Professional Documents

Culture Documents

ENGINEERING STANDARD - Standard Piping Material Specification

Uploaded by

Ganesh Eshwar100%(2)100% found this document useful (2 votes)

993 views33 pagesNGINEERING STANDARD- Standard Piping Material Specification

Original Title

ENGINEERING STANDARD- Standard Piping Material Specification

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentNGINEERING STANDARD- Standard Piping Material Specification

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

993 views33 pagesENGINEERING STANDARD - Standard Piping Material Specification

Uploaded by

Ganesh EshwarNGINEERING STANDARD- Standard Piping Material Specification

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 33

ENGINEERING STANDARD

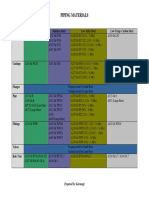

Title: PIPING MATERIAL SPECIFICATION Standard No.... Doc. No...

Page : 1 of 15

Issue Date : December, 2011

Approvals: Sponsor Manager, Stationary Equipment Director, Specialty Engineering

Name: M.C. Donald A. Lincoln S. Stallone

Signature: on org file on org file on org file

Date: 2011-11-12 2011-11-12 2011-11-12

TABLE OF CONTENTS

SCOPE Page

1.0 SCOPE ....................... 2

2.0 CODES, STANDARDS AND REFERENCES ....................... 2

3.0 GENERAL REQUIREMENTS ....................... 3

3.1 Design Considerations ....................... 3

3.2 Line Class Notes ....................... 3

3.3 Item Descriptions ....................... 3

4.0 SPECIFIC REQUIREMENTS ....................... 3

4.1 Pipe ....................... 3

4.2 Fittings ....................... 3

4.3 Flanges ....................... 3

4.4 Branch Connections ....................... 3

4.5 Gaskets ....................... 3

4.6 Valves ....................... 3

4.7 Assembly Details ....................... 3

4.8 Testing and Examination ....................... 3

4.9 Pressure/Temperature Limits ....................... 3

ATTACHMENTS

5.0 Abbreviations for Piping Specifications ....................... 4

5.1 Valve Tag Numbering ....................... 5

ATTACHMENTS FIGURES

Fig. 5.2 Standard Installation Detail - Utility Station - ....................... 6

Fig. 5.2.1 Special Fabricated Larger Diameter Reducers ....................... 7

Fig. 5.2.2 Four Weld 90 LR Miter Elbow ....................... 8

Fig. 5.2.3 Four Weld 45 LR Miter Elbow ....................... 9

Fig. 5.2.4 Perforated Temporary Conical Strainers ....................... 10

Fig. 5.2.5 T-Type Strainers ....................... 11

Fig. 5.2.6 Drip Rings ....................... 12

Fig. 5.2.7 Product Sampler Cooler ....................... 13

Fig. 5.2.8 Tolerances for Pipe Fabrication ....................... 14

Fig. 5.2.9 Marking of Line Blinds & Spectacle Blinds ....................... 15

1.0 SCOPE

1.1 This Standard contains the basic information for piping material and Valve

specifications. The actual specifications are contained in Piping Material and Valve

Specifications Manuals, available in the "Client" Intranet system. The Piping Material

and Valve Specifications are considered a part of this Standard and shall be used in

conjunction with this Standard.

1.1.1 These specifications are intended to supplement the full technical requirements

defined in accordance with the "Client" Standards referenced below.

1.2 Where approvals are indicated in this Standard, this refers to "Client" or its

designated representative, hereinafter referred to as "Client".

1.3 Any discrepancy between this Standard and other contract or procurement

documents or specification, unless specifically indicated as an exception, shall be

submitted by the Contractor/Manufacturer/Supplier to "Client" for a written ruling.

1.4 All measurements are expressed in U.S. Conventional System of Measurement,

followed by, in parenthesis, the equivalent SI units (metric). All SI units are for

reference only and shall not be interpreted as a precise conversion.

1.5 Any proposed deviations from this Standard shall be submitted in writing to "Client"

for review and approval. It is the responsibility of the individual(s) who request

deviation to submit a request form in a timely manner, and in accordance with "Client"

Procedure SEP 107B, Preparation of Addenda to and Deviations from "Client"

Engineering Standards.

2.0 CODES, STANDARDS AND REFERENCES

The latest editions of the following Codes and Standards in effect on the date of

contract award shall be used.

2.1 "Client" Engineering Standards and Guidelines

Doc. No... Piping

Doc. No... Flanges, Bolting and Gaskets

Doc. No... Piping Stress Analysis and Pipe Supports

Doc. No... Piping Layout Arrangement and Accessibility

Doc. No... Valves

Doc. No... Piping Systems for Gaseous Oxygen Service

Doc. No... Valve Procurement

Doc. No... Galvanizing

Doc. No... Coatings for Buried Steel Pipe

Doc. No... Welding of Pressure Vessels, Piping and Tankage

Doc. No... Temperature Instrumentation

Doc. No... Flange Bolt-Up

Doc. No... Substitutes for Asbestos Based Gasketing

Doc. No... Materials of Construction for Low Temperature Service

Doc. No... Materials of Construction (MOC) for General Services

2.2 American Petroleum Institute (API)

API 594 Wafer Check Valves

API 600 Steel Gate Valves, Flanged or Buttwelding Ends

API 602 Compact Carbon Steel Gate Valves

API 607 Fire Test for Soft-Seated Quarter Turn Valves

API 608 Metal Ball Valves

API 609 Butterfly Valves, Lug Type and Wafer Type

2.3 American Society of Mechanical Engineers (ASME)

ASME B1.20.1 Pipe Threads, General Purpose (inch)

ASME B16.5 Steel Pipe Flanges and Pipe Fittings

ASME B16.9 Wrought Steel Buttweld Fittings

ASME B16.10 Face-to-Face and End-to-End Dimensions Ferrous Valves

ASME B16.11 Forged Steel Fittings Socketwelding and Threaded

ASME B16.20 Metallic Gaskets for Pipe Flanges - Ring-Joint, Spiral Wound and

Jacketed

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME B16.25 Buttwelding Ends

ASME B16.34 Steel Valves - Flanged and Buttwelding Ends

ASME B16.36 Orifice Flanges

ASME B16.47 Large Diameter Steel Flanges

ASME B16.48 Steel Line Blanks

ASME B31.1 Power Piping

ASME B31.3 Chemical Plant and Petroleum Refinery Piping

ASME B36.10 Welded and Seamless Wrought Steel Pipe

ASME B36.19 Stainless Steel Pipe

Boiler and Pressure Vessel Codes:

Section I Power Boilers

Section II Material Specifications

Section VIII Pressure Vessels, Division 1

2.4 Manufacturer Standard Society Practice (MSS)

MSS SP-25 MSS Standard Marking System for Valves, Fittings, Flanges and Unions

MSS SP-45 Bypass and Drain Connection Standard

2.5 Process Industry Practice (PIP)

PIP PNSM0001 Piping Line Class Designator System

3.0 GENERAL REQUIREMENTS

3.1 Design Considerations

3.1.1 Unless otherwise noted in the specifications, all pressures and temperatures

referred to shall be considered Design Conditions. Design Conditions shall be as defined

in Doc. No....

