Professional Documents

Culture Documents

Cladiri Inalte Model

Uploaded by

Bogdan BîngăCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cladiri Inalte Model

Uploaded by

Bogdan BîngăCopyright:

Available Formats

Technical University Gh.

Asachi from Iasi

Faculty of Civil Engineering and Building Services

Master of Structural Engineering

REINFORCED CONCRETE

STRUCTURES FOR TALL

BUILDINGS

Student: Coordinator:

Irimia Cristian Radu Prof. dr. ing. Gosav Ionel

1. Project theme

It is required that each student to design one floor (n

th

=1) from the reinforced concrete

structure with the height of P+17E.

The used number of floor designed is: n=1

There are given the following data:

- The building is placed in city of Bucharest

- The structure is made of reinforced concrete frames, the infilling is made of B.C.A.

blocks

- The foundation system is realized by a general mat with foundation beams and piles.

- The buildings destination: Block of flats

- The 1

st

floor height is 4.8 m, current floors height is 3.45 m, and the floors 16

th

and

17

th

have a height of 4.95 m.

- In plan dimensions are: 32.45 by 29.6 m

The materials used are:

E

b

=30500 N/mm

2

(C25/30)

E

bg

=0.6E

b

for beams and floors

E

bs

=0.8E

b

for columns

2. Structure element pre-sizing and load computation

2.1.Load computation

2.1.1 Permanent loads

a. Thermo-insulation weight:

b. Floor self weight and leveling screed:

c. Infilling walls self weight:

d. Plaster self-weight:

2.1.2 Variable loads

a. Snow load:

Where:

- form factor for flat roofs

- exposure factor

- thermal coefficient for roofs with usual thermo-insulation

characteristic value for snow load from the soil level (CR 1-1-32005)

b. Live load

2.1.3 Exceptional loads (Seismic action)

According to P100/2006 we have the following coefficients:

corner period

behaviour factor

factor depending on the importance class

maximum dinamic amplify factor

ground acceleration factor

2.2.Element pre-sizing

2.2.1. Determining the beam dimensions (modulated to plus 50 mm)

(P-E5:)

h

g

=max(L;T)/8=max(825; 819) mm 850 mm

b

g

=(0,3 0,5)h

g

=0.5 h

g

=425 mm 450 mm

(E6-E11)

h

g

=max(L;T)/10=max(660; 655) mm 700 mm

b

g

=(0,3-0,5)h

g

= 0.5 h

g

=350 mm

(E12-E17)

h

g

=max(L;T)/12=max(550; 546) mm =550 mm

b

g

=(0,3-0,5)h

g

=0.5 h

g

=275mm 300 mm

L and T

maximum opening on longitudinal and transversal direction

L=6600 mm T=6550 mm

Ed

s

cd

N

h

f u

=

2.2.2. Determining the floor height (modulated to plus 10 mm)

h

p

=max(h

p1

; h

p2

)=max (156; 152.5) mm=156 mm 160 mm

h

p1

=20mm + P/180=20+24500/180=156 mm

P=2(L

0

+T

0

)=2(6100+6150)=24500 mm

L

0

and T

0

the maximum span on longitudinal and transversal direction

h

p2

= min (L

0

;T

0

)/40=min (154;152.5) mm =152.5 mm

L

0

=L- b

g

=6600-450=6150 mm

T

0

=T- b

g

=6550-450=6100 mm

2.2.3. Determining the secondary beam dimensions from the 16

th

and 17

th

floors (modulated

to plus 50 mm)

h

gs

=max(L;T)/15=max(6600; 6550)/15=max (440; 437) mm=440mm 450mm

b

gs

=(0,3-0,5)h

gs

=0.5 h

gs

=225mm 250 mm

2.2.4. Column pre-sizing (modulated to plus 50 mm)

The columns will have 3 steps in section variation (P-E5), (E6-E11) i (E12-E17)

The maximum axial forces from the columns will be determined using the data from the

combination: 1P+0.4U+0.4Z.

In order to determine the final dimensions for the columns we first impose an initial section

of 400X400 mm, after one run with a structural program we obtain the following axial forces

and we determined the actual section for each column:

Where:

-the section area of the column

- the column height

- normalized axial force coefficient

2 Ed

bs s s s

cd

N

A b h h

f u

= = >

=25/1.5=16.66 N/mm

2

- design compressive strength for concrete C25/30

- design axial force

a. P-E5

- Marginal column N

1m

=3902.22 kN

- Central column N

1c

=5947.13 kN

b. E6-E11

- Marginal column N

2m

=2449.59 kN

- Central column N

2c

=3511.11 kN

c. E12-E17

- Marginal column N

3m

=1112.56 kN

- Central column N

3c

=1768.28 kN

3. Static computation

With all element dimensions are determined we can now compute a final structural

analysis in order to obtain the final efforts, displacements, period of vibration and diagrams.

