Professional Documents

Culture Documents

Aws d1.5 PQR

Uploaded by

jacquesmayol0 ratings0% found this document useful (0 votes)

380 views2 pagesPlat e Pip e Box Tube Sheet Variables Actual Values Used Qualification Range Welding Process SMAW SMA W Process Type Manual Manu al Electrode (Single or Multiple) Single Single Current Type / Polarity DCEP Backing (Yes or No) Yes Yes n / a Filler Metal Classification (AWS Classified) E7018 Any AWS A5 Class Approved Filler Metal F-Number 4 4 (low-hydrogen only) Gas

Original Description:

Original Title

aws d1.5 pqr

Copyright

© © All Rights Reserved

Available Formats

RTF, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPlat e Pip e Box Tube Sheet Variables Actual Values Used Qualification Range Welding Process SMAW SMA W Process Type Manual Manu al Electrode (Single or Multiple) Single Single Current Type / Polarity DCEP Backing (Yes or No) Yes Yes n / a Filler Metal Classification (AWS Classified) E7018 Any AWS A5 Class Approved Filler Metal F-Number 4 4 (low-hydrogen only) Gas

Copyright:

© All Rights Reserved

Available Formats

Download as RTF, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

380 views2 pagesAws d1.5 PQR

Uploaded by

jacquesmayolPlat e Pip e Box Tube Sheet Variables Actual Values Used Qualification Range Welding Process SMAW SMA W Process Type Manual Manu al Electrode (Single or Multiple) Single Single Current Type / Polarity DCEP Backing (Yes or No) Yes Yes n / a Filler Metal Classification (AWS Classified) E7018 Any AWS A5 Class Approved Filler Metal F-Number 4 4 (low-hydrogen only) Gas

Copyright:

© All Rights Reserved

Available Formats

Download as RTF, PDF, TXT or read online from Scribd

You are on page 1of 2

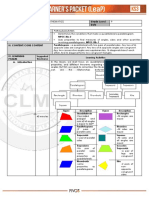

Welding Performance Qualification Record (WPQR)

Welding Code: AWS D1.5

Company Name: Quinn Construction, Inc.

Company Address: 1321 77th Street, East Palmetto, Florida, 34221, USA

Welder's Name: David Turk Identification No: 5240

Type of welder:

Welder

Welding Performance Qualification Record WPQR No. DT-5240 QC-11-SMAW-

1

Qualification Date:

5/4/13

Welding Procedure Specification WPS No. QC-11-SMAW-1 Rev. 0

BASE METALS USED

Material Specification, Type or Grade: ASTM A 36 (T<= 3/4 in. [20 mm])

Plat

e

Pip

e

Box

Tube Sheet

Welded to

Material Specification, Type or Grade: ASTM A 36 (T<= 3/4 in. [20 mm])

Plat

e

Pip

e

Box

Tube Sheet

Variables Actual Values Used Qualification Range

Welding Process SMAW

SMA

W

Process Type Manual

Manu

al

Electrode (Single or Multiple) Single Single

Current Type/Polarity DCEP

Backing (Yes or No) Yes Yes

Testing Position(s) and Qualified Welding Position(s):

Groove n/a n/a

Fillet 3F

F, H,

V

Vertical Progression Uphill Uphill

Plug or Slot Welds

Base Metals Thickness in (mm):

Groove n/a n/a

Fillet

1/2 in. (12 mm), Fig.

5.21

Unlim

ited

Plug or Slot Welds n/a n/a

Base Metals Diameter in (mm) (Pipe or Tube):

Groove n/a n/a

Fillet

Plate

tested n/a

Filler Metal Specification (SFA) A5.1

Filler Metal Classification (AWS Classified) E7018 Any AWS A5 Class Approved

Filler Metal F-Number 4 4 (low-hydrogen only)

Gas/Flux (SAW) n/a n/a

Other Variable (coating type/thickness, etc.) n/a n/a

Results

Visual Inspection of Completed Weld (D1.5, 6.26.1): Acceptable

YE

S NO

Guided Bend Test Type and Results (D1.5, 5.27.3): n/a

Result and Comments:

Fillet-Weld Test Results (D1.5, 5.27.4 and 5.27.6):

Appearance:

Acceptable Fillet Size in (mm): .385

Fracture Test Root Penetration: Acceptable Macroetch: Acceptable

(Describe the location, nature, and size of any crack or tearing of the specimen.)

Result and Comments: Resource id #9

Inspected by: Jonathan B. Stringer Test Number: G-0239-S

Organization: Renegade Testing & Inspection Inc. Date: 5-4-2013

Alternative * Radiographic Test Results (D1.5, 5.26.1) : * In lieu of Guided Bend Test, except for GMAW-S

Film Identification No. Results Remarks

Film Identification

No. Results Remarks

n/a

Film interpreted by:

n/a

Test Number:

n/a

Organization: n/a Date: n/a

Other information: n/a

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in conformance with

the requirements of AWS D1.5M/D1.5:2010, Bridge Welding Code.