3.1.2 Piping component wall thicknesses are based on pressure design thickness,

taking into account the specified corrosion allowance and any permitted manufacturer

under tolerance. Piping component wall thickness does not include additional thickness

that may be required to compensate for design considerations such as thermal loads

due to restraints, live loads, hydraulic shock, loads on underground pipe, or loads or

forces from other sources. Additional loads will need to be considered in the design of

piping systems.

3.1.3 Unless otherwise indicated in the specifications, piping components are specified

to be adequate for the full flange rating of the pressure class.

3.2 Line Class Notes

3.2.1 Each pipe specification contains specific numbered notes (in parenthesis) that

pertain to one individual component or to a group of components, as well as a list of

additional requirements that pertain to the entire specification.

3.2.2 Line class notes are provided in page 4 of this Standard. The information

contained in these notes shall be read and adhered to ensure compliance with the line

class specification.

3.3 Item Descriptions

3.3.1 The item descriptions on the individual line class are abbreviated, and may be

used for purchasing the item with the exception of Valves. Abbreviations are contained

in page 4 of this Standard.

3.2.2 The complete purchase description for Valves is contained in the Valve

specifications, and shall be followed to ensure compliance with the pipe specifications.

4.0 SPECIFIC REQUIREMENTS

4.1 Pipe

4.1.1 Welded pipe shall not be substituted for seamless pipe. Seamless pipe may be

substituted for welded pipe in all services, sizes and materials.

4.1.2 Where "CALC" is specified for piping material wall thickness, the wall thickness

shall be calculated in accordance with the applicable ASME B31 Code.

4.1.3 Stainless steel, electric fusion welded (EFW) pipe (ASTM A 358) may be

substituted for ASTM A 312 EFW pipe for sizes 14 in. NPS and above.

4.1.4 Carbon steel seamless pipe, ASTM A 106B, may be substituted for ASTM A 53B,

Type S, and seamless pipe in all sizes.

4.1.5 Where joint factors are specified for pipe, these factors shall be taken as

minimum values. Use of pipe with joint factors in excess of these values is acceptable.

If pipe manufactured with a higher joint factor than listed on the specification is used,

the minimum joint factor listed on the specification shall be used when calculating wall

thicknesses of the pipe.

4.1.6 Double Submerged Arc Welded (DSAW) pipe shall be used for all EFW stainless

steel pipes. If DSAW pipe is not available, EFW pipe with a single butt joint having a

joint factor of 0.80 shall be used for 8 in. NPS and smaller.

4.2 Fittings

4.2.1 Welded fittings shall not be substituted for seamless fittings. Seamless fittings

may be substituted for welded fittings in all services, sizes and materials.

4.2.2 Dimensions of all fittings shall be in accordance with the industry standard

referenced on the individual specification.

4.2.3 Buttweld fittings shall have a wall thickness to match the wall thickness of the

adjoining pipe. Fittings of commercially available wall thickness shall be used even

though the fitting may have a slightly larger wall thickness than the adjoining pipe. The

ends of the fitting shall be taper bored if the thickness of the fittings exceeds that of the

pipe by more than 1/16 in. (1.6 mm). Taper boring shall not result in an infringement

on the minimum wall thickness.

4.2.4 Long radius elbows are required for all buttweld elbows. Short radius elbows

shall only be used with "Client" approval.

4.2.5 Use of Lokring Fittings

LOKRING fittings are generally recognized in the industry as a robust pressure

containing device that can be easily and quickly installed without a hot work permit.

These features can be highly attractive when considering the installation cost. However,

there is limited experience within "Client" on the overall long term performance for

these fittings, so the potential for long term reliability and maintenance issues must be

considered, such as inspection limitations and the potential for crevice corrosion, water

freeze damage and stress corrosion cracking due to the inherent crevice between

components and the high sealing stresses. For these reasons LOKRING fittings are

considered an acceptable alternative for use in pipe specifications provided all the

limitations described below have been met:

1. Must be approved for the intended service by the local jurisdiction or governing

body for pressure equipment. (Note: ASME B31 proof testing requirements have

been satisfied.)

2. The fittings are used in Category D (as defined in Doc. No...) or utility services as

follows:

Air, Water, Nitrogen (Outdoor Service Only) and Low pressure steam and

condensate service with a maximum design pressure of 200 PSIG.

3. The applicable pipe specification allows the use of Socket Weld construction for

the services described in item 2 above.

4. Installation shall be only for Carbon Steel piping systems up to 500F (260C) and

Stainless Steel piping systems up to 120F (49C).

5. Sizes up to and including 3 in. NPS.

6. Manufacturer trained and certified personnel must perform the installation

utilizing manufacturer approved tool kits and installation procedures. Consult

LOKRING for guidance: www.lokring.com.

7. These fittings shall not be installed in piping systems which historically have

shown susceptibility to crevice corrosion.

8. No installations shall be made in service applications with high pulsation or

vibration forces.

9. No installation in any piping systems that require post weld heat treatment.

10. Fittings shall be grit blasted and painted in accordance to Doc. No....

11. Fittings operating below 300F (149C) shall be sealed with a temperature

resistant silicone caulking to prevent the ingress of water.

12. After installation, perform 100% visual inspection to verify the NOGO gage

markings are indicating proper installation (marking partially covered), the fitting

body protrudes from underneath the swage ring, and remaining gaps are

acceptable per the LOKRING installation procedure.

4.3 Flanges

4.3.1 Dimensions and surface finishes of all flanges shall be in accordance with the

industry standard referenced on the individual specification.

4.3.2 Buttweld flanges shall have a wall thickness to match the wall thickness of the

adjoining pipe. Flanges of commercially available wall thickness shall be used even

though the flange may have a slightly larger wall thickness than the adjoining pipe. The

end of the flange shall be tapering bored if the thickness of the flange exceeds that of

the pipe by more than 1/16 in. (1.6 mm). Taper boring shall not result in an

infringement on the minimum wall thickness.

4.3.3 Orifice flanges shall be Class 300 minimum. Orifice flanges shall be ordered in

pairs and shall have Socketweld taps. Class 150 utility services, specifications PLC...

and PLC..., may use threaded orifice taps.

4.3.4 When mating to cast iron flat-face flanges is required, a carbon steel flat-face

flange with a full-face gasket shall be used. Full-face gasket material shall be

compatible with process stream and shall be in accordance with Doc. No...

requirements.

4.3.5 When mating to cast steel flat-face flanges is required; a raised-face flange shall

be used. The gasket shall be of a type and material that meets the requirements of the

piping specification.

4.3.6 Flanges installed in acid/caustic service (as defined in Doc. No...) or other

hazardous material shall be protected with a flange safety shield when a potential for

exposure to personnel and/or equipment exists.

4.4 Branch Connections

4.4.1 ASME B16.9 welding tees shall be used when branch connections are size on

size. Reducing tees shall be used when the branch run is one nominal size less than the

header run.

4.4.2 Except where indicated on the individual line classes, integrally reinforced branch

connections shall be used for branch runs NPS 8 and smaller.

