Professional Documents

Culture Documents

Report

Uploaded by

Awais Mumtaz0 ratings0% found this document useful (0 votes)

23 views13 pagesGas Turbines

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGas Turbines

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views13 pagesReport

Uploaded by

Awais MumtazGas Turbines

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 13

1

NATIONAL UNIVERSITY OF SCIENCES & TECHNOLOGY

CONTROL SYSTEMS

PROJECT REPORT

DC MOTOR CONTROL

(USING GENERIC MICRO-CONTROLLER BOARD)

Submitted To: Mr. Naqash Afzal

Submitted By:

Arslan Ahmad 10-NUST-BE-ME-23

Maaz Hussain 10-NUST-BE-ME-45

Umer Farooq 10-NUST-BE-ME-90

Abdul Saboor 10-NUST-BE-ME-03

Section: A

Date: 10

th

Jan, 2014

2

Table of Contents

Objective -------------------------------------------------------------------------------------------------------------- 3

Project Description ------------------------------------------------------------------------------------------------- 3

Circuit ------------------------------------------------------------------------------------------------------------------ 3

Program Code -------------------------------------------------------------------------------------------------------- 6

Code Explained ------------------------------------------------------------------------------------------------------- 9

Conclusion ----------------------------------------------------------------------------------------------------------- 12

3

OBJECTIVE

To control the RPM of a DC Motor (ran by an H-Bridge) using a Generic Microcontroller

Board.

PROJECT DESCRIPTION

This project is used to control the speed of a DC Motor (ran by an H-Bridge). The Micro-

controller generates a Square Wave of 200 Hz Frequency which is used to give the Motor its

Duty Cycle. A feedback is implemented in the code which states that the motor should achieve

the speed defined in the code as soon as the encoder is attached to the motor.

CIRCUIT

This project consists of 2 circuits

1. Generic Micro-controller Board

2. H-Bridge

1. Generic Micro-controller Board

Function

The Generic Micro-controller Board acts like a computer's motherboard, and acts

as a general purpose controller.

Components

The components used in this circuit are

1. Atml 89C51 (8051 micro-controller) 1

4

2. 74LS245 (Byte Addressable Registers) 4

3. LED Bar Graph: To display output on Microcontroller Port pins 4

4. Respack (9 pins): 10k-ohm, for Pulling-up P0 Port 1

5. Respack (9-pins): 330 ohm, with LED Bar Graph 4

6. Crimp Shell (8-pins): For interfacing with external inputs/outputs 8

7. Capacitors: 33 pF (2), 10 uF (1)

8. Crystal (12 MHz): For Calculations 1

9. Push Button: For activating Reset 1

10. Resistor (8.2k-ohm): For Reset circuitry 1

11. Ziff: Bed for Micro-controller 1

12. IC Beds: For easy removal of ICs from circuit 16

5

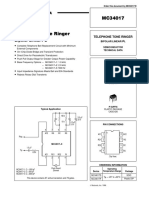

2. H-Bridge

Function

The H-Bridge is used to run a DC motor and control its direction. For the project,

we run the motor in only one direction.

Components

We have used an H-bridge IC for this purpose commonly known by the name

L293D.

6

PROGRAM CODE

The Code burned into the Micro-controller is:

#include <reg51.h>

int encoder_counts = 0, dutycycle = 50, cycle=0;

float ppr=64;

unsigned char repetition = 0;

unsigned int reference_speed=50, speed;

sbit Enable0 = P2^7;

sbit Enable1 = P2^6;

sbit Enable2 = P2^5;

sbit Enable3 = P2^4;

sbit pulse = P0^0;

L293D Circuit

7

void Initialize();

void SpeedDisplay();

void main (void)

{

Initialize();

while(1)

{

;

}

}

void Initialize()

{

P1 = 0xFF; pulse = 1;

P2=0x00;

EA=1;EX0=1;ET0=1;ET1=1;

TMOD=0x11; //Timer 0 and Timer 1 in mode 1 (16-bit mode)

IT0=1; //edge triggered

TH0=0x3C; //t=50ms

TL0=0xB0;

TR0=1;

TH1 = 0xFF; //t=50us (t=T/100)

TL1 = 0xCD;

TR1 = 1;

}

void SpeedDisplay()

{

int i;

P2=speed%10; Enable0 = 1; for(i=0;i<100;i++); Enable0 = 0;