Manufacturer/ Contractor Authorized By:

Welding Engineer

Name: Jonathan B. Stringer Name:

Title: CWI - 10081211 Title:

Signature: Signature:

Date: 5-4-13 Date:

You might also like

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- PT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Baosteel hot rolled steel plate quality certificateDocument3 pagesBaosteel hot rolled steel plate quality certificateDang TranNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- D17.1 D17.1M 2017 Sample PQTR FormDocument1 pageD17.1 D17.1M 2017 Sample PQTR FormPabloLamelaNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- W-55 PLATE ID CARDDocument6 pagesW-55 PLATE ID CARDKrishnan TnNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

- Wps A53 SMAW+GTAW R00Document3 pagesWps A53 SMAW+GTAW R00Richard Periyanayagam50% (2)

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- AWS WPQR WPS FormularioDocument1 pageAWS WPQR WPS FormularioAntonio RuscittoNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PSV Data BookDocument16 pagesPSV Data Bookkenoly123No ratings yet

- Cruiser Lines PlansDocument1 pageCruiser Lines PlansjacquesmayolNo ratings yet

- API 570 QuizDocument6 pagesAPI 570 Quizjacquesmayol100% (1)

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- BikehangerDocument1 pageBikehangerjacquesmayolNo ratings yet

- ASTM F1554 - Portland BoltDocument1 pageASTM F1554 - Portland BoltjacquesmayolNo ratings yet

- Deck Fitting HardwareDocument137 pagesDeck Fitting HardwarejacquesmayolNo ratings yet

- Seismic Analysis of Steel Liquid Storage Tanks by Api-650Document129 pagesSeismic Analysis of Steel Liquid Storage Tanks by Api-650haschere67% (3)

- API 571 Exercises, Rev2Document11 pagesAPI 571 Exercises, Rev2ariyamanjula2914100% (4)

- API 570 piping classification and inspection intervalsDocument34 pagesAPI 570 piping classification and inspection intervalsjacquesmayol0% (1)

- Eyewash Ansi 2015 DUCHASDocument6 pagesEyewash Ansi 2015 DUCHASbrujula24No ratings yet

- Featured (/featured/) Write An Instructable (/about/create - JSP) (/)Document9 pagesFeatured (/featured/) Write An Instructable (/about/create - JSP) (/)jacquesmayolNo ratings yet

- Understanding Abrasive Blasting StandardsDocument3 pagesUnderstanding Abrasive Blasting StandardsjacquesmayolNo ratings yet

- Eyewash Ansi 2015 DUCHASDocument6 pagesEyewash Ansi 2015 DUCHASbrujula24No ratings yet

- PurgingDocument10 pagesPurgingSai PrasathNo ratings yet

- Int 9 MeterDocument9 pagesInt 9 MeterjacquesmayolNo ratings yet

- Setup Guide for Velbon Super Mag Slider Macro SliderDocument2 pagesSetup Guide for Velbon Super Mag Slider Macro SliderjacquesmayolNo ratings yet

- SSPC GuideDocument7 pagesSSPC GuidejacquesmayolNo ratings yet

- How To Get Your Apartment Off The Grid - LOW-TECH MAGAZINEDocument33 pagesHow To Get Your Apartment Off The Grid - LOW-TECH MAGAZINEjacquesmayolNo ratings yet

- Solar OvenDocument6 pagesSolar OvenjimitkapadiaNo ratings yet

- Ganymede Offsets PDFDocument2 pagesGanymede Offsets PDFjacquesmayolNo ratings yet

- Risk and Reliability of Radiographic and Phased Array Ultrasonic Test On The Inspection of Boiler Connections, Based On FMEA ModelDocument9 pagesRisk and Reliability of Radiographic and Phased Array Ultrasonic Test On The Inspection of Boiler Connections, Based On FMEA ModelSwapnil VichareNo ratings yet

- Brockwayfull PDFDocument38 pagesBrockwayfull PDFjacquesmayolNo ratings yet

- PurgingDocument10 pagesPurgingSai PrasathNo ratings yet

- Devlin Designing Boat BuildersDocument2 pagesDevlin Designing Boat Buildersjacquesmayol100% (1)

- BlondieDocument13 pagesBlondiejacquesmayolNo ratings yet

- Delftship ManualDocument81 pagesDelftship ManualjacquesmayolNo ratings yet

- Tierra y LunaDocument13 pagesTierra y LunaLuis MorenoNo ratings yet

- Apple Pie 2Document16 pagesApple Pie 2Pedro Loureiro100% (1)

- Boat Plans of Mystic Seaport - by Anne and Maynard Bray - OffCenterHarbor Com Digital Version PDFDocument217 pagesBoat Plans of Mystic Seaport - by Anne and Maynard Bray - OffCenterHarbor Com Digital Version PDFCarlos Garcia100% (5)