3.1.Static combinations

We will use the following combinations:

A. ULS:

i. 1.35P+1.5U+1.05Z

ii. 1.35P+1.05U+1.5Z

iii. P+0.4U+0.4Z+1.2S

x

+

iv. P+0.4U+0.4Z+1.2S

x

-

v. P+0.4U+0.4Z+1.2S

y

+

vi. P+0.4U+0.4Z+1.2S

y

-

B. SLS:

i. P+0.4U+0.4Z+0.72S

x

+

ii. P+0.4U+0.4Z+0.72S

x

-

iii. P+0.4U+0.4Z+0.72S

y

+

iv. P+0.4U+0.4Z+0.72S

y

-

3.2.Diagrams

3.2.1. Vibration modes

a. Mode 1 of vibration: T=1.410 s b. Mode 2 of vibrations: T=1.352 s

c. Mode 3 of vibration: T=1.132 s

3.2.2. Effort diagrams for columns Fx, Fy, Fz, My, Mz (SLU1-4, envelope min-max)

i. Fx:

a. Marginal column

b. Central column

ii. Fy:

a. Marginal column

b. Central column

iii. Fz:

a. Marginal column

b. Central column

iv. My:

a. Marginal column

b. Central column

v. Mz:

a. Marginal column

b. Central column

3.2.3. Bending moment diagram for beams My (kNm) (SLU1-4, envelope min-max)

a. Beam on x direction

b. Beam on y direction

3.2.4. Bending moment diagram for floor m

xx

(kNm/m) (SLU1 or SLU2-E3)

3.2.5. Bending moment diagram for floor m

yy

(kNm/m) (SLU1 or SLU2-E3)

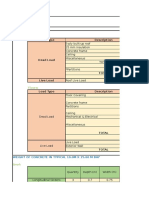

4. Floor design

Determining the reinforcement area for direction x

Panel

Mxx (kNm) b d fcd

Reinforcement

area (mm2)

Support Span mm mm N/mm2 Support Span Support Span Support Span

p1 28.34 26.69 1000 130 16.66 0.1007 0.0948 0.1063 0.0998 767.46 720.29

p2 13.27 17.39 1000 130 16.66 0.0471 0.0618 0.0483 0.0638 348.68 460.59

p3 25.96 24.49 1000 130 16.66 0.0922 0.0870 0.0969 0.0911 699.53 657.93

p4 27.49 23.93 1000 130 16.66 0.0976 0.0850 0.1029 0.0889 743.12 642.15

p5 36.11 36.27 1000 130 16.66 0.1283 0.1288 0.1377 0.1384 994.38 999.14

p6 31.74 27.95 1000 130 16.66 0.1127 0.0993 0.1199 0.1048 865.76 756.28

p7 23.04 31.24 1000 130 16.66 0.0818 0.1110 0.0855 0.1179 617.15 851.21

p8 30.04 27.33 1000 130 16.66 0.1067 0.0971 0.1131 0.1023 816.42 738.55

p9 33.68 31.18 1000 130 16.66 0.1196 0.1107 0.1278 0.1177 922.53 849.46

p10 39.67 38.7 1000 130 16.66 0.1409 0.1375 0.1525 0.1485 1101.16 1071.88

p11 30.06 27.71 1000 130 16.66 0.1068 0.0984 0.1132 0.1038 817.00 749.41

p12 20.86 34.71 1000 130 16.66 0.0741 0.1233 0.0771 0.1320 556.31 952.89

p13 11.57 5.64 1000 130 16.66 0.0411 0.0200 0.0420 0.0202 303.03 146.09

p14 30.26 29.05 1000 130 16.66 0.1075 0.1032 0.1140 0.1091 822.78 787.86

p15 39.35 38.45 1000 130 16.66 0.1398 0.1366 0.1512 0.1474 1091.48 1064.36

p16 33.75 30.16 1000 130 16.66 0.1199 0.1071 0.1281 0.1136 924.59 819.89

p17 25.58 35.54 1000 130 16.66 0.0909 0.1262 0.0954 0.1354 688.75 977.45

p18 25.72 24.86 1000 130 16.66 0.0914 0.0883 0.0960 0.0926 692.72 668.38

p19 29.14 24.15 1000 130 16.66 0.1035 0.0858 0.1095 0.0898 790.45 648.34

p20 38.39 38.86 1000 130 16.66 0.1364 0.1380 0.1472 0.1491 1062.55 1076.70

p21 31.52 28.88 1000 130 16.66 0.1120 0.1026 0.1190 0.1085 859.35 782.97

p22 19.36 30.06 1000 130 16.66 0.0688 0.1068 0.0713 0.1132 514.76 817.00

p23 32.37 26.81 1000 130 16.66 0.1150 0.0952 0.1225 0.1002 884.14 723.71

p24 30.06 35.58 1000 130 16.66 0.1068 0.1264 0.1132 0.1356 817.00 978.64

p25 37.67 37.31 1000 130 16.66 0.1338 0.1325 0.1442 0.1427 1040.94 1030.17

Determining the effective reinforcement area on x direction

Panel

Effective

reinforcement

Number of bar/m

area (mm2)

