Professional Documents

Culture Documents

Experimental Investigation On The Characteristics of The Partitioned Tank Applied To The Solar Air Conditioning

Uploaded by

Syed Muztuza AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Investigation On The Characteristics of The Partitioned Tank Applied To The Solar Air Conditioning

Uploaded by

Syed Muztuza AliCopyright:

Available Formats

Proceedings of the 7

th

Asian Conference on Refrigeration and Air Conditioning

ACRA2014

May 18-21, 2014, Jeju, KOREA

ACRA2014-281

Experimental Investigation On The Characteristics of The Partitioned Tank

Applied To The Solar Air Conditioning

Jin Su-min , Wang Ai-huiSun Shu-hua

Department of Energy, Nanjing University of TechnologyNo.30 Puzhu Nanlu Road Nanjing 211816P.R.China

ABSTRACT: A experimental investigation of partitioned heat storage tank used in solar air conditioning is

discussed, and the characteristics are analyzed, the results show that the partitioned tank using in solar air

conditioning system can significantly improve the property of the system, which causes the hot water

maintain in the optimal temperature for a long time, as a result, the refrigeration system can maintain the

COP in the high range for a long time. Although there have been some deviation in the test, the solution of

these problems of the partitioned tank provide a feasible reference for the practical application. In general, it

is feasible that the partitioned tank using in the solar air conditioning system, and it can reduce the heat

consumption of the generator in refrigerating machine, improve energy efficiency.

1. INTRODUCTION

With the development of society, how to use the

new energy sources have became a extremely urgent

problem, and solar energy as one kinds of natural

pollution-free clean energy, more and more people has

get attention to it. In our country, the building energy

consumption take a significant proportion of total energy

consumption, if the solar energy using in air conditioning

system, it will achieve a good energy saving effect,

which can also avoid the ozone depletion compared to

common air conditioning. But the solar energy exist

some problems like low energy flux density,

inhomogeneity, intermittent, and so on. so the heat

storage device can make the solar energy air

conditioning system maintained more stable, more

efficient.

At present, the thermal storage of the solar energy

air conditioning system is studied by more and more

people, the study of the Solar Heat Pump Systems with

Seasonal Storage

[1]

points out, if there is no short-term

heat storage, assurance factor of solar energy will fell

sharply; The double cistern system used in the solar

energy water heater

[2]

can improve the solar energy

efficiency; the study of the phase change materials used

for heat storage

[3-5]

said that, the joined of phase change

materials in tank can improve the thermal efficiency of

heat storage system, but it is complicated; Also some

scholars study the water tank of temperature

stratification under the solar energy air conditioning

system

[6]

, the later study improved it

[7]

, but the tank of

temperature stratification demand a high running

condition, it is unstable, and the time of achieving high

temperature is long. This paper puts forward a kind of

partition tank to heat storage for solar air conditioning,

which can rapidly reach the high temperature to run, and

keep a long time, that can improve the performance of

the system.

2. SYSTEM CHARACTERISTICS

The solar air conditioning using partitioned tank

for heat storage can fast achieve the best temperature of

heat source to work, and the temperature can keep for a

long time. We know, for single effect LiBr- H

2

O

absorption refrigeration system, there is a high sensitivity

of temperature of heat source, and the best temperature is

88 ~94 , if under this value, the COP will reduce

violently, so, to maintain the best temperature for a long

time can improve the COP of system, which can also

make full use of heat source.

2.1 THE CHARACTERISTICS OF THE

PARTITIONED TANK

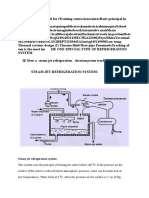

The design of the partitioned tank, show as the F

ig. 1, is to divide the tank into operation area and storage

area. Its working principle is showed in figure 1, the left

Fig. 1 The schematic diagram of the partitioned tank

i

Drain pipe Drain pipe

Water supply pipe

Outlet of the

hot water

Inlet of the hot

water

Inlet of the

circulating

water

Outlet of the circulating water

side is the operation area, and the right is storage area.

