Professional Documents

Culture Documents

Stainless Steel Eductors: Model Number T0M T2M T3M T4M T5 T6 T22M

Uploaded by

Simbu ArasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel Eductors: Model Number T0M T2M T3M T4M T5 T6 T22M

Uploaded by

Simbu ArasanCopyright:

Available Formats

BEX

www.bex.com

INLET SIDE OUTLET SIDE

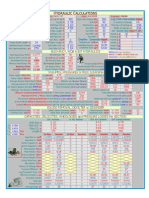

STAINLESS STEEL EDUCTORS

EDUCTOR PRINCIPLES:

BEX eductors use a unique venturi design

which enables smaller pumps to circulate

large volumes of tank solution. The eductor

will circulate four to five gallons of solution for

each gallon pumped.

BEX eductors are used for mixing chemicals,

suspending solids, adjusting pH, sweeping

debris or sludge toward a filter intake and

many other useful applications.

CONSTRUCTION:

Standard materials are cast CF8M (316)

Other materials are available upon request.

TYPICAL APPLICATIONS:

Plating Tanks

Cleaning Tanks

Phosphating Tanks

Fertilizer Tanks

Pulp Tanks

Sludge Tanks

Anodizing Tanks

Cooling Towers

Decorative Fountains

The capacity table provides the flow

of water through the nozzle orifice.

To determine discharge, multiply this

value by five (5).

MODEL Pipe Dim. Dim.

NUMBER Size L D

T0M

3

/

8

NPT Male 4

1

/

2

2

1

/

8

T2M

3

/

4

NPT Male 6

3

/

8

3

T3M 1 NPT Male

8

1

/

2

3

3

/

4

T4M

1

1

/

2

NPT Male 9

7

/

8

4

5

/

8

T5 2" NPT Female

12

1

/

4

4

7

/

8

T6 3" NPT Female

17

1

/

8

7

1

/

2

T22M

3

/

4

NPT Male 6

3

/

8

3

10 15 20 25 30 35 40 50

psi psi psi psi psi psi psi psi

T0M 0.288 7.5 9.2 10.6 11.9 13.0 14.0 15.0 16.8

T22M 0.386 13.5 16.5 19.1 21.0 23.0 25.0 27.0 30.0

T2M 0.422 16.1 19.7 22.8 25.0 27.0 30.0 32 36

T3M 0.481 21.0 26.0 30.0 33 36 39 42 47

T4M 0.612 33 40 47 52 57 62 66 74

T5 0.781 55 67 78 57 95 103 110 123

T6 1.188 126 154 178 199 218 236 252 282

Model

Max. Free

Passage

(in)

CAPACITY AT VARIOUS PRESSURES

(USGPM)

20 30 40 60 80 100 120 150

psi psi psi psi psi psi psi psi

T0M 0.288 136 175 214 293 371 450 214 646

T2M 0.386 212 273 334 456 579 701 334 1006

T3M 0.481 352 453 555 758 861 1164 555 1671

T4 0.612 590 760 930 1270 1610 1950 930 2800

T5 0.781 896 1154 1412 1929 2445 2962 1412 4253

T6 1.188 1975 2544 3113 4252 5390 6528 3113 9374

Model

Max. Free

Passage

(in)

STEAM CAPACITIES (lbs/hr)

AT VARIOUS PRESSURES (psi)

USING BEX EDUCTORS AS

STEAM SPARGERS:

APPLICATIONS:

BEX Steam Spargers heat water and other

liquids quickly and efficiently by direct

injection of steam. They are designed

for tank immersion and eliminate water

hammer noise.

SELECTING THE RIGHT EDUCTOR:

(1) Calculate the required steam flow rate from

the following equation:

(2) Knowing the steam flow rate and the steam

pressure available at the sparger, choose the

sparger(s) from the table below. Using several

small spargers may be advisable to using one

large sparger.

(3) To help eliminate steam hammer, ensure

that the minimum absolute pressure of the

eductor is at least twice the absolute pressure

inside the tank, at eductor depth.

Note:

1 Imperial gallon of water = 10.00 lbs.

1 cubic foot of water = 62.40 lbs.

1 U.S. gallon of water = 8.33 lbs.

1 litre of water = 2.20 lbs.

Temp. increase of water (F)

x weight of water (lbs.)

