Professional Documents

Culture Documents

Computer Modeling and Simulation of Coalbed Methane Resources

Uploaded by

Davirson AjahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Modeling and Simulation of Coalbed Methane Resources

Uploaded by

Davirson AjahCopyright:

Available Formats

.

International Journal of Coal Geology 35 1998 369379

Computer modeling and simulation of coalbed

methane resources

G.B.C. Young

)

Adanced Resources International, Inc., Dener, Colorado, USA

Received 9 September 1996; accepted 24 July 1997

Abstract

Coal seam gas reservoirs are complex both geologically and in the mechanism of gas

.

production. Understanding these naturally fractured reservoirs for two-phase gaswater flow

conditions is often limited by a lack of data. This paper illustrates that reservoir simulation is a

powerful tool which can be used to determine key data requirements, and how variability in

reservoir properties and operating practices affect performance at the field level. The paper

presents examples of how reservoir simulation can be used to assess the efficiency of well

.

completions fracturing or cavitation , identify candidate wells for remedial treatment, examine

methane drainage in advance of mining, and assess the impact of errors in measured data on

long-term gas production forecasts. q1998 Elsevier Science B.V.

Keywords: coalbed methane; simulation; naturally fractured reservoirs; coal fields; degasification; reservoir

properties

1. Introduction

Reservoir simulation is a particularly useful tool to study gas-bearing coal beds. This

is because gas storage and production mechanisms in coal beds are more complex and

data intensive than in conventional settings. In a conventional reservoir rock, gas is

stored in the pore spaces. In a coal reservoir, methane is physically bound or adsorbed to

the solid coal surface of fracture systems. The methane does not become a free gas and

migrate to the wellbore until pressure is reduced. In addition to the material presented in

this volume, an excellent discussion of the theory of gas storage and transport in

coalbeds is provided by Law and Rice, 1993.

)

Corresponding author. Fax: q1-303-2952833; e-mail: gyoung@advres-intl.com.

0166-5162r98r$19.00 q 1998 Elsevier Science B.V. All rights reserved.

.

PII S0166- 5162 97 00042- 6

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 370

Pressure reduction normally occurs by pumping water from the coal beds, which

initiates gas desorption. The desorbed gas must move by diffusion through the very low

.

permeability coal matrix secondary porosity in order to reach the natural fracture or

.

cleat primary porosity system. Once in the cleats, which have a high permeability

relative to the matrix and are normally saturated with water, gas and water flow

according to Darcys law and gaswater relative permeability. Even the cleat permeabil-

ity is usually too low to deliver gas in commercial quantities unless the producing wells

are stimulated by induced hydraulic fracturing or other means.

In this paper, numerical modeling techniques, software applications, and data require-

ments for coal reservoirs are described, and some specific examples of computer

modeling various types of gas wells are presented. A more general discussion on the

reservoir engineering aspects of coalbed methane can be found in Saulsberry et al.

.

1996 .

2. Modeling flow through coal beds

Although a number of approaches have been taken to model coalbed methane

.

behavior King and Ertekin, 1989 , a nonequilibrium formulation in which sorption is

pressure and time dependent is required to account for the time lag incurred during gas

diffusion through matrix pores.

The nonequilibrium models may be classified by how the diffusion process is

handled. In pseudosteady state formulations, the diffusion coefficient depends on the

geometry of the matrix elements and time, but not gas concentration, while in steady

state models gas concentration is included as a variable. As a third category, the

unsteady state approach is the most rigorous, since it includes the effects of the gas

concentration gradient, but it is also the most expensive computationally to solve.

The major difference between the results from the pseudosteady state and unsteady

state formulations is in the early-time behavior of coal-seam gas wells, which is

important in analyzing pressure transient tests. Comparison of the two approaches shows

that while the pseudosteady state method underestimates gas rates in the first several

days or so, simulated gas rates at longer times from the pseudosteady state and unsteady

.

state models are virtually the same Kolesar et al., 1990 .

.

The COMETe coalbed methane simulation software used in this study is a

.

nonequilibrium, pseudosteady state formulation based on the Warren and Root 1963

.

model of dual-porosity reservoirs Paul et al., 1990; Sawyer et al., 1990 . As applied to

.

coal beds, the orthogonal natural fractures cleats are treated as a system of connected

pipes which divide the matrix into small elements the distance between cleats is about

.