Support Span Support Span

p1 1017 904 9 8

p2 565 565 5 5

p3 904 904 8 8

p4 904 791 8 7

p5 1243 1243 11 11

p6 1130 1017 10 9

p7 791 1130 7 10

p8 1017 904 9 8

p9 1130 1130 10 10

p10 1356 1356 12 12

p11 1017 1017 9 9

p12 678 1243 6 11

p13 565 565 5 5

p14 1017 1017 9 9

p15 1356 1356 12 12

p16 1130 1017 10 9

p17 904 1243 8 11

p18 904 904 8 8

p19 1017 791 9 7

p20 1356 1356 12 12

p21 1130 1017 10 9

p22 678 1017 6 9

p23 1130 904 10 8

p24 1017 1017 9 9

p25 1356 1356 12 12

Determining the reinforcement on y direction

Panel

Myy (kNm) b d fcd

Reinforcement

area (mm2)

Support Span mm mm N/mm2 Support Span Support Span Support Span

p1 19.90 12.49 1000 118 16.66 0.0858 0.0538 0.0898 0.0554 588.58 362.87

p2 13.49 7.87 1000 118 16.66 0.0582 0.0339 0.0600 0.0345 392.85 226.22

p3 14.07 7.93 1000 118 16.66 0.0607 0.0342 0.0626 0.0348 410.30 227.98

p4 17.36 7.77 1000 118 16.66 0.0748 0.0335 0.0779 0.0341 510.26 223.30

p5 22.93 17.09 1000 118 16.66 0.0988 0.0737 0.1043 0.0766 683.37 502.00

p6 32.94 31.48 1000 118 16.66 0.1420 0.1357 0.1538 0.1464 1008.04 959.51

p7 31.96 31.37 1000 118 16.66 0.1378 0.1352 0.1489 0.1459 975.42 955.87

p8 37.21 33.09 1000 118 16.66 0.1604 0.1426 0.1759 0.1546 1152.47 1013.05

p9 42.14 35.52 1000 118 16.66 0.1817 0.1531 0.2021 0.1671 1324.19 1094.85

p10 42.06 35.06 1000 118 16.66 0.1813 0.1511 0.2016 0.1647 1321.36 1079.27

p11 22.83 17.46 1000 118 16.66 0.0984 0.0753 0.1038 0.0783 680.22 513.33

p12 15.26 20.28 1000 118 16.66 0.0658 0.0874 0.0681 0.0916 446.27 600.39

p13 11.23 14.97 1000 118 16.66 0.0484 0.0645 0.0496 0.0668 325.31 437.48

p14 16.35 15.65 1000 118 16.66 0.0705 0.0675 0.0732 0.0699 479.40 458.10

p15 28.38 19.81 1000 118 16.66 0.1223 0.0854 0.1309 0.0894 857.85 585.79

p16 40.52 38.97 1000 118 16.66 0.1747 0.1680 0.1934 0.1851 1267.15 1213.14

p17 39.49 38.48 1000 118 16.66 0.1702 0.1659 0.1879 0.1825 1231.20 1196.18

p18 13.64 9.45 1000 118 16.66 0.0588 0.0407 0.0606 0.0416 397.36 272.62

p19 36.18 33.31 1000 118 16.66 0.1560 0.1436 0.1705 0.1557 1117.28 1020.41

p20 37.09 35.18 1000 118 16.66 0.1599 0.1517 0.1752 0.1653 1148.36 1083.33

p21 20.07 20.80 1000 118 16.66 0.0865 0.0897 0.0906 0.0941 593.86 616.58

p22 22.09 30.13 1000 118 16.66 0.0952 0.1299 0.1003 0.1396 656.94 915.01

p23 38.98 40.28 1000 118 16.66 0.1680 0.1736 0.1852 0.1921 1213.49 1258.75

p24 39.59 39.68 1000 118 16.66 0.1707 0.1711 0.1884 0.1889 1234.68 1237.81

p25

22.43 19.88 1000 118 16.66 0.0967 0.0857 0.1019 0.0897 667.63 587.96

Determining the effective reinforcement area on y direction

Panel

Effective

reinforcement

Number of bar/m

area (mm2)