Time allowed to heat

tank (hrs.) x 1000

BEX_TM_STAINLESS 30-Oct-2013

You might also like

- TopLine Katalog Original EnglDocument36 pagesTopLine Katalog Original EnglAnonymous KB3AksTpBNo ratings yet

- Zullar PumpDocument2 pagesZullar PumpKeyur ShahNo ratings yet

- API 521 Flare Knockout Drum SizingDocument35 pagesAPI 521 Flare Knockout Drum Sizingnghiemta1892% (13)

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 pagesSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranNo ratings yet

- Climmy TopLine ENG Lindab PDFDocument43 pagesClimmy TopLine ENG Lindab PDFMussawer HasnainNo ratings yet

- Check-Mate: Ram and Uni-Drum Package Selection GuideDocument11 pagesCheck-Mate: Ram and Uni-Drum Package Selection Guidevasuraj002No ratings yet

- Dokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex deDocument19 pagesDokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex decarlosNo ratings yet

- Tutorial 1Document5 pagesTutorial 1Abhishek KumarNo ratings yet

- SVS Well hydraulic calculations and drilling parametersDocument1 pageSVS Well hydraulic calculations and drilling parametershuangjlNo ratings yet

- Industrial Steam Tray ST5 PDFDocument4 pagesIndustrial Steam Tray ST5 PDFKim Swee LimNo ratings yet

- Boiler Specification 2Document3 pagesBoiler Specification 2AbdulBasitNo ratings yet

- Efficient Pumps for Wastewater and Sewage HandlingDocument39 pagesEfficient Pumps for Wastewater and Sewage HandlingpapashoNo ratings yet

- Wevic 0001 enDocument5 pagesWevic 0001 enamekkehNo ratings yet

- Mud Tool KitDocument52 pagesMud Tool KitChris RoarkNo ratings yet

- Costing For SwroDocument1,021 pagesCosting For Swroganesh100% (2)

- Brahma Pumps MaintananceDocument19 pagesBrahma Pumps MaintanancePavel SokolovNo ratings yet

- Grit Removal DesignDocument5 pagesGrit Removal Designnassif75No ratings yet

- E-Self Priming PumpsDocument27 pagesE-Self Priming PumpsTeguh SetionoNo ratings yet

- CMSH Brochure ReducedDocument6 pagesCMSH Brochure ReducedTim SquareNo ratings yet

- Equipment DesignDocument8 pagesEquipment Designnirmal_subudhiNo ratings yet

- TM - MHW - 2010 - 50-60Hz (UMITA)Document21 pagesTM - MHW - 2010 - 50-60Hz (UMITA)Rodrigo Neira De Fino100% (2)

- Fuel Oil PumpDocument8 pagesFuel Oil PumprezashahalamNo ratings yet

- 131A Piping Brochure PDFDocument12 pages131A Piping Brochure PDFAnonymous UCKYGHcL100% (1)

- Cold Box Pipe Sizing GuideDocument16 pagesCold Box Pipe Sizing GuideLuiz RibeiroNo ratings yet

- Hydraulic Triplex Pumps at The Heart of IndustryDocument12 pagesHydraulic Triplex Pumps at The Heart of IndustryLui Yi BlancoNo ratings yet

- 05 - 3 Piston Cartridge PumpsDocument2 pages05 - 3 Piston Cartridge PumpsJose FernandezNo ratings yet

- PROPANE TANK SPECIFICATIONS AND PROPERTIESDocument25 pagesPROPANE TANK SPECIFICATIONS AND PROPERTIESNicandroGonzalesNo ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNo ratings yet

- KSB B Deep Well Turbine Pump Technical DataDocument36 pagesKSB B Deep Well Turbine Pump Technical DataKishore Krishna0% (1)

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Document5 pagesVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardNo ratings yet

- 131A Piping BrochureDocument12 pages131A Piping Brochuredeanewing11No ratings yet

- SP2710X15 PDFDocument2 pagesSP2710X15 PDFDaniel PerezNo ratings yet

- BB CB SprayMaster Boiler-BookDocument7 pagesBB CB SprayMaster Boiler-BookMOHAMMADNo ratings yet

- Sheffer Piston AccumulatorsDocument4 pagesSheffer Piston AccumulatorsSean PorterNo ratings yet

- Cylinder and Container GuideDocument12 pagesCylinder and Container GuideClaudio SantellanesNo ratings yet

- ARO Flo 1500 SeriesDocument11 pagesARO Flo 1500 SeriesEliasNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetsyamsudin200683% (6)

- Design flow and dimensions of bar screen and fine screenDocument73 pagesDesign flow and dimensions of bar screen and fine screenDavid LambertNo ratings yet

- Grundfosliterature 146014Document12 pagesGrundfosliterature 146014Mario Daniel MoreiraNo ratings yet

