Professional Documents

Culture Documents

8112-OPC 43 Grade

Uploaded by

Ashish KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8112-OPC 43 Grade

Uploaded by

Ashish KumarCopyright:

Available Formats

. .

-r

I S 8112: 1989

I ndian Standard

43 GRADE ORDI NARY PORTLAND

CEMENT - SPECI FI CATI ON

( Firs-t Revision )

UDC 666.942.2

0 BI S 1990

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARC3

NEW DELHI 110002

May 1990

Price Group 4

( Reaffirmed 2005 )

Cement and Concrete Sectional Committee, CED 2

FOREWORD

This Indian Standard ( First Revision ) was adopted by the Bureau of Indian Standards on30 October

1989, after the draft finalized by the Cement and Concrete Sectional Committee had been approved

by the Civil Engineering Division Council.

This standard was first published in 1976 under the title Specification for high strength ordinary

Portland cement. Since publication of this standard, large number of amendments have been issued

from time to time in order to modify various requirements based on experience gained with the use

of the standard and the requirements of the users and also keeping in view the raw materials and fuel

available in the country for manufacture of cement. The important amendments include increasing the

value of total loss on ignition from 4 to 5 percent, modifying the requirement of total sulphur content

calculated as sulphuric anhydride ( SOa ) reducing the fineness by specific surface of cement from 350

ma/kg to 225 ma/kg, making autoclave soundness test compulsory irrespective of magnesia content,

incorporating a provision for retest in respect of autoclave soundness test after aeration of the

cement, incorporating a clause on false set of cement, permitting packaging of cement in 25 kg bags

and making compulsory provision for issuing a certificate indicating the total chloride content in*

cement. Further, in view of the decision to designate ordinary Portland cement by its 28-day compressive

strength, the title of this standard was modified as 43 grade ordinary Portland cement -Specification.

In view of these large number of amendments, the Sectional Committee decided to bring out tic tust

revision of the standard incorporating all these amendments, so as to make it more convenient or the

users.

This specification intends to cover the requirements of ordinary Portland cement used for the manu-

facture of prestressed concrete sleepers also. Some requirements of 43 grade ordinary Portland cement

for uses, such as, manufacture of railway sleepers and precast products may be agreed to between the

purchaser and the supplier.

Mass of cement packed in bags and the tolerance requirements shall be in accordance with thorelevant

provisions of the Standards of Weights and Measures ( Packaged Commodities ) Rufes, 1977 ani! B-1.2

( see Annex B for information ). Any modification in these rules in respect of tolerance 01~ mass of

cement would apply automatically to this standard.

X.

This standard contains 11.4.1 which permits the purchaser to use his option for testing and 6.1, 6.5,

9.2.1 and 9.3 which call for agreement between the purchaser and the manufacturer.

In the formulation of this standard considerable assistance has been rendered by National Council for

Cement and Building Materials, New Delhi as many of these modifications are based on studies c;+rriej

out by them.

The composition of the committee responsible for the formulation of this stai>d:ird is given ;!!

Annex C.

For the purpose of deciding whether a parriculat requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test or analysis, shall be rountfcd off in

accordance with IS 2 : 1960 Rules for rounding off nurnerlcal vaiues ( revised ). The rl.unaber of

significant places retained in the rounded otT value shou!d he the same as that of the specified value in

this standard.

L

.

4

.

, .

.

I..

.I.

*

+_-- __ - ._^ _~ .- * ___&;a ._1___~.

,~ __. .-

t

IS 8Il2 : 1989

I ndian Standard

43 GRADE ORDINARY PORTLAND

CEMENT- SPECIFICATION

( First Revision )

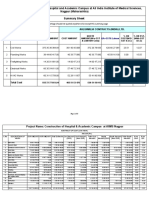

1 SCOPE Table 1 Chemical Requirements for High

I.1 This standard covers the manufacture, chemi-

Strength Portland Cement

cal and physical requirements of 43 grade ordinary

( &use 5.1 )

Portland cement. S1 No. Characteristic Reaolrement

2 REFERENCES

(1) (2) - (3)

i) Ratio of percentage of

lime to percentages of

Not greater than 1.02

and not less than 0.66

2.1 The Indian Standards listed in Annex A are

necessary adjuncts to this standard.

silica, alumina and irdn

oxide, when calculated

by the formula:

3 TERMINOLOGY

3.1 For the purpose of this standard, the defini-

tions given in IS 4845 : 1968 shall apply.

CaO - 0.7 sot

28 Si~6;F2.$~0, +

I *

ii) Ratio of percentage of Not less than 066

alumina to that of iron

oxide

4 MANUFACTURE

iii) Insoluble residue, per- Not more than 2

cent by mass

4.1 43 grade ordinary Portland cement shall be

manufactured by intimately mixing together

calcareous and agrillaceous and/or other silica,

alumina or iron oxide bearing materials, burning

them at a clinkering temperature and grinding

the resultant clinker so as to produce a cement

capable of complying with this specification. No

material shall be added after burning other than

gypsum ( natural or chemical ) or water or both,

and not more than done percent of air-entraining

agents or other agents, which have proved not to

be harmful.

iv) Magnesia, percent by mass Not more than 6

v) Total sulphur content Not more than 25

calculated as sulphuric and 30 when trical-

anhydride ( SOa ). per-

cent by mass

cium aluminate ( see

Note 1 ). ~percent -by

mass is 5 or less and

greater than 5 respac-

tively

vi) Total loss on ignition Not more than 5 per-

cent

NOTES

5 CHEMICAL REQUIREMENTS

5.1 When! tested in accordance with the methods

given in IS 4032 : 1985. 43 grade ordinary Port-

land cement shall comply with the chemical

requirements given in Table 1.

6 PHYSICAL REQUIREMENTS

6.1 Fineness

When tested for fineness by Blaines air permea-

bility method as described in IS 4031 ( Part 2 ) :

1988, the specific surface of cement Fhall not be

less than 225 m/kg.

ment between the purchaser and the manutacturer.