Operation area is small, and is linked together with the

heat source; the solar heat collection is used to satisfy the

requirement of this area in the daytime, that cause the

temperature reaches a higher value to take charge of the

load first, when the temperature is higher than a set value,

the heat reaches the storage area through the heat

exchanger; the storage area is linked together with the

operation area by heat exchanger, in the daytime, it is

responsible for accumulation of the redundant heat from

the operation area. Because the operation area is small,

the temperature reduces fast at night, at this time, the

temperature of the storage area will be higher than the

operation area, it will improve the temperature of the

operation area through heat transfer, which makes the

operation area work on.

2.2 The Characteristics of solar air conditioning

with partitioned tank

Compared with the typical solar air conditioning,

this new kind of system has the following characteristics:

(1)In the initial condition, all of the heat used to heat

up the operation area first, making the water temperature

of the operation area lift quickly to achieve the operating

requirements of the system, so as to form the fast effect

of startup.

(2)When the temperature of the operation area

arrived the best value, the solar heat collection is used to

meet the heat consumption of the load first, and then

keep the temperature of the operation area, at the same

time, transfer the excess heat to the storage area through

the heat exchanger, achieve the purpose of heat

accumulation; the temperature of the operation area

maintaining a high value as the heat source of the

refrigerating system cooling system, make the

refrigeration unit running in a high COP for a long time,

which improve the average COP of the system.

(3)The increase of the COP reduced the heat

consumption of the system, and so, in a sunny summer

day, the system can need not auxiliary energy, as a result,

reduce the consumption of the auxiliary heat.

3. EXPERIMENT SYSTEM

The proposed water tank was tested, including heat

source system, heat storage system and cooling system,

the whole device as shown in figure 2.

3.1 HEAT SOURCE SYSTEM

The electric heating was used as heat source, while

the hot water through the heater, its temperature was ris

en, and flowed into the operation area, heated the water;

as the cooling load was existed in this area, the temperat

ure will be reduced, the backflow in the bottom of the tan

k makes the low temperature water flow to the heater hea

ting again, so the cycle. In order to installing thermal resi

stance Pt100, the special process was used in the import

and export of the water tank, which used for measuring t

he temperature of the operation area, at the same time, th

e flow regulator and flow meter were installed, for achie

ving the measurement and control of the energy.

3.2 HEAT STORAGE SYSTEM

In the test, the operation area 40 L, storage area

100 L, the heat exchanger was decorated in the tank for

the heat transfer. In order to compare with the integral

tank, two tubes were designed in the outside of the tank,

so as to meet the effect of the integral tank; the two tubes

were distributed in the top and bottom of the tank.

The heat exchanger can transmit the redundant hea

t to the storage area in the daytime; the temperature of th

e operation area will reduce in the night, the heat will tra

nsfer from storage area to operation area, which result th

e temperature of the operation area rise, the system can c

ontinue to work.

3.3 COOLING SYSTEM

In practice, the generator was driven by hot water

in summer, the water was exothermic, and the

temperature decreased. The heat was considered in test,

and the condensing device was used to consume this part

of heat, so as to realize the system simulation; heating

power was 800W, the cooling load was simulated as the

form of heat dissipation, which power was controlled in

400W or so. With 75 for initial temperature the test

was began; Heating and cooling for 5.5 hours, and then

the test was done only for cooling.

4. OPERATION CHARATERISTICS EXPERIME

NT AND ANALYSIS

When the heating power was 800 W, and cooling

load was 400 W, the variation of temperature of hot

water tank was showed in figure 3. For the partitioned

water tank, when the temperature of operation area was

higher than 90 , the electromagnetic valve should open,

heat exchange tube started to work, but it was showed in

figure 3 that, if the temperature of operation area reach

85 , the heat transfer was appeared, this was mainly

because that the electromagnetic valve was in the end of

heat pipe, which can't control the flow of the thermal

steam; When the water temperature of the operation area

reached 90 , and the electromagnetic valve has been

open, the temperature of upper water of storage area was

continue to up, at the same time, the temperature of

bottom water also started to up, this was because the heat

transfer medium realized the circulation flow through

opening the electromagnetic valve, heat transfer was

consummate, and in the next period, the increase of the

temperature of operation area was slower, and the

increase of the temperature of storage area was

intensified.

