions are good today

and we need to capitalise on periods of good weather. The

concrete pour is going ahead on schedule.

In some locations on this multi-storey, mixed-use

development, the floor slabs are 700mm thick. Shear links

of this length may have been particularly problematic to

install and would have significantly increased congestion

in an already heavily reinforced slab.

MAY 2009 CONCRETE

CONCRETE REINFORCEMENT

26

Figure 3 top: Stud rails

arranged around a

column head.

Figure 4 above: Kings

Dock Mill, Liverpool.

Figure 5 right: Example

radial rail layout.

Figure 6 far right:

Example orthogonal rail

layout.

CONCRETE May 09 17-32.indd 26 21/04/2009 15:25:27

Concluding remarks

Stud rails are an effective means of reinforcing flat con-

crete slabs against punching shear at column locations.

They offer considerably reduced fixing times when com-

pared to loose shear links and are designed using free

calculation software available from stud rail manufactur-

ers. Double-headed steel studs are supplied welded to flat

steel rails, at the designed centres. The rails ensure stud

alignment and the accurate vertical positioning of the

studs within the slab.

CONCRETE MAY 2009 27

CONCRETE REINFORCEMENT

References:

1. BRITISH STANDARDS INSTITUTION, BS 8110. Structural use of concrete. Part 1 Code of practice for design and construction.

BSI, 1997.

2. BRITISH CEMENT ASSOCIATION. Prefabricated punching shear reinforcement for reinforced concrete flat slabs. BCA,

Camberley, 2001.

Spacers that pass the

flavour test

Keeping our water uncontaminated is

a prime consideration when deciding

on the use of any product during

construction of potable water retaining

structures. Even the smallest source of

contamination can have a potentially

devastating effect upon public health.

W

hen it comes to ensuring the quality of our drinking

water supply, it is increasingly important to ensure

that all possible safeguards are in place. Outbreaks of cryp-

tosporidium and similar have heightened public awareness

of the need for vigilance. It is therefore partly beholden on

the construction industry to ensure that the public is pro-

tected at all times and in every way possible.

Standards

Standards for components that can potentially come in

contact with potable water have been developed but these

have not been applied to most traditional products in use

for many years or for those offering a small surface area to

the water. These have been automatically permitted with-

out testing. This is changing and for public safety it should

be an imperative that all permanent products in the works,

no matter how small, nor for how long they have previ-

ously been in use, should prove their suitability for potable

water applications.

Materials used in contact with drinking water, whether

within structures or in the water supply system, require

testing and approval to show that they will not adversely

affect water quality. For a product that only has a small

contact surface, the only testing required for non-metallic

materials used in contact with drinking water is Water

Regulations Advisory Scheme (WRAS)/BS 6920

(1)

. The

more rigorous approval to DWI CPP Regulation 31, for

Products and Processes for use in Public Water Supply

(2)

,

DAVID WILSON, MAX FRANK

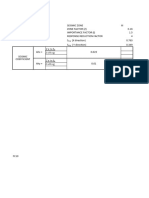

Figure 7: Stud spacing.

Figure 1 above:

Extruded fibre concrete

spacers have a tested

and proven watertight

bond to concrete.

Figure 2 left: Extruded

fibre concrete distance

tubes ensure that there

are no preferential

water flow paths along

the tubeconcrete

interface.

(

P

h

o

t

o

s

:

M

a

x

F

r

a

n

k

L

t

d

.

)

CONCRETE May 09 17-32.indd 27 21/04/2009 15:25:34

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesFrom EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesRating: 3.5 out of 5 stars3.5/5 (13)

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsFrom EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsNo ratings yet

- Flat Slab Design - Engineering DissertationsDocument34 pagesFlat Slab Design - Engineering DissertationsBobby LupangoNo ratings yet

- 30 - Analysis of Moment Resisting Frame and Lateral LoadDocument8 pages30 - Analysis of Moment Resisting Frame and Lateral LoadMUTHUKKUMARAMNo ratings yet

- RCE Shear DesignDocument25 pagesRCE Shear DesignWindi AstutiNo ratings yet

- Theory of Beams: The Application of the Laplace Transformation Method to Engineering ProblemsFrom EverandTheory of Beams: The Application of the Laplace Transformation Method to Engineering ProblemsRating: 3.5 out of 5 stars3.5/5 (2)

- Column With Biaxial MomentDocument26 pagesColumn With Biaxial MomentRajanvmNo ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- CADS RC Slab DesignerDocument2 pagesCADS RC Slab DesignerOscarKonzultNo ratings yet

- Hollow Core Tech DataDocument1 pageHollow Core Tech Datacr231181100% (1)

- Structural Analysis Exam PapersDocument3 pagesStructural Analysis Exam Papersfesada1100% (1)