P2=(speed/10)%10; Enable1 = 1; for(i=0;i<100;i++); Enable1 = 0;

P2=(speed/100)%10; Enable2 = 1; for(i=0;i<100;i++); Enable2 = 0;

P2=speed/1000; Enable3 = 1; for(i=0;i<100;i++); Enable3 = 0;

}

void PwmGeneration()

{

int error,tempdc;

error = reference_speed - speed;

//tempdc = dutycycle + error;

if(error>0)tempdc = dutycycle + 1;

else tempdc = dutycycle -1;

if(tempdc>100) dutycycle = 100;

else if(tempdc<0) dutycycle = 0;

else dutycycle = tempdc;

}

void encoder() interrupt 0

{

encoder_counts++;

}

8

void rpm() interrupt 1

{

if (repetition==9)

{

speed = (encoder_counts/ppr)*60.0*2.0;

encoder_counts=0;

SpeedDisplay();

PwmGeneration();

repetition = 0;

TR0=0;

TH0=0x3C;

TL0=0xB0;

TR0=1;

}

else

{

repetition++;

TR0=0;

TH0=0x3C;

TL0=0xB0;

TR0=1;

}

}

void pwm() interrupt 3

{

if(cycle<dutycycle-1)

{

pulse = 1;

cycle++;

}

else if(cycle<99)

{

pulse = 0;

cycle++;

}

else

{

cycle = 0;

pulse = 1;

}

TR1=0;

TH1 = 0xFF;

TL1 = 0xCD;

TR1 = 1;

}

9

CODE EXPLAINED

#include <reg51.h>

int encoder_counts = 0, dutycycle = 50, cycle=0; // defining

integers

float ppr=64; // pulse per revolution... we keep it a

float so the calculations results are also in float.. if we used

integer the software will round off to integer causing inaccuracy

unsigned char repetition = 0;

unsigned int reference_speed=50, speed; //reference speed is the rpm

of motor that has to be maintained.. that is required. our program's

function is to maintain the rpm of motor at this value

sbit pulse = P0^0; //through this pin we will send a pulse to the

motor via h-bridge

void Initialize(); //we are basically stating that a function

named initialize will be used. the detail of what the function will

do is stated at end

void SpeedDisplay();

void main (void)

{

Initialize(); // we are calling the function initialize.. go

down t see what that function is doing

while(1) //infinite loop . just so that code keeps running

{

;

}

}

void Initialize()

{

pulse = 1; //setting value of pulse at 1

EA=1;EX0=1;ET0=1;ET1=1; //EA=1 states that we will be using

interrupts... but we also have to tell which of the interrupts we will

use...... EX0 tells we are using external interrupt ( basically pin

3.2 in which the motor is giving its feedback pulse) ET0 refers to

timer 0 interrupt while et1 refers to timer1 interrupt

TMOD=0x11; //Timer 0 and Timer 1 in mode 1 (16-bit mode)

IT0=1; //edge triggered.. the pin 3.2 will

detect how many edges came

TH0=0x3C; //we have set timer to run for t=50ms...

basically we have to see speed every 0.5 seconds... so we will run

this timer 10 times to get 0.5s (50ms*10) and then do calculations to

10

find out rpm

TL0=0xB0;

TR0=1; // timer 0 started

TH1 = 0xFF; //t=50us (t=T/100) // the purpose of this

timer is to generate a pulse that has to be sent to the motor..

calculatons are done such that it sends 200 hertz... why 200...

because datasheet states that at 200 motor runs the best

TL1 = 0xCD;

TR1 = 1; starting timer 1

}

void PwmGeneration() // most important part... applies control

concepts

{

int error,tempdc; // two variables defines... error and

temporarydc ( dc for dutycycle)

error = reference_speed - speed; //error is defined

if(error>0)tempdc = dutycycle + 1; // if u refer to upper line

u will see that a positive error means that the motor is running

slower than required... this means that we have to increase the

speed... hence we increase dutycycle by 1.. its initial value was 50..