Fig. 2 Experimental device of the partitioned tank.

In the heat dissipation test, the data of the end of

the heating section has been used as the initial value, and

the results were shown in figure 4. When the figure was

taken as a whole, the cooling load was 380 W, the

temperature of hot water in operation area was reduced

from 95 to 71 in 5.5 hours, and the temperature of

upper water in storage area was reduced from 88 to

80 , while the temperature of bottom water only

dropped 3 , to 77 . Theoretically, for the heat

exchange tube in storage area was decorated uniformly,

the temperature stratification shouldn't appear seriously,

it was appeared in the test mainly because the difference

of the temperature in the beginning in the test; but we

also can see, the layered different of temperature of the

hot water was also reduced gradually in the period of

heat dissipation.

In order to comparison, the test of integral water ta

nk was done in the same working conditions, and the exp

erimental results were shown in figure 5. From the result

s, it can be seen that the operation area of partition water

tank would reach a higher temperature more easily than

the integral water tank. With the same condition of heatin

g power and dissipation power, when the temperature of

hot water of operation area in partition tank reached 90

, the integral water tank can only reach 80 , as the h

eat sources of one effect LiBr absorption chiller, the influ

ence of the temperature difference on the COP of the syst

em was considerable, and after 4.7 hours, the temperatur

e of the integral water tank arrived 90 , the effect of re

frigeration is not as good as the partition of the water tan

k. But there was also a obvious problem: because of the

heat transfer was not full, the heating time is too long, an

d it made the temperature of operation area higher than c

ritical value of 95 .

For the partitioned water tank, in the same

conditions of test, the temperature of theoretical analysis

Fig. 3 The temperature distribution of the hot water

in heating phases

10 11 12 13 14 15 16

75

80

85

90

95

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

e

h

o

t

w

a

t

e

r

(

)

Time(h)

Theupper temperatureof thestoragearea

Theaveragetemperature

of theoperation area

Thebottomtemperatureof thestoragearea

Fig. 4 The temperature distribution of the hot

water in cooling phases

16 17 18 19 20 21 22

70

75

80

85

90

95

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

e

h

o

t

w

a

t

e

r

(

)

Time(h)

The upper temperatureof thestoragearea

Theaveragetemperatureof the operation area

Thebottomtemperature of thestoragearea

Fig. 5 The temperature and heat gain power of the

hot water

15 16 17 18 19 20 21 22

74

76

78

80

82

84

86

88

90

92

Time(h)

T

h

e

a

v

e

r

a

g

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

e

h

o

t

w

a

t

e

r

(

)

Fig. 6 The distribution of the theoretical

temperature

10 12 14 16 18 20 22

72

76

80

84

88

92

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

e

h

o

t

w

a

t

e

r

(

)

Time(h)

Thetemperatureof the

operation area

Thetemperatureof the

storagearea

Fig. 7 The distribution of the average temperature

of the test

10 12 14 16 18 20 22

70

75

80

85

90

95

T

h

e

t

e

m

p

e

r

a

t

u

r

e

o

f

t

h

e

h

o

t

w

a

t

e

r

(

)

Time (h)

The temperature of the

operation area

The temperature of the

storagearea

were shown in the figure 6, it can be seen that, the trend

of the theoretical value and the test value was consistent,

but there were some deviation. Theoretically, the

temperature stratification shouldn't appear in storage

area; the heat transfer did not exist when the

electromagnetic valve was closed; in the period of heat

dissipation, the temperature difference of the two areas

was 2.8 and the highest temperature of the storage

area was 88 . From the result of the test, the

temperature stratification existed in the storage area, and

the temperature of upper water was 90.6 , the

temperature of bottom water was only 80.7 ; in the

period of heat dissipation, the decrease of temperature of

the operation area was faster than storage area, if it was

researched as the average temperature, the results were

shown in figure 7. For the reason of the circumstance, it

was due to the inappropriate position of the

electromagnetic valve, the overlarge liquid-filled ratio,

the poor technology of welding and so on.