Support Span Support Span

p1 1017 904 9.00 8.00

p2 565 565 5.00 5.00

p3 904 904 8.00 8.00

p4 904 791 8.00 7.00

p5 1243 1243 11.00 11.00

p6 1130 1017 10.00 9.00

p7 791 1130 7.00 10.00

p8 1017 904 9.00 8.00

p9 1130 1130 10.00 10.00

p10 1356 1356 12.00 12.00

p11 1017 1017 9.00 9.00

p12 678 1243 6.00 11.00

p13 565 565 5.00 5.00

p14 1017 1017 9.00 9.00

p15 1356 1356 12.00 12.00

p16 1130 1017 10.00 9.00

p17 904 1243 8.00 11.00

p18 904 904 8.00 8.00

p19 1017 791 9.00 7.00

p20 1356 1356 12.00 12.00

p21 1130 1017 10.00 9.00

p22 678 1017 6.00 9.00

p23 1130 904 10.00 8.00

p24 1017 1017 9.00 9.00

p25

1356 1356 12.00 12.00

5. Beam design

5.1.Determining the design bending moment on x direction

5.1.1. Determining the longitudinal reinforcement in the supports

d= h

w

-a-/2 (mm)=850-30-20/2=810mm

2

14 13 14 13

(0.5 )

14 0.5 ( )

2

c

Ed MAX c

q h

M M R h kNm

= +

14 13 13 14

14 ( )

2

MAX SLU

M M qL

R kN

L

+

= +

2

Ed

w cd

M

b d f

=

(1 1 2 ) x d =

2

2 2

( )

w cd

w cd s yd s w

yd

x b f

x b f A f A b d mm

f

= = >

0.5

ctm

yk

f

f

=

f

cd

= 16,66

(N/mm

2

) C25/30

f

yd

= f

yk

/

s

=345/1,15=300

(N/mm

2

) PC52

f

ctm

= 2,6

(N/mm

2

) C25/30

M

rb2

=A

s2r

f

yd

(d-0,5x

r

) (kNm)

Support A:

( ) ( )

=520

) ( )

Support B:

( ) ( )

=520

) ( )

2

( )

s r yd

r

w cd

A f

x mm

b f

=

Support C:

( ) ( )

=420

) ( )

Support D:

( ) ( )

=420

) ( )

Support E:

( ) ( )

=420

) ( )

Support F:

( ) ( )

=420

) ( )

5.1.2. Determining the longitudinal reinforcement in mid span

-if the beam connects with marginal column

-if the beam connects with central column

Span 1:

2

Ed

eff cd

M

b d f

=

2

1 1 2

0.5 ( )

eff cd

eff cd s yd s w s r

yd

x b f

x b f A f A b d A mm

f

= = > >

1

( )

s r yd

r

f cd

A f

x mm

b f

=

eff s

b h =

2

eff s f

b h h = +

( ) ( )

=522

Span 2:

( ) ( )

=420

Span 3:

( ) ( )

=420

Span 4:

( ) ( )

=420

Span 5:

( ) ( )

=420

5.2.Determining the design bending moment on y direction

5.2.1. Determining the longitudinal reinforcement in the supports

d= h

w

-a-/2 (mm)=850-30-20/2=810mm

f

cd

= 16,66

(N/mm

2

) C25/30

f

yd

= f

yk

/

s

=345/1,15=300

(N/mm

2

) PC52

2

14 13 14 13

(0.5 )

14 0.5 ( )

2

c

Ed MAX c

q h

M M R h kNm

= +

14 13 13 14

14 ( )

2

MAX SLU

M M qL

R kN

L

+

= +

2

Ed

w cd

M

b d f

=

(1 1 2 ) x d =

2

2 2

( )

w cd

w cd s yd s w

yd

x b f

x b f A f A b d mm

f

= = >

0.5

ctm

yk

f

f

=

f

ctm

= 2,6

(N/mm

2

) C25/30

M

rb2

=A

s2r

f

yd

(d-0,5x

r

) (kNm)

Support A:

( ) ( )

=420

) ( )

Support B:

( ) ( )

=420

) ( )

Support C:

( ) ( )

2

( )

s r yd

r

w cd

A f

x mm

b f

=

=420

) ( )

Support D:

( ) ( )

=420

) ( )

Support E:

( ) ( )

=420

) ( )

Support F:

( ) ( )

=420

) ( )

5.2.2. Determining the longitudinal reinforcement in mid span

-if the beam connects with marginal column

-if the beam connects with central column

Span 1:

( ) ( )

=520

2

Ed

eff cd

M

b d f

=

2

1 1 2

0.5 ( )

eff cd

eff cd s yd s w s r

yd

x b f

x b f A f A b d A mm

f

= = > >

1

( )

s r yd

r

f cd

A f

x mm

b f

=

eff s

b h =

2

eff s f

b h h = +

Span 2:

