Professional Documents

Culture Documents

ST TF Acousticmat Tds

Uploaded by

yanickdouce5408Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST TF Acousticmat Tds

Uploaded by

yanickdouce5408Copyright:

Available Formats

Issued May 2005

C

o

n

s

t

r

u

c

t

i

o

n

Sika Acoustic Matt

Page 1 of 2

C

o

n

s

t

r

u

c

t

i

o

n

Sika Acoustic

Matt

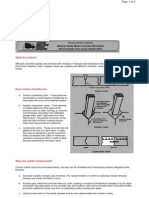

Sound Insulating System for Timber Flooring

Description

The Sika Acoustic Matt system consists of the sound dampening, one

component adhesive, SikaBond-T55 (J ) and the Sika Acoustic Rubber Matt.

Uses

The Sika Acoustic Matt is used to bond timber floors in residential, office and

industrial buildings. The system provides a sound dampening effect

improving the acoustic insulation of a room.

Advantages

Reduced noise and vibration transmission.

Low floor zone thickness.

Remains permanently flexible.

Thin construction with high performance.

Simple and easy to install.

Available in a variety of sheets, sizes, strips or pads.

Resists ageing and deformation.

Consistent density and thickness for maximum performance

Use of Australian recycled rubbers.

Instructions for Use

Surface Preparation

All surfaces must be clean, dry, sound and free from dust and loose particles.

Paint, laitance and other poorly adhering particles must be removed by

grinding. Standard construction rules or the timber manufacturers or the

timber manufacturers instructions regarding moisture content of concrete,

cement screeds or wooden substrates must be observed.

Concrete/cement screed substrate: No preparation is necessary on a dry,

dense, wearable substrate. For other substrate conditions, the floor must be

grinded and thoroughly cleaned with an industrial vacuum cleaner.

(Important: Pre-Trials absolutely necessary)

Other substrates: In case of flowable screeds and other unknown substrates

we recommend that you consult your local Sika Technical Representative.

Priming

The moisture content should be measured in accordance with the Floor

Coverings Standard, AS1884-1985. A method of testing concrete moisture is

given in the appendix of this standard.

When the moisture content of the concrete is found to be below 5.5%, the

substrate is considered suitable for SikaBond-T55 (J ) to be applied without a

primer.

When the moisture content of the concrete is found to be between 5.5% and

10%, Sika Primer MB must be used as a primer before applying SikaBond-

T55 (J ).

When the moisture content of the concrete is greater than 10%, EpoCem

(Sikafloor-81 or Sikagard-720) should be used as a temporary moisture

barrier. Sika Primer MB should then be used as a prime coat before applying

SikaBond-T55 (J ).

When priming with Sika Primer MB, a continuous visible film of cured epoxy

must be observed on the surface. The application rate will depend on the

porosity of the substrate.

Application

Sausage: Place the sausage in the application gun and snip off the end. Cut

the tip off the nozzle to suit the application and apply the adhesive with

suitable hand or compressed air gun.

Pail: Remove lid off pail and cut open foil liner. Once opened, the entire

contents of the pail should be used within a short period of time.

Do not apply SikaBond-T55 (J ) at temperatures below 5C or above 35C.

The optimum temperature for substrate and adhesive is between 15C and

25C.

The adhesive should be applied over a large surface areas with a notched

spreader (notch depth approx. 6mm to achieve 4mm head height). The

coverage will vary from 800ml to 1000ml per m. Avoid air entrapment when

making the bond or filling joints.

Issued May 2005

C

o

n

s

t

r

u

c

t

i

o

n

C

o

n

s

t

r

u

c

t

i

o

n

Sika Acoustic Matt

Page 2 of 2

Sika Australia Pty Limited www.sika.com.au

ABN 12 001 342 329 Tel: 1300 22 33 48

Application (continued)

Apply firm pressure when bringing the Acoustic Matt in contact with the

SikaBond T55 (J ). After twelve hours of application of the Acoustic Matt,

screed another layer of Sikabond T55 (J ) to the Matt and apply timber

planks. Keep the components under pressure for at least 3 hours until the

adhesive has partially cured.

