Professional Documents

Culture Documents

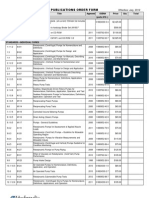

Previews HI 9 6 4 2009 Pre

Uploaded by

SHAMSIK200250%(2)50% found this document useful (2 votes)

787 views11 pagespump

Original Title

previews_HI_9_6_4_2009_pre

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

787 views11 pagesPreviews HI 9 6 4 2009 Pre

Uploaded by

SHAMSIK2002pump

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

6 Campus Drive

First Floor North

Parsippany, New Jersey

07054-4406

www.Pumps.org

A

N

S

I

/

H

I

9

.

6

.

4

-

2

0

0

9

ANSI/HI 9.6.4-2009

American National Standard for

Rotodynamic

Pumps

for Vibration Measurements and

Allowable Values

This page intentionally blank.

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

ANSI/HI 9.6.4-2009

American National Standard for

Rotodynamic Pumps

for Vibration Measurements and

Allowable Values

Sponsor

Hydraulic Institute

www.Pumps.org

Approved May 13, 2009

American National Standards Institute, Inc.

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

Approval of an American National Standard requires verification by ANSI that the

requirements for due process, consensus and other criteria for approval have been met

by the standards developer.

Consensus is established when, in the judgement of the ANSI Board of Standards

Review, substantial agreement has been reached by directly and materially affected

interests. Substantial agreement means much more than a simple majority, but not nec-

essarily unanimity. Consensus requires that all views and objections be considered,

and that a concerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence does

not in any respect preclude anyone, whether he has approved the standards or not,

from manufacturing, marketing, purchasing, or using products, processes, or proce-

dures not conforming to the standards.

The American National Standards Institute does not develop standards and will in no

circumstances give an interpretation of any American National Standard. Moreover, no

person shall have the right or authority to issue an interpretation of an American

National Standard in the name of the American National Standards Institute. Requests

for interpretations should be addressed to the secretariat or sponsor whose name

appears on the title page of this standard.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at

any time. The procedures of the American National Standards Institute require that

action be taken periodically to reaffirm, revise, or withdraw this standard. Purchasers of

American National Standards may receive current information on all standards by call-

ing or writing the American National Standards Institute.

Published By

Hydraulic Institute

6 Campus Drive, First Floor North

Parsippany, NJ 07054-4406

www.Pumps.org

Copyright 2009 Hydraulic Institute

All rights reserved.

No part of this publication may be reproduced in any form,

in an electronic retrieval system or otherwise, without prior

written permission of the publisher.

Printed in the United States of America

ISBN 978-1-880952-82-5

American

National

Standard

Recycled

paper

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

iii

Contents

Page

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values. . . . . . . . . . . . . . . . . . . . . 1

9.6.4.1 Introduction and scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9.6.4.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9.6.4.1.2 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9.6.4.2 Bearing housing vibration measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9.6.4.2.1 Measurement units and procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9.6.4.2.2 Vibration measurement instrumentation and transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9.6.4.2.3 Measurement locations and directions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9.6.4.2.4 Vibration acceptance tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

9.6.4.2.5 Allowable pump bearing housing vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appendix A Test Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Appendix B Factors Affecting Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

B.1 Residual mechanical unbalance of rotating parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

B.2 Residual mechanical unbalance of rotating parts - abrasive fluids . . . . . . . . . . . . . . . . . . . . . . . 17

B.3 Pump and driver natural frequency and resonance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B.4 Miscellaneous mechanical problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B.5 Hydraulic disturbances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B.6 Hydraulic resonance in piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B.7 Effect of rigidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix C Recommended Default Initial Field Alarm and Trip Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appendix D Vibration Source Identification Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix E Vibration Transducer Mounting and Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix F Vibration Transducer Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Appendix G Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figures

9.6.4.2.2.2 Mounting methods for vibration transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

9.6.4.2.3.1 Measurement locations and directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

9.6.4.2.5.1a Allowable pump vibration, pump types BB1, BB2, BB3, BB4, BB5, OH1, OH2, OH3,