0.6 cm or 0.25 in. . The matrix elements, which can be slabs, cylinders or spheres, act as

.

the source of gas that diffuses, by Ficks first law Adamson, 1973 , into the cleats.

Desorption of methane is described by a Langmuir isotherm, which relates matrix gas

. . .

content, V P , to the coal-bed cleat pressure, P, according to: V P sV Pr PqP

L L

where V is the maximum amount of gas that can be adsorbed, and P , a characteristic

L L

pressure, is a measure of residence time for a gas molecule on the surface. Both V and

L

P can be determined from gas desorption measurements on coal core samples. The

L

above equation provides the necessary boundary condition at the matrix-cleat interface.

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 371

The COMETe computer model is fully three-dimensional to account for vertical

wells intercepting multiple coal seams, structural features such as reservoir dip and

.

no-flow barriers faults and shale breaks , and gaswater gravity segregation. Other

unique features of coal reservoirs that are modeled are stress-induced changes in cleat

porosity and permeability, and matrix shrinkage due to release of adsorbed gas.

What makes a simulator useful is the availability of boundary conditions that can be

.

modeled Paul, 1996 . These conditions mainly relate to the types of wells vertical or

.

horizontal and well completions, which can be unstimulated, or stimulated by hydraulic

.

fractures vertical or horizontal, finite or infinite conductivity or open-hole cavity

methods.

3. Simulator applications and data requirements

.

Simulator applications for coalseam gas include the following: 1 test how well the

.

geologic model describes the real reservoir by matching performance history, 2

provide a basis for forecasting future production as a function of various operating

.

strategies such as variations in well spacing, 3 determine the ultimate economic

.

recovery for a field, that is the gas rate versus time, 4 confirm the physics of a

.

recovery process such as simulating a laboratory desorption test, 5 discover and

.

diagnose production problems such as wells which are performing below potential, 6

.

determine areas of the reservoir least depleted in order to properly locate infill wells, 7

.

design the best well completion scheme, such as single versus multiple seam, 8 predict

gas recovery from degasification of underground coal mines using both gob wells and

.

horizontal drainholes, and 9 determine sensitivity of simulated production to changes

in various data and identify weaknesses in critical data.

Data requirements for coalbed methane simulation may be grouped into three types:

.

1 reservoir description data, such as geometry, structure, depth, net thickness, stratifi-

.

cation and initial water saturation and pressure, 2 fluid PVT pressurevolumetem-

. .

perature data, such as gas viscosity and composition and 3 time-dependent well data,

such as fluid rates and bottomhole pressures. Some data are so important that they might

be considered a minimal data set for simulation. These minimal data are all in the

.

reservoir description category and include the following: 1 absolute cleat permeability

.

which determines rate of gas recovery, 2 initial gas content for determining gas-in-place

.

and the recovery target, 3 adsorption isotherm for determining timing of initial gas

.

show and ultimate gas recovery and 4 cleat porosity which is the site of water storage

in coal beds and determines volume of water produced.

The above minimal properties permeability, gas content, adsorption isotherm, and

.

porosity are critical because they determine project economics. The permeability can be

evaluated with pressure transient testing, while the gas content and adsorption isotherm

can be determined by direct laboratory measurements on coal samples. However, cleat

porosity is not readily measured and should be estimated by accurate history matching

of the gas and water production and pressure data. Without at least some measurements

of them, the modeler is left with considerable guesswork and a corresponding uncer-

tainty in the computed results. In this case, a sensitivity analysis should be performed

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 372

with the simulator to assess the range of probable outcomes as a function of the

uncertain data.

4. Examples of simulation

4.1. Multi-seam fractured well

The multi-seam fractured well problem is an example of how history matching well

performance using a simulator can be used, in conjunction with field measurements, to

determine coal reservoir properties.

.

The measured data involved the zone isolation packer ZIPe tool, shich were

developed from the need to examine flows from a single completion zone in a well

.

completed in multiple coal seams Saulsberry et al., 1991 . The ZIPe tool provided an

opportunity to confirm heterogeneity of coalbed cleat permeability between the Mary

Lee and Black Creek coal groups during a history match of production and pressure

.

performance of eight wells at the Gas Research Institutes GRI Rock Creek field,

.

Black Warrior Basin, Alabama in the United States Young et al., 1993 .