NOTE - A higher fineness of cement, when speci-

fically required

.

may be agreed to by mutual agree-

. _ ^

1 The tricalcium aluminate content ( CIA ) is cal-

culated by thz formula:

GA - 265 ( AllOr ) - 169 ( FelOI ),

where each symbolin brackets refers to the percent

( by mass of total cement ) of the oxide, excluding

any contained in insoluble residue referred to at

Sl No. ( iii ).

2 Alkali aggregrate reactions have been noticed in

aggregates in some parts of the country. On large

and important jobs where the concrete is likely to

be exposed to humid atmosphere or wetting action

it is advisable that the aggregate be tested for alkali

aggregate reaction. In the case of reactive aggre-

gates, the use of, cement with alkali content below

0.6 percent expressed as sodium oxide< Na,O ) is

recommended.

3 Total chloride content in cement shall not exceed

0.05 percent by mass for cement used in prestressed

concrete structures and long span reinforced con-

crete structures.Method of test for determination of

chloride content in cement is given in IS 12423 : 1988.

4 The limit of total chloride content in cement for

use in plain and other reinforced concrete structures

is being reviewed. Till that time, the limit may be

mutually agreed to between the purchaser and the

manufacturer.

I

L

-... jl_m,.- _ .a.. ___ , ._*.-e.e

6.2 Soundness

6.2.1 When tested by the Le-Chatelier method

and autoclave test described in IS 4031 ( Part 3 ) :

1988, unaerated cement shall. nor have an

-expansion of more than 10 mm and 08 percent

respectively.

6.2.1.1 In the event of cements failing to comply

with any one or both the requirements specified

in 6.2.1, further tests in respect of each failure

shall be made as described in IS 4031 ( Part 3 ) :

1988 from another portion of the same sample

after aeration. The aeratian shall be done by

spreading out the sample.to a depth of 75 mm at

a relative humidity of 50 to 80. percent for a.total

period of 7 days. The expansion of cements so

aerated shall be not more than: 5 mm and 06

percent when tested by Le-Chatelier method, and

autoclave test respectively.

6.3 Setting Time

The setting time of cement, when tested by the

Vicat apparatus method described in- IS 4031

( Pact. 5), : 1988 shall confor.m to the following

requirements:

a) Initial. setting time in minutes - not less

than 30

b) Final setting time in minutes - ;;;rm;;

63.1. If cement exhibits false set, the ratio of

final penetration measured after 5 minutes ~of

completion ofmixing period to the initial penetra-

tion measured exactly after 20 seconds of com-

pletion of mixing, period, expressed as percent,

shall be not less than 50. In the event of cement

exhibiting. false set, the initial and final setting

time of cement when tested by the method

described in IS 4031 ( Part 5~ )c: 1988 after break-

ing the false set,. shall conform to 6.3.

6.4 Compressive Strength

The, average compressive strength. of at least three

mortar cubes ( area of face 50 cm? ) composed of

one part of cement, three parts of standard sand

( conforming to IS 650 : 1966 ) by mass and P/4

+ 30 percent ( of combined mass of cement

plus. sand ). water, and prepared, stored and tested

in the manner described in IS 4031 ( Part 6 ) :

1988, shall be as follows:

a) 72 fl hour not less than 23 MPa

b) 168 f2 hours not less than 33 MPa

c) 672 f4 hours not less than, 43 MPae

NOTE - P isthe percentage of water required to

produce a paste of standard consistency ( see 11.3 ).

6.5 By agreement between the purchaser and the

manufacturer, transverse strength test of plastic

mortar in accordance with the method described

in IS 403 1 ( Part 8 ) : 1988 may be specified in

addition to the test specified in 6.4. The permis-

sible values of the transverse strength shall be

mutually agreed to between the purchaser andlthe

supplier at the time of placing order.

6.6 Notwithstanding the strength requirements

specified in 6.4 and 6.5, cement shall show a

progressive increase in strength from the strength

at 72 hours.

7.1 The cement shall be stored in suuh a manner

as to permit easy access for proper inspection and

in a suitable weather-tight building to protect the

cement from dampness and to minimize warehouse

deterioration.

8 MANUFACTURERS CERTIFICATE

8.1 The manufacturer shall satisfy himself that

the cement conforms to the requirements of this

standard, and,if requested, shah furnish a certi-

ficate to this effect to the purchaser or his

representative, within ten days of dcspatch of the

cement.

8.2 The manufacturer shall furnish a certificate,

within ten days of despatch of cement, indioating

the total chloride content in -percent by mass of

cement.

Y DELIVERY

YJ The cement shall be packed in bags [jute

sacking bag conforming to IS 2580 : 1982, double

hcssian bituminized, ( CR1 type ), multiwall paper

conforming to IS 11761 : 1986, polyethylene lined

( CR1 type ) jute, light weight jute conforming to

IS 12154 : 1987, woven HDPE conforming to

IS 11652 : 1986, woven polypropylene conforming

to lS 11653 : 1986, jute synthetic union conform-

ing to IS 12174.: 1987 or any other approved

composite bags ] bearing the manufacturers name

or his registered trade-mark, if any, and the words

43 Grade Ordinary Portland Cement. The

number of bags ( net mass ) to the tonne or the

average net mass of the cement shall be legibly

and indelibly marked on each bag. Bags shall be

in good condition at the time of inspection.

9.1.1 Similar information shall be provided in the

delivery advices accompanying the shipment of

packed or bulk cement ( see 9.3 ).

9.2 The average net mass of cement per bag shall

be 50 kg (see Annex B.).

2

IS 8112 : 1989

9.2:1 The average net mass of cement per bag tested in the manner described in the relevant

may also be 25 kg subject to tolerances as given clauses.

in 9.2.1.1 and packed in suitable bags as agreed

to between the purchaser and the manufacturer.