- Design Principles For Composite BeamsDocument11 pagesDesign Principles For Composite BeamsNaftary GathimbaNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteFrom EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteNo ratings yet

- EN1993 BenchmarksDocument212 pagesEN1993 BenchmarksDomostatikosNo ratings yet

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- A Multistory Building Higher Than 21m or 21 To 29 Floor Buildings With Unknown Height Described As HighDocument10 pagesA Multistory Building Higher Than 21m or 21 To 29 Floor Buildings With Unknown Height Described As HighTri Haryadi LinggialloNo ratings yet

- Lecture 3Document42 pagesLecture 3Harold Jackson MtyanaNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Analysis and Design of Flat Slabs Using Various CodesDocument5 pagesAnalysis and Design of Flat Slabs Using Various CodesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Development LengthDocument22 pagesDevelopment LengthAlok Mam100% (1)

- Braced Frameworks: An Introduction to the Theory of StructuresFrom EverandBraced Frameworks: An Introduction to the Theory of StructuresNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Australian Guidebook For Structural Engineers by Lonnie Pack 1138031852Document5 pagesAustralian Guidebook For Structural Engineers by Lonnie Pack 1138031852Frans ChandraNo ratings yet

- RC 8Document14 pagesRC 8ianiroy13No ratings yet

- California Infrastructure Projects: Legal Aspects of Building in the Golden StateFrom EverandCalifornia Infrastructure Projects: Legal Aspects of Building in the Golden StateNo ratings yet

- 04a Chapter 4 Design of RC Beams Part 1Document38 pages04a Chapter 4 Design of RC Beams Part 1Zul AshraffNo ratings yet

- Analysis and Design of Network of Interacting Primary and Secondary Beams in Large Span ConstructionDocument9 pagesAnalysis and Design of Network of Interacting Primary and Secondary Beams in Large Span ConstructionselinaNo ratings yet

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- Structural Theorems and Their Applications: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Theorems and Their Applications: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4 out of 5 stars4/5 (4)

- VaultDocument1 pageVaultpassagerx007No ratings yet

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- The Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Basement Floor SlabDocument4 pagesBasement Floor SlabthirumalaichettiarNo ratings yet

- Scaffold Basic PartsDocument57 pagesScaffold Basic PartsSn Carbonel100% (1)

- 10 Multi-Storey Frames (Revised)Document100 pages10 Multi-Storey Frames (Revised)susan87No ratings yet

- ideCAD Structural 5Document9 pagesideCAD Structural 5Gandhi HammoudNo ratings yet

- 760mm/30 3-IN-1 MACHINE: User ManualDocument12 pages760mm/30 3-IN-1 MACHINE: User ManualBruno PilieciNo ratings yet

- Reciprocating Air Saw: User ManualDocument18 pagesReciprocating Air Saw: User ManualBruno PilieciNo ratings yet

- Strecher - Shrinker 8836249Document2 pagesStrecher - Shrinker 8836249Bruno PilieciNo ratings yet

- Thermal Imager: User ManualDocument14 pagesThermal Imager: User ManualBruno PilieciNo ratings yet

- Air Drill 8843914 PDFDocument14 pagesAir Drill 8843914 PDFBruno PilieciNo ratings yet

- Metal Shear 8096000 PDFDocument7 pagesMetal Shear 8096000 PDFBruno PilieciNo ratings yet

- Project Scheduling and Monitoring ToolDocument13 pagesProject Scheduling and Monitoring ToolBruno PilieciNo ratings yet

- Excel Gantt Chart TemplateDocument15 pagesExcel Gantt Chart TemplateBruno PilieciNo ratings yet

- 2011 Mad PogDocument81 pages2011 Mad PogBruno Pilieci100% (1)

- Csi Masterformat 1995 Edition PDFDocument2 pagesCsi Masterformat 1995 Edition PDFrobelineNo ratings yet

- Princess Auto Full Catalogue 277Document300 pagesPrincess Auto Full Catalogue 277Bruno PilieciNo ratings yet

- 1500 SeriesDocument12 pages1500 SeriesBruno PilieciNo ratings yet

- PCM 875 - F 15 335 eDocument48 pagesPCM 875 - F 15 335 eBruno PilieciNo ratings yet

- 2500 Watt Inverter GeneratorDocument48 pages2500 Watt Inverter GeneratorBruno PilieciNo ratings yet

- Craftsman 917257720Document60 pagesCraftsman 917257720Bruno PilieciNo ratings yet

- Series 1845 SpecsDocument4 pagesSeries 1845 SpecsBruno Pilieci100% (2)

- VW Mkiv Hatch Pop KitDocument8 pagesVW Mkiv Hatch Pop KitBruno PilieciNo ratings yet

- User'S Guide: One-Way AM RemoteDocument8 pagesUser'S Guide: One-Way AM RemoteBruno PilieciNo ratings yet

