Professional Documents

Culture Documents

Gasification Solution

Uploaded by

Sumitskb0 ratings0% found this document useful (0 votes)

29 views6 pagesFoster Wheeler is a major player in gasification, handling gasification, GTL, liquefaction, IGCC, oil shale, and heavy oil processing. We are a major contributor to the UK and USA governments' clean coal research programs.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFoster Wheeler is a major player in gasification, handling gasification, GTL, liquefaction, IGCC, oil shale, and heavy oil processing. We are a major contributor to the UK and USA governments' clean coal research programs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views6 pagesGasification Solution

Uploaded by

SumitskbFoster Wheeler is a major player in gasification, handling gasification, GTL, liquefaction, IGCC, oil shale, and heavy oil processing. We are a major contributor to the UK and USA governments' clean coal research programs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

High-Value Gasifcation Solutions

Better technology for a cleaner world

Auxiliary Equipment

Condensers

Feedwater Heaters

Biomass Gasifers

Plant Operation

Plants owned and

operated by FW

Long-term Service

Agreements

Portucel

Location: Portugal

Customer: Portucel

Start-Up Year: 1985

Capacity: 15 MWth

Fuel: Biomass,

Bark

Corenso

Location: Varkaus, Finland

Customer: Corenso United Ltd.

Start-Up Year: 2000

Capacity: 13 MWe (50 MWth)

Fuel: Mixed Al-Plastics

Rejected from

Juice Container

Recycling Process

Lahti

Location: Lahti, Finland

Customer: Lahti Energia

Start-Up Year: 1997

Capacity: 7-23 MWe (50 MWth)

Fuel: Demolition Wood,

Railroad Ties, Plastic,

Tires, Recycled Fuels,

Bark, Forest Residue,

Sawdust

Norrsundet

Location: Sweden

Customer: Norrsundet Bruks Ab

Start-Up Year: 1984

Capacity: 25 MWth

Fuel: Biomass, Bark,

Sawdust

Electrabel

Location: Ruien, Belgium

Customer: Electrabel

Start-Up Year: 2002

Capacity: 8-30 MWe (50 MWth)

Fuel Dependent

Fuel: Bark, Wood Chips,

Recycled Dry Wood

& Board Residue,

Forest Residue

As a major player in gasification, Foster Wheeler has the necessary in-house

expertise located in our major engineering design centers around the world.

We are a major contributor to the UK and USA governments clean coal research

programs and have a long and successful history in coal and solids, handling

gasification, GTL, liquefaction, IGCC, oil shale, and heavy oil processing.

COMPLETE

EXPERTISE

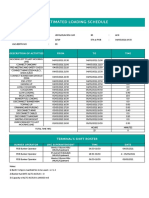

Foster Wheeler Fluidized Bed Gasifer Reference List

Start-up Date Customer Country Steam MWth Primary Fuel Application

2008 NSE Biofuels Oy Ltd. Finland 12 Biomass Biomass to Renewable Diesel

2002 Electrabel Belgium 50 Biomass Biomass Co-Firing in PC

2000 Corenso United Ltd. Finland 50 Plastic Waste Recycling and Energy Recovery of Waste

1997 Lahti Energia Finland 50 Biomass, Recycled Fuels Biomass Co-Firing in PC

1993 Sydkraft Sweden 18 Biomass Biomass IGCC

1986 Kemira Oy Finland 4 Coal, Peat Test Facility

*1985 Portucel Portugal 15 Biomass, Bark Biomass Derived Lime Kiln

*1984 ASSI Karlsborg Sweden 27 Biomass, Bark Biomass Derived Lime Kiln

*1984 Norrsundet Bruks Ab Sweden 25 Biomass, Bark Biomass Derived Lime Kiln

*1983 Oy W. Schauman Ab Finland 35 Biomass, Bark Biomass Derived Lime Kiln

1981 Hans Ahlstrom Laboratory Finland 3 Misc. Test Facility

*A. Ahlstrom Corp. Technology

Gasifcation is a process that can

fnd new value in traditional fuels

such as coal, wood, and oil.

More impressively, Gasification

can unlock the energy value of

waste materials such as waste

wood from construction, forest,

lumber, and paper industries,

as well as household waste

from towns and cities.

