Professional Documents

Culture Documents

Separator Design Guide

Uploaded by

laleye_olumideOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Separator Design Guide

Uploaded by

laleye_olumideCopyright:

Available Formats

Separator Design Guide

7-Feb-2000

Worley

Resources & Energy

ACN 001 279 812

Worley Limited

Level 2, 80 Albert Street

Brisbane !eensland "000 A!stralia

#$ Bo% 81, Albert Street

Brisbane !eensland "002 A!stralia

&el' ()1 7 *221 7"""

Fa%' ()1 7 *221 7791

Web' +tt,'--.../.orleylimited/0om

1 Co,yri2+t

2000 Worley Limited

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e i ' 5ev B ' 7-Feb-2000

CONTENTS

56S$75C6S 8 6N659:////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// ;

A##6N<;C6S//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// ;;

A S6#A5A&$5 S;=;N9 S#56A<S>66&///////////////////////////////////////////////////////////////////////////////////////////// ;;

B 56C$??6N<6< L;7;< 56S;<6NC6 &;?6////////////////////////////////////////////////////////////////////////////////// ;;

1/ ;N&5$<7C&;$N/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 1

1/ ;N&5$<7C&;$N/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 1

2/ <6S;9N C$NS;<65A&;$NS//////////////////////////////////////////////////////////////////////////////////////////////////////////// 2

2/ <6S;9N C$NS;<65A&;$NS//////////////////////////////////////////////////////////////////////////////////////////////////////////// 2

*/ >$5;=$N&AL @S @65&;CAL S6#A5A&$5 S6L6C&;$N/////////////////////////////////////////////////////////////*

*/ >$5;=$N&AL @S @65&;CAL S6#A5A&$5 S6L6C&;$N/////////////////////////////////////////////////////////////*

*/1 &+eory oA >oriBontal Se,arators////////////////////////////////////////////////////////////////////////////////////////////// *

*/2 &+eory oA @erti0al Se,arators////////////////////////////////////////////////////////////////////////////////////////////////// "

*/* &+eory oA Se,arators A,,lied &o @-L Systems////////////////////////////////////////////////////////////////////////"

*/" Advanta2es 8 <isadvanta2es oA >oriBontal - @erti0al Se,arators////////////////////////////////////////////4

"/ S6&&L;N9 @6L$C;&: CALC7LA&;$NS////////////////////////////////////////////////////////////////////////////////////////// 7

"/ S6&&L;N9 @6L$C;&: CALC7LA&;$NS////////////////////////////////////////////////////////////////////////////////////////// 7

"/1 Conventional A,,roa0+/////////////////////////////////////////////////////////////////////////////////////////////////////////// 7

"/2 Alternative A,,roa0+///////////////////////////////////////////////////////////////////////////////////////////////////////////////// 8

4/ S6#A5A&$5 S;=;N9 #5;NC;#L6S ///////////////////////////////////////////////////////////////////////////////////////////// 10

4/ S6#A5A&$5 S;=;N9 #5;NC;#L6S ///////////////////////////////////////////////////////////////////////////////////////////// 10

4/1 @erti0al @a,o!r-LiC!id Se,arators///////////////////////////////////////////////////////////////////////////////////////// 10

4/1/1 SiBin2 <iameter////////////////////////////////////////////////////////////////////////////////////////////////////////// 10

4/1/2 SiBin2 @essel Len2t+////////////////////////////////////////////////////////////////////////////////////////////////// 10

4/2 SiBin2 <emister #ads////////////////////////////////////////////////////////////////////////////////////////////////////////////// 11

Appendices

A Separator Sizing Spreadsheet

B Recoended !i"uid Residence Tie

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e ii ' 5ev B ' 7-Feb-2000

#$ %NTROD&CT%ON

Separators play an important role in the chemical industry and are critical to the success of almost all

processes. The usage of phase separators range from functions as diverse as ensuring that final

product quality meets often stringent standards to protecting downstream equipment from undesirable

impurities. In the petrochemical industry the most common uses