For application details of timber flooring systems, contact the timber

manufacturer.

Technical Data (Typical)

1. Sika Acoustic Matt

Type Prefabricated medium density rubber underlay designed for noise and

vibration insulation and resilience.

Colour Black

Density 350 kg/m

3

Thickness 5 mm

Dimensions 1 m wide

1 m long

1 m

2

/matt

2. SikaBond T55 (J)

Type One part polyurethane

Colour Beige

Density 1.35 kg/litre

Tack Free Time Approximately 90 minutes (at 23C & 50% r.h)

Rate of Cure 3 mm in 24 hours (at 23C & 50% r.h)

Shore A 38 (DIN 53505)

Tensile Strength >1.5 MPA (DIN 53504)

Tensile Shear Strength >1.0 MPA (DIN 281)

Elongation at Break >400% (DIN 53504)

Service Temperature -40C & +80C

Packaging 600 ml sausage, 2 kg sausage, 16 kg pail

Important Notes

Floors can be walked on 24 hours after installation (no traffic or heavy

concentrated loads). The floor is fully serviceable after 48 hours.

For proper curing of the SikaBond-T55 (J ), it must be allowed to

moisture cure (i.e. either from the substance or the air).

SikaBond-T55 (J ) should not be used on polyethylene, polypropylene,

Teflon & other plasticised synthetic materials. (Trials should be

conducted if in doubt).

Consult Sika Primer MB Technical Data Sheet for detailed priming

information.

Timber flooring systems should be allowed to acclimatise to the

environment it is to be placed in to allow for expansion and shrinkage

problems that may occur. Refer to the timber manufacturers

installation and design procedures.

Important Notification

The information, and, in particular, the recommendations relating to the application

and end-use of Sikas products, are given in good faith based on Sikas current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions. . In practice, the differences in materials,

substrates and actual site conditions are such that no warranty in respect of

merchantability or of fitness for a particular purpose, nor any liability arising out of

any legal relationship whatsoever, can be inferred either from this information, or

from any written recommendations, or from any other advice offered. The

proprietary rights of third parties must be observed. All orders are accepted

subject of our terms and conditions of sale. Users should always refer to the most

recent issue of the Technical Data Sheet for the product concerned, copies of

which will be supplied on request.

PLEASE CONSULT OUR TECHNICAL DEPARTMENT FOR FURTHER

INFORMATION.

You might also like

- Scott Resio PantojaDocument12 pagesScott Resio Pantojayanickdouce5408No ratings yet

- 3 Project Natural Environment: 3.1 BathymetryDocument9 pages3 Project Natural Environment: 3.1 Bathymetryyanickdouce5408No ratings yet

- Waves and Currents Near ShoreDocument5 pagesWaves and Currents Near Shoreyanickdouce5408No ratings yet

- 21 - Climate Variability of Tropical CyclonesDocument21 pages21 - Climate Variability of Tropical Cyclonesyanickdouce5408No ratings yet

- CraneDocument36 pagesCraneGautam Paul100% (2)

- Separation of Wind Sea and Swell From Nearshore Ocean Wave SpectraDocument4 pagesSeparation of Wind Sea and Swell From Nearshore Ocean Wave Spectrayanickdouce5408No ratings yet

- Design of Circular Concrete TanksDocument85 pagesDesign of Circular Concrete TanksRoda Cadiz88% (8)

- 21 - Climate Variability of Tropical CyclonesDocument21 pages21 - Climate Variability of Tropical Cyclonesyanickdouce5408No ratings yet

- 21 - Climate Variability of Tropical CyclonesDocument21 pages21 - Climate Variability of Tropical Cyclonesyanickdouce5408No ratings yet

- 19 BraceDocument10 pages19 BraceAbtin DadgarNo ratings yet

- Methods For Design of Hoppers, Silo's, Bins & BunkersDocument10 pagesMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzeNo ratings yet

- Industrial Silo Optimization: Varun GopinathDocument70 pagesIndustrial Silo Optimization: Varun Gopinathyanickdouce5408100% (1)

- Abhrjul Aug 84 89435 Durack PDFDocument6 pagesAbhrjul Aug 84 89435 Durack PDFyanickdouce5408No ratings yet