5. CONCLUSION

(1) Using partitioned tank in the solar energy air

conditioning, the system can more quickly achieve the

best working temperature. Under the condition of the test,

this temperature can be reached early 4.7 hours than the

whole water tank system, and the temperature can be

maintained to the end of heating, this can significantly

improve the performance of the LiBr absorption chiller.

(2) The test results showed that the heat exchange tube,

which designed for heat transfer, cannot reach the best

effect. Because of the insufficiency of the heat, there is a

tendency of the temperature to higher than 95 in

operation tank, while the temperature of the storage tank

is just 85.6 , the difference is large .

(3) For the whole, the test results conformed to the

theoretical analysis, but there were still some problems:

the installation of the electromagnetic valve was

improper, the filling liquid rate of the heat exchange tube

was too large, and the defects of the processing

technology, the solution of these problems will provide

feasible reference for the actual application of the

partitioned water tank.

REFERENCES

[1] YU Guo-qing, CHEN Peng, FENG Chuan-zhen.

2007, Study of Solar Heat Pump Systems with Seasonal

Storage by Simulations [J ]. Construction Conserves

Energy, 7:pp.43-46.

[2] Xu Yi-shi. 2010Optimized Design of Heat Storage

and Auxiliary Heating Equipments of Solar Hot Water

System[J ].China water & Waste waterVol.26(14):pp.

59-61.

[3] Mehling H.2003, PCM-module to improve hot water

heat stores with stratification [J ].Renewable Energy, Vol.

28, pp.699-711.

[4]Luisa F.Cabeza,Manuel Ibanez.2005 ,

Experimentation with a water tank including a PCM

module [J ].Solar energy materials & solar cells,.

[5]N.Nallusamy,S.Sampath, R.Velraj. 2007,Experimental

investigation on a combined sensible and latent heat

storage system integrated with constant/varying heat

sources [J ]. Renewable Energy, Vol.32, pp.12061227.

[6] YU Guoqing, TANG J inhua, ZOU Zhijun.2007

Research on the Effect of Temperature Stratification in

Water Tank in Solar Domestic Hot Water System[J ]. Buil

ding Science, Vol.23(4), pp.7073

[7] Z. F. Li and K. Sumathy2001, Experiment studies

on a solar powered air conditioning system with par

titioned hot water storage tank [J ]Solar Energy

200171(5) : 285297

You might also like

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Research On Solar High-Temperature Absorption Air-Conditioning SystemsDocument5 pagesResearch On Solar High-Temperature Absorption Air-Conditioning SystemsArman MalikNo ratings yet

- Ecp57vol5 012Document8 pagesEcp57vol5 012anishbabupdNo ratings yet

- Experiment No 4: ObjectiveDocument4 pagesExperiment No 4: ObjectiveAliNo ratings yet

- Experiment No 4: ObjectiveDocument4 pagesExperiment No 4: ObjectiveAliNo ratings yet

- Experimental Investigation On Solar Absorption Refrigeration System in Malaysia PDFDocument5 pagesExperimental Investigation On Solar Absorption Refrigeration System in Malaysia PDFRana Abdul RehmanNo ratings yet

- Ijet V2i6p2Document6 pagesIjet V2i6p2International Journal of Engineering and TechniquesNo ratings yet

- Termosifón Tubo de CalorDocument6 pagesTermosifón Tubo de CalorLuis Enrique GonzálezNo ratings yet

- Performance Studies On The Reversing Valve Incorporated Air-To-Water Heat Pump With Heat Storage DeviceDocument10 pagesPerformance Studies On The Reversing Valve Incorporated Air-To-Water Heat Pump With Heat Storage DeviceTJPRC PublicationsNo ratings yet

- A Case Study On Solar Vapour Absorption Refrigeration SystemDocument7 pagesA Case Study On Solar Vapour Absorption Refrigeration SystemShivam MaheraNo ratings yet