11.2 Temperature for Testing

9.2.1.1 The number of bags in a sample taken for

weighment showing a minus error greater than 2

percent of the specified net mass shall be not

more than 5 percent of the bags in the sample.

Also the minus error in none of such bags in the

sample shall exceed 4 percent of the specified net

mass of cement in the bag. However, the average

net mass of cement in a sample shall be equal to

or more than 25 kg.

9.3 Supplies of cement in bulk may be made by

arrangement between the purchaser and the

supplier ( manufacturer or stockist ).

The temperature range within wh-ich physical tests

may be carried out shall, as far as possible. be

27 $2C. The actual temperature during. the

testing shall be recorded.

11.3, Consistency of Standard Cement Paste

The quantity of water required to produce a ,paste.

of standard consistency, to be used for the deter-

mination of the water content of mortar for the

compressive strength tests and for the determina-

tion of soundness and setting time, shall be

obtained by the method described in IS 4031

( Part 4 ) : 1988.

NOTE - A single bag or container containing 1 000

kg or more net mass of cCment shall be considered

as bulk supply of cement. Supplies of cement may

11.4 Independent Testing

also be made in intermediate containers,

for 11.4.1 If the purchaser or his representative

example, drums of 200 kg, by agreement between the

purchaser and the manufacturer.

requires independent tests, the samples shall be

taken before or immediately after delivery at t&

10 SAMPLING

option of the purchaser or his, representa&e, and

_the tests shall be carried out in accordance with

10.1 Samples for Testing and by Whom to be

this standard on the written instruction of the

Taken

purchaser or his representative.

A sample or samples for testing may be taken by

the purchaser or his representative, or by any

person appointed to superintend the work for

purpose of which the cement is required or by

latters representative.

-10.1.1 The samples shall be taken within three

weeks of the delivery and all the tests shall be

commenced within one week of sampling.

10.1.2 When it is not possible to test the samples

within one week, the samples shall be packed and

stored in air-tight containers till such time that

they are tested.

11.4.2 Cost of Testing

The manufacturer shall supply, free of charge, the

cement required for testing. Unless otherwise

specified in~the enquiry and order, the cost of the

tests shall be borne as follows:

a) by the manufacturer if the results show that

the cement does not comply with this stan-

dard, and

b) by the purchaser if the results show that the

cement complies with this standard.

10.2 In addition to the requirements of 10.1, the

11.4.3 After a representative sample has been

methods and -procedure of sampling shall be in

d

rawn, tests on the sample shall be carried out as

accordance with IS 3535 : 1986.

expeditiously as possible.

10.3 Facilities for Sampling and Identification

The manufacturer or supplier shall afford every

facility, and shall provide all labour and materials

for taking and packing the samples for testing the

cement and for subsequent identification of the

cement sampled.

11 TESTS

11.1 The sample or samples of cement for test

shall be taken as described in 10 and shall be

12 REJ ECTION

12.1 Cement may be rejected if it does not comply

with any of the requirements of this specification.

12.2 Cement remaining in bulk storage at the

mill, prior to shipment. for more than six months,

or cement in bags in local storage in the hands of

a vendor for more than 3 months after completion

df tests, may be retested before use and may be

rejected, if it fails to conform to any of the

requirements of this specification.

3

-Is 8112:1989

IS jvo.

650 : 1966

2580: 1982

3535: 1986

ANNEX A

( Clause 2.1 )

LIST OF REFERRED INDIAN STANDARDS

Title I S No.

Specification for standard sand 11652 -: 1986

for testing of cement (first

revision )

Speci6cation for jute sacking 11653 : 1986

bags for packing cement ( second

revision )

Methods of sampling hydraulic 11761 : 1986

cements (first revision )

4031 Methods of physical test for

( Parts 1 to 13 ) hydraulic cement (first fevifion ) 12 154 : 1 gg7

4032: 1985 Method of Chemical analysis of

hydraulic cement ($Frsr revision ) 12174 : 1987

4845 : 1968 Definitions and terminology

relating to hydraulic cement

12423 : 1988

4905 : 1968 Methods for random sampling

Title

Specification for high density

polyethylene ( HDPE ) woven

sacks for packing cement

Specification for -polypropylene

( PP ) woven sacks for packing

cement

Specification for multi wall paper

sacks for cement, valved-sewn-

gussetted type

Specification for light weight

jute bags for packing cement

Specification for jute synthetic

union bag for packing cement

Method for calorimetric analysis

of hydraulic cement

ANNEX B

( Clause 9.2 )

TOLERANCE REQUIREMENTS FOR THE MASS OF CEMENT

PACKED IN BAGS

B-l The average net mass of cement packed in

bags at the plant in a sample shall be equal to~or

more than 50 kg. The number of bags in a sample

shall be as given below:

Batch Size Sample Size

100 to I50 20

151 to 280

31

281 to 500 50

501 to I 200 80

1 201 to 3 200 125

3 201 and over 200

The bags in a sample shall be selected at random

( see IS 4905 : 1968 ).

B-l.1 The number of bags in a sample showing a

minus error greater than 2 percent of the specified

net mass ( 50 kg ) shall be not more than 5 per-

cent of the bags in the sample. Also the minus

error in none of such bags in the sample shall

exceed 4 percent of the specified net mass of

cement in the bag.

NOTE -The matter given in B-l and B-l.1 arc

extracts based on the Standards of Weights and

Measures (Packaged Commodities ) Rule+ 1977 to

which reference shall be made for full datails. Any

modification made in these Rules and other related

Acts and Rules would apply automatically.

B.l.2 ln case of a wagon/truck load of 20 to 25

tonnes, the overall tolerance on net mass of

cement shall be Otto +05 percent.

NOTE - The mass of a jute sacking bag conform-

ing to IS 2580 : 1982 to hold 50 kg of cement is 531 g.

the mass of a double hessian bituminized (CR1

type ) bag to hold 50 kg of cement is 630 g. the mass

of a 6.~1~ paper bag to hold 50 kg of cement is

approximately 400 g and the mass of a polyethylene

lined ( CR1 type ) jute bag to hold 50 kg of cement

is approximately 480 g.