( ) ( )

=420

Span 3:

( ) ( )

=420

Span 4:

( ) ( )

=420

Span 5:

( ) ( )

=420

5.3. Determining the transversal reinforcement

5.3.1. Determining the transversal reinforcement for beam on x direction

1

,max

( )

( )

cw w cd

Rd Ed

b z v f

V V kN

ctg tg

o

u u

= >

+

ctgu

cw

=1 coefficient that takes into account the efforts from compressed fiber

z=0.9d

v

1

=0,6 coefficient of strength reduction for cracked concrete due to shear force

max (ctg

1

; ctg

2

)1 (if the condition is not satisfied, the section must be modified)

ctg2.5 (if results a greater value, it is taken into account ctg =2.5)

s=100 mm

f

ywd

=0.8f

ywk

=0.8255=204 (N/mm

2

) OB37

]

[ ( )

- it is required transversal reinforcement

Propose for transversal reinforcement bar 10

,

( )

SW

Rd s ywd Ed

A

V z f ctg V kN

s

u = s

2

4

bw

SW r

d

A n

t

=

the transversal reinforcement will be placed by construction reasons

5.3.2. Determining the transversal reinforcement for beam on y direction

]

[ ( )

- it is required transversal reinforcement

Propose for transversal reinforcement bar 10

the transversal reinforcement will be placed by construction reasons

6. Column design

6.1.Marginal columns

6.1.1. Determining the design bending moments

Establish of external bending moments is made on each direction (x and y) with the

relation:

, ,max

Rb

Ed y Rd y

Eb

M

M M

M

= - -

Where:

I direction (x or y)

- designing moment on I direction

- over strength factor

- maximum bending moment on column from structural analysis (seismic

combination)

- actual resisting moment on girder disposed in I direction who intersect the node

- bending moment on girder disposed in I direction who intersect the node resulted from

structural analysis

Evaluation of slenderness is obtained according with relation:

the slenderness can be ignored.

6.1.2. Longitudinal reinforcement

a. Direction x

) ( )

the concrete doesnt crack and the column is reinforced by using the minimum

reinforcement percent.

( )

b. Direction y

) ( )

the concrete doesnt crack and the column is reinforced by using the minimum

reinforcement percent.

( )

6.1.3. Checking the biaxial moment

(

6.1.4. Determining the shear force design value

,1 ,2 db db

Ed

level

M M

V

H

+

=

, ,

min(1, )

Rb

db i Rd Rb i

Rc

M

M M

M

= - -

Rd

over strength factor with value 1.2;

M

Rb,i

actual bending moments of the girder that enter the node

M

Rb,i

actual bending moments of the column that enter the node

(

) (

) ( )

(

) (

) ( )

Maximum shear stress level

Constructive reinforcement is needed.

6.1.5. Checking of the relative displacements

ULS checking:

()

SLS checking:

6.2.Central columns

6.2.1. Determining the design bending moments

Establish of external bending moments is made on each direction( x and y) with the

relation:

, ,max

Rb

Ed y Rd y

Eb

M

M M

M

= - -

slenderness can be ignored.

6.2.2. Longitudinal reinforcement

a. Direction x

) ( )

the concrete doesnt crack and the column is reinforced by using the minimum

reinforcement percent.

( )

b. Direction y

6.2.3. Checking the biaxial moment

(

6.2.4. Determining the shear force design value

,1 ,2 db db

Ed

level

M M

V

H

+

=

, ,

min(1, )

Rb

db i Rd Rb i

Rc

M

M M

M

= - -

) (

) ( )

(

) (

) ( )

Maximum shear stress level

Constructive reinforcement is needed

6.2.5. Checking of the relative displacements

ULS checking:

()

SLS checking:

7. Node checking

7.1.Horizontal shear force design

a. Central node

( )

Rd

=1.2 over resisting factor

A

s1

, A

s2

the reinforcement areas from supperior and inferior part of the beams

V

Ed

shear force from the column beneath the node

b. Marginal node

7.2. Checking the horizontal shear force

a. Central node

) (

) ( )

b. Marginal node

7.3.Checking the transversal reinforcement

a. Central node

)

( ) ( )

A

sh

- total area of horizontal stirrups in the node

n

e

- the number of horizontal stirrups in the node

b. Marginal node

)

( )

7.4.Checking the longitudinal reinforcement from the node

A

sv

=8157+4928=6184mm

2

- the vertical reinforcement that pass through the node

A

sh

- the total stirrup area from the node

h

jc

=d-a=890-20=870 mm inter-ax distance between the column reinforcement

h

jw

=d-a=740-20=720 mm inter-ax distance between the beam reinforcement

You might also like

- Structural design and analysis of a low-rise buildingDocument42 pagesStructural design and analysis of a low-rise buildingMohammed SumerNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- The Universe As A HologramDocument8 pagesThe Universe As A HologramMichael Shain100% (1)