OH4, OH5, and OH7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9.6.4.2.5.1b Allowable pump vibration, pump types VS1, VS2, VS3, VS4, VS5, VS6, VS7, and VS8 . . . . . . . . 8

9.6.4.2.5.1c Allowable pump vibration, solids-handling pump types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

9.6.4.2.5.1d Allowable pump vibration, slurry pump types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B.1 Center of gravity displacement or acceptable residual unbalance (balance grade G6.3)

metric units (Ref. ISO 1940) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

B.2 Center of gravity displacement or acceptable residual unbalance (balance grade G6.3)

US customary units (Ref. ISO 1940) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

B.3 Single suction impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

iv

B.4 Double suction impeller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

E.1 Typical response of three mounting types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Tables

9.6.4.2.5.2a Additional acceptance criteria for pumps operating at 600 rpm and below. . . . . . . . . . . . . . . . . . 10

9.6.4.2.5.2b Additive values to Table 9.6.4.2.5.2a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

v

Foreword (Not part of Standard)

Purpose and aim of the Hydraulic Institute

The purpose and aims of the Institute are to promote the continued growth of pump knowledge for the interest of

pump users and manufacturers and to further the interests of the public in such matters as are involved in manufac-

turing, engineering, distribution, safety, transportation and other problems of the industry, and to this end, among

other things:

a) To develop and publish standards for pumps;

b) To collect and disseminate information of value to its members and to the public;

c) To appear for its members before governmental departments and agencies and other bodies in regard to mat-

ters affecting the industry;

d) To increase the amount and to improve the quality of pump service to the public;

e) To support educational and research activities;

f) To promote the business interests of its members but not to engage in business of the kind ordinarily carried on

for profit or to perform particular services for its members or individual persons as distinguished from activities

to improve the business conditions and lawful interests of all of its members.

Purpose of Standards

1) Hydraulic Institute Standards are adopted in the public interest and are designed to help eliminate misun-

derstandings between the manufacturer, the purchaser and/or the user and to assist the purchaser in

selecting and obtaining the proper product for a particular need.

2) Use of Hydraulic Institute Standards is completely voluntary. Existence of Hydraulic Institute Standards

does not in any respect preclude a member from manufacturing or selling products not conforming to the

Standards.

Definition of a Standard of the Hydraulic Institute

Quoting from Article XV, Standards, of the By-Laws of the Institute, Section B:

An Institute Standard defines the product, material, process or procedure with reference to one or more of the fol-

lowing: nomenclature, composition, construction, dimensions, tolerances, safety, operating characteristics, perfor-

mance, quality, rating, testing and service for which designed.

Comments from users

Comments from users of this standard will be appreciated, to help the Hydraulic Institute prepare even more useful

future editions. Questions arising from the content of this standard may be sent to the Technical Director of the

Hydraulic Institute. The inquiry will then be directed to the appropriate technical committee for provision of a suit-

able answer.

If a dispute arises regarding contents of an Institute standard or an answer provided by the Institute to a question

such as indicated above, the point in question shall be sent to the Technical Director of the Hydraulic Institute, who

shall initiate the Appeals Process.

Revisions

The Standards of the Hydraulic Institute are subject to constant review, and revisions are undertaken whenever it is

found necessary because of new developments and progress in the art. If no revisions are made for five years, the

standards are reaffirmed using the ANSI canvass procedure.

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

vi

Major revisions

This standard, ANSI/HI 9.6.4-2009 Rotodynamic Pumps for Vibration Measurements and Allowable Values, was

last published as ANSI/HI 9.6.4-2000. This updated edition is essentially a complete rewrite as compared to the

previously published standard. In order to assist users of the standard in recognizing the changes, major revisions

to the standard are provided as follows.

Tutorial information regarding dynamic analysis has been removed. This topic will be covered in a new document

that is planned to be published as new guideline, ANSI/HI 9.6.8 Dynamics of Pumping Machinery. The new docu-

ment was in the development stage at the time of this writing and a precise publication date is not known.

The scope of application of the standard has been clarified to identify pump types that are excluded from the stan-

dard.

Metric units are now primary, with US customary units secondary. For speeds above 600 rpm, the measurement

quantity to be used for measuring the vibration of nonrotating parts of rotodynamic pumps is velocity in millimeters

per second RMS or inches per second RMS.