4.4.3 Full area replacement shall be used for branch connections above NPS 8. The

reinforcing pad thickness shall equal the header thickness, and the reinforcing pad

width shall equal 1/2 the outside diameter of the branch. The material of the reinforcing

pad shall match the material of the header.

4.4.4 Reserved

4.4.5 If an economic incentive exists, the dimensions of the reinforcing pad may be

calculated in accordance with ASME B31.1 or ASME B31.3 as applicable. In this case,

"Client" shall approve dimensions of reinforcing pads.

4.5 Gaskets

4.5.1 Gasket types shall be as indicated on the individual piping specification and shall

conform to the additional requirements of Doc. No....

4.5.2 Reserved

4.5.3 Inner rings are required on all spiral wounds PTFE filled gaskets.

4.5.4 Inner rings are required on all spiral wound graphite filled gaskets.

4.6 Valves

4.6.1 Valve tag numbers are listed on the individual piping material specification. The

individual Valve specification sheet for the tag number and the requirements defined in

Doc. No... shall be met to ensure compliance with the line class specification.

4.6.2 The basic Valve design shall be in accordance with the referenced standard on

the Valve specification sheet. Valves designed in accordance with API 600 may be

substituted for ASME B16.34 Valves.

4.6.3 The following Industry Codes/Standards apply to the specific design aspects of

Valves:

Pressure/Temperature Rating

ASME B16.34 (Excluding API Class 800)API

602

End-to-End Dimensions ASME B16.10

End Flange Dimensions and Surface

Finish

ASME B16.5 (NPS 2 thru 24)

ASME B16.47 (NPS 24 and above)

Socketweld/Threaded Ends ASME B16.11

Buttweld Ends ASME B16.25

Buttweld Ends Bore Size

ASME B36.10

ASME B36.19

4.6.4 API trim numbers specified on non-API Valves are for reference only. The trim

number defines the minimum requirements for Valve trim.

4.6.5 Bonnet gaskets shall be as specified on the Valve specification sheets. When

PTFE based gaskets are used; the gasket shall be fully confined on both the inner and

outer diameter.

4.6.6 Class 150 Gate Valves with oval Bonnet design that cannot fully contain a PTFE

based gasket shall use the manufacturer's standard metal Bonnet gasket. The gasket

shall meet the requirements defined in API 600, and shall be of metallurgy compatible

with the intended fluid service.

4.6.7 Full port Ball Valves shall only be used with prior "Client" approval.

4.6.8 When both a lift Check Valve and a swing Check Valve are specified, the

following criteria shall apply:

In carbon steel and low alloy services, the spring loaded lift Check Valve is the

preferred type. Swing type Check Valves shall be used as an alternate.

In stainless steel and higher alloy services, the swing Check Valve is the preferred

type. Spring-loaded lift Check Valves shall be used as an alternate.

4.7 Assembly Details

4.7.1 Assembly details on individual specifications are for reference only. Branch

connections and block Valves for take-offs shall be specified in the specification. The

following requirements apply to the assembly details on the specifications.

4.7.2 Pipe nipples shall be fabricated from line class pipe. Length of pipe nipple shall be

adequate to clear insulation.

4.7.3 When a threaded x Socket Weld Valve is specified for assembly details, the

Valves shall be welded to the pipe nipple. A line class threaded plug shall be used for

plugging threaded and threaded Socket Weld vent and drain Valves.

4.7.4 When a flanged Valve is specified for assembly details, a line class flange shall be

used on the pipe nipple for mating. A line class blind flange and gasket shall be used for

plugging flanged end vent and drain Valves.

4.7.5 Valved vent shall be provided at every high point.

4.7.6 All underground piping shall be coated and wrapped in accordance with Doc.

No....

4.7.7 Flange bolt up shall be per Doc. No.....

4.8 Testing and Examination

4.8.1 Unless otherwise specified on the individual line class specification, all non-

destructive examination shall be in accordance with Doc. No....

4.8.2 Radiography, as required for special service piping and non-ferrous materials,

shall be in accordance with ASME B31.3 and Doc. No....

4.9 Pressure/Temperature Limits

4.9.1 Pressure/temperature limits are based on ASME B16.5. Maximum and minimum

temperatures shall be in accordance with Doc. No....

4.9.2 Stainless steel specified as Dual Marked/Dual Certified (i.e., 304/304L,

316/316L) may be used at the pressure/temperature rating and the allowable stress of

the straight grade stainless steel through 800F (427C). Use of this material

specification is limited to 800F (427C).

4.9.3 For piping systems not designed and installed per these specifications, the use of

the higher pressure/temperature rating and allowable stress for dual marked stainless

steel is not permitted.

4.9.4 The use of stainless steel marked and certified to only one grade of stainless

steel is permitted at the pressure/temperature rating and allowable stress of the grade

marked on the piping components.

4.9.5 Actual pressure or temperature limits for specifications may be reduced due to

limitations on individual components such as pipe wall thickness, gasket materials or

Valve internals. Individual specification shall be consulted to determine any limiting

components for a specification.

4.9.6 For specifications where the Valve's material is not the same as the flange

material, the pressure/temperature rating shall be based on the component with the

lower pressure/temperature rating.

4.10 Miscellaneous Components

4.10.1 See page 5 for steam trap detail installation, page 11 for strainers and page 15

for spectacle blinds.

4.10.2 Flexible components such as metallic hoses shall only be used in accordance

with plant specific requirements and procedures. As a minimum, the temperature rating

and pressure class of the metallic hose shall meet the applicable pipe specification

pressure and temperature rating. Written engineering approval is required for plant

sites without applicable procedures.

Abbreviations for Piping SpecificationsAPIAmerican Petroleum InstituteJFJoint FactorASMEAmerican

Society of Mechanical EngineersLJLap JointASTMAmerican Society for Testing & MaterialsLRLong

RadiusBEBeveled EndsLGTHLengthBGOBeveled Gear OperatorLOLIntegrally Reinforced

Lateral Branch Connection

( e.g.: laterolet )BHNBrinnel Hardness NumberMATLMaterialBLDBlindMFGManufacturerBWButt

WeldMIMalleable IronCICast IronMINMinimumCLClassMOMolybdenumCPLGCouplingMSSManufacturer

Standardization SocietyCPVCChlorinated Polyvinyl ChlorideNIPPNippleCRChromeNPSNominal Pipe

SizeCSCarbon SteelPEPlain EndsCONCConcentricPIPProcess Industry

PracticeCONNConnectionPROJProjectionDEGDegreePTFEPolyTertaFluorEthyleneDIDuctile

IronRRadiusDIADiameterRFRaised FaceDIMDimensionRTJRing Type JointDSAWDouble Submerged Arc

WeldedSWSocket

WeldDWGDrawingSCHScheduleEAEachSCRDScrewedECCEccentricSMLSSeamlessEFWElectric Fusion

WeldedSOLIntegrally Reinforced

Socketweld Branch Connection

( e.g.: sockolet )ELLElbowSRShort RadiusOLIntegrally Reinforced

Elbow Branch Connection

( e.g.: elbolet )SSStainless SteelERWElectric Resistance WeldedSTDStandardFFFlat

Face FIGFigureT&CThreaded &

CoupledFLGFlangeTFETetraFluorEthyleneFLGDFlangedTHKThicknessFRPFiberglass Reinforced