- RCC Design Based in Indian CodesDocument43 pagesRCC Design Based in Indian Codeschaos_atulNo ratings yet

- Beam Design Data and CalculationsDocument43 pagesBeam Design Data and CalculationsJessie Radaza TutorNo ratings yet

- Offshore Pipelines Local Buckling AnalysisDocument4 pagesOffshore Pipelines Local Buckling AnalysisshervinyNo ratings yet

- Example Beam Simply Supported With Lateral RestraintDocument11 pagesExample Beam Simply Supported With Lateral RestraintjplezpNo ratings yet

- Roof Calculation Book - UBC DESIGN PDFDocument70 pagesRoof Calculation Book - UBC DESIGN PDFStephanie CampbellNo ratings yet

- Mander's ModelDocument120 pagesMander's Modelpcaizas2No ratings yet

- Soil Bearing Capacity CalcuationsDocument26 pagesSoil Bearing Capacity CalcuationsBishal Thapa MagarNo ratings yet

- Two Way Slab Design (DRAFT)Document72 pagesTwo Way Slab Design (DRAFT)ابو عمر الأسمريNo ratings yet

- PAD FOUNDATION DESIGN To BS 81101997Document15 pagesPAD FOUNDATION DESIGN To BS 81101997Carlos Valverde Portilla100% (1)

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara84% (25)

- Abutment Stability Check BRG 103+500Document33 pagesAbutment Stability Check BRG 103+500Aziz ul HakeemNo ratings yet

- Design of Stair Case With Central Stringer BeamDocument45 pagesDesign of Stair Case With Central Stringer BeamCONSTHURAG2012No ratings yet

- PSC Girder DesignDocument26 pagesPSC Girder DesignLokesh M Yadav100% (5)

- (Arfken) Mathematical Methods For Physicists 7th SOLUCIONARIO PDFDocument525 pages(Arfken) Mathematical Methods For Physicists 7th SOLUCIONARIO PDFJulian Montero100% (3)

- Mindful Math 2: Use Your Geometry to Solve These Puzzling PicturesFrom EverandMindful Math 2: Use Your Geometry to Solve These Puzzling PicturesNo ratings yet

- The History and Physics of Magnetic Particle InspectionDocument51 pagesThe History and Physics of Magnetic Particle InspectiondaemsalNo ratings yet

- Spreadsheets To Eurocode 2: M:N Interaction Chart For 800 X 1,000 Section, Grade 40 ConcreteDocument7 pagesSpreadsheets To Eurocode 2: M:N Interaction Chart For 800 X 1,000 Section, Grade 40 ConcreteAnbalaganVNo ratings yet

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocument34 pagesSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoNo ratings yet

- What Is A Magnetic FieldDocument7 pagesWhat Is A Magnetic Fieldruxandra tudorascuNo ratings yet

- Girder design calculationsDocument16 pagesGirder design calculationsbharatgbNo ratings yet

- Worked Examples Ec2 Def080723Document120 pagesWorked Examples Ec2 Def080723dan_ospir67% (3)

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- A Study On Cohesive Zone ModelDocument19 pagesA Study On Cohesive Zone ModelabishayNo ratings yet

- Design of Water Tank-311207Document32 pagesDesign of Water Tank-311207Uttam Kumar GhoshNo ratings yet

- Anchor and Base Plate CalculationDocument6 pagesAnchor and Base Plate Calculationselahattin_erturk06No ratings yet

- SteelDocument9 pagesSteelMohammedAlasaadNo ratings yet

- Culvert (Excel)Document97 pagesCulvert (Excel)Dwi Ist56% (9)

- Design of Concrete Domes Calculation SheetDocument3 pagesDesign of Concrete Domes Calculation Sheetvaibhavamore0% (1)

- Bridge structural analysis documentDocument847 pagesBridge structural analysis documentras_deepNo ratings yet

- TCC51 Column Load Take-Down DesignDocument202 pagesTCC51 Column Load Take-Down DesignSorinStanescuNo ratings yet

- Strap FootingDocument16 pagesStrap FootingSudan ShresthaNo ratings yet

- Design of Slab Integrated Group 1Document12 pagesDesign of Slab Integrated Group 1let's talkNo ratings yet

- Cven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)Document11 pagesCven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)fflegendsNo ratings yet

- Base Plate For Large MomentsDocument176 pagesBase Plate For Large Momentsfaizan ashiqueNo ratings yet

- WALLAP Run AnalysisDocument11 pagesWALLAP Run AnalysisNizar HalabiNo ratings yet