- Bobcat 873 Repair ManualDocument506 pagesBobcat 873 Repair Manualfernandojimenezde85% (27)

- 6500 GeneratorDocument25 pages6500 GeneratorBruno PilieciNo ratings yet

- Case - 1845C Spec SheetDocument2 pagesCase - 1845C Spec SheetBruno Pilieci50% (2)

- Bobcat S130 SkidsteerDocument6 pagesBobcat S130 SkidsteerBruno PilieciNo ratings yet

- Chapter 3Document7 pagesChapter 3Haftom GebreegziabiherNo ratings yet

- Fiber Reinforced Concrete Lif Takviyeli BetonDocument70 pagesFiber Reinforced Concrete Lif Takviyeli BetonaygunbayramNo ratings yet

- UHAW92433030 Whipple Drawings-DS TMKDocument3 pagesUHAW92433030 Whipple Drawings-DS TMKtuong buiNo ratings yet

- BondPropertiesOfCarbonFiber Nolan May98Document10 pagesBondPropertiesOfCarbonFiber Nolan May98Matias GaitanNo ratings yet

- Curtain WallDocument29 pagesCurtain WallCindy AzaliaNo ratings yet

- Chemrite - CNIDocument2 pagesChemrite - CNIghazanfarNo ratings yet

- Alform System Formwork Procedures October 2016Document40 pagesAlform System Formwork Procedures October 2016Syerifaizal Hj. MustaphaNo ratings yet

- 3 Manufacture of ConcreteDocument14 pages3 Manufacture of ConcreteRueleo MaoNo ratings yet

- Cement Factory Design CriteriaDocument13 pagesCement Factory Design CriteriaUzair Maqbool Khan100% (2)

- Design of Column Using Channel (Front)Document8 pagesDesign of Column Using Channel (Front)Nitesh SinghNo ratings yet

- Civil Engineering Drawing PDFDocument54 pagesCivil Engineering Drawing PDFgeos100189% (9)

- Calculation For 6m X 5.5m RCC Box CulvertDocument14 pagesCalculation For 6m X 5.5m RCC Box CulvertDev Lamichhane100% (1)

- High Slump Concrete Mix Design 2Document68 pagesHigh Slump Concrete Mix Design 21man1bookNo ratings yet

- Guide To Thatch Construction in South Africa1Document97 pagesGuide To Thatch Construction in South Africa1sebby_s20100% (1)

- Simply Supported UDL Beam Formulas - Bending Moment EquationsDocument8 pagesSimply Supported UDL Beam Formulas - Bending Moment EquationsSara AdNo ratings yet

- Steel Box Girder Bridges Design Guides and Methods PDFDocument22 pagesSteel Box Girder Bridges Design Guides and Methods PDFbahrullmusaffaNo ratings yet

- Name: - Rida M. Talon - Date: - Nov.13,2020 - Program/Year/Section: - BSCE-3B - Instructor: Engr. Ryan A. LimcoDocument3 pagesName: - Rida M. Talon - Date: - Nov.13,2020 - Program/Year/Section: - BSCE-3B - Instructor: Engr. Ryan A. LimcoRico BelledoNo ratings yet

- Prestressed BeamDocument15 pagesPrestressed BeamMohamed Abbassy100% (1)

- CH 10 - Reinforced - Concrete - Fundamentals and Design ExamplesDocument143 pagesCH 10 - Reinforced - Concrete - Fundamentals and Design ExamplesVeronica Sebastian EspinozaNo ratings yet

- Rectangle BeamDocument5 pagesRectangle BeamAlok SarkarNo ratings yet

- Cement: Nilanjan MitraDocument25 pagesCement: Nilanjan MitrassriramiitNo ratings yet

- Module 1Document135 pagesModule 1Alesther MarianoNo ratings yet

- QAUDocument90 pagesQAUakclams77No ratings yet

- NZS 3101-2006 Example 001Document8 pagesNZS 3101-2006 Example 001RMM100% (1)

- Veneer Stone Vs Natural Stone Which To Buy and InstallDocument4 pagesVeneer Stone Vs Natural Stone Which To Buy and InstallRi SovannaphumiNo ratings yet

- Eurocode 6 - IntroductionDocument24 pagesEurocode 6 - IntroductionAyis ANo ratings yet

- BbsDocument72 pagesBbsAkd DeshmukhNo ratings yet

- Structure Magazine 02 Feb 2019 PDFDocument52 pagesStructure Magazine 02 Feb 2019 PDFmoizoro100% (1)

- Shear Key CalculationDocument4 pagesShear Key CalculationdakshataNo ratings yet

- Analysis of Shear Reinforcement For BeamDocument28 pagesAnalysis of Shear Reinforcement For BeamFRIEMLY A. BAYRONNo ratings yet