- Punjabi MCQ Test (Multi Choice Qus.)Document11 pagesPunjabi MCQ Test (Multi Choice Qus.)Mandy Singh80% (5)

- Sgs Cbe Academy Sri Lanka Training Prospectus 2021 enDocument10 pagesSgs Cbe Academy Sri Lanka Training Prospectus 2021 enKaisigmazen Quality QwestNo ratings yet

- Cube Roots of Unity (Definition, Properties and Examples)Document1 pageCube Roots of Unity (Definition, Properties and Examples)Nipun RajvanshiNo ratings yet

- Dominance and State Power in Modern India - Francine FrankelDocument466 pagesDominance and State Power in Modern India - Francine FrankelSanthoshi Srilaya RouthuNo ratings yet

- PMP Training 7 2010Document5 pagesPMP Training 7 2010srsakerNo ratings yet

- Software Engg. Question Paper - 40 CharacterDocument14 pagesSoftware Engg. Question Paper - 40 Characteranon_572289632No ratings yet

- Palpation and Assessment SkillsDocument305 pagesPalpation and Assessment SkillsElin Taopan97% (34)

- Cranial Strains and MalocclusionDocument5 pagesCranial Strains and MalocclusionRyan Dobbeck100% (1)

- Math - Grade 4 Lesson 2b - Using Mental Math To AddDocument3 pagesMath - Grade 4 Lesson 2b - Using Mental Math To Addapi-296766699100% (1)

- Mother Tongue Lesson Week 7Document7 pagesMother Tongue Lesson Week 7ElsieJhadeWandasAmandoNo ratings yet

- pr1-module-week-5-6-i-what-is-a-research-title1-1-the-most-important-element-that-defines-theDocument28 pagespr1-module-week-5-6-i-what-is-a-research-title1-1-the-most-important-element-that-defines-theJerelyn MalacasteNo ratings yet

- Ryan G Sharma - EPQ (Final)Document26 pagesRyan G Sharma - EPQ (Final)ryan sharmaNo ratings yet

- Differianted Math Lesson Plan Triangular Prisms - Diego MenjivarDocument4 pagesDifferianted Math Lesson Plan Triangular Prisms - Diego Menjivarapi-491433072No ratings yet

- Table of Specification (TOS)Document2 pagesTable of Specification (TOS)Charlene FiguracionNo ratings yet

- Mathematics 9 3: Learning Area Grade Level Quarter Date I. Lesson Title Ii. Most Essential Learning Competencies (Melcs)Document4 pagesMathematics 9 3: Learning Area Grade Level Quarter Date I. Lesson Title Ii. Most Essential Learning Competencies (Melcs)Marjury Bernadette BuenNo ratings yet

- Fauquier County Public Schools: Continuity of Learning Plan Phase Three and Beyond 2020-2021Document12 pagesFauquier County Public Schools: Continuity of Learning Plan Phase Three and Beyond 2020-2021Fauquier NowNo ratings yet

- 3rd Monthly ExamDocument4 pages3rd Monthly ExamRoselyn PinionNo ratings yet

- Scholarship Scavenger HuntDocument1 pageScholarship Scavenger HuntmortensenkNo ratings yet

- 0452 s18 Ms 12Document14 pages0452 s18 Ms 12Seong Hun LeeNo ratings yet

- Architecture Literature Review SampleDocument7 pagesArchitecture Literature Review Samplec5pnw26s100% (1)

- 50 Hydraulics Probs by Engr. Ben DavidDocument43 pages50 Hydraulics Probs by Engr. Ben DavidEly Jane DimaculanganNo ratings yet

- Thesis Ideas (List of Titles)Document13 pagesThesis Ideas (List of Titles)kimberl0o0% (2)

- PMBOK Review QuestionsDocument5 pagesPMBOK Review QuestionsIRVIN100% (1)

- Basketball Prison Ball Lesson PlansDocument4 pagesBasketball Prison Ball Lesson Plansapi-273012822No ratings yet

- Extension Cord MakingDocument3 pagesExtension Cord MakingAaron VillanuevaNo ratings yet

- 2023eju Bulletin enDocument35 pages2023eju Bulletin enpokemoknaNo ratings yet

- Core OM - Term 1 - 2019Document5 pagesCore OM - Term 1 - 2019chandel08No ratings yet

- 02 eLMS Activity 1 (NSTP)Document1 page02 eLMS Activity 1 (NSTP)Yuki C. ArutaNo ratings yet

- Early Reading 11 - Will Is Ill PDFDocument6 pagesEarly Reading 11 - Will Is Ill PDFKatharina KrawtschenkoNo ratings yet

- Newsletter 201003Document23 pagesNewsletter 201003Tim LinNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Stand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailFrom EverandStand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailRating: 3 out of 5 stars3/5 (3)