PipeTHRDThreadedFSForged SteelTOLIntegrally Reinforced

Threaded Branch ConnectionGALVGalvanizedTSWThreaded x Socket WeldGJGround

JointTYPTypicalGRGradeVAValveGOGear

OperatedVERTVerticalHASTHastelloyWLDWelededHEXHexagonalWNWeld

NeckHORIZHorizontalWOLIntegrally Reinforced

Buttweld BranchINSULInsulationWTWall Thickness

Valve Tag Numbering

Material Class Valve Type Valve Ends

A - Ductile 0 - Class 1500 0 - Gate 0 - Threaded

B - Hastelloy B 1 - Class 150 1 - Globe 1 - Socketweld

C - Carbon Steel 2 - Class 2500 2 - Swing Check 2 - Flanged, Raised Face

D - Chrome Moly 3 - Class 300 3 - Wafer Check 3 - Flanged, Flat Face

E - 316 Stainless

Steel

4 - Class 4000 4 - Plug 4 - Flanged, Ring Type Joint

F - 316L Stainless

Steel

5 - Class 3000 5 - Ball 5 - Buttweld, Bore to Match Pipe

G - Cast Iron 6 - Class 600 6 - Butterfly 6 - Threaded x Socketweld

H - 304 Stainless

Steel

7 - Class 6000

7 - Lift Check (Ball or

Piston)

7 - Integral Male Socketweld x Female

Threaded

I - 304L Stainless

Steel

8 - API Class 800 8 - Knife Gate 8 - Hub Connector - Grayloc

J - PVC 9 - Class 900 9 - Diaphragm 9 - Buttweld x Hub end

K - PTFE Lined

L - Monel

M - Hastelloy C

N - 321 Stainless

Steel

O - Alloy 20

P - FRP

Tag Number shall be: V-Material Code / Pressure Class / Type / Ends / Two Digit Sequence

Example: V-C80100

(V) Valve

(C) Carbon Steel

(8) Class 800

(0) Gate Valve

(1) Socket Weld

(00) and the first of this type in sequence.

All Valve sequence numbers shall start at 00 and number ascending through 99.

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

6 of 15

Standard Installation Detail - Utility Station

Coupling legend Type

Steam: Type

GB-8-3/4"

Female NPT end

or approved

equal

A

Water: Type

AM-8-3/4"

Female NPT end

or approved

equal

B

Air: Type AM-

8-3/4" Female

NPT end or

approved equal

C

Nitrogen: Type

GJ-50-3/4" Male

NPT end or

approved equal

D

Notes:

1. Pipe, Valves, flanges and fittings ro conform with piping

spec. 1....

2. Use close nipples where 3" nipples cause excessive

dimensions

3. Hose racks are required for all utility stations

4. Service designation tags required for each line

5. Surface preparation shall be per Doc. No...

6. Insulation shall be per Doc. No...

7. All branch connections are from top of header

Standard No....

Doc. No....

PIPING

MATERIAL

SPECIFICATION

Issue Date

December,

2011

Page

6 of 15

DOCS MATL SOCIETIES PIPES FLANGES FITTINGS VALVES BOLTS GASKETS EQPT SPECIALS STEEL DIN STEAM OTHERS

Page 7-15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

7 of 15

Special Fabricated Larger Diameter Reducers

Reducer

O.D.

A B

Reducer

O.D.

A B

Reducer

O.D.

A B

Reducer

O.D.

A B

26 x 24 24 1 40 x 32 24 4 52 x 46 30 8 66 x 60 36 3

26 x 22 24 2 40 x 30 24 5 54 x 52 30 1 66 x 54 36 6

26 x 20 24 3 * 40 x 28 24 6 54 x 50 30 2 66 x 48 36 9

26 x 18 24 4 42 x 40 24 1 54 x 48 30 3 66 x 42 36 12

26 x 16 24 5 42 x 38 24 2 54 x 46 30 4 68 x 64 36 2

28 x 26 24 1 42 x 36 24 3 54 x 44 30 5 68 x 60 36 4

28 x 24 24 2 42 x 34 24 4 54 x 42 30 6 68 x 54 36 7

* 28 x 22 24 3 42 x 32 24 5 54 x 38 30 8 68 x 48 36 10

28 x 20 24 4 42 x 30 24 6 54 x 36 30 9 68 x 42 36 13

28 x 18 24 5 44 x 42 24 1 54 x 34 30 10 70 x 66 42 2

30 x 28 24 1 44 x 40 24 2 54 x 32 30 11 70 x 60 42 5

30 x 26 24 2 44 x 38 24 3 54 x 30 30 12 70 x 54 42 8

30 x 24 24 3 44 x 36 24 4 56 x 54 30 1 70 x 48 42 11

* 30 x 22 24 4 * 44 x 34 24 5 56 x 52 30 2 70 x 42 42 14

30 x 20 24 5 * 44 x 32 24 6 56 x 50 30 3 72 x 66 42 3

32 x 30 24 1 46 x 44 28 1 56 x 48 30 4 72 x 60 42 6

32 x 28 24 2 46 x 42 28 2 56 x 46 30 5 72 x 54 42 9

32 x 26 24 3 46 x 40 28 3 56 x 44 30 6 72 x 48 42 12

32 x 24 24 4 46 x 38 28 4 56 x 42 30 7 72 x 42 42 15

* 32 x 22 24 5 * 46 x 36 24 5 58 x 56 30 1 78 x 72 48 3

* 32 x 20 24 6 * 46 x 34 24 6 58 x 54 30 2 78 x 66 48 6

34 x 32 24 1 48 x 46 28 1 58 x 52 30 3 78 x 60 48 9

34 x 30 24 2 48 x 44 28 2 58 x 48 30 5 78 x 54 48 12

* 34 x 28 24 3 48 x 42 28 3 58 x 44 30 7 78 x 48 48 15

34 x 26 24 4 48 x 40 28 4 58 x 42 30 8 84 x 78 48 3

34 x 24 24 5 * 48 x 38 24 5 60 x 56 30 2 84 x 72 48 6

36 x 34 24 1 * 48 x 36 24 6 60 x 54 30 3 84 x 66 48 9

36 x 32 24 2 50 x 48 24 1 60 x 52 30 4 84 x 60 48 12

36 x 30 24 3 50 x 46 24 2 60 x 48 30 6 84 x 54 48 15

* 36 x 28 24 4 50 x 44 24 3 60 x 42 30 9 84 x 48 48 18

36 x 26 24 5 50 x 42 24 4 62 x 58 30 2 90 x 84 48 3

36 x 24 24 6 50 x 40 24 5 62 x 54 30 4 90 x 78 48 6

38 x 36 24 1 50 x 38 24 6 62 x 52 30 5 90 x 72 48 9

38 x 34 24 2 50 x 36 24 7 62 x 48 30 7 90 x 66 48 12

38 x 32 24 3 52 x 44 30 1 62 x 44 30 9 90 x 60 48 15

38 x 30 24 4 52 x 42 30 2 64 x 60 36 2 96 x 90 48 3

38 x 28 24 5 52 x 40 30 3 64 x 56 36 4 96 x 84 48 6

38 x 26 24 6 52 x 38 30 4 64 x 54 36 5 96 x 78 48 9

40 x 38 24 1 52 x 36 30 5 64 x 52 36 6 96 x 72 48 12

40 x 36 24 2 52 x 50 30 6 64 x 48 36 8 96 x 66 48 15

40 x 34 24 3 52 x 48 30 7 64 x 42 36 11

Notes:

1. All dimensions are given in Inches.

2. These reducers are to be used only when authorized by the piping spec's for the job.

3. Material shall be as specified in the job piping materials specification class.

4. Welding shall be in accordance with the job specifications.

5. Alloy material;s over 1/8" thk. and carbon steel materials 3/16" thk. and over shall have ends beveled

for welding in accordance with ASME B16.25 standard.