For the total field, cumulative gas and water production over seven years history

were matched with the simulator to within 3 and 1%, respectively. The match on gas

.

rate for one of the multi-seam wells P5 is shown in Fig. 1. The simulated and

measured data both show that the distribution of gas rate between the two coal groups is

Fig. 1. Gas rate versus time for the Rock Creek P5 well showing the relative contribution of the Mary Lee and

Black Creek coal groups to total production.

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 373

what would be expected based on cleat permeabilities determined from pressure

transient testing. Coalbed production from the Mary Lee Group is roughly an order of

magnitude higher than that from the coal beds of the Black Creek Group. Had the Mary

Lee:Black Creek coal bed production ratio been lower, a damaged or poor Mary Lee

completion would be indicated. This turned out to be the case for several of the wells,

which when coal beds were refractured in the Mary Lee Group yielded increased gas

flows up to sevenfold.

4.2. Open-hole caity well

In portions of the Fruitland coal play of the northern San Juan Basin of New Mexico

and Colorado, open-hole cavity wells outperform hydraulically fractured wells by more

than a factor of two. A study of a cavity well at GRIs Completion Optimization and

.

Assessment Laboratory COAL project was undertaken to determine how the downhole

conditions differ between cavity and fractured wells, and how these conditions impact

long-term well performance.

.

A radial grid was constructed with the cavity well in the center Fig. 2 . Twelve rings

were used in the grid; to preserve detail, not all the rings are shown in Fig. 2. The

.

innermost, 2.4 m 8 ft diameter, ring corresponds to the estimated cavity diameter, and

was used to represent the wellbore. A history match was performed using this grid by

specifying the observed gas rates and allowing the simulator to calculate the water rate

and bottomhole pressure in the well. It became apparent during the history match that

the coalbed cleat permeability around the well had been increased due to cavitation to a

value somewhat greater than the 25 md value determined from earlier well tests. Good

Fig. 2. Schematic diagram showing the radial grid used in the simulation analysis of the COAL site cavity

well.

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 374

Table 1

Simulated cumulative gas production

9 3

.

Well type Gas, 10 m Bcf

.

Open-hole cavity 0.077 2.70

Hydraulically fractured

. .

Undamaged skin factor s0 0.077 2.70

. .

Damaged skinsq3.3 0.030 1.06

matches between simulated and observed performance were obtained with an enhanced

. .

permeability zone of 250 md to a radius of 40 m 130 ft from the well center Fig. 2 .

While the reservoir characteristics derived from the history match are not unique, the

results do represent a closely bounded set of downhole conditions from which to assess

cavity well performance.

Using the grid in Fig. 2, history matching was again performed to find the

undamaged, infinite conductivity induced fracture half-length which turned out to be 64

.

m or 210 ft , that gave the same production profile and cumulative gas production as the

.

cavity well. Five-year gas production forecasts were then performed for: 1 the cavity

. .

well using the history match parameters, 2 the equivalent undamaged hydraulically

.

fractured well and 3 a damaged hydraulically fractured well. As shown in Table 1,

induced hydraulic fractures can yield performance equivalent to open-hole, cavity

completed wells if damage is avoided and highly conductive fractures are created.

4.3. Mine degasification with horizontal wells

The study of a mine degasification project for one of the Pocahantas coal seams

.

undergoing active mining in the Central Appalachian Basin eastern USA was under-

taken to determine the optimum spacing for horizontal degasification wells. Reservoir

simulation was used to evaluate different well spacings and mining advance rates to

achieve the required level of methane reduction prior to and during longwall mining

operations.

Simulated degasification was performed of a section of a coal mine longwall panel of

. .

dimensions 213=229 m 700=750 ft . Coal thickness is 1.67 m 5.5 ft . The longwall

section was represented by a 25=14=1 grid as illustrated in a plan view in Fig. 3. Gas

.

production was modeled from three unstimulated, 8.9 cm 3.5 in. diameter horizontal

.

wells located at 61 m 200 ft intervals along one coal face of the mine. Outgassing of

the coal mine face, which was exposed to atmosphere on three sides, was simulated by

.

setting a 101.3 kPa 14.7 psia boundary condition in thin rows of blocks representing

.

the three coal faces. The initial coal reservoir pressure was set at 2 MPa 300 psia .

The total time simulated was 90 days. For the first 10 days, only the coal mine face

was allowed to produce gas; no wells were producing. Thereafter, wells were brought on

.

production at 10 day intervals left to right in Fig. 3 . All wells were produced

.

unconstrained under a flowing bottomhole pressure of 207 kPa 30 psia . Peak gas rates

3 3

.