.

IS 8112 : 1989

ANNEX A

. .

COMPOSITION OF THE TECHNICAL COMWTIEE

. CEMENT AND CONCRETE SECTIONAL COMMITTEE, CED 2 #

Chdff?Wl

DR H. C. VI SVESVARAYA

Members

SHRI K. P. BANERI EE

SHRI HARI SH N. MALANI ( illrernare )

SHRI S. K. BANERJ ~B

CHIEF ENQINEER j BD )

SHRI J . C. BASUR ( Aflernate )

CHI EF ENOI NEER ( DESI GNS )

SUPERI NTENDI NO ENGI NEER ( S & S )

( Alrernare )

CHIEF ENGI NEER ( RESEARCH-CUM-

DI RECTOR )

RESEARCH OFFI CER ( CONCRETE

TECHNOLOGY ) ( Alrernare )

DI RECTOR

J OI NT DI RECTOR ( Alrernare )

DI RECTOR

CHI EF RESEARCH OFFI CER ( AI rernura )

. DI RECTOR ( C & MDD-I I )

DEPUTY DI RECTOR ( C & MDD-I I )

f, Alrernure )

SHRI V. K. GHANEKAR

SHRI S. GOPI NATH

SHRI A. K. GUPTA

SHRI J . SUN GUPTA

SHRI P. J . J AGUS

DR A. K. CHATTERJ EE ( AI rernure )

J OI NT DI RECTOR STANDARDS ( B & S )/CB-I

J OI NT DI RECTOR STANDARDS ( B dr S )/

CB-I I ( Alrernure )

SHRI N. G. J &HI

SHRI R. L. KAPOOR

SHRI R. K. SAXENA ( AI rernure )

DR A. K. MULLI CK

SHRI G. K. MAJ UMDAR

SHRI P. N. MEHTA

SHRI S. K. MATHUR ( AI rernure )

SHRI NIRMAL SINGH

SHRI S. S. MI ~LANI ( AI rernure )

SHRI S. N. PAL

SHRI BIMAN D.WWPTA ( AI rernure )

SHRI R. C. PARAIE

L-r-COL R. K. SI N~H ( Airernure )

SHRI 13. S. PASRI CHA

SHRI Y. R. PHULL

SHRI S. S. SEEHRA ( Alrernare )

DR MOHAN RAI

DR S. S. REHSI ( Afternate )

SHRI A. V. RAMI NA

DR K. C. NARAN~ ( Alrernure )

SHRI G. RAMDAS

SHRI T. N. SUBBA RAO

SHRI S. A. REDDI ( AIrernare )

Representing

National Council for Cement and Building Materials, New Delhi

Larsen and Toubro Limited, Bombay

National Test House, Calcutta

Bhalcra Beas Management Board, Nangal Township

Central Public Works Department, New Delhi

I rrigation Department, Government of Punjab

A. P. Engineering Research Laboratories, Hyderabad

Central Soil and Matirials Research Station, New Delhi

Central Water Commission, New Delhi

Structural Engineering Research Centre ( CSI R ), Ghaziabad

The I ndia Cements Limited, Madras

Hyderabad I ndustries Limited, Hyderabad

National Buildings Organization. New Delhi

The Associated Cement Companies Ltd. Bombay

Research, Designs and Standards Organization ( Ministry of

Railways ), Lucknow

I ndian Hume Pipes Co Limited, Bombay

Roads Wing ( Ministry of Transport ), Department of Surface

Transport, New Delhi

National Council for Cement and Building Materials, New Delhi

Hospital Services Coosultaocy Corporation ( I ndia ) Ltd.

New Delhi

Geological Survey of I ndia, Calcutta

Development Commissioner for Cement I ndustry ( Ministry of

I ndustry ). New Delhi

M.N. Dastur and Company Private Limited, Calcutta

Engineer-in-Chiefs Branch, Army Headquarters

Hindustan Prefab Limited, New Delhi

Indian Roads Congress, New Delhi; und dentral Road Research

I nstitute ( CSI K ). New Delhi

Central Road Research I nstitute ( CSI R ), New Delhi

Central Building Research I nstitute ( CSI R ). Roorkee

Dalmia Cement ( Bharat ) Limited, New Delhi

Directorate General of Supplies and Disposals, New Delhi

Gammon I ndia Limited, Bombay

IS 8112 : 1989

Membera

DR M. RAMAIAH

D@A. G. MADH~VA RAO ( Alfernate )

SHRI A. U. RIJ HSIN~HANI

SHRI C. S. SHARMA (-Alternate )

SECRETARY

SHRI K. R. SAXENA ( Alternate )

SUPERINTENDINQ ENGINEER ( DESIGNS )

E~ECUTI~ ENGINEER ( SMD DIVISION )

( Alternate )

SHRI L. SWAR~OP

SHRI H. BHATTACHARYA

( Alternate )

SHRI S. K. GUHA THAKURTA

SHRI S.P. SANKARNARAYANAN

( Alternate )

DR H. C. VISVESVARAYA

SHRI D. C. CHATURV~DI ( Alternate )

SHRI G. RAMAN,

Direcror ( Civ Engg )

Representing

.

Strucfuisii Engmeering Research Cenfte ( CSIR ), Madras

Cement Coiporatibn of Ilidia; Neti Delhi

Ct%tral Board of Irrigation and Power, New Delhi

Public Works Department, Government of Tamil Nadu

Orissa Cement Limited, New Delhi

Gannon Dunkerly & Co Ltd. Bombay

The Institution of Engineers ( India ), Calcutta

Director General, BIS ( Ex-officio Member )

Secretary

SHRI N. C. BANDYOPADHYAY

J oint DireCtor (Civ Engg ), BIS

Cement, Pozzolana and Cement Additives Subcommittee, CED 2 : 1

Convener

DR H. C. V~SV~SVARAYA

Members

National Council for Cement and Building Materials.