6. Reducers marked with asterisk ( * ) and 50" and higher are not ASME B16.9.

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

7 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

8 of 15

Four Weld 90 Long Radius Miter Elbow

NOM.

DIA

A Min.

R

Radius

S

Inches

M

30 42w" 45" 17p"

32 44s" 48" 18s"

34 47r" 51" 19f"

36 49f" 54" 21w"

38 52i" 57" 22r"

40 55w" 60" 23i"

42 57s" 63" 24p" 8r"

44 60r" 66" 25s"

46 62f" 69" 27"

48 65i" 72" 28i" 9p"

50 68w" 75" 29r"

52 70s" 78" 30i"

54 73r" 81" 31p" 10f"

56 75f" 84" 32f"

58 78i" 87" 34"

60 81w" 90" 35w"

62 83s" 93" 36y"

64 86y" 96" 37i"

66 88f" 99" 38p"

68 91i" 102" 39f"

70 94w" 105" 41"

72 96s" 108" 42r"

78 104i" 117" 45s" 15r"

84 112y" 126" 49i"

86 115" 129" 50y"

Notes:

1. All dimensions are given in Inches.

2. Welding shall be in accordance with the job specifications.

3. These Miter elbows are to be used when authorized by the piping spec's.

4. Use "A" dimension only where necessary to meet close clearance requirements or when connecting to

flange or fitting.

5. Material shall be as specified in the job piping materials specification class.

6. "M" dimension does not include taper bore length.

7. The "M" dimension must be calculated for Miter elbows other than 78", 54", 48" and 42".

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

8 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

9 of 15

Two Weld 45 Long Radius Miter Elbow

DIA

NOM.

A

B

C

(1)

D

(1)

M

Min (3) LR Ell Dim

3" 2" 2" 1s" 1w" t"

4" 2i" 2i" 2y" 1t" u"

6" 3s" 3s" 3i" 2" p"

8" 5" 5" 4s" 2p" d"

10" 6r" 6r" 5f" 3t" 1q"

12" 7i" 7i" 7w" 3g" 1r"

14" 8s" 8s" 8r" 4p" 1y"

16" 10" 10" 9i" 5r" 1o"

18" 11r" 11r" 10s" 5f" 1s"

20" 11i" 1" - 0i" 11f" 6o" 2"

22" 1" - 0r" 1" - 1i" 1" - 1w" 6g" 2e"

24" 1" - 1r" 1" - 3" 1" - 2r" 7f" 2y"

26" 1" - 1s" 1" - 4" 1" - 3i" 8r" 2o"

28" 1" - 2s" 1" - 5y" 1" - 4q" 9q" 2s"

30" 1" - 3i" 1" - 6i" 1" - 5f" 9o" 2g"

32" 1" - 4i" 1" - 7f" 1" - 7" 10y" 3e"

34" 1" - 5i" 1" - 9w" 1" - 8r" 11" 3y"

36" 1" - 6r" 1" - 10r" 1" - 9i" 11i" 3o"

38" 1" - 7" 1" - 11i" 1" - 10p" 1" - 0e" 3s"

40" 1" - 7s" 2" - 0s" 1" - 11f" 1" - 0d" 3g"

42" 1" - 8i" 2" - 2" 2" - 1" 1" - 1i" 4w" 8y"

44" 1" - 9i" 2" - 3r" 2" - 2r" 1" - 2w" 4y"

46" 1" - 10i" 2" - 4i" 2" - 3y" 1" - 2d" 4o"

48" 1" - 11r" 2" - 5s" 2" - 4p" 1" - 3u" 4s" 9p"

50" 2" - 0r" 2" - 7" 2" - 5s" 1" - 4w" 4g"

52" 2" - 1" 2" - 8r" 2" - 7" 1" - 4s" 5w"

54" 2" - 1s" 2" - 9i" 2" - 8r" 1" - 5y" 5y" 10f"

56" 2" - 2s" 2" - 10s" 2" - 9y" 1" - 6q" 5o"

58" 2" - 3i" 3" - 0" 2" - 10i" 1" - 6s" 5s"

60" 2" - 4r" 3" - 1r" 2" - 11s" 1" - 7y" 5g"

62" 2" - 5r" 3" - 2i" 3" - 1" 1" - 8" 6w"

64" 2" - 6" 3" - 3s" 3" - 2w" 1" - 8o" 6t"

66" 2" - 7" 3" - 5" 3" - 3y" 1" - 9t" 6o"

68" 2" - 7s" 3" - 6r" 3" - 4i" 1" - 10" 6s"

70" 2" - 8i" 3" - 7i" 3" - 5s" 1" - 10p" 6g"

72" 2" - 9i" 3" - 8s" 3" - 6f" 1" - 11t" 7w"

74" 2" - 10r" 3" - 10" 3" - 8e" 1" - 11f" 7y"

76" 2" - 11" 3" - 11r" 3" - 9y" 2" - 0o" 7o"

78" 3" - 0" 4" - 0u" 3" - 10i" 2" - 1e" 7s" 150"

80" 3" - 0s" 4" - 1q" 3" - 11s" 2" - 1d" 7g"

82" 3" - 1s" 4" - 2g" 9" - 0t" 2" - 2i" 8e"

84" 3" - 2i" 4" - 4e" 4" - 2w" 2" - 3w" 8y"

86" 3" - 3r" 4" - 5u" 4" - 3t" 2" - 3s" 8o"

88" 3" - 4r" 4" - 6g" 4" - 4i" 2" - 4u" 8s"

90" 3" - 5" 4" - 7f" 4" - 5o" 2" - 5q" 8g"

92" 3" - 6" 4" - 9e" 4" - 6f" 2" - 5o" 9w"

94" 3" - 7" 4" - 10y" 4" - 8w" 2" - 5y" 9y"

96" 3" - 4i" 4" - 11p" 4" - 9r" 2" - 7" 9o"

98" 3" - 8i" 5" - 0f" 4" - 10i" 2" - 7p" 9s"

100" 3" - 9" 5" - 2w" 4" - 11q" 2" - 8t" 9g"

102" 3" - 10" 5" - 3f" 5" - 0f" 2" - 8q" 10w"

104" 3" - 11" 5" - 4p" 5" - 2q" 2" - 9o" 10t"

106" 3" - 11s" 5" - 5f" 5" - 3r" 2" - 10r" 10o"

108" 4" - 0i" 5" - 7w" 5" - 4u" 2" - 10f" 10s"