- Study of solar-powered air conditioning using lithium bromide absorption systemsDocument8 pagesStudy of solar-powered air conditioning using lithium bromide absorption systemsJaime Haro EstropNo ratings yet

- Steam Jet Refrigeration: How it WorksDocument6 pagesSteam Jet Refrigeration: How it WorksbbaytlNo ratings yet

- Conclusion & Recomendation Thermo Exp 4Document2 pagesConclusion & Recomendation Thermo Exp 4Zoltar JRNo ratings yet

- Direct steam generation solar power plant with integrated thermal storageDocument9 pagesDirect steam generation solar power plant with integrated thermal storageJoão MarcosNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- How steam jet and thermoelectric refrigeration systems workDocument6 pagesHow steam jet and thermoelectric refrigeration systems workbbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Steam jet refrigeration systemDocument7 pagesSteam jet refrigeration systembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- How steam jet refrigeration systems workDocument6 pagesHow steam jet refrigeration systems workbbaytlNo ratings yet

- Steam jet refrigeration systemDocument7 pagesSteam jet refrigeration systembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Enhancement Method'S On Boiler EfficiencyDocument16 pagesEnhancement Method'S On Boiler Efficiencysidan magnaNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration Systembbaytl100% (1)

- GEOTHERMAL HEAT PIPE TURBINEDocument6 pagesGEOTHERMAL HEAT PIPE TURBINESanjoy BasakNo ratings yet

- Ceylan 2016Document23 pagesCeylan 2016MichelNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Improving The Performance of Household Refrigerator by Recovering Heat From The CondenserDocument3 pagesImproving The Performance of Household Refrigerator by Recovering Heat From The CondenserIjsrnet EditorialNo ratings yet

- Refrigeration Sysy TypeDocument6 pagesRefrigeration Sysy TypebbaytlNo ratings yet

- Boost Boiler Efficiency with EconomizersDocument5 pagesBoost Boiler Efficiency with Economizersreyalene gallegos100% (1)

- Using Thermal Energy From 2 Wells To Heat The Sussex Hospital in New BrunswickDocument10 pagesUsing Thermal Energy From 2 Wells To Heat The Sussex Hospital in New BrunswickART'S PLACENo ratings yet

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Steam jet refrigeration system explainedDocument6 pagesSteam jet refrigeration system explainedbbaytlNo ratings yet

- Full ReportDocument16 pagesFull ReportafiqahanuwarNo ratings yet

- Solar Assisted Heat Pump DryerDocument6 pagesSolar Assisted Heat Pump DryerRajeshKolheNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- Refrigeration Sysy TypeDocument6 pagesRefrigeration Sysy TypebbaytlNo ratings yet

- Steam Jet Refrigeration SystemDocument6 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- المشروع PresentationDocument48 pagesالمشروع PresentationFaraj AlferjaniNo ratings yet

- Heat Pump Lab ExperimentDocument19 pagesHeat Pump Lab Experimentakmal100% (2)

- Shopmillingmsme: Steam Jet Refrigeration SystemDocument7 pagesShopmillingmsme: Steam Jet Refrigeration SystembbaytlNo ratings yet

- Steam Jet RefrigerationDocument6 pagesSteam Jet RefrigerationbbaytlNo ratings yet

- Cooling Tower ReportDocument13 pagesCooling Tower Reportjuaxxo100% (1)

- Steam Jet Refrigeration SystemDocument7 pagesSteam Jet Refrigeration SystembbaytlNo ratings yet

- INA3-6 HRSG Final ReportDocument30 pagesINA3-6 HRSG Final ReportgpowerpNo ratings yet

- Laboratory-Scale Cooling Tower Performance AnalysisDocument17 pagesLaboratory-Scale Cooling Tower Performance AnalysisHazieqah100% (1)

- Steam jet refrigeration systemDocument6 pagesSteam jet refrigeration systembbaytlNo ratings yet

- Refrigeration Sysy TypeDocument6 pagesRefrigeration Sysy TypebbaytlNo ratings yet