The Gasification Process uses

heat to break down solids and

liquids into their basic gaseous

chemical components.

A portion of these gaseous

components consists of hydrogen

and carbon monoxide, which

are high value feedstocks for

producing chemicals, liquid

fuels, and heat for production

of steam and power.

What is Gasifcation?

Chemicals

Steam

Coal

Refnery Residues

Petroleum Coke

Refnery Offgas

Orimulsion

Biomass

Sewage Sludge

Black Liquor

Municipal Solid Waste

Gasifcation

Coupled to

Complimentary

Process

Power

Chemicals

Synthetic

Natural Gas

Liquid

Transportation

Fuels

INVESTING IN ADVANCED

TECHNOLOGY FOR A

CLEANER AND MORE

EFFICIENT TOMORROW

Steam

Solids & Liquids Combustible Gas

Gasifcation

Process

C O

CO

H

2

H - Hydrogen

C - Carbon

O - Oxygen

C

H

H

O

2

NSE - Production of Carbon-Neutral

Transportation Fuels

Together with NSE Biofuels Oy Ltd., Foster Wheeler

developed a CFB biomass gasifcation and syngas

cleaning system which was part of NSEs new-

generation renewable diesel demonstration project

at Stora Ensos Varkaus Mill in Finland. This project

demonstrated the conversion of biomass fuels

into clean syngas that can be used to produce

renewable transportation fuels.

Value Points

Reduces use and dependence on fossil-based

diesel fuel needed to fuel the plants lime kiln

Demonstrated the production of a carbon-

neutral transportation fuel to reduce greenhouse

gas emissions

The town of Lahti in Finland utilizes a pulverized coal

(PC) power plant to produce electricity and district heat

to power and heat the town. To reduce the carbon

footprint of the plant and to utilize local biomass and

waste materials, the local utility decided to add a gasifer

to the existing PC plant. The gasifcation system allowed

the plant to utilize local carbon-neutral fuels and waste

streams resulting in reduced environmental impact of the

plant, while meeting energy needs of the community.

Value Points

Reduces waste going to local landfll

Reduces the towns carbon profle

Reduces the plants SOx and NOx emissions

Saved the town from the large investment

needed to build a new plant capable of burning

the biomass and waste directly

In Lahti, Co-Firing Solid Fuels in Existing

Steam Generators, not Capable of Directly

Burning Carbon Neutral Fuels

BIOMASS GASIFICATION

A Versatile and Flexible Solution for Polygeneration

Foster Wheeler Offers the Most

Fuel-Flexible Gasifcation Technology

Unlike other gasifcation technologies, our gasifers

utilize fuel-fexible fuidized bed technology.

Fluidized bed technology is the most fuel

fexible gasifcation technology since it utilizes

vigorous mixing and long particle residence

times to effciently gasify the feedstock. Other

technologies use high temperature and short

residence times, which is not as effcient,

especially for lower quality fuels.

Another beneft of low-temperature fuid

bed gasifcation technology is that the

feedstocks ash never melts, allowing the

use of feedstocks considered too corrosive

for other gasifer technologies.

Complete Customer Service

In addition to supplying the most advanced

gasifcation technology, Foster Wheeler also

offers a full range of support services, such as:

Overall fowsheet integration

Energy optimization

Selection of technologies

Value engineering

Reliability studies

Cost estimates and economic analysis

Control system philosophy

Among its many products, Stora Enso Oy produces

juice containers with an inner aluminum liner. The

Corenso gasifcation plant enables them to recycle

the used containers into valuable steam needed

to support their manufacturing process, while

separating the aluminum for further recycling,

allowing them to reduce their dependence on fuel

oil, helping their bottom line and the environment

simultaneously.

Value Points

Innovative solutions for recycling juice containers

into energy and an aluminum recycling stream

Displaces expensive fossil fuels to help the

companys bottom line and the environment

Reduces the companys carbon footprint

Reduces wastes going to landflls

CORENSO - Recycling of Aluminum

Foil-Lined Juice Containers

BIOMASS GASIFICATION

A Versatile and Flexible Solution for Polygeneration

We offer a full range of steam generator equipment, aftermarket products and services to the power, industrial,

and waste-to-energy sectors. Our global manufacturing and engineering network can deliver cutting-edge products

and expertise, quickly and cost competitively with best-in-class quality. Established in 1891, our experience comes from

over a century of designing, servicing, and continually improving for the energy sector equipment.