110" 4" - 1i" 5" - 8t" 5" - 5o" 2" - 11i" 10g"

112" 4" - 2r" 5" - 9o" 5" - 6d" 3" - 0e" 11w"

114" 4" - 3" 5" - 10d" 5" - 8" 3" - 0d" 11t"

116" 4" - 4" 6" - 0q" 5" - 9e" 3" - 1u" 11i"

118" 4" - 5" 6" - 1t" 5" - 10y" 3" - 2w" 11s"

120" 4" - 5s" 6" - 2o" 5" - 11p" 3" - 2s" 11g"

122" 4" - 6i" 6" - 3d" 6" - 0d" 3" - 3t" 12w"

124" 4" - 7y" 6" - 5q" 6" - 2" 3" - 4" 12y"

126" 4" - 8r" 6" - 6r" 6" - 3e" 3" - 4q" 12o"

128" 4" - 9" 6" - 7i" 6" - 4y" 3" - 5r" 12s"

130" 4" - 10" 6" - 8s" 6" - 5o" 3" - 6" 12g"

132" 4" - 10s" 6" - 10" 6" - 6s" 3" - 6o" 13w"

134" 4" - 11i" 6" - 11r" 6" - 8" 3" - 7r" 13t"

136" 5" - 0i" 7" - 0i" 6" - 9w" 3" - 7q" 13i"

138" 5" - 1r" 7" - 1s" 6" - 10y" 3" - 8o" 13s"

140" 5" - 2r" 7" - 3" 6" - 11i" 3" - 9r" 13g"

Notes:

1. All dimensions are given in Inches.

2. "C" and "D" dimensions are approximate. Do not use for fabrication.

3. These Miter elbows are to be used when authorized by the piping spec's.

4. Use "A" minimum dimension only where necessary to meet close clearance requirements.

5. Use butt-weld "A" only where necessary to connect to flange or fitting. Use Miter weld for pipe

connection.

6. Material shall be as specified in the job piping materials specification class.

7. Welding shall be in accordance with the job specifications.

8. "M" dimension does not include taper bore length.

9. The "M" dimension must be calculated for Miter elbows other than 78", 54", 48" and 42".

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

9 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

10 of 15

Perforated Temporary Conical Strainers

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

10 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

11 of 15

T-Type Strainers

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

11 of 15

DOCS MATL SOCIETIES PIPES FLANGES FITTINGS VALVES BOLTS GASKETS EQPT SPECIALS STEEL DIN STEAM OTHERS

Page 12-15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

12 of 15

Drip Rings

NPS A

B

150# 300# 600# 900# 1500#

1 1.1/8 2.1/2 2.3/4 2.3/4 3 3

1.1/2 1.5/8 3.1/4 3.5/8 3.5/8 3.3/4 3.3/4

2 2.1/8 4 4.1/4 4.1/4 5.1/2 5.1/2

2.1/2 2.1/2 4.3/4 5 5 6.3/8 6.3/8

3 3.1/8 5.1/4 5.3/4 5.3/4 6.1/2 6.3/4

4 4.1/8 6.3/4 7 7.1/2 8 8.1/8

6 6.1/8 8.5/8 9.3/4 10.3/8 11.1/4 11

8 8 10.1/4 12 12.1/2 14 13.3/4

10 10.1/8 13.1/4 14.1/8 15.5/8 17 17

12 12 16 16.1/2 17.3/4 19.3/8 20.1/4

Notes:

1. Drip ring material in accordance with pipe specification

2. Finish of gasket surface shall be machined. (150%-300% / 250-500 AARH),

(600%-1500% / 100-250 AARH)

Standard No.... Doc. No....

PIPING MATERIAL

SPECIFICATION

Issue Date

December,

2011

Page

12 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

13 of 15

Product Sampler Cooler

MARK DESCRIPTION MATERIAL

1 FLANGE SW RF NPS 1/2

CL 150

As per connecting piping

classes

to be stated on requisition

2 COIL NPS 1/2 LINE PIPE

SCH 80

3 LINE PIPE NPS 3/4 SCH

80

4 FLANGE WN RF NPS 3/4

CL 150

5 LINE PIPE NPS 1.1/2 SCH

80

6 FLANGE SO RF NPS 1.1/2

CL 150

7 LINE PIPE NPS 10 SCH 30

8 BOTTOM PLATE

May be carbon steel

9 CLEATS

10 STRIP

Standard No.... Doc.

No....

PIPING MATERIAL

SPECIFICATION

Issue Date

December,

2011

Page

13 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

14 of 15

Tolerances for Pipe Fabrication

A - Variations in the indicated dimensions for Center to Face. Location of attachments

etc, shall not exceed 3 mm. (Tolerance shall be cumulative)

B - For Piping Bends having a radius equal to SIX times the diameter or larger

variations in the finished pipe caused by bending including any folds and bulges shall

not exceed 3% x Nominal of the Pipe.

C - Lateral translation of flanges in any direction from the indicated position shall not

exceed 1.5 mm.

D - Rotation of flanges from the indicated position as shown shall not exceed 1.5 mm.

E - Aligment of flanges shall not deviate from the indicated position measured across

any diameter more than 0.75 mm.

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

14 of 15

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

15 of 15

Line Blinds NPS 1/2 - NPS 24

Notes:

1. Nominal size and class shall be stamped as indicated on plate

2. Edges of test blancs shall be free from rough burn finish and burrs

Line Blinds NPS 26 - NPS 60

Notes:

1. Nominal size and class shall be stamped as indicated on plate

2. Edges of test blancs shall be free from rough burn finish and burrs

Spectacle Blinds NPS 1/2 - NPS 24

ASME B16.48 was used as the basis for calculating the blind thicknesses listed in this

table.

Common ASTM Materials of Construction: Carbon Steel - A515 Gr. 70, 65 & 60; A516

Gr. 70, 65 & 60. Stainless Steel - A240 Gr. 316, 316L, 304 & 304L.Reference Table 1A

in ASME B16.5 for a list of other acceptable plate material specifications for each

different material group.

Standard No.... Doc. No....

PIPING MATERIAL SPECIFICATION

Issue Date

December, 2011

Page

15 of 15

You might also like

- Piping Material SpecificationDocument29 pagesPiping Material SpecificationSathiyaseelan Sakthi Shanmugam100% (2)

- Piping Material Specification 2010014 00 l0 Gs 001Document215 pagesPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Halfaya Project Surface Facility Piping SpecificationDocument77 pagesHalfaya Project Surface Facility Piping SpecificationVignesh Panchabakesan67% (3)

- ES - Piping Material SpecificationDocument14 pagesES - Piping Material SpecificationJegan Cheng100% (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Piping Design CriteriaDocument15 pagesPiping Design CriteriaSubash Chandrabose0% (1)

- Thumb RuleDocument42 pagesThumb RuleShabeer KiblaalamNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- Piping Material Selection StandardDocument425 pagesPiping Material Selection StandardJitendra Bhosale100% (3)

- Piping SpecificationsDocument67 pagesPiping SpecificationsVedran Kosanovic100% (3)

- Piping Material SpecificationDocument108 pagesPiping Material SpecificationgeroldhemNo ratings yet