- Refrigeration Sysy TypeDocument6 pagesRefrigeration Sysy TypebbaytlNo ratings yet

- Steam jet refrigeration system explainedDocument7 pagesSteam jet refrigeration system explainedbbaytlNo ratings yet

- Steam jet refrigeration system explainedDocument7 pagesSteam jet refrigeration system explainedbbaytlNo ratings yet

- Solar Water Heating LabDocument11 pagesSolar Water Heating LabElle XNo ratings yet

- Affordable solar water heater designDocument4 pagesAffordable solar water heater designrassNo ratings yet

- Operation of Reheat Steam Temperature Control Concept in Sub Critical Boiler: Operational Review Practices and MethodologyDocument6 pagesOperation of Reheat Steam Temperature Control Concept in Sub Critical Boiler: Operational Review Practices and MethodologyNuraini Abdul AzizNo ratings yet

- Experimental and Theoretical Investigations of SpeDocument5 pagesExperimental and Theoretical Investigations of Spefaiz firdausiNo ratings yet

- Pagination WR 114961Document11 pagesPagination WR 114961Syed Muztuza AliNo ratings yet

- ANSYS Fluent Theory GuideDocument814 pagesANSYS Fluent Theory GuideEnrique Flores100% (2)

- Forward Osmosis System AnalysisDocument27 pagesForward Osmosis System AnalysisSyed Muztuza AliNo ratings yet

- Thermodynamic Modelling and Performance Study of An Engine Waste Heat Driven Adsorption Cooling SystemDocument10 pagesThermodynamic Modelling and Performance Study of An Engine Waste Heat Driven Adsorption Cooling SystemSyed Muztuza AliNo ratings yet

- A New Generation Cooling Device Employing MOFDocument8 pagesA New Generation Cooling Device Employing MOFSyed Muztuza AliNo ratings yet

- A New Generation Cooling Device Employing MOFDocument8 pagesA New Generation Cooling Device Employing MOFSyed Muztuza AliNo ratings yet

- Multiple Parameters Analysis For Energy Efficiency of Building Air Conditioning SystemDocument4 pagesMultiple Parameters Analysis For Energy Efficiency of Building Air Conditioning SystemSyed Muztuza AliNo ratings yet

- Adsorption and Desorption Surface Reactions PDFDocument8 pagesAdsorption and Desorption Surface Reactions PDFSyed Muztuza AliNo ratings yet

- Design and Development of Crioadsorption Chamber For Methane Storage On MOFDocument5 pagesDesign and Development of Crioadsorption Chamber For Methane Storage On MOFSyed Muztuza AliNo ratings yet

- A New Generation Cooling Device Employing MOFDocument8 pagesA New Generation Cooling Device Employing MOFSyed Muztuza AliNo ratings yet

- SUBMERSIBLE PUMP SelectionDocument6 pagesSUBMERSIBLE PUMP SelectionSyed Muztuza AliNo ratings yet

- Pumps and Motors PDFDocument28 pagesPumps and Motors PDFபத்மநாபன் ஶ்ரீநிவாஸன்No ratings yet

- Socio-Economic Baseline Survey of CHTDocument355 pagesSocio-Economic Baseline Survey of CHTSyed Muztuza AliNo ratings yet

- Goulds Residential Pump Guide PDFDocument44 pagesGoulds Residential Pump Guide PDFSyed Muztuza Ali100% (1)

- Child Labour Resource Guide Executive Summary 5b46b80Document26 pagesChild Labour Resource Guide Executive Summary 5b46b80Syed Muztuza AliNo ratings yet

- L320 Range Rover Sport - Brochure 2012 AUStralia (3552-11)Document72 pagesL320 Range Rover Sport - Brochure 2012 AUStralia (3552-11)RedacTHOR100% (1)

- 95 8657 2.3 FlexSonic AcousticDocument37 pages95 8657 2.3 FlexSonic Acousticsudipta_kolNo ratings yet

- L00161 1121Document29 pagesL00161 1121aboofazilNo ratings yet

- Laboratory Manual: II Year B. Tech I-Semester Mechanical EngineeringDocument45 pagesLaboratory Manual: II Year B. Tech I-Semester Mechanical Engineeringmuhammad ahsanNo ratings yet