Additional requirements have been added for operational speeds 600 rpm and lower. For speeds 600 rpm and

below, measurement of the overall peak-to-peak displacement is required in addition to overall RMS velocity.

The Hydraulic Institute standard pump type nomenclature provided in ANSI/HI 1.1-1.2 Rotodynamic (Centrifugal)

Pumps for Nomenclature and Definitions and ANSI/HI 2.1-2.2 Rotodynamic (Vertical) Pumps for Nomenclature and

Definitions has been incorporated, with a new system of icons introduced to assist the user in recognizing the

pump types and identifying the measurement locations.

Although this standard requires that the vibration test location is in the field by default, levels are provided for

optional factory tests for most pump types.

The allowable vibration requirements have been updated to reflect acceptable performance both for field and fac-

tory tests, based on hundreds of data points obtained in surveys conducted since the publication of the previous

edition. The revised allowable values have been compared with those presented by other standards organizations,

including ISO and API, and can be considered as commensurate.

Values are presented for preferred operating region (POR) and allowable operating region (AOR).

To assist the user of the standard, a suggested vibration test report form is provided in an appendix.

Recommended default initial field alarm and trip settings are provided in an appendix.

A vibration troubleshooting chart is provided in an appendix.

Information on transducer types, mounting, and sensitivity is provided in two appendices.

Units of measurement

Metric units of measurement are used, and corresponding US customary units appear in brackets. Charts, graphs,

and sample calculations are also shown in both metric and US customary units. Since values given in metric units

are not exact equivalents to values given in US customary units, it is important that the selected units of measure to

be applied be stated in reference to this standard. If no such statement is provided, metric units shall govern.

Consensus

Consensus for this standard was achieved by use of the canvass method. The following organizations, recognized

as having interest in rotodynamic pumps for vibration measurements and allowable values, were contacted prior to

the approval of this revision of the standard. Inclusion in the list does not necessarily imply that the organization

concurred with the submittal of the proposed standard to ANSI.

Anspach Consulting

Baldor Electric Company

Bechtel Power Corporation

Black & Veatch

Budris Consulting

Buse, Fred Consultant

Flowserve Pump Division

Grundfos Pumps Corporation

Healy Engineering

ITT - Industrial Process

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

vii

ITT - Residential & Commercial Water

Malcolm Pirnie

National Pump Company, LLC

Patterson Pump Company

Peerless Pump Company

Pentair Water

Powell Kugler, Inc.

Sulzer Pumps (US) Inc.

Weir Floway, Inc.

Weir Minerals North America

Weir Specialty Pumps

Committee List

Although this standard was processed and approved for submittal to ANSI by the Canvass Method, a working com-

mittee met many times to facilitate its development. At the time it was developed, the committee had the following

members:

Chair Jack Claxton, Patterson Pump Company

Vice-Chair Michael Cropper, Sulzer Pumps (US) Inc.

Committee Members Company

Stefan Abelin ITT - Water & Wastewater

Graeme Addie GIW Industries, Inc.

Thomas Angle Weir Specialty Pumps

John Anspach John Anspach Consulting

Julian Atchia SJE-Rhombus

Allen Behring A.G. Behring Company

James Bonifas Emerson Motors/US Motors

Charles Cappellino ITT - Industrial Process

James Healy Healy Engineering

Thomas Hendrey Whitley Burchett & Associates

Greg Highfill A.R. Wilfley & Sons, Inc.

Michael Hiscock South Florida Water Management District

Allen Hobratschk National Pump Company, LLC

Al Iseppon Pentair Water

Garr Jones Brown and Caldwell

Dimitar Kalchev Peerless Pump Company

Mika Kaplan King County Wastewater Treatment Division

Yuri Khazanov InCheck Technologies Inc.

Zan Kugler Powell Kugler, Inc.

William Marscher Mechanical Solutions, Inc.

Tony Radcliff Grundfos Pumps Corporation

James Roberts ITT - Residential & Commercial Water

Mark Rosebraugh Yeomans Chicago Corporation

Aleksander Roudnev Weir Minerals North America

Arnold Sdano Fairbanks Morse Pump Corporation

Ernest Sturtz CDM

Roger Turley Flowserve Pump Division

Fred Walker Weir Floway, Inc.