- Aterial Specification & All Thickness CalculationDocument35 pagesAterial Specification & All Thickness CalculationPanjiUte100% (1)

- Piping Material Specification Rev CDocument44 pagesPiping Material Specification Rev Cmengelito almonte100% (4)

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- What Is Piping MTO or Material Take-OffDocument4 pagesWhat Is Piping MTO or Material Take-Offvenkatraju.Y100% (1)

- MR For Ball ValvesDocument12 pagesMR For Ball Valvesengr_umer_01100% (1)

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiNo ratings yet

- Ma'aden Piping Material SpecificationDocument35 pagesMa'aden Piping Material Specificationkhyle093009No ratings yet

- Piping Isometrics ChecklistDocument3 pagesPiping Isometrics ChecklistSomnath Laha100% (1)

- Corporate Piping SpecDocument56 pagesCorporate Piping Specamanojp100% (2)

- 094135-PE-SPC-001 Piping Material Specification-REV 4Document76 pages094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- Flange Types and ClassificationsDocument11 pagesFlange Types and Classificationsrajesh119100% (1)

- Piping Interview Questionnaire 5Document2 pagesPiping Interview Questionnaire 5Valli RajuNo ratings yet

- Critical Line ListDocument20 pagesCritical Line ListCristhian Solano Bazalar100% (1)

- Orifice FlangeDocument70 pagesOrifice FlangePaulo SousaNo ratings yet

- Ashwin Udhe 1 Introduction To Piping Engineering PDFDocument6 pagesAshwin Udhe 1 Introduction To Piping Engineering PDFPoonam AshwinNo ratings yet

- Iit MumbaiDocument243 pagesIit MumbaiYogesh JagdaleNo ratings yet

- To Be A Piping Designer You Should KnowDocument7 pagesTo Be A Piping Designer You Should KnowQusroo AhmedNo ratings yet

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocument81 pagesC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- Rubber LinedDocument6 pagesRubber LinedPrasanta Kumar BeheraNo ratings yet

- Training Manual-Piping: Piping Study Underground PipingDocument30 pagesTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- Piping System Project ChecklistDocument2 pagesPiping System Project ChecklistMohsen KeramatiNo ratings yet

- Piping MaterialsDocument1 pagePiping MaterialsKalaiYarasanNo ratings yet

- Format From EIL 5 2744 0212 F1 - REV2Document27 pagesFormat From EIL 5 2744 0212 F1 - REV2sshastrimechNo ratings yet

- Weld Flange To PipeDocument1 pageWeld Flange To PipeGraham MooreNo ratings yet

- Specification For PipingDocument34 pagesSpecification For PipingjeswinNo ratings yet

- Piping Engineering Course OverviewDocument2 pagesPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Gate Globe Check Butterfly and Needle Valve Specification - 0000-TS-L007 Rev 2Document32 pagesGate Globe Check Butterfly and Needle Valve Specification - 0000-TS-L007 Rev 2Susan Sue Berrospi Merino100% (1)

- Check List For IsometricsDocument4 pagesCheck List For IsometricsashokNo ratings yet

- Lined Pipes & Fittings GuideDocument68 pagesLined Pipes & Fittings Guidegilbert4285No ratings yet

- Piping Design Requirements PDFDocument6 pagesPiping Design Requirements PDFkarunaNo ratings yet

- Universal Y StrainerDocument2 pagesUniversal Y Strainerabdi zakiNo ratings yet

- Piping SpecificationDocument24 pagesPiping SpecificationMd asrar aliNo ratings yet

- Inventory List of Pipes and FittingsDocument4 pagesInventory List of Pipes and FittingsBiginchNo ratings yet

- Pipe Support Criteria For B31.3Document9 pagesPipe Support Criteria For B31.3pipestressNo ratings yet

- Pipe Support Criteria For ASME B31.3 Metallic PipingDocument11 pagesPipe Support Criteria For ASME B31.3 Metallic PipingUsman Naseem100% (4)

- Ball Valves Specification - 0000-TS-L006 Rev 6Document23 pagesBall Valves Specification - 0000-TS-L006 Rev 6Agis Rijal Atmawijaya100% (1)

- HFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedDocument77 pagesHFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedVignesh Panchabakesan100% (1)

- Sans 719 PipeDocument19 pagesSans 719 PipeFabio Miguel100% (1)

- Piping BasisDocument32 pagesPiping Basislowermine100% (2)

- BES-L007 Pig LaunchersReceiversDocument13 pagesBES-L007 Pig LaunchersReceiversRakesh PanchalNo ratings yet

- Pipe Support Reference 8-29-14Document108 pagesPipe Support Reference 8-29-14HITESHNo ratings yet

- 903-10004-SPC-M-001 Piping Material SpecificationDocument15 pages903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNo ratings yet

- MS-6.1 Piping SupportsDocument19 pagesMS-6.1 Piping SupportsLe Thanh HaiNo ratings yet

- B88-14 Standard Specification For Seamless Copper Water TubeDocument7 pagesB88-14 Standard Specification For Seamless Copper Water TubeislamakthamNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- 04 Samss 003Document4 pages04 Samss 003Moustafa Bayoumi100% (1)

- Compressed Air Installation SpecificationDocument28 pagesCompressed Air Installation SpecificationTemur LomidzeNo ratings yet

- GEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsDocument107 pagesGEN-L-XXX-SP-0001 - 5 - Specification For Piping and Valve MaterialsWilliam Smith100% (3)

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- CEEW Access To Clean Cooking Energy and Electricity 11jan19 - 0 PDFDocument126 pagesCEEW Access To Clean Cooking Energy and Electricity 11jan19 - 0 PDFGanesh EshwarNo ratings yet

- India's Resource Nexus: Overview of The Research LandscapeDocument26 pagesIndia's Resource Nexus: Overview of The Research LandscapeGanesh EshwarNo ratings yet

- CPMDocument19 pagesCPMatifmd1No ratings yet

- General Tamil Part 1Document10 pagesGeneral Tamil Part 1Ganesh EshwarNo ratings yet

- 24 - 01 - 2016 - General - Tamil - ANSWER KEYDocument26 pages24 - 01 - 2016 - General - Tamil - ANSWER KEYsasNo ratings yet

- TEST - 6 English, History, Apps PDFDocument39 pagesTEST - 6 English, History, Apps PDFAnandhSmartNo ratings yet

- TNPSC Current Affairs November 2015 in Tamil WWW Tnpscportal inDocument23 pagesTNPSC Current Affairs November 2015 in Tamil WWW Tnpscportal inGanesh EshwarNo ratings yet

- General Studies 101 To 200Document20 pagesGeneral Studies 101 To 200Ganesh EshwarNo ratings yet

- NHGKJDocument9 pagesNHGKJChandan V ChanduNo ratings yet

- IDPCDocument68 pagesIDPCRaja SubramanianNo ratings yet

- General Studies 81-100Document5 pagesGeneral Studies 81-100vikNo ratings yet

- 7th Social ScienceDocument159 pages7th Social ScienceGanesh EshwarNo ratings yet