- Pulsed Cleanout and Stimulation Tool: HydroblastDocument6 pagesPulsed Cleanout and Stimulation Tool: HydroblastsuifengniliuNo ratings yet

- Safety Relief Valves For Steam, Air, Gas and Vapors: F-SSRV - QXD 4/11/08 2:18 PM Page 1Document12 pagesSafety Relief Valves For Steam, Air, Gas and Vapors: F-SSRV - QXD 4/11/08 2:18 PM Page 1sathiya narayananNo ratings yet

- Modern High-Efficiency Heat PumpsDocument14 pagesModern High-Efficiency Heat PumpsbejntNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- KELTEC Water SeparatorsDocument1 pageKELTEC Water SeparatorsSAUL OSPINONo ratings yet

- Eaton Vickers Cylinders Hydro TransDocument592 pagesEaton Vickers Cylinders Hydro TransCentral HydraulicsNo ratings yet

- Design of AbsorberDocument18 pagesDesign of AbsorberAdeel Ahmed100% (2)

- Torque Values for Spiral Wound GasketsDocument11 pagesTorque Values for Spiral Wound GasketsloqNo ratings yet

- General: Lutz-Jesco GMBHDocument8 pagesGeneral: Lutz-Jesco GMBHsushant_jhawerNo ratings yet

- Catalog Lowara PDFDocument47 pagesCatalog Lowara PDFMariana VacaruNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- Grundfos UPBasic Circulator pumps data bookletDocument12 pagesGrundfos UPBasic Circulator pumps data bookletwwwdotcomatNo ratings yet

- Maximum Pull Load Capacity Api Sucker Rods: "Complete Rod Pumping Optimization, Design & Services"Document1 pageMaximum Pull Load Capacity Api Sucker Rods: "Complete Rod Pumping Optimization, Design & Services"AngelosNo ratings yet

- Review - 2 - 20bt01d079Document25 pagesReview - 2 - 20bt01d079Jay Sheth9No ratings yet

- Revised DraftDocument45 pagesRevised DraftEva LloydNo ratings yet

- Reservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesDocument15 pagesReservoir Accessories: Filler Breathers, Strainers, Diffusers, Fluid Level/Temperature GaugesPartsGopher.comNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.From EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.No ratings yet

- OPES2024_Brochure_V7Document12 pagesOPES2024_Brochure_V7Simbu ArasanNo ratings yet

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- XtrasDocument3 pagesXtrasSimbu ArasanNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- Steam Turbine Q & ADocument47 pagesSteam Turbine Q & Asrikanth9555100% (1)

- Thermal fatigue and brittle fracture mechanismsDocument3 pagesThermal fatigue and brittle fracture mechanismsSimbu Arasan100% (1)

- My Desk: Time Is GoldDocument22 pagesMy Desk: Time Is GoldSimbu ArasanNo ratings yet

- Serag4000 NotesDocument19 pagesSerag4000 NotesSimbu ArasanNo ratings yet

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocument4 pagesMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanNo ratings yet

- 510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFDocument1 page510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFshakeelahmadjsrNo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- CSWIP-WI-6-92 13th Edition July 2015 PDFDocument17 pagesCSWIP-WI-6-92 13th Edition July 2015 PDFjaisonaeroNo ratings yet

- Uts, Utn, Dry - Weld History Sheet - MasterDocument461 pagesUts, Utn, Dry - Weld History Sheet - MasterSimbu ArasanNo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocument8 pages001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- 003 - Standard Procedure For Coating and WrappingDocument6 pages003 - Standard Procedure For Coating and WrappingSimbu ArasanNo ratings yet

- SaarnaDocument3 pagesSaarnagueridiNo ratings yet

- 004 - Standard Procedure For Surface Preparation and PaintingDocument9 pages004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanNo ratings yet

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Document4 pagesTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- EPS Withdrawal FormDocument5 pagesEPS Withdrawal FormArun AbNo ratings yet

- BHEL Earthing SystemDocument8 pagesBHEL Earthing SystemSimbu ArasanNo ratings yet

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocument2 pagesSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanNo ratings yet

- UF NF Dispatch Master Data 04-11-15Document47 pagesUF NF Dispatch Master Data 04-11-15Simbu ArasanNo ratings yet

- 2645r - Waterproofing Compounds For Concrete and Cement MortarsDocument13 pages2645r - Waterproofing Compounds For Concrete and Cement MortarsSimbu ArasanNo ratings yet