New Delhi

DR A. K. MULLICK

DR ( SHRIMATI ) S. LAXMI

3

( AI ternufes to Dr H. C. Visvesvaraya )

SHRI S. K. BANERJ EE

SARI N. G. BASAK

SHRI T. MADNFZSHWAR ( Affernafe )

SHRI SOMNATFZ BANFRJ EE

CHIEP ENOINEER ( RESEARPH-CUM-

DIRECTOR )

National Teit House, Calcutta

Directorate General of Technical Development, New Delhi

RUURCH OFFICER ( CT ) ( Alternate )

SHRI N.. B. DE.QI c

SHRI J . K. ~PATEL ( Alternate )

DIRECTOR

RESEARCH OPPICER ( Alternate )

DIRE~~~~(C&MDDII)

De~un DIRECTOR ( C t MDD II )

( Al;ternufe )

SHRI R. K. GA~ANI

SHRI R. K. VAISHNAV~( Alternote )

SHRI J . SEN GLPTA

SHRI P. J . J AIXJ S

DR A. K. CHA~TERJ EE (hernate )

JOINT DIRECTOR, STANDARDS

( B & S )/CB-I

J OINT DIRECTOR, STANDARDS

( B &, $ )/CB-II ( Alternate )

SHRI R. L. KAPOOR

SHRI R. K. DA?TA ( Afternute )

SHRI W. N. KARODE

SHRI R. KUNJ ITHAPATTAY

SXRI G. K. MAJ UMDAR

Cement Manufacturers Association, Bombay

Irrigation Department, Government of Punjab

Gujarat Engineering Research Institute, Vadodara

Maharashtra Engineering Research Institute, Nasik

Central Water Commission, New Delhi

Shree Digvijay~Cement Co Ltd. Bombay

National Buildings Organization, New Delhi

The Associated Cement Companies Ltd. Bombay

Research, Designs and Standards Organization, Lucknow

Roads Wing (Ministry of Transport ) ( Department of Surface

Transport ), New Delhi

The Hindustan Construction Co Ltd, Bombay

Chettinad Cement Corporation Ltd, Poliyur, Tamil Nadu

Hospital Services Consultancy Corporation ( India ) Lad,

New Delhi

6

.

Members

SHRI K. P. MQHIDEEN

SHRI NIRMAL SINGH

SHRI S. S. MICILANI ( Alternate )

SHRI Y. R. PHULL

SHRI M. R. CHA-ITERI~E ( Alternate )

SHRI A. V. RAMANA

DR K. C. NARANO ( Alternate )

COL V. K. RAO

SHRI N. S. GALAND@( AIlernare )

SHRI S. A. REDDI

DR S. S. REHSI

DR IRSHAD MASOOD ( Alternate )

SHRI A. U. RIJHSIN~HAN~

SHRI M. P. SINGH

SUPERINTENDING ENGINEER (D)

SIZNIOR DEPUTY CHIEP ENO~NEER

( GENERAL ) ( Alternafe )

SHRI L. SWAR~~P

SHRI I-I. BHATTACHARYA ( Alrernute )

SHRI V. M. WAD

IS 8112 : 1989

Representing

Central Warehousing Corporation, I&w Delhi

Development Commissioner for Cement Industry ( Ministry of

Industry )

Central Road Research Institute ( CSIR ), New Delhi

Dalmia Cement ( Bharat ) Ltd, New Delhi

Engineer-in-Chiefs Branch, Army Headquarters

Gammon India Ltd. Bombay

Central Building Research Institute~( CSIR ), Roorkee

Cement Corporation of India Ltd, New Delhi

Federation of Mini Cement Plants, New Delhi

Public Works Department, Government of Tamil Nadu

Orissa Cement Ltd. New Delhi

Bhilai Steel Plant, Bhilai

?

.

.

,

, I

Bureau efIn&an Standards -*

.-

.BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to pfomote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permissicn in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a~standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Slandards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BIS Handbook and Standards Monthly Addition... \

This Indian Standard has been developed from Dot: No. CED 2 ( 4746 )

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah &far Marg, New Delhi 110002

Telephones: 323 0131,323 33 75,323 94 02

Regional Offices:

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern : l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCU?TA 700054

Northern : SC0 335-336, Sector 34-A, CHANDIGARH 160022

Southern : C.I.T. Campus, IV Cross Road, CHENNAI 600113

. Western : Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. >GHAZIABAD: GUWAHATI.

HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

. ,

Telegrams: Manaksanstha

(Common to all offices)

Telephone

32376 17,3233841

{ 337 337 84 86 99,337 9120 85 61

26,337

1 60 60 38 20 43 25

1 235 235 02 15 16,235 04 23 42 15 19,235

832 92 95,832 78 58

832 78 91,832 78 92

PATNA. PUNE. THIRUVANANTHAPURAM.

Printed at Dee Kay Printers, New Delhi, India

AMENDMENT NO. 1 J ANUARY 1991

TO

IS 8112 : 1989 43 GRADE ORDINARY PORTLAND

CEMENT - SPECIFICATION

( First Revision )

( Page 3, Chuse 9.2.1.1 ) - Insert the following new clauses

after 9.2.1 .l:

9.2.2 When cement is intended for export and if the purchaser so

requires, packing of cement may be done in bags other than those given

in 9.2 and 9,2.1 with an average net mass of cement per bag as agreed to

between the purchaser and the manufacturer.

9.2.2.1 For this purpose the permission of the certifying authority shall

be obtained in advance for each export order.

9.2.2.2 The words FOR EXPORT and the average net mass of cement per

bag shall be clearly marked in indelible ink on each bag.

9.2.2.3 The packing material shall be as agreed to between the supplier

and the purchaser.

9.2.2.4 The tolerance requirements for the mass of cement packed in

bags shall be as given in 9.2.1.1 except the average net mass which shall

be equal to or more than the quantity in 9.2.2.