Brett Zerba TACO, Inc.

Alternate Company

Charles Allaben CDM

Edward Allis Peerless Pump Company

Lech Bobowski Peerless Pump Company

Randal Ferman Flowserve Pump Division

Mark Jaminet ITT - Water & Wastewater

John Kelly Yeomans Chicago Corporation

Gary Leander Weir Minerals North America

Patrick Moyer ITT - Residential & Commercial Water

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

viii

Michael Mueller Flowserve Pump Division

Richard O'Donnell ITT - Industrial Process

Sami Sarrouh Brown and Caldwell

Robert Visintainer GIW Industries, Inc.

Experts

Lyn Greenhill Dyna Tech

Mark Corbo No Bull Engineering

Additional Contributors

William A. Beekman

Fred Buse

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

HI Rotodynamic Pumps for Vibration Measurements and Allowable Values 2009

1

9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values

9.6.4.1 Introduction and scope

9.6.4.1.1 Introduction

This standard pertains to evaluation of vibration when the vibration measurements are made on nonrotating parts

(bearing housings) of rotodynamic pumps. It provides specific maximum allowable vibration values measured on

bearing housings of rotodynamic pumps in field and factory test environments.

For certain vertical pump types, the vibration probes shall be located near the top of the motor support (refer to Fig-

ure 9.6.4.2.3.1, Measurement locations and directions). For vertical pump types, the reference to bearing housing

refers to this location.

Vibration measurements can be useful for many purposes, such as acceptance tests, diagnostic or analytic investi-

gations, and operational monitoring.

A general description of the principles to be applied for the measurement and assessment of vibration on rotody-

namic pumps is given for vibration on nonrotating parts.

This standard is based on experiences from pump users and manufacturers as well as vibration measurements by

many companies. Vibration data from both factory test and field test environments have been incorporated into the

maximum allowable vibration values. Values are applicable when the pump is installed per Hydraulic Institute Stan-

dards or the manufacturers specifications.

9.6.4.1.2 Scope

This standard applies to the evaluation of vibration on rotodynamic pump applications absorbing more than 2 kW

(3 hp) and of the types as indicated in Figure 9.6.4.2.3.1. It pertains to evaluation of vibration when the vibration

measurements are made on nonrotating parts (bearing housing vibration).

The general evaluation criteria are included for acceptance tests in field environments or at the manufacturers test

facility, as appropriate and as defined in the standard.

The following types of pumping equipment and associated equipment are excluded from this standard:

Submersible pumps (refer to ANSI/HI 11.6)

Submersible vertical turbine pumps

Wet pit cantilever belt-driven pumps with overhung motors

API 610 or ISO 13709 pumps (refer to API 610 or ISO 13709)

Reciprocating engine-driven pumps

Separately mounted drivers (i.e., vertical motors on separate floors)

Right-angle gear drives

Maritime applications

For these pumping equipment types, refer to other industry standards, if available, or the pump manufacturer.

Torsional vibration is not dealt with in this standard.

Hydraulic Institute Standards, Copyright 1997-2009, All Rights Reserved

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- HIS For Vertical PumpDocument72 pagesHIS For Vertical PumpVaibhavSharma100% (2)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryFrom EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNo ratings yet

- ANSI - HI 9.6.2-2001 Centrifugal and Vertical Pumps For Allowable Nozzle Loads PDFDocument46 pagesANSI - HI 9.6.2-2001 Centrifugal and Vertical Pumps For Allowable Nozzle Loads PDFRoro83% (6)

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Ansi Hi 9.1-9.5-2000 PDFDocument78 pagesAnsi Hi 9.1-9.5-2000 PDFandhucaos100% (1)

- Ansi Hi 9 6 1Document24 pagesAnsi Hi 9 6 1Maqsood Ibn Shaikhul Arfeen100% (2)

- HIS 1.4 Centrifugal Pumps Installation OperationDocument66 pagesHIS 1.4 Centrifugal Pumps Installation OperationAyon Bose100% (2)

- HI 1.3 For Design and Application PDFDocument96 pagesHI 1.3 For Design and Application PDFmbgs31100% (2)