3

reached about 5.1=10 m rday 180 Mscfd for each of the wells and about 3.4=10

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 375

Fig. 3. Schematic diagram showing the plan view of the cartesian grid used in the simulation analysis of the

degasification of a longwall panel.

3

.

m rday 120 Mscfd for the coal mine face. After 90 days, the coal mine gas content

was reduced by 55% throughout the longwall panel. Additional degasification with

vertical andror gob wells would be required to further reduce coalbed gas content.

4.4. Sensitiity analysis

Sensitivity analysis was part of a GRI-industry study of the variability of Fruitland

.

coalbed properties and the effect on gas production Young et al., 1992 . The objectives

.

were to determine the sensitivity of long-term gas and water production to: 1 the

.

desorption pressure for fully saturated coals and 2 the initial gas content relative to the

.

capacity of the coal bed to hold gas degree of coal undersaturation .

If the initial coal reservoir conditions of gas content and pressure lie on the isotherm

.

Fig. 4 , the coal bed is said to be saturated, and both gas and water are produced upon

.

pumping. In this case, the desorption pressure P and initial coal reservoir pressure

d

.

P are identical. In some coals, the initial gas content lies below the sorption isotherm

i

.

Fig. 5 , which yields undersaturated coal reservoir conditions. For undersaturated

conditions, significant pressure drawdown must occur before methane can be released

from the coal bed. During this drawdown period, only water is produced while the coal

.

reservoir pressure remains above the release or desorption pressure P)P .

d

.

The isotherm used Figs. 4 and 5 represents an average curve determined from

several measured curves for the San Juan Basin wells. It is characterized by V s13.33

L

3

. .

m rtonne 427 scfrton and P s2.2 MPa 315 psia . Using the Langmuir equation

L

.

previously presented and an initial coal reservoir pressure of 9.1 MPa 1320 psia , these

3

.

constants yield an initial gas content of 10.76 m rtonne 345 scfrton .

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 376

Fig. 4. Adsorption isotherm used for the sensitivity analysis of a saturated coal.

Fig. 5. Adsorption isotherm for the sensitivity analysis of a undersaturated coal.

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 377

Fig. 6. Simulated gas rate versus time for variable desorption pressure.

Simulated results as a function of initial gas content for the three saturated cases in

Fig. 4 are shown in Fig. 6. For these simulations, initial coal reservoir pressure was

adjusted to equal the selected desorption pressure for each case. Because of the shape of

.

the isotherm, a difference in more than 7 MPa 1000 psia results in only a 15%

variation in initial gas content for fully saturated conditions. Gas recovery increases with

. .

increasing initial coal reservoir desorption pressure Fig. 6 , with most of the increased

recovery in the first 5 years.

To evaluate the performance of undersaturated coal reservoirs, initial gas content was

3

.

decreased from the saturated value of 10.76 m rtonne 345 scfrton while maintain-

.

ing the sorption isotherm and initial reservoir pressure unchanged Fig. 5 . As the

desorption pressure decreases with decreasing initial gas content, both gas and water

production decrease with the more notable differences occurring in the gas recovery. A

3

.

reduction in gas content from 10.76 to 4.53 m rtonne 345 to 145 scfrton results in a

.

93% loss in gas recovery Fig. 7 , with the greatest reduction occurring once the

desorption pressure falls below P . Fig. 7 illustrates the magnitude and timing of the

L

reductions in gas rate associated with decreasing degrees of coal gas saturation; only a

3

3

.

1.56 m rtonne 50 ft rton or 14% reduction in initial gas content results in an

approximate 60% fall in the gas rate during the initial period of production. Thus, a

small error in measured gas content can have a relatively large effect on forecasted gas

rates. As the area of effective pressure reduction around the well expands with continued

production, larger volumes of the coal reservoir are lowered below the desorption

pressure and the gas rates for the undersaturated coal beds show some increase. The

difference between the pressure at which gas can begin to desorb and the specified

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 378

Fig. 7. Simulated gas rate versus time for variations in initial gas content.

.

bottomhole pressure of 689 kPa 100 psia decreases with decreasing gas content for

undersaturated coal beds. This reduction in pressure differential has less impact on water

production because the water storage capacity of the coal bed is not as affected by the

lower desorption pressure.