- TT1 Take Up Foundation New Proposed As Per Depth 2.5m and EccentricDocument21 pagesTT1 Take Up Foundation New Proposed As Per Depth 2.5m and EccentricaashuranjanNo ratings yet

- SSB L SectionDocument20 pagesSSB L SectionMuhammad Azeem KhanNo ratings yet

- Singly Reinforced Concrete Beams AS3600Document6 pagesSingly Reinforced Concrete Beams AS3600Preston WilliamNo ratings yet

- Assignment of SteelDocument25 pagesAssignment of SteelSamih S. BarzaniNo ratings yet

- Job Information: Engineer Checked Approved Name: DateDocument17 pagesJob Information: Engineer Checked Approved Name: DateZitheeq UmarNo ratings yet

- Earthquakemodule 13Document4 pagesEarthquakemodule 13dash1991No ratings yet

- Base Plate IPE200 Fe250Document32 pagesBase Plate IPE200 Fe250Tejas SawantNo ratings yet

- Design (With CB+FP)Document36 pagesDesign (With CB+FP)Subir KundaNo ratings yet

- Perhitungan BlockDocument102 pagesPerhitungan BlockShinta SabrinaNo ratings yet

- Solution: Conservation of EnergyDocument8 pagesSolution: Conservation of Energydist2235No ratings yet

- Design of Scissor Stair - Z TypeDocument9 pagesDesign of Scissor Stair - Z TypebbwhaleNo ratings yet

- Structural ComputationsDocument238 pagesStructural ComputationsbambagenNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Wireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesFrom EverandWireless Power Transfer: Using Magnetic and Electric Resonance Coupling TechniquesNo ratings yet

- Exemplu de Plan SarpantaDocument1 pageExemplu de Plan SarpantaBogdan BîngăNo ratings yet

- Plan ParterDocument1 pagePlan ParterBogdan BîngăNo ratings yet

- Exemplu de Plan SarpantaDocument1 pageExemplu de Plan SarpantaBogdan BîngăNo ratings yet

- Section Through StaircaseDocument1 pageSection Through StaircaseBogdan BîngăNo ratings yet

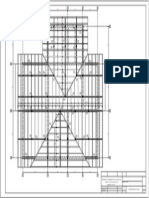

- Formwork PlanDocument1 pageFormwork PlanBogdan BîngăNo ratings yet

- Chapter 12.1 Critical PathDocument1 pageChapter 12.1 Critical PathBogdan BîngăNo ratings yet

- Column Reinforcement ExampleDocument1 pageColumn Reinforcement ExampleBogdan BîngăNo ratings yet

- Plan ParterDocument1 pagePlan ParterBogdan BîngăNo ratings yet

- ReadmeDocument1 pageReadmeBogdan BîngăNo ratings yet

- Plan ParterDocument1 pagePlan ParterBogdan BîngăNo ratings yet

- Force displacement analysis of a beam structureDocument4 pagesForce displacement analysis of a beam structureBogdan BîngăNo ratings yet

- Thermal Insulation Computation AnalysisDocument14 pagesThermal Insulation Computation AnalysisBogdan BîngăNo ratings yet

- Binga Bogdan Advanced Dynamics 2012-2013Document12 pagesBinga Bogdan Advanced Dynamics 2012-2013Bogdan BîngăNo ratings yet

- Special Structures ModelDocument30 pagesSpecial Structures ModelBogdan BîngăNo ratings yet

- Statically Determinate Arches: The Parabolic ArchDocument0 pagesStatically Determinate Arches: The Parabolic ArchSarbu AlexandruNo ratings yet

- Guide RC Project Nagy-Gyorgy T 2013-04-09Document69 pagesGuide RC Project Nagy-Gyorgy T 2013-04-09Bogdan BîngăNo ratings yet

- Systems Theory: Home Work No. 1Document7 pagesSystems Theory: Home Work No. 1Bogdan BîngăNo ratings yet

- Proiect Cladiri RevizuitDocument30 pagesProiect Cladiri RevizuitBogdan BîngăNo ratings yet

- 1 d.o.f. Structures Seismic ResponseDocument18 pages1 d.o.f. Structures Seismic ResponseAlex RotariuNo ratings yet

- Licenta CCIA-partea Scrisa Completa Dupa Eurocod-Strcutura Pe CadreDocument105 pagesLicenta CCIA-partea Scrisa Completa Dupa Eurocod-Strcutura Pe CadreBogdan Bîngă100% (2)

- C4 F (Mod AteDocument13 pagesC4 F (Mod AteRazvanCosminNo ratings yet

- 2 GeotehnicaDocument20 pages2 GeotehnicaBogdan BîngăNo ratings yet

- FEA of A StrcutureDocument22 pagesFEA of A StrcutureBogdan BîngăNo ratings yet

- Student: Bîngå Bogdan Advisor: Dr. Ing. Rosca OctavianDocument21 pagesStudent: Bîngå Bogdan Advisor: Dr. Ing. Rosca OctavianBogdan BîngăNo ratings yet