- Previews HI 9 6 1 2012 PreDocument12 pagesPreviews HI 9 6 1 2012 Prearundhamodharan4294No ratings yet

- Cebtrifugal Pump VibrationDocument15 pagesCebtrifugal Pump VibrationHarsh Khatri100% (1)

- Effects of Liquid ViscosityDocument44 pagesEffects of Liquid ViscosityVicky GautamNo ratings yet

- Pumps - General Guidelines: American National Standard ForDocument5 pagesPumps - General Guidelines: American National Standard ForDendi HanafiNo ratings yet

- Previews HI 9 6 1 2012 PreDocument12 pagesPreviews HI 9 6 1 2012 Pretexwan_100% (2)

- Ansi-Hi 9.6.4 (2000)Document38 pagesAnsi-Hi 9.6.4 (2000)Esteban Tobar88% (17)

- HI 9-6-6 2009 PreDocument13 pagesHI 9-6-6 2009 PreAnonymous CMS3dL1T0% (1)

- Previews 2502414 PreDocument9 pagesPreviews 2502414 PreAlex Andre RojasNo ratings yet

- ANSI-HI 9.8 - 1998 Pump Intake DesignDocument82 pagesANSI-HI 9.8 - 1998 Pump Intake DesignHala915882% (17)

- Npsa in Pumps Ansi Hi 9 6-3-1997Document18 pagesNpsa in Pumps Ansi Hi 9 6-3-1997Luis Garrido Marín100% (4)

- Ansi Hi 9 6 5Document40 pagesAnsi Hi 9 6 5Carlos Esaú López Gómez100% (5)

- Hi 1.6 (2000)Document46 pagesHi 1.6 (2000)mishraengg100% (2)

- Ansi Hi 12.1-12 PDFDocument106 pagesAnsi Hi 12.1-12 PDFjabarcan100% (2)

- Hi 1.3 PDFDocument103 pagesHi 1.3 PDFVenkatNo ratings yet

- Ansi Hi 1 4 2000 M103Document66 pagesAnsi Hi 1 4 2000 M103Himanshu Chaturvedi100% (4)

- ANSI-HI Centrifugal PumpsDocument74 pagesANSI-HI Centrifugal Pumpsvicky88100% (5)

- 03 Vertical Pump Test ANSI HI 2.6 2000Document48 pages03 Vertical Pump Test ANSI HI 2.6 2000Benny RivasNo ratings yet

- Ansi-Hi 9 6 3-1997 Centrifugal and Vertical PumpsDocument15 pagesAnsi-Hi 9 6 3-1997 Centrifugal and Vertical Pumpssalgora100% (1)

- Ansi Hi 1.1 1.2 2000 Centrifugal PumpsDocument74 pagesAnsi Hi 1.1 1.2 2000 Centrifugal Pumps김규백100% (1)

- Fehniger Steve-Pump VibrationDocument35 pagesFehniger Steve-Pump VibrationSheikh Shoaib100% (1)

- Ansi Hi 14 6 2011Document11 pagesAnsi Hi 14 6 2011Karlykr25% (16)

- ANSI HI 1 6 2000 M104 HI 1-6 PreDocument9 pagesANSI HI 1 6 2000 M104 HI 1-6 PreyuchiayiNo ratings yet

- ANSI-HI-9-6-1 Centrifugal and Vertical Pumps For NPSH MarginDocument24 pagesANSI-HI-9-6-1 Centrifugal and Vertical Pumps For NPSH Marginnoxleek100% (5)

- Rotodynamic Pumps: American National Standard ForDocument10 pagesRotodynamic Pumps: American National Standard ForDaniel Carlos Reyes ReyesNo ratings yet

- Ansi Hi Pumps Standards 2006pdf PDFDocument12 pagesAnsi Hi Pumps Standards 2006pdf PDFAbhi NandanaNo ratings yet

- 2858 021975Document4 pages2858 021975jskrippa100% (1)

- Ansi-Hi 9.6.6-2009-Rotodynamic Pumps For Pump PipingDocument51 pagesAnsi-Hi 9.6.6-2009-Rotodynamic Pumps For Pump PipingSamir Kumar Saha100% (3)