5. Conclusions

Reservoir simulation is a versatile and powerful tool which can yield insight into gas

well performance in complex coal seam gas reservoirs. Pseudosteady state, nonequilib-

rium sorption formulations are required to model the mechanisms of gas release and

transport. The primary constraint in the application of a simulator is the lack of adequate

data with which to characterize reservoir performance. It is therefore essential that

reservoir simulation be used not as a stand alone analytical tool, but as an integral part

of other data collection programs designed to assist in the evaluation of coalbed methane

reservoir producibility and operating practices.

A major benefit of reservoir simulation is an economic one: a simulator can be run

many times at little expense while the field can be produced only once. Simulation can

provide several other benefits as well. For example, simulation provides rates of fluid

recovery with time, simulation can produce a better reservoir description than geology or

production testing alone, and simulation applies on any scale laboratory cores, single

wells, or entire fields. Because of the increasing need to justify economics and support

( )

G.B.C. YoungrInternational Journal of Coal Geology 35 1998 369379 379

decisions with accurate technical data, simulation has become an indispensable tool for

managing andror predicting reservoirs.

Acknowledgements

Advanced Resources International wishes to gratefully acknowledge the guidance and

support of GRI, in particular R.A. McBane and R.A. Schraufnagel, for most of the

research results discussed in this paper. On a more personal note, the author deeply

appreciates the insights and invaluable contributions of J.E. McElhiney and G.W. Paul

to an improved understanding of the principles presented here.

References

Adamson, A.W., 1973. A Textbook of Physical Chemistry. Academic Press, New York, pp. 67, 696.

King, G.R., Ertekin, T.M., 1989. A survey of mathematical models related to methane production from coal

seams. In: Proc. Coalbed Methane Symp. Univ. of Alabama, Tuscaloosa, pp. 125155.

Kolesar, J.E., Ertekin, T.M., Obut, S.T., 1990. The unsteady-state nature of sorption and diffusion phenomena

in the micropore structure of coal. SPE Formation Evaluation, pp. 6371.

Law, B.E., Rice, D.D., 1993. Hydrocarbons from coal. AAPG Studies in Geology No. 38, Tulsa, OK, 394 pp.

Paul, G.W., 1996. Simulating Coalbed Methane Reservoirs. In: Saulsberry, J.L., Schafer, P.S., Schraufnagel,

.

R.A. Eds. , A Guide to Coalbed Methane Reservoir Engineering. Gas Research Institute, Reference No.

GRI-94r0397, pp. 6.16.48.

Paul, G.W., Sawyer, W.K., Dean, R.H., 1990. Validation of 3D Coalbed Simulators. In: Proc. 65th SPE Annu.

Tech. Conf. and Exhibition. SPE Paper 20733, New Orleans, LA, pp. 203210.

Saulsberry, J.L., Lambert, S.W., Dobscha, F.X., 1991. Determining production from individual coal groups in

multi-zone wells with a zone isolation packer. In: Proc. Coalbed Methane Symp. Univ. of Alabama,

Tuscaloosa, pp. 353357.

Saulsberry, J.L., Schafer, P.S., Schraufnagel, R.A., 1996. A Guide to Coalbed Methane Reservoir Engineering.

Gas Research Institute, Reference No. GRI-94r0397.

Sawyer, W.K., Paul, G.W., Schraufnagel, R.A., 1990. Development and Application of a 3-D Coalbed

Simulator. In: Proc. 65th CIMrSPE Int. Tech. Meeting. CIMrSPE Paper 90-119, Calgary, Alberta.

Warren, J.E., Root, P.J., 1963. The behavior of naturally fractured reservoirs. Soc. Petrol. Eng. J., 245255.

Young, G.B.C., Paul, G.W., McElhiney, J.E., McBane, R.A., 1992. A parametric analysis of Fruitland coalbed

methane reservoir producibility. In: Proc. 67th SPE Annu. Tech. Conf. and Exhibition. SPE Paper 24903,

Washington, D.C., pp. 461473.