Brochure_Gasifcation_111313

Steam Generators

Circulating Fluid Bed

Pulverized Coal

Oil & Gas

Solar

Bubbling Fluid Bed

Package

Grate and MSW

Metallurgical Waste Heat

HRSG

Environmental Products

Circulating Fluid Bed Scrubbers

Fabric Filters

SCR and SNCR Systems

Low NOx Combustion Systems

Biomass Combustion Retrofts

Coal/Air Control System

Upgrades

Aftermarket Services

Condition Assessment

Engineered and Replacement

Pressure Parts

Weld Overlay and Refractory

Upgrades

Replacement Parts

Cyclone Burner Retrofts

Coal Mill Service and Upgrades

Maintenance Services

Outage Construction

Engineering Studies

Auxiliary Equipment

Condensers

Feedwater Heaters

Biomass Gasifers

Plant Operation

Plants owned and

operated by FW

Long-term Service

Agreements

CONTACT US

GLOBALLY

www.fwc.com

CHINA

Unit 1 on 6/F

Raffes City Beijing Offce Tower

No. 1 Dongzhimen South Street

Dongcheng District

Beijing, 100007 China

T +86 (0) 10 8409 8855

8

th

& 5

th

Floor, UC Tower

500 Fushan Road

Pudong New Area

Shanghai 200122 China

T +86 (0) 21 5058 2266

FINLAND

Metsnneidonkuja 8

Fl-02130 Espoo, Finland

T +358 (0) 10 393 11

Relanderinkatu 2

Fl-78201 Varkaus, Finland

T +358 (0) 10 393 11

GERMANY

Hassenstrasse 57

47809 Krefeld, Germany

T +49 (0) 2151 36337 10

Am Zollstock 1

61381 Friedrichsdorf, Germany

T +49 (0) 6172 26628-0

POLAND

Aleja Jana Pawla II 15

00-828 Warsaw, Poland

T +48 (0) 22 697 6870

ul. Staszica 31

41-200 Sosnowiec, Poland

T +48 (0) 32 368 1300

SAUDI ARABIA

PO Box 79311

Al-Khobar 31952

T +966 (0 ) 3 882 2398

SOUTH KOREA

2738, West Center

Center 1, Bldg 26

Eulji-ro 5-gil, Jung-gu

Seoul, Korea

T +82 (0) 2 6030 8855

SPAIN

Calle Gabriel Garcia Mrquez, 2

28230 Las Rozas

Madrid, Spain

T +34 (0) 91 336 2400

SWEDEN

Lindvgen 75

602 28 Norrkping, Sweden

T +46 (0) 11 285 330

THAILAND

9th Floor, Maneeya Bldg

518/5 Ploenchit Road

Lumpini, Pathumwan

Bangkok 10330, Thailand

T +66 (0) 2 652 0760

USA

Perryville Corporate Park

53 Frontage Road

P.O. Box 9000

Hampton, New Jersey 08827 USA

T +1 (1) 908 730 4000

9780 Mt. Pyramid Court, Suite 260

Englewood, Colorado 80112-7060 USA

T +1 (1) 303 784 4880

VIETNAM

Suite 706-708, 7th Floor, Central Bldg

31 Hai Ba Trung Street

Hanoi, Vietnam

T +84 (0) 4 39393809

You might also like

- Technical Specification For Fly Ash Handling System, R0Document7 pagesTechnical Specification For Fly Ash Handling System, R0SumitskbNo ratings yet

- Commissioning ProcedureDocument24 pagesCommissioning ProcedureSumitskb100% (14)

- Boiler Inspection - DailyDocument31 pagesBoiler Inspection - DailySumitskb100% (2)

- Caustic GougingDocument57 pagesCaustic GougingSumitskbNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Electronic Injector Brochure Feb 2015Document4 pagesElectronic Injector Brochure Feb 2015Muhammad rizkiNo ratings yet

- Pasi Rousu - Revenues From ResiduesDocument20 pagesPasi Rousu - Revenues From ResiduesAsia Clean Energy ForumNo ratings yet

- 3liquefied Natural Gas, Distribution, & Construction - CourseraDocument4 pages3liquefied Natural Gas, Distribution, & Construction - CourseraRajKumarNo ratings yet