- RO Plant Operation GuidelinesDocument5 pagesRO Plant Operation GuidelinesSimbu ArasanNo ratings yet

- 006 CBCRDT Tata ProjectsDocument3 pages006 CBCRDT Tata ProjectsSimbu ArasanNo ratings yet

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocument3 pagesHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244No ratings yet

- UF Membrane Storage & PreservationDocument1 pageUF Membrane Storage & PreservationSimbu ArasanNo ratings yet

- Structural Tank Instructions 11967-ADocument22 pagesStructural Tank Instructions 11967-Aiftikhar_khalid_1No ratings yet

- JK Paper Q4FY11 Earnings Call TranscriptDocument10 pagesJK Paper Q4FY11 Earnings Call TranscriptkallllllooooNo ratings yet

- A6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Document12 pagesA6 2018 D Validation Qualification Appendix6 QAS16 673rev1 22022018Oula HatahetNo ratings yet

- Advanced Ultrasonic Flaw Detectors With Phased Array ImagingDocument16 pagesAdvanced Ultrasonic Flaw Detectors With Phased Array ImagingDebye101No ratings yet

- Telco XPOL MIMO Industrial Class Solid Dish AntennaDocument4 pagesTelco XPOL MIMO Industrial Class Solid Dish AntennaOmar PerezNo ratings yet

- Chapter 16 - Energy Transfers: I) Answer The FollowingDocument3 pagesChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1No ratings yet

- Sto - Cristo Proper Integrated School 1 Grading Grade 9 Science Table of SpecializationDocument2 pagesSto - Cristo Proper Integrated School 1 Grading Grade 9 Science Table of Specializationinah jessica valerianoNo ratings yet

- Current Relays Under Current CSG140Document2 pagesCurrent Relays Under Current CSG140Abdul BasitNo ratings yet

- Motor GraderDocument24 pagesMotor GraderRafael OtuboguatiaNo ratings yet

- Lightwave Maya 3D TutorialsDocument8 pagesLightwave Maya 3D TutorialsrandfranNo ratings yet

- DK Children Nature S Deadliest Creatures Visual Encyclopedia PDFDocument210 pagesDK Children Nature S Deadliest Creatures Visual Encyclopedia PDFThu Hà100% (6)

- The Templist Scroll by :dr. Lawiy-Zodok (C) (R) TMDocument144 pagesThe Templist Scroll by :dr. Lawiy-Zodok (C) (R) TM:Lawiy-Zodok:Shamu:-El100% (5)

- Cyclograph User ManualDocument15 pagesCyclograph User ManualPeter BateNo ratings yet

- O2 Orthodontic Lab Catalog PDFDocument20 pagesO2 Orthodontic Lab Catalog PDFplayer osamaNo ratings yet

- QP (2016) 2Document1 pageQP (2016) 2pedro carrapicoNo ratings yet

- Discuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?Document4 pagesDiscuss The Challenges For Firms To Operate in The Hard-Boiled Confectionery Market in India?harryNo ratings yet

- Ancient MesopotamiaDocument69 pagesAncient MesopotamiaAlma CayapNo ratings yet

- Swami Rama's demonstration of voluntary control over autonomic functionsDocument17 pagesSwami Rama's demonstration of voluntary control over autonomic functionsyunjana100% (1)

- ML AiDocument2 pagesML AiSUYASH SHARTHINo ratings yet

- g4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDocument144 pagesg4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDevin DickenNo ratings yet

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranNo ratings yet

- Chain Surveying InstrumentsDocument5 pagesChain Surveying InstrumentsSachin RanaNo ratings yet

- FST Handbook 2014-Final Copy 1 PDFDocument382 pagesFST Handbook 2014-Final Copy 1 PDFDelvon DownerNo ratings yet

- Monster of The Week Tome of Mysteries PlaybooksDocument10 pagesMonster of The Week Tome of Mysteries PlaybooksHyperLanceite XNo ratings yet

- What Is DSP BuilderDocument3 pagesWhat Is DSP BuilderĐỗ ToànNo ratings yet

- Library Dissertation in Community DentistryDocument9 pagesLibrary Dissertation in Community DentistryPayForPaperCanada100% (1)

- Sradham ChecklistDocument9 pagesSradham ChecklistpswaminathanNo ratings yet

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDocument10 pagesOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiNo ratings yet

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocument81 pages1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- Air Wellness QRSDocument2 pagesAir Wellness QRSapi-3743459No ratings yet

- Hyperbaric WeldingDocument17 pagesHyperbaric WeldingRam KasturiNo ratings yet