- SSC CGL Tier 1&2 Syllabus 2016: Subjects and TopicsDocument3 pagesSSC CGL Tier 1&2 Syllabus 2016: Subjects and TopicsGanesh EshwarNo ratings yet

- General Tamil Part 2Document9 pagesGeneral Tamil Part 2Ganesh EshwarNo ratings yet

- Make in India Week Mumbai Feb 2016Document23 pagesMake in India Week Mumbai Feb 2016Ganesh EshwarNo ratings yet

- Exporter Guide New Delhi India 1-21-2016Document52 pagesExporter Guide New Delhi India 1-21-2016Ganesh EshwarNo ratings yet

- 10th TamilDocument118 pages10th TamilGanesh EshwarNo ratings yet

- 9th PArt - 3Document26 pages9th PArt - 3Ganesh EshwarNo ratings yet

- Purchase Order 008Document2 pagesPurchase Order 008Ganesh EshwarNo ratings yet

- India’s leading solar energy solution providerDocument15 pagesIndia’s leading solar energy solution providerGanesh EshwarNo ratings yet

- 8TH Tamil NotesDocument13 pages8TH Tamil NotesGanesh Eshwar67% (3)

- Brochure XLDocument17 pagesBrochure XLGanesh EshwarNo ratings yet

- 10th Science DrawingsDocument11 pages10th Science DrawingsGanesh EshwarNo ratings yet

- Factors Affecting Labour ProductivityDocument18 pagesFactors Affecting Labour ProductivityViralkumar ShahNo ratings yet

- WFI#01910 Address: No:1141, KG Kilanas, JLN Tutong - Darussalam - BSB BF 252 - BRUNEI. WebDocument1 pageWFI#01910 Address: No:1141, KG Kilanas, JLN Tutong - Darussalam - BSB BF 252 - BRUNEI. WebGanesh EshwarNo ratings yet

- 6th Social ScienceDocument35 pages6th Social ScienceGanesh EshwarNo ratings yet

- 8th Tamil Part 3Document18 pages8th Tamil Part 3Ganesh EshwarNo ratings yet

- 9 TH Tamil p1Document35 pages9 TH Tamil p1Ganesh EshwarNo ratings yet

- Physics DrawingsDocument27 pagesPhysics DrawingsGanesh EshwarNo ratings yet

- How to Optimize Your Website for SEODocument30 pagesHow to Optimize Your Website for SEOGanesh EshwarNo ratings yet

- Zap Screwlok Gen Proposal - Rev0107Document22 pagesZap Screwlok Gen Proposal - Rev0107ludwingNo ratings yet

- New M.S. Students: Me 8Xx Me 9XxDocument4 pagesNew M.S. Students: Me 8Xx Me 9XxFatima GORINENo ratings yet

- Melfa Basic VDocument516 pagesMelfa Basic VAnderson Gomez Castro67% (3)

- Access Diploma To Higher Education in Social Work (OCNOTC) AccountingDocument3 pagesAccess Diploma To Higher Education in Social Work (OCNOTC) Accountingahi2000No ratings yet

- Work Shop Manual GR 15 Matr 1-5302-467Document74 pagesWork Shop Manual GR 15 Matr 1-5302-467Neznanog Junaka Sest VranjeNo ratings yet

- 4aa5 5473enwDocument28 pages4aa5 5473enwvimal_rajkkNo ratings yet

- KN238EGB A - OpsMan (Maxima II TM) - (#C3797 or Higher) PDFDocument212 pagesKN238EGB A - OpsMan (Maxima II TM) - (#C3797 or Higher) PDFurkkkkNo ratings yet

- PCB Layer StackupDocument92 pagesPCB Layer Stackupdanielradu27No ratings yet

- Percent Decimal Fraction Conversion Comparison PDFDocument16 pagesPercent Decimal Fraction Conversion Comparison PDFChris21Jinky100% (1)

- Ultrasonic Examination of The Weld Zone of Welded Pipe and TubingDocument4 pagesUltrasonic Examination of The Weld Zone of Welded Pipe and TubingERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- FAQ - FactoryTalk Historian SE CollectivesDocument2 pagesFAQ - FactoryTalk Historian SE CollectivesjaysonlkhNo ratings yet

- Amit Kumar Android Developer Resume SEODocument2 pagesAmit Kumar Android Developer Resume SEOamitNo ratings yet

- Pressure Reducing Valve Technical SpecificationsDocument4 pagesPressure Reducing Valve Technical SpecificationsjajakaNo ratings yet

- Case Study 55 Baker StreetDocument4 pagesCase Study 55 Baker Streetsunny_nsecNo ratings yet

- FreePBX Training Neocenter Jun19 23 Pag - 37 170Document134 pagesFreePBX Training Neocenter Jun19 23 Pag - 37 170jose sanchezNo ratings yet

- Creating Web Page Using HTMLDocument40 pagesCreating Web Page Using HTMLTejas PatelNo ratings yet

- TGB Blade 425 400 Manual de Reparatie WWW - Manualedereparatie.infoDocument229 pagesTGB Blade 425 400 Manual de Reparatie WWW - Manualedereparatie.infohonoregerard100% (1)

- More power and reliability from 655W bifacial solar moduleDocument2 pagesMore power and reliability from 655W bifacial solar modulerafaelluquezNo ratings yet

- O o o O: QuestionsDocument49 pagesO o o O: QuestionsDr. Mohamed E. HarbNo ratings yet

- Boomer S 1D PDFDocument4 pagesBoomer S 1D PDFlorenzo henerNo ratings yet

- 8.5.2 Identification and TraceabilityDocument5 pages8.5.2 Identification and Traceabilitymedtaher missaoui0% (1)

- Operation & Maintenance Manual: EC22N2 EC25N2 EC25EN2 EC25LN2 EC30N2 EC30LN2Document8 pagesOperation & Maintenance Manual: EC22N2 EC25N2 EC25EN2 EC25LN2 EC30N2 EC30LN2cristian faundes0% (2)

- M.S. SHEET AND PLATE SPECIFICATIONSDocument3 pagesM.S. SHEET AND PLATE SPECIFICATIONSvjvijay88No ratings yet

- Instruction Manual: 1000 Standard Orbital ShakerDocument35 pagesInstruction Manual: 1000 Standard Orbital Shakermanuela HurtadoNo ratings yet

- Asme Sec II D Ma App 2Document3 pagesAsme Sec II D Ma App 2GicuNo ratings yet

- Focus - FLL (2004)Document740 pagesFocus - FLL (2004)RobboNo ratings yet

- Conventional Zone Interface Module P/N 55-055 and 55-060 2-Wire Detector Compatibility DocumentDocument10 pagesConventional Zone Interface Module P/N 55-055 and 55-060 2-Wire Detector Compatibility DocumentErnesto OtazuNo ratings yet

- ConfigurationData 2020 06 16 12 17 09Document4,077 pagesConfigurationData 2020 06 16 12 17 09Anonymous oLo6cDDNo ratings yet

- (PDF) Village Road ConstructionDocument25 pages(PDF) Village Road ConstructionpradeepNo ratings yet

- Rights of Persons with Disabilities Act 2008 SummaryDocument6 pagesRights of Persons with Disabilities Act 2008 SummaryAlia ShahiraNo ratings yet