(CED 2)

Printed at Dee Kay Printers, New Delhi-l 10015, India.

AMENDMENT NO. 2 NOVEMBER 1991

TO

IS 8112 : 1989 43 GRADE ORDINARY PORTLAND

CEMENT - SPECIFICATION

(First Revision)

( Page 4, clause B-l.2 ) - Substitute up to 25 tonnes for of 20 to 25

tonnes.

(CED2)

-

Printed at Dee Kay Printers, New Delhi- 1 iO0 15, India.

AMENDMENT NO. 3 NOVEMBER 1993

TO

IS 8112 : 1989 43 GRADE ORDINARY PORTLAND

CEMENT - SPECIFICATION

( First Revision)

[ Page 3, clause 9.2.1.1 ( see also Amendment No. 1 )] - Substitute the

following for the existing matter:

9.2.2 When cement is intended for export and if the purchaser so requires,

packing of cement may be done in bags or in drums with an average net mass

of cement per bag or drum as agreed to between the purchaser and the

manufacturer.

9.2.2.1 For this purpose the permission of the certifying authority shall be

obtained in advance for each export order.

9.2.2.2 The words FOR EXPORT and the average net mass of cement per

bag/drum shall be clearly marked in indelible ink on each bag/drum.

9.2.2.3 The packing material shall be as agreed to between the manufacturer

and the purchaser.

9.2.2.4 The tolerance requirements for the mass of cement packed in

bags/drum shall be as given in 9.2.1.1 except the average net mass which shall

be equal to or more than the quantity in 9.2.2.

(CED2)

Printed at Dee Kay Printers, New Delhi-l 10015, India.

AMENDMENT NO. 4 OCTOBER 1998

TO

IS 8112 : 1989 43 GRADE ORDINARY PORTLAND

CEMENT - SPECIFICATION

(FkstRevEon)

(Page 3, clause 94.1) - Substitute the following for the existing clause:

93.1 The average net mass of cement per bag may also be 25 kg, 10 kg, 5 kg,

2 kg or 1 kg, subject to tolerances as given in 9.2.1.1 and packed in suitable bag

as agreed to between the purchaser and the manufacturer.

(Page 3, clause 93.1.1) - Substitute the following for the existing clause:

9.2.1.1 The number of bags in a sample taken for weighment showing a minus

error greater than 2 percent of the specified net mass shall not be more than

5 percent of the bags in the sample. Also the minus error in none of such bags in

the sample shall exceed 4 percent of the specified net mass of cement in the bag.

However, the average mass of the cement in a sample shall be equal to or more

than 25 kg, 10 kg, 5 kg, 2 kg or 1 kg, as the case may be.

( Page 4, clause B-1.2 ) - Substitute up to 25 tonnes@ 20 to 25 tonnes.

(CED2)

Repqraphy Unit, BE, New Delhi, India

AMENDMENT NO. 5 OCTOBER1999

TO

IS 8112 : 1989 43 GRADE ORDINARY PORTLAND

CEMENT - SPECIFICATION

(First Reviim)

(Page 1, clause 5.1) -Insert the following after the clause:

5.2 Total chloride content in cement shall not exceed 0.1 percent by mass for

cement used in structures other than prestressed concrete. For determination of

chloride content in cement, IS 12423 may be referred.

NOTE - For use in special structures like prestressed concrete, where chloride is a critical

parameter, the limit of chloride content shall be 0.05 percent and shall be required to be

measured if desired by the purchaser.

[ Page 1, Table 1, Sl No. (iii), co1 3 ] -Substitute 3.ofor 2.

[ Page 1, Table 1, Sl No. (iv), co1 3 ] - Substitute 6.0 for 6.

( Page 1, Table 1, Notes 3 and 4 ) - Delete.

(CED2)

Reprography Unit, BIS, New Delhi, India

AMENDMENT NO. 6 J UNE 2000

TO

I S 8112 : 1989 43 GRADE ORDI NARY PORTLAND

CEMENT - SPECI FI CATI ON

( First Revbion )

Substitute net mass for average net mass wherever it appears in the

standard.

( Cover page 2, para 3 of Foraoord ) - Substitute the following for the

existing text:

Specific requirements of ordinary Portland cement for manufacture of railway

sleepers to be designated as 43-S grade are given in the standard in 5.2, 6.1,

6.2.2, 6.3, 6.4 and 9.1. To differentiateit with normal grade, 43-S grade shall

be marked on the bags/packages for such cement in place of 43-S grade.

(Page 1, clause 5 )- I laert a new clause 5.2 as follows:

5.2 Cement used for railway sleepers shall satisfy the following

chemical/mineralogical requirements and shall be designated as 43-S grade:

i) Magnesia, percent by mass - Not more than 5.0

ii) Tricalcium atuminate content, percent -Not more than 10.0

iii) Tricalcium silicate, percent - Not less than 45

(Page 1, clause 6.1) - Insert the following at the end of the clause:

For 43-S grade cement, the specific surface shall not be less than 370 m2/kg.

(Page 1, TabZe 1, Note 1 ) - Insert the following at the end:

The tricalcium silicate content (C3S) is calculated by the formula:

C3S = 4.07 CaO - 7.60 Si02 - 6.72 A203 - 1.43 Fe203 - 2.85 SO3

(Page 2, clause 6.2.1.1) - Insert a new clause 6.2.2 as follows:

6.2.2 For 43-S grade cement, soundness of unaerated cement when tested by the

Le-Chatelier method shall not have an expansion of more than 5 mm.

1

Anrend No. 6 to IS 0112 : 19X9

(Page 2, clause 6.3 ) - Insert the following under (a) :

Initial setting time for 43-S grade cement in minutes - Not less than 60.

(Page 2, clause 6.4 ) - Insert the following as new para:

For 43-S grade cement, compressive strength at 168 f 2 h shall not be less than

37.5 MPa .

( Page 2, cluctse 9.1, line 12 ) - Insert the following after 43 Grade

Ordinary Portland cement:

or 43-S Grade Ordinary Portland Cement, whichever is applicable.