- Service Manual: Color TelevisionDocument21 pagesService Manual: Color TelevisionLuis MorenoNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument25 pagesFM Global Property Loss Prevention Data Sheets: List of Figureskw teoNo ratings yet

- FMEA - Review - List - 916 PBDocument5 pagesFMEA - Review - List - 916 PBajeyan879No ratings yet

- A 2.2!21!17 05 Bitumen SprayerDocument1 pageA 2.2!21!17 05 Bitumen SprayerNisanth ThulasidasNo ratings yet

- SA02-16 - General Requirement RTUDocument60 pagesSA02-16 - General Requirement RTUhiryanizamNo ratings yet

- FDP 21-30 SuDocument2 pagesFDP 21-30 SuAmit ModiNo ratings yet

- Altes00365 1Document57 pagesAltes00365 1abhiNo ratings yet

- Mike Wyatt J.F. Brennan Co., IncDocument8 pagesMike Wyatt J.F. Brennan Co., IncThomas EnglishNo ratings yet

- PI Raptor300 enDocument14 pagesPI Raptor300 enmetalmak ltdaNo ratings yet

- Job Shop Manufacturing Types ExplainedDocument3 pagesJob Shop Manufacturing Types ExplainedFarooqChaudharyNo ratings yet

- Manual OfcDocument38 pagesManual OfcAnonymous eWMnRr70qNo ratings yet

- IR21 KHMSM Smart Axiata Co. Ltd. 20210112043557Document34 pagesIR21 KHMSM Smart Axiata Co. Ltd. 20210112043557FauZul ArifinNo ratings yet

- Promocion Tiendas Te-Ka Bodega 2021-9Document22 pagesPromocion Tiendas Te-Ka Bodega 2021-9Beiker Jose Palencia SarmientoNo ratings yet

- User Guide PDFDocument2,011 pagesUser Guide PDFSonny Jason ANo ratings yet

- Privacy and Integrity Presrving Range Queries in Sensor NetworksDocument22 pagesPrivacy and Integrity Presrving Range Queries in Sensor NetworksSangeetha Bajanthri100% (1)

- Master Coursework UmpDocument6 pagesMaster Coursework Umpf67m6abx100% (2)

- Manually Configure Devices by Using Device Manager: Windows XPDocument4 pagesManually Configure Devices by Using Device Manager: Windows XPlucky_4u15No ratings yet

- 5 Ways I Bypassed Your Web Application Firewall (WAF)Document18 pages5 Ways I Bypassed Your Web Application Firewall (WAF)JOSÉ IGNACIO PARRA VALENZUELA100% (1)

- The Role of KM Portal in Indian Banking SectorDocument9 pagesThe Role of KM Portal in Indian Banking SectorAbdul LathifNo ratings yet

- Basic Computer SkillDocument61 pagesBasic Computer SkillSyed Umar Shirazi Hashmi100% (2)

- Operating Instructions: Linde Fork Lift TruckDocument96 pagesOperating Instructions: Linde Fork Lift TruckVictorNo ratings yet

- En PSAAS Public Train BookDocument27 pagesEn PSAAS Public Train BookMariano MartinezNo ratings yet

- HMK12AA Product Specification and Performance DataDocument4 pagesHMK12AA Product Specification and Performance DataMarcos EvansNo ratings yet

- Linde PLC LE Brochure Customized Air Separation Plants 2020 EN 41271 RZ VIEW2 tcm19-392416Document16 pagesLinde PLC LE Brochure Customized Air Separation Plants 2020 EN 41271 RZ VIEW2 tcm19-392416DZADZA YAOVINo ratings yet

- Lean manufacturing waste identification using COMMWIPDocument3 pagesLean manufacturing waste identification using COMMWIPSandeep ChallaNo ratings yet

- Check Point 5000 Appliances: Getting Started GuideDocument47 pagesCheck Point 5000 Appliances: Getting Started Guidevuabai racNo ratings yet