adding 1 makes it 51... this means that 49 part of the time we will be

sending 0pulse while 51 part of the time we will be sending full

voltage(1 pulse) .... hence increasing overall power being given to

the motor

else tempdc = dutycycle -1; // if error negative.. we have to

do the opposite that is reduce power to the motor

if(tempdc>100) dutycycle = 100; // we dont want dutycycle to

go beyond 100 it will disturb the logic.. as such 100 or any value

above it tells us that we are sending full voltage for the whole time

period

else if(tempdc<0) dutycycle = 0; // we dont want dutycycle to go

below 0 it will disturb the logic.. as such 0 or any value below it

tells us that we are sending no voltage for the whole time period that

is motor wont be moving

else dutycycle = tempdc; //we had stored value in a temporary

variable tempdc... this is just writing the value in variable named

dutycycle which is the one used in generating pulse

}

void encoder() interrupt 0 // this is basically external interrupt..

it gets activated at every falling edge.. pin no. 3.2 it was... so

every time we detect a falling edge we increment a variable named

encountercounts

11

{

encoder_counts++;

}

void rpm() interrupt 1 // interrupt of timer 0

{

if (repetition==9) // recall that timer ran for 50ms.. but we

needed 0.5 seconds... so we are waiting that when the timer has run 10

times (from 0 to 10) go in loop

{

speed = (encoder_counts/ppr)*60.0*2.0; //we are

calculating rpm.. since we got value for 0.5 seconds and we needed it

for 1min... we multiply by 60*2 (120)

encoder_counts=0; //we reset this to zero so that pin 3.2

can start counting again from 0 for the next 0.5seconds

PwmGeneration(); // see below

repetition = 0;

TR0=0;

TH0=0x3C;

TL0=0xB0;

TR0=1;

}

else

{

repetition++;

TR0=0; // this is that if 10 times has not been

done we first increment varaiable repitition ( it basically tells how

many times the timer has run) and then start timer again

TH0=0x3C;

TL0=0xB0;

TR0=1;

}

}

void pwm() interrupt 3 //timer 1

{

if(cycle<dutycycle-1) // this all below is sending a

pulse to motor through h-bridge.... from 0 till the dutycycle value (

initially set at 50 ) pulse 1 is sent .... then from dutycle to 100

pulse 0 is sent... an example if dutycle is changed to 30... from 0 to

30 pulse1 will b sent and from 30 to 100 pulse 0 will n sent..that

means motor will be receiving power only 30% of the time

{

pulse = 1;

cycle++;

}

12

else if(cycle<99)

{

pulse = 0;

cycle++;

}

else

{

cycle = 0;

pulse = 1;

}

TR1=0;

TH1 = 0xFF;

TL1 = 0xCD;

TR1 = 1;

}

// additional question maybe why use h-bridge.... answer is that

microcontroller gives 5V and very less amperes... the motor requires

12V and high currents... so use H-bridge....

why divide pulse in 100 parts u could just divide it in 4... because

we wanted accuracy...

why havent u used digital display... because sir u stated that you

would be using tachometer to see speed...

If tachometer gives wrong reading or it isnt present show a simulation

showing that it works perfectly in software..

if feedback is removed what will happen.. the program will be getting

0 pulses and will calculate speed at 0.. it will deduce that speed

should be increased... it will keep increasing dutycycle so that motor

can speed up... hence eventually it will be sending full voltage

100percent of the time and motor will run at full speed

if sir puts some extreme load on motor... lets say ur required speed

was 200 but its working on 100... ur Ans will b that putting load

limits the max speed a motor can rotate at.. currntly the motor is

rotating at full speed poss.. that is a pulse is sent which is high

100% of the time.

CONCLUSION

The circuit is used to control the speed of motor running at 200Hz frequency. A

reference speed is set and given to the motor through the program code. On powering up the

motor, it starts to perform its operation. The generic microcontroller board can also be used for

other purposes.

13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ETAi Study GuideDocument8 pagesETAi Study GuideShelia Murray-HargroveNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Special One: The Secret World of Jose Mourinho - Exclusive ExtractDocument13 pagesThe Special One: The Secret World of Jose Mourinho - Exclusive ExtractAnonymous ikUR753am80% (5)

- Valtra Fault CodesDocument4 pagesValtra Fault Codeshelio100% (1)

- Introduction To Fire Alarm SystemDocument9 pagesIntroduction To Fire Alarm SystemAwais MumtazNo ratings yet

- GA IntroDocument93 pagesGA IntroAwais MumtazNo ratings yet

- Requested FileDocument30 pagesRequested FileAwais MumtazNo ratings yet

- Upright 1 SimulationXpress Study 1Document11 pagesUpright 1 SimulationXpress Study 1Awais MumtazNo ratings yet