(CED2)

Reprography Unit, BIS, New Delhi, India

2

AMENDMENT NO. 7 DECEMBER 2003

TO

IS 8112:1989 43 GRADE ORDINARY PORTLAND

CEMENT SPECIFICATION

( Page 1, clause

existing sentence:

( First Reviswtt )

4.1, last sentence ) Substitute the following for the

No material shall be added after burning, other than gypsum (natural or

chemical) or water or both; performance improvers; and not more than one

percent of air-entraining agents or other agents including colouring agents,

which have proved not to be harmful. Limit of addition of performance

ireprovers shall be as follows and shall be inclusive of one percent additives as

mentioned above:

Perfimnanw [mprowr Percentage Requirement

Addition, Max

Fly ash 5 As per IS 3812 (Part 1)

Granulated slag 5 As per IS 12089

Silica fume 5 As per IS 15388

Limestone 5 CaCO~ content calculated from CaO content sfrdl not be

less than 75 percent when tested as per IS 1760 (Part 3)

Rice husk ash 5 a) Reactive sitica shaIl not be less than 85 percent when

tested as per IS 3812 (Part I)

b) Pozzolanic Activity Index shall nor be less than 90

percent when tesIed as per 10 of IS 1727

c) f...osson ignition sha!t not be more than 8 percent when

tested as per 1S 1727

a) Sificon dioxide (Sioz) phss ahsminium oxide (Abo3)

plus iron oxide (Fc203) in percent by mass shall not

& less than 95 percent when tested as per IS 1727

b) Loss on ignition shall not be more than 1 percent

when tested as per IS 1727

c) Total alkalis as sodium oxide (NazO) in percent by

mass shall not be more than 0.6 percent when tested

as per IS 4032

d) Particles retained on 45 micron N sieve ( wet sieving)

shall not be more than 1 percent when test as per

IS 1727

1

Metakaoline 5

Amend No. 7 to IS 8112:1989

If a combination of above performance improvers is added, the maximum limit

of addition shall be 5 percent.

[ Page 1, Table 1, S1 No. (iii) ( see also Amendment No. 5 ) ] Substitute

the following for the existing matter:

S1No. Characteristic Requirement

(1) (2) (3)

iii) Insoluble residue, percent a) [n case no flyash, silica fume, rice husk ash and

by mass metakaoline is added Not more than 3.0

b) In case of addition of fly ash and/or silica fume an~or

rice husk ash and/or metakaoline Not more than 5.0

( Page 2, clause 6.3.1. line 6 ) Substitute less than for the words not

less than.

( Page 2, clause 9.1, last sentence) Insert the following sentence before

the existing sentence:

Bags shall also be marked with the type and the percentage of performance

improvers added.

( Page 4, Annex A ) Insert the following matter at the appropriate place:

IS No. Title

1727:1967 Methods of test for pozzolanic materials @-strevision)

1760 (Part 3): Methods of chemical analysis of limestone, dolomite and allied

1992 materials : Part 3 Determination of iron oxide, alumina, calcium

oxide and magnesia (first revision)

3812 ( Part 1 ): Pulverized fuel ash Specification : Part I For u$e w

2003

12089:1987

15388:2003

(CED2)

pozzolana in cement cement mortar and concrete (second

revision)

Granulated slag for the manufacture of Portland slag cement

Specification

Silica fume Specification

Reprography Unit, BIS, New Delhi, India

2

/

----

s,.,. . -

,..

AMENDMENT NO. 8 MAY 2005

IS 8112:1989 43t!iADE ORDINARY

PORTLAND CEMENT SPECIFICATION

( First Revisiun )

( Page 2, clause 8.2) Insert the following new clause after clause 8.2

8.3 In case performance improvers are added, the manufacturers certificate

shall also indicate the type and percentage of performance impro~ers added.

[ Page 2, clause 9.1, last sentence (see also Amendment No. 7) ]

Substitute the following for the existing sentence before the last sentence:

In case performance improvers are added, the bags shall also be marked

Permitted performance improvers are added.

{

. ..- ,

,.

(CED2)

Reprography Unit, BIS, New Delhi, India

[

.,.

You might also like

- Lab Manual.1pdfDocument31 pagesLab Manual.1pdfAshish KumarNo ratings yet

- 2.2 Matrices in Matlab: IndexingDocument30 pages2.2 Matrices in Matlab: IndexingkiranmannNo ratings yet

- Ball Mill OperationDocument12 pagesBall Mill OperationAshish KumarNo ratings yet

- Is 12894: 1990Document6 pagesIs 12894: 1990mukaslam100% (7)

- Concrete Admixtures - Specification 9103Document19 pagesConcrete Admixtures - Specification 9103Sravan KumarNo ratings yet

- 53 Grade Ordinary Portland CementDocument23 pages53 Grade Ordinary Portland CementAshish KumarNo ratings yet

- Survey 2Document2 pagesSurvey 2Ashish KumarNo ratings yet

- 4032Document44 pages4032Ashish KumarNo ratings yet

- 8112 - Ls 43 Grade OpcDocument10 pages8112 - Ls 43 Grade OpcPooja ChoudharyNo ratings yet

- Survey IDocument29 pagesSurvey IAshish KumarNo ratings yet

- Methods of Physical Tests FOR Hydrauliccement: Indian StandardDocument8 pagesMethods of Physical Tests FOR Hydrauliccement: Indian StandardAshish KumarNo ratings yet

- Manual of Civil Engineering LaboratoryDocument44 pagesManual of Civil Engineering Laboratoryjobsinabroad_ig67% (3)

- Concrete Admixtures - Specification 9103Document19 pagesConcrete Admixtures - Specification 9103Sravan KumarNo ratings yet