- Sco Tiipco 2017Document11 pagesSco Tiipco 2017Sirwan SaeedNo ratings yet

- LNG Liquefaction Plant Block Flow DiagramDocument2 pagesLNG Liquefaction Plant Block Flow DiagramgenergiaNo ratings yet

- Pengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasDocument17 pagesPengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasMuhammad Sadiqul ImanNo ratings yet

- LNG, CNG and LPG Comparison StudyDocument15 pagesLNG, CNG and LPG Comparison StudyAli MahmoudNo ratings yet

- Bio Oil From Pyrolisis of Cashew Nut ShellDocument5 pagesBio Oil From Pyrolisis of Cashew Nut ShellEnna SaenaNo ratings yet

- Clean Coal Technologies: Question BankDocument20 pagesClean Coal Technologies: Question BankMukul KumarNo ratings yet

- Waste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesDocument8 pagesWaste Plastic Pyrolysis Oil As Alternative For SI and CI EnginesShahidulHoqueSohelNo ratings yet

- Detroit Diesel Seidel Diesel GR Crin 42 Injectors Are Used On The Detroit DieselDocument3 pagesDetroit Diesel Seidel Diesel GR Crin 42 Injectors Are Used On The Detroit DieselGiovaniBalzaniNo ratings yet

- European Marketscan: European Products ($/MT) ICE FuturesDocument9 pagesEuropean Marketscan: European Products ($/MT) ICE FuturesWallace YankotyNo ratings yet

- Single Burner Rice Husk StoveDocument2 pagesSingle Burner Rice Husk Stoveyasin_erşahinNo ratings yet

- Catalog 2019 Jyhy DieselDocument10 pagesCatalog 2019 Jyhy DieselAndre vatar andreNo ratings yet

- LFRM - Els - PLC - 2021 - 11719 - 04 - 05 - 2021 B3 Acr LFRM - Els - PLC - 2021 - 11719-1Document2 pagesLFRM - Els - PLC - 2021 - 11719 - 04 - 05 - 2021 B3 Acr LFRM - Els - PLC - 2021 - 11719-1LêVănPhúNo ratings yet

- JETTI Dealers ManualDocument105 pagesJETTI Dealers Manualjudith matienzo100% (1)

- Business PlanDocument74 pagesBusiness PlanandysupaNo ratings yet

- NKRI Merah Putih - Company ProfileDocument11 pagesNKRI Merah Putih - Company ProfileFeizal RezaNo ratings yet

- BP's Biofuel StrategyDocument17 pagesBP's Biofuel Strategyscorpion2001glaNo ratings yet

- 25 Hylube ProcessDocument2 pages25 Hylube ProcesssumitNo ratings yet

- مصفاة نفط روسيةDocument23 pagesمصفاة نفط روسيةKFG MAGHREBNo ratings yet

- Boifuel ProgrammeDocument33 pagesBoifuel ProgrammeMohindra KaushalNo ratings yet

- Hubbert's Peak TheoryDocument16 pagesHubbert's Peak TheoryHrishikesh ChappadiNo ratings yet

- VF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Document197 pagesVF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Phạm Tấn PhướcNo ratings yet

- Synthesis Paper Title: BiofuelsDocument24 pagesSynthesis Paper Title: Biofuelspati_deeps234No ratings yet

- Ammonia Revamp Webinar For DownloadDocument37 pagesAmmonia Revamp Webinar For Downloadtatoo1No ratings yet

- ETN Hydrogen Gas Turbines 2020Document22 pagesETN Hydrogen Gas Turbines 2020imant197812gmail.comNo ratings yet

- Task 42 BookletDocument16 pagesTask 42 BookletBalaKumar KarthikeyanNo ratings yet

- What Is LNGDocument4 pagesWhat Is LNGMeghali BorleNo ratings yet

- Visbreaking Residues As Components of Feedstock For Paving Asphalts N. Yu. Belokon', V. G. Kompaneets, T. M. Stepanova, and L. N. ShabalinaDocument5 pagesVisbreaking Residues As Components of Feedstock For Paving Asphalts N. Yu. Belokon', V. G. Kompaneets, T. M. Stepanova, and L. N. ShabalinaMizanul HoqueNo ratings yet