- ANSI-HI 9.6.5 (2000) Centrifugal and Vertical Pump. For Condition MonitoringDocument40 pagesANSI-HI 9.6.5 (2000) Centrifugal and Vertical Pump. For Condition Monitoringjohan diazNo ratings yet

- Ansi-Hi Pump StandardsDocument2 pagesAnsi-Hi Pump StandardsAndrés Eduardo100% (1)

- HI 9.6.3 - Rotodynamic Pumps - Guideline For Operating RegionDocument10 pagesHI 9.6.3 - Rotodynamic Pumps - Guideline For Operating RegionMansoor Ahamed Abbas67% (3)

- Type VS1 and VS6 Vertical Turbine Pumps Wet Pit and Double CasingDocument76 pagesType VS1 and VS6 Vertical Turbine Pumps Wet Pit and Double CasingVgvr Gvlsv100% (2)

- ANSI - Liquid Viscosity Pump PerformanceDocument38 pagesANSI - Liquid Viscosity Pump Performanceyhon fredy100% (1)

- Hydraulic Data For Pump ApplicationDocument28 pagesHydraulic Data For Pump ApplicationedwinramonNo ratings yet

- Schedule Large Vertical TurbineDocument1 pageSchedule Large Vertical TurbineGodwin ChagotaNo ratings yet

- Hi 9.6.8Document3 pagesHi 9.6.8AH0% (2)

- Whitepaper - BaseplatesDocument10 pagesWhitepaper - Baseplatesrhusseinpos4765No ratings yet

- ISO 9906 pumps hydraulic performance tests gradesDocument1 pageISO 9906 pumps hydraulic performance tests gradesAhmed SaedNo ratings yet

- ASME B73 Pump Standards OverviewDocument16 pagesASME B73 Pump Standards Overviewdang2172014No ratings yet

- Horizontal and Vertical Line-Shaft Pumps: AWWA StandardDocument84 pagesHorizontal and Vertical Line-Shaft Pumps: AWWA StandardHary100% (1)

- API 610 12th Edition Major ChangesDocument4 pagesAPI 610 12th Edition Major ChangesTyas Utami83% (6)

- BS en Iso 9905-1998+a1-2011Document72 pagesBS en Iso 9905-1998+a1-2011Tasawwur TahirNo ratings yet

- RUHRPUMPEN Pump - VTP - B - EN PDFDocument8 pagesRUHRPUMPEN Pump - VTP - B - EN PDFhenryNo ratings yet

- Iso 5199Document40 pagesIso 5199babis1980100% (1)

- 27 Ways To Kill Your PD PumpDocument12 pages27 Ways To Kill Your PD PumpArsalan QadirNo ratings yet

- Previews HI 9-6-4 PreDocument9 pagesPreviews HI 9-6-4 PreZoebairNo ratings yet

- 9 6 4cDocument2 pages9 6 4cAce SageNo ratings yet

- HI 9-8 2012 PreDocument11 pagesHI 9-8 2012 PreAnonymous CMS3dL1T50% (2)

- ANSI HI 9 6 2 2001 American NationalDocument48 pagesANSI HI 9 6 2 2001 American NationalMochamad Taufik0% (1)

- Safety Standard For Belt Manlifts: ASME A90.1-2015Document4 pagesSafety Standard For Belt Manlifts: ASME A90.1-2015Sugi AriyantoNo ratings yet

- Asme A90.1-2009Document34 pagesAsme A90.1-2009ManInBar50% (2)

- Asme B89.4.22-2004 (2019)Document58 pagesAsme B89.4.22-2004 (2019)maad100% (2)

- Turbine & Its Governing and Turbo Generator AlokDocument143 pagesTurbine & Its Governing and Turbo Generator AlokSHAMSIK2002100% (3)

- TA English PDFDocument6 pagesTA English PDFchinna rajaNo ratings yet

- APHDocument32 pagesAPHSHAMSIK2002No ratings yet

- Syllb For CertifDocument3 pagesSyllb For CertifJASWANT ADILENo ratings yet

- Refresher Course Material - 1.0 PDFDocument268 pagesRefresher Course Material - 1.0 PDFajithkrak100% (1)