- BSA Alert 14.01 Line Failure On A Compressed Air PipeDocument1 pageBSA Alert 14.01 Line Failure On A Compressed Air Pipeyanickdouce5408No ratings yet

- Joints in Concrete SlabsDocument2 pagesJoints in Concrete Slabsyanickdouce5408No ratings yet

- Freehaul, Overhaul Calculation and Mass Haul DiagramDocument5 pagesFreehaul, Overhaul Calculation and Mass Haul Diagramferdyak1No ratings yet

- Chapter 7 Section 7.5Document12 pagesChapter 7 Section 7.5yanickdouce5408No ratings yet

- HDS No. 5Document368 pagesHDS No. 5kodiak31No ratings yet

- Pavement FactsDocument6 pagesPavement Factsyanickdouce5408No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Revised Man As A Biological BeingDocument8 pagesRevised Man As A Biological Beingapi-3832208No ratings yet

- Seminar #22 Vocabury For Speaking PracticeDocument7 pagesSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegNo ratings yet

- Trove Research Carbon Credit Demand Supply and Prices 1 June 2021Document51 pagesTrove Research Carbon Credit Demand Supply and Prices 1 June 2021Ceren ArkancanNo ratings yet

- IEC-60721-3-3-2019 (Enviromental Conditions)Document12 pagesIEC-60721-3-3-2019 (Enviromental Conditions)Electrical DistributionNo ratings yet

- Tugas B InggrisDocument6 pagesTugas B Inggrisiqbal baleNo ratings yet

- 9AKK101130D1664 OISxx Evolution PresentationDocument16 pages9AKK101130D1664 OISxx Evolution PresentationfxvNo ratings yet

- Published Filer List 06072019 Sorted by CodeDocument198 pagesPublished Filer List 06072019 Sorted by Codeherveduprince1No ratings yet

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Document285 pagesExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniNo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- Bitcoin MambaDocument17 pagesBitcoin MambaJean MilenixNo ratings yet

- Febrile SeizureDocument3 pagesFebrile SeizureClyxille GiradoNo ratings yet

- All MeterialsDocument236 pagesAll MeterialsTamzid AhmedNo ratings yet

- Interna Medicine RheumatologyDocument15 pagesInterna Medicine RheumatologyHidayah13No ratings yet

- SQL 1: Basic Statements: Yufei TaoDocument24 pagesSQL 1: Basic Statements: Yufei TaoHui Ka HoNo ratings yet

- Analysis of VariancesDocument40 pagesAnalysis of VariancesSameer MalhotraNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Test SessionDocument2 pagesTest SessionMuhammad Fiaz AslamNo ratings yet

- Raychem Price ListDocument48 pagesRaychem Price ListramshivvermaNo ratings yet

- D257272 1200 FDD 002 R1 PDFDocument420 pagesD257272 1200 FDD 002 R1 PDFTap Toan100% (1)

- Crash Cart - General Checklist For Medical Supplies On Crash CartsDocument3 pagesCrash Cart - General Checklist For Medical Supplies On Crash CartsYassen ManiriNo ratings yet

- LLM DissertationDocument94 pagesLLM Dissertationjasminjajarefe100% (1)

- C ClutchesDocument131 pagesC ClutchesjonarosNo ratings yet

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Document28 pagesMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palNo ratings yet

- ArtigoPublicado ABR 14360Document14 pagesArtigoPublicado ABR 14360Sultonmurod ZokhidovNo ratings yet

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocument6 pages99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaNo ratings yet

- Biomechanics of Advanced Tennis: January 2003Document7 pagesBiomechanics of Advanced Tennis: January 2003Katrien BalNo ratings yet

- Jesus - The Creator Unleashes Our Creative PotentialDocument1 pageJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNo ratings yet

- Java MCQ QuestionsDocument11 pagesJava MCQ QuestionsPineappleNo ratings yet

- R4 User GuideDocument48 pagesR4 User GuideAaron SmithNo ratings yet

- MKT-case StudyDocument7 pagesMKT-case StudyJoe Thampi KuruppumadhomNo ratings yet