Young, G.B.C., Paul, G.W., Saulsberry, J.L., Schraufnagel, R.A., 1993. Characterization of coalbed methane

reservoirs at the Rock Creek project site, Alabama. In: Proc. Int. Coalbed Methane Symp. Univ. of

Alabama, Tuscaloosa, pp. 705714.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bab 1Document4 pagesBab 1Davirson AjahNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Muhammad Bin Abdul Wahab Kitab TauhidDocument291 pagesMuhammad Bin Abdul Wahab Kitab TauhidMohd Asmad SulaimanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Retaining WallDocument34 pagesRetaining WallDavirson Ajah100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Review On Coal Bed Methane As Natural Gas: J Patel, P Patel and P SaxenaDocument4 pagesReview On Coal Bed Methane As Natural Gas: J Patel, P Patel and P SaxenaDavirson AjahNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Soal Psikotest - Antonim (Lawan Kata)Document3 pagesSoal Psikotest - Antonim (Lawan Kata)SigmaAdi PengenNgertiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Student Work Experience Programme (SWEP) For 2019/2020 SessionDocument31 pagesThe Student Work Experience Programme (SWEP) For 2019/2020 SessionModesola Shoroye100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Corrosion of MartensiticDocument40 pagesCorrosion of MartensiticDinta PratiwiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- General Science Questions and Answers With Tests For PracticeDocument3 pagesGeneral Science Questions and Answers With Tests For PracticeMohan Raj100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Schaeffler Diagram PDFDocument1 pageSchaeffler Diagram PDFyusrilhanafiNo ratings yet

- Fischer-Tropsch: IncorporationDocument6 pagesFischer-Tropsch: Incorporationamirhosein saqafiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- High Electron Mobility Transistor (Hemt)Document4 pagesHigh Electron Mobility Transistor (Hemt)ijsretNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Astm E77 14 2021Document7 pagesAstm E77 14 2021Paola Andrea Avendaño RiveraNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Waterproofing and Weatherproofing MaterialsDocument37 pagesWaterproofing and Weatherproofing MaterialsSanjay Areyoukiddingme Somnath50% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Physiol PH v25n3p189 enDocument4 pagesPhysiol PH v25n3p189 enJin SniperNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- US20030143313A1Document7 pagesUS20030143313A1Thuận LêNo ratings yet

- A Review On Energy Harvesting Potential From Living Plants: Future Energy ResourceDocument17 pagesA Review On Energy Harvesting Potential From Living Plants: Future Energy ResourceEzequiel CancliniNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)Document5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)joshi madhavNo ratings yet

- Ethylene Decomposition Relief Sizing High Pressure Polyethylene IndustryDocument11 pagesEthylene Decomposition Relief Sizing High Pressure Polyethylene Industryoscarxsmith01No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CEeNews2 04Document6 pagesCEeNews2 04Antonio MezzopreteNo ratings yet

- Uji Fitokimia Ekstrak Etanol Daun Kemangi (Ocimum Basilicum L)Document6 pagesUji Fitokimia Ekstrak Etanol Daun Kemangi (Ocimum Basilicum L)Kezia VristianNo ratings yet

- Activated Sludge Microbiology Problems and Their ControlDocument21 pagesActivated Sludge Microbiology Problems and Their ControlDaniel Pérez100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bed CoilDocument8 pagesBed CoilMahadev KovalliNo ratings yet

- Photocolorimetry and SpectrophotometryDocument11 pagesPhotocolorimetry and SpectrophotometryRay Mondy100% (1)

- Analytical System Integration HRE-1942BDocument4 pagesAnalytical System Integration HRE-1942BTuan DoNo ratings yet

- Jotafloor SL UniversalDocument6 pagesJotafloor SL UniversalrogandatambunanNo ratings yet

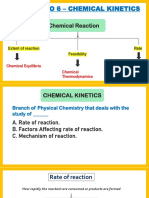

- Chapter No 6 - Chemical KineticsDocument45 pagesChapter No 6 - Chemical KineticsTanish SalviNo ratings yet

- 1100-Data Sheets PDFDocument3 pages1100-Data Sheets PDFPaturu VijayNo ratings yet

- Dow Corning Corporation Material Safety Data SheetDocument7 pagesDow Corning Corporation Material Safety Data SheetSalvador NegreteNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Light and Shadow FormationDocument13 pagesLight and Shadow FormationNikil J.PNo ratings yet

- Personal Care & Cosmetics: Oxarol C80Document1 pagePersonal Care & Cosmetics: Oxarol C80Mohamed AdelNo ratings yet

- MSDS of Pine OilDocument3 pagesMSDS of Pine OilMauricioNo ratings yet

- Fernandes 2019Document8 pagesFernandes 2019Jagan KbNo ratings yet

- MC Cabe Graphical Model-Based Distillation Column DesignDocument21 pagesMC Cabe Graphical Model-Based Distillation Column DesignReguloNo ratings yet

- Materials Terminology For Road and PavementDocument4 pagesMaterials Terminology For Road and PavementmanojNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)