- DELD - Short Answer Questions and AnswersDocument23 pagesDELD - Short Answer Questions and AnswersPasupuleti Venkata RamanaNo ratings yet

- UltraPulse 5000Document78 pagesUltraPulse 5000Daniel TegelerNo ratings yet

- Logic Probe MK IIBDocument8 pagesLogic Probe MK IIBJose GarciaNo ratings yet

- 32cs460 PDFDocument53 pages32cs460 PDFpepe100% (1)

- MC 34017Document9 pagesMC 34017Eric Fabian GómezNo ratings yet

- National Semiconductor Is Now Part of Texas InstrumentsDocument13 pagesNational Semiconductor Is Now Part of Texas InstrumentsJavier AparicioNo ratings yet

- Mentorgraphic Tools: VLSI Lab ManualDocument46 pagesMentorgraphic Tools: VLSI Lab Manualgreeshma nNo ratings yet

- Luggage Security System: S.Vandana 180040468 SONALI KUMARI 180040632 CH - KALYANI 180040688Document12 pagesLuggage Security System: S.Vandana 180040468 SONALI KUMARI 180040632 CH - KALYANI 180040688Priya CNo ratings yet

- 555 Ic TimerDocument21 pages555 Ic TimerAbdul FatahNo ratings yet

- Allen Practice AnalogDocument23 pagesAllen Practice AnalogvarunjothishNo ratings yet

- Operational AmplifierDocument10 pagesOperational AmplifierSalman AliNo ratings yet

- ProH Series New Datasheet-All RatingsDocument4 pagesProH Series New Datasheet-All RatingsKD7 ITSolutionNo ratings yet

- ThermoFlex Narrow UG 04sepDocument68 pagesThermoFlex Narrow UG 04sepmsamsoniukNo ratings yet

- RF SYstem Design Main TopicsDocument75 pagesRF SYstem Design Main TopicssrinidhiNo ratings yet

- Honda Goldwing GL1500 1993 Electrical Troubleshooting Manual-6051BDocument160 pagesHonda Goldwing GL1500 1993 Electrical Troubleshooting Manual-6051BSverker OttossonNo ratings yet

- Optical ComputingDocument29 pagesOptical ComputingrakeshranjanlalNo ratings yet

- Reviewer in ITDocument15 pagesReviewer in ITclara san miguelNo ratings yet

- GcbasicDocument855 pagesGcbasicmoriartiiNo ratings yet

- Wheatstone Bridge: Operational AmplifiersDocument8 pagesWheatstone Bridge: Operational AmplifiersNida KhairiyahNo ratings yet

- UL Appliances Motors For Motor Manuf Whitepaper 06292010 UL 1004Document5 pagesUL Appliances Motors For Motor Manuf Whitepaper 06292010 UL 1004Rip_BarNo ratings yet

- Ap9212 AdsdDocument12 pagesAp9212 AdsdKartheeswaran Arumugam33% (3)

- imageRUNNER ADVANCE 4500 III Series - Service ManualDocument1,212 pagesimageRUNNER ADVANCE 4500 III Series - Service Manualjoe100% (1)

- Details Syllabus of 2015-2016Document34 pagesDetails Syllabus of 2015-2016RabiulAlamNo ratings yet

- Principles and Applications of Electrical Engineering 7Th Edition Giorgio Rizzoni 2 Download PDF ChapterDocument51 pagesPrinciples and Applications of Electrical Engineering 7Th Edition Giorgio Rizzoni 2 Download PDF Chaptervanessa.rider154100% (8)

- Quizizz: CC221-Q2: Quiz Started On: Thu 30, Jul 04:39 AM Total Attendance: 89 Average Score: 16292 Class Level # CorrectDocument83 pagesQuizizz: CC221-Q2: Quiz Started On: Thu 30, Jul 04:39 AM Total Attendance: 89 Average Score: 16292 Class Level # CorrectDarwin VargasNo ratings yet

- Pantalla Repetidora LG M2262DL ManualDocument27 pagesPantalla Repetidora LG M2262DL ManualJair Jesús Cazares RojasNo ratings yet

- MyRIO Project GuideDocument112 pagesMyRIO Project GuideDo Duc HanhNo ratings yet

- Isolated Mosfet Gate Driver PaperDocument6 pagesIsolated Mosfet Gate Driver PapergenwittsNo ratings yet