- Line Diagram-MasterDocument75 pagesLine Diagram-MasterSHAMSIK2002No ratings yet

- Power Plant Chemistry: Cooling Water SystemDocument31 pagesPower Plant Chemistry: Cooling Water SystemSHAMSIK2002No ratings yet

- Cea Reviw On Strengthening of O&M PractivesDocument74 pagesCea Reviw On Strengthening of O&M Practivesrbdubey2020No ratings yet

- Perform Achieve & Trade (PAT) : A Journey ThroughDocument20 pagesPerform Achieve & Trade (PAT) : A Journey ThroughSHAMSIK2002No ratings yet

- Acq NormsDocument2 pagesAcq NormsSHAMSIK2002No ratings yet

- Energy Audit ManualDocument240 pagesEnergy Audit Manualprashantsingh04100% (2)

- Boiler IBRDocument4 pagesBoiler IBRSHAMSIK2002No ratings yet

- Erection Manual-Pc PipingDocument219 pagesErection Manual-Pc Pipingalinor_tn100% (2)

- Chapter3 1Document234 pagesChapter3 1mspd2003No ratings yet

- Letter No.412 - UNL - 2013 - UPRVUSA Dt. 03.09.2014Document10 pagesLetter No.412 - UNL - 2013 - UPRVUSA Dt. 03.09.2014SHAMSIK2002No ratings yet

- ABB Relay Test Block-Proposal PDFDocument12 pagesABB Relay Test Block-Proposal PDFanand.balaNo ratings yet

- Generator ProtectionDocument36 pagesGenerator Protectiongloby_pnbNo ratings yet

- Properties of Coal Classification and AnalysisDocument7 pagesProperties of Coal Classification and AnalysisJaco KotzeNo ratings yet

- 32 EfficiencyDocument10 pages32 EfficiencyRoosevelt MillerNo ratings yet

- Generator & GT ProtectionDocument36 pagesGenerator & GT ProtectionDeepen SharmaNo ratings yet

- DC Ground Fault Protectors ExplainedDocument2 pagesDC Ground Fault Protectors ExplainedSHAMSIK2002No ratings yet

- Thermal Power Plant: Perform Achieve TradeDocument12 pagesThermal Power Plant: Perform Achieve TradeSHAMSIK2002No ratings yet

- PassportApplicationForm Main English V2.0Document2 pagesPassportApplicationForm Main English V2.0Ramya NairNo ratings yet

- ACC Fuel Flex Presentation 2011Document78 pagesACC Fuel Flex Presentation 2011SHAMSIK2002No ratings yet

- Pumps and SystemsDocument5 pagesPumps and SystemsYashwant Kumar Saini100% (2)

- 7SJ602x Manual A5 V035201 enDocument300 pages7SJ602x Manual A5 V035201 enEngr Huzaifa QureshiNo ratings yet

- ACC Fuel Flex Presentation 2011Document78 pagesACC Fuel Flex Presentation 2011SHAMSIK2002No ratings yet

- 86 C29 D63 D 01Document716 pages86 C29 D63 D 01Nhung Hong NguyenNo ratings yet

- 7SJ61xx Manual A3 V042001 UsDocument456 pages7SJ61xx Manual A3 V042001 UsSHAMSIK2002No ratings yet

- Probabilistic Seismic Hazard Analysis of Nepal: Bidhya Subedi, Hari Ram ParajuliDocument6 pagesProbabilistic Seismic Hazard Analysis of Nepal: Bidhya Subedi, Hari Ram ParajuliPrayush RajbhandariNo ratings yet

- Human Resource Management Practices in A Transition EconomyDocument8 pagesHuman Resource Management Practices in A Transition EconomyMohit Maheshwari100% (3)

- (Pocket Guide To Social Work Research Methods) James Drisko, Tina Maschi - Content Analysis (2015, Oxford University Press) PDFDocument209 pages(Pocket Guide To Social Work Research Methods) James Drisko, Tina Maschi - Content Analysis (2015, Oxford University Press) PDFCarolina Bagattolli100% (2)

- Statistics MCQs and Practice QuestionsDocument38 pagesStatistics MCQs and Practice Questionsarjunmba119624No ratings yet