- Analysis of Soil Structure, Texture, Grain Size Distribution and Clay Mineral ClassificationDocument27 pagesAnalysis of Soil Structure, Texture, Grain Size Distribution and Clay Mineral ClassificationBogdan BîngăNo ratings yet

- Suport Curs Examen Beton II, AsachiDocument32 pagesSuport Curs Examen Beton II, AsachiLungu Lucian DumitruNo ratings yet

- Basic Concepts: Partial Differential Equations (Pde)Document19 pagesBasic Concepts: Partial Differential Equations (Pde)Aztec MayanNo ratings yet

- Roses Amend 12Document477 pagesRoses Amend 12Koert OosterhuisNo ratings yet

- Aircraft Flight Dynamics 2015 - 04 - 13 PDFDocument34 pagesAircraft Flight Dynamics 2015 - 04 - 13 PDFShoeb Ahmed SyedNo ratings yet

- Rolling Friction CoefficientsDocument3 pagesRolling Friction CoefficientsChypraNo ratings yet

- Chapter 11-Seismic Design of Wood and Masonry Buildings PDFDocument60 pagesChapter 11-Seismic Design of Wood and Masonry Buildings PDFKwan-Rin Ratchaneeya100% (1)

- Rh35v-Zik DC 1R 113466Document3 pagesRh35v-Zik DC 1R 113466José Hildo PereiraNo ratings yet

- Applied Mecanics Lab ManualDocument52 pagesApplied Mecanics Lab ManualHasnain BukhariNo ratings yet

- BAM: Enumeration of Escherichia Coli and The Coliform BacteriaDocument8 pagesBAM: Enumeration of Escherichia Coli and The Coliform BacteriatintfenNo ratings yet

- Systematic Approach To Planning Monitoring Program Using Geotechnical InstrumentationDocument19 pagesSystematic Approach To Planning Monitoring Program Using Geotechnical InstrumentationKristina LanggunaNo ratings yet

- Behavior of Steel Under TensionDocument6 pagesBehavior of Steel Under TensionAshNo ratings yet

- CH203 Fall 2014 NMR Practice Quiz 1Document8 pagesCH203 Fall 2014 NMR Practice Quiz 1BUCH203100% (1)

- Evidence My Presentation OutlineDocument6 pagesEvidence My Presentation OutlineJavier Alexis Herrera0% (1)

- Air Bearing 1Document30 pagesAir Bearing 1YashOdeepAthawaleNo ratings yet

- Title Composite Material Data Sheets TabDocument7 pagesTitle Composite Material Data Sheets TabffontanaNo ratings yet

- Luigia Binda-Learning From Failure - Long-Term Behaviour of Heavy Masonry Structures - WIT Press (2008) PDFDocument248 pagesLuigia Binda-Learning From Failure - Long-Term Behaviour of Heavy Masonry Structures - WIT Press (2008) PDFFerenczi Z. SámuelNo ratings yet

- Webers Electrodynamics For Hydrogen AtomDocument8 pagesWebers Electrodynamics For Hydrogen AtomdaveklodavekloNo ratings yet

- Meteoric Water Mobility ProcedureDocument6 pagesMeteoric Water Mobility ProcedureJose ValdesNo ratings yet

- Conservation of MomentumDocument5 pagesConservation of MomentumwscienceNo ratings yet

- Translation Table Annex VII of The CLP Regulation GodalaDocument37 pagesTranslation Table Annex VII of The CLP Regulation GodalaRiccardo CozzaNo ratings yet

- Study BG 462 9 Beams On Elastic FoundationDocument15 pagesStudy BG 462 9 Beams On Elastic Foundationmanish mehtaNo ratings yet

- 1429 (Math and State)Document2 pages1429 (Math and State)Zameer HussainNo ratings yet

- Quantitative Estimation of Tannins by HPLC: Der Pharmacia Lettre March 2016Document5 pagesQuantitative Estimation of Tannins by HPLC: Der Pharmacia Lettre March 2016kun antaNo ratings yet

- Nonlinear Continuum Mechanics Nonlinear Continuum Mechanics: 2. MotionDocument68 pagesNonlinear Continuum Mechanics Nonlinear Continuum Mechanics: 2. Motionahmadomar89No ratings yet

- Fatigue and Fracture PDFDocument31 pagesFatigue and Fracture PDFpericharla ravivarmaNo ratings yet

- Surprising Number Patterns Part I - Pola Bilangan Menakjubkan Bag. IDocument3 pagesSurprising Number Patterns Part I - Pola Bilangan Menakjubkan Bag. IWew NiggaNo ratings yet