- AcneDocument7 pagesAcneAshish KumarNo ratings yet

- CVEN365 Introduction To Geotechnical Engineering Laboratory ManualDocument134 pagesCVEN365 Introduction To Geotechnical Engineering Laboratory ManualAshish KumarNo ratings yet

- Is 383 Specification For Coarse and Fine Aggregates From Nat.180180049Document21 pagesIs 383 Specification For Coarse and Fine Aggregates From Nat.180180049love9No ratings yet

- 1727 - Test Method For Pozalana MaterialDocument51 pages1727 - Test Method For Pozalana MaterialAshish KumarNo ratings yet

- Determination of Moisture ContentDocument59 pagesDetermination of Moisture ContentAshish Kumar100% (2)

- 2506 - Concrete Vibrator-Speed Board TypeDocument11 pages2506 - Concrete Vibrator-Speed Board TypeAshish KumarNo ratings yet

- CVEN365 Introduction To Geotechnical Engineering Laboratory ManualDocument134 pagesCVEN365 Introduction To Geotechnical Engineering Laboratory ManualAshish KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Millennium 60x120cm Gossy Domestic E-Catalogue Aug 22Document155 pagesMillennium 60x120cm Gossy Domestic E-Catalogue Aug 22sssadangiNo ratings yet

- The Complete Metal Raceway SolutionsDocument14 pagesThe Complete Metal Raceway Solutionscetc qatarNo ratings yet

- Aiims - NagpurDocument85 pagesAiims - NagpurSalman ShahNo ratings yet

- Journal of Building Engineering: SciencedirectDocument17 pagesJournal of Building Engineering: SciencedirectShimizu KokuruNo ratings yet

- Material Safety Data Sheet SikabondingDocument3 pagesMaterial Safety Data Sheet SikabondingHarieNo ratings yet

- 2013 Fenwick CatalogDocument22 pages2013 Fenwick Catalogretrospect1000No ratings yet

- Tugas Translate STRK Beton 25-27Document4 pagesTugas Translate STRK Beton 25-27Farmady HadiantoNo ratings yet

- Petra Steel Door E-BrochureDocument12 pagesPetra Steel Door E-Brochuresatyam.pulkam7490No ratings yet

- AeroBath SF-230 Shower FilterDocument4 pagesAeroBath SF-230 Shower FilterFabian DeeNo ratings yet

- Design of Steel StructuresDocument2,529 pagesDesign of Steel StructuresStructural Spreadsheets75% (8)

- Analisis Pengendalian Kualitas Statistik: Injection Moulding Produk Cup PlastikDocument18 pagesAnalisis Pengendalian Kualitas Statistik: Injection Moulding Produk Cup Plastikandre josuaNo ratings yet

- Improvement of Adhesion Properties of Glass Prepared Using SiC-deposited Graphite Mold Via Low-Temperature Chemical Vapor DepositionDocument7 pagesImprovement of Adhesion Properties of Glass Prepared Using SiC-deposited Graphite Mold Via Low-Temperature Chemical Vapor DepositionheheNo ratings yet

- Revised BOQ Civil Works 11.02.2022Document35 pagesRevised BOQ Civil Works 11.02.2022Head Development ProjectNo ratings yet

- Results in Physics: SciencedirectDocument11 pagesResults in Physics: SciencedirectbharatNo ratings yet

- KASEZ Working Unit List 2018 19Document26 pagesKASEZ Working Unit List 2018 19Vijay SuraniNo ratings yet

- High Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1Document3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 110kv Power Cable 1SanalicaNo ratings yet

- Mechanical Behaviour, Testing and Manufacturing Properties of MaterialsDocument26 pagesMechanical Behaviour, Testing and Manufacturing Properties of Materialssengcan100% (1)

- ODMFT610Document1 pageODMFT610santois1891No ratings yet

- C913-18 StandardSpec - Precast Concrete - WT-WWDocument6 pagesC913-18 StandardSpec - Precast Concrete - WT-WWDavid Skidgel100% (1)

- Suitability of Sintered Fly Ash Lightweight Aggregate in Structural ConcreteDocument8 pagesSuitability of Sintered Fly Ash Lightweight Aggregate in Structural ConcreteAjmal MuhammedNo ratings yet

- Sciencedirect: Effect of Heat Treatment On Microstructure and Property of Cr13 Super Martensitic Stainless SteelDocument7 pagesSciencedirect: Effect of Heat Treatment On Microstructure and Property of Cr13 Super Martensitic Stainless SteelAkdri Bagus ZulvikarNo ratings yet

- Section 3: American Ductile Iron PipeDocument35 pagesSection 3: American Ductile Iron Pipejosesantimateo100% (2)

- Transmission Line Incoming Material ReportDocument7 pagesTransmission Line Incoming Material ReportVicky Vjmsd100% (1)

- Engineering Materials ME-221) : Instructor: Dr. Rafiq Ahmad Assistant ProfessorDocument19 pagesEngineering Materials ME-221) : Instructor: Dr. Rafiq Ahmad Assistant ProfessorAhmad NawazNo ratings yet

- Technical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableDocument1 pageTechnical Specification of Nyy Flexible 1x10 RM 0.6/1.0 (1.2) KV CableRasel AhmedNo ratings yet

- The Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteDocument6 pagesThe Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteGladys Eras ValladolidNo ratings yet

- Company Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004Document6 pagesCompany Grade Origin Port: Base Oil Grades Imported Into Indian Ports of Mumbai, JNPT & Chennai - January 2004georgevoommen100% (1)

- Evaluation of The Bulk Specific Gravity For Granular MaterialsDocument1 pageEvaluation of The Bulk Specific Gravity For Granular MaterialsProf. Prithvi Singh KandhalNo ratings yet

- New Project ACI - PoltakDocument13 pagesNew Project ACI - PoltakD.b. TampubolonNo ratings yet

- Engineering Specification Stamping, Drawing, and Cutting LubricantsDocument2 pagesEngineering Specification Stamping, Drawing, and Cutting Lubricants김동훈No ratings yet