- Calc CH 2 Solutions CPMDocument21 pagesCalc CH 2 Solutions CPMAngel Villa50% (4)

- KWSP2 - Taklimat Di Intan 300610Document21 pagesKWSP2 - Taklimat Di Intan 300610rml1804No ratings yet

- Research Paper On Forensic Accounting in IndiaDocument6 pagesResearch Paper On Forensic Accounting in Indialsfxofrif100% (1)

- Project: Recruitment and Selection of Sales Associates in Aarong AbstractDocument8 pagesProject: Recruitment and Selection of Sales Associates in Aarong AbstractShakib AL MohiNo ratings yet

- Use of Social Media by College Students: Relationship To Communication and Self-ConceptDocument4 pagesUse of Social Media by College Students: Relationship To Communication and Self-Conceptพรรณพรรษ โพธิ์ทองNo ratings yet

- The T-Value For A One-Tailed Test With 1% Significance Level and 18 Degrees of Freedom Is 2.878. According To The T Value TableDocument3 pagesThe T-Value For A One-Tailed Test With 1% Significance Level and 18 Degrees of Freedom Is 2.878. According To The T Value TableRichmond BaculinaoNo ratings yet

- Nandini Raizada: Unit-I: Introduction To Forensic ScienceDocument2 pagesNandini Raizada: Unit-I: Introduction To Forensic ScienceAmanKumarNo ratings yet

- The Impact of Social Media Influencers On Purchase Intention Towards Cosmetic Products in ChinaDocument18 pagesThe Impact of Social Media Influencers On Purchase Intention Towards Cosmetic Products in ChinaHương MaiNo ratings yet

- OECD QA Guide for GLP ComplianceDocument10 pagesOECD QA Guide for GLP ComplianceMiley LeNo ratings yet

- Learning CompetencyDocument38 pagesLearning CompetencyJean S. FraserNo ratings yet

- Ranjitha .O (Print Out Document)Document64 pagesRanjitha .O (Print Out Document)Nithya RajNo ratings yet

- Lab Report Bochem 1 PipettorsDocument4 pagesLab Report Bochem 1 PipettorsMuhamad Syazwan Bin MisranNo ratings yet

- Settlement InvestigationDocument58 pagesSettlement InvestigationDarwisy SallehNo ratings yet

- International Journal of Quality & Reliability ManagementDocument22 pagesInternational Journal of Quality & Reliability ManagementKaLi RodriguezNo ratings yet

- COPARDocument12 pagesCOPARGlenn Asuncion PagaduanNo ratings yet

- Project On Employee Attrition AnupamaDocument6 pagesProject On Employee Attrition AnupamaIshank GuptaNo ratings yet

- Crisis Management Ebook 81419 PDFDocument16 pagesCrisis Management Ebook 81419 PDFJohn AguilarNo ratings yet

- RM - Class - Notes - 2017Document40 pagesRM - Class - Notes - 2017John KAlespiNo ratings yet

- Chapter 4 DDocument5 pagesChapter 4 DVikash SharmaNo ratings yet

- Engineering Project Detailed Research PlanDocument2 pagesEngineering Project Detailed Research PlanSandratriniaina RazafimahafalyNo ratings yet

- Team 1-Funmilade Opeyemi Adenlu - 1984153 - Assignsubmission - File - MGMT 582 - Assignment 2 - Team 1Document14 pagesTeam 1-Funmilade Opeyemi Adenlu - 1984153 - Assignsubmission - File - MGMT 582 - Assignment 2 - Team 1Kush SharmaNo ratings yet

- Seismic Analysis BenchmarkDocument17 pagesSeismic Analysis Benchmarkarian20202020No ratings yet

- Master of Business Administration - Semester 3Document7 pagesMaster of Business Administration - Semester 3Roger S Pacheco100% (1)

- MMW - Correlation AnalysisDocument5 pagesMMW - Correlation AnalysisAliana CorralNo ratings yet

- Research LP (3RD Quarter)Document7 pagesResearch LP (3RD Quarter)Jaidee BiluganNo ratings yet

- Mock Test: Sub.: Business Research Methods Paper Code:C-203Document7 pagesMock Test: Sub.: Business Research Methods Paper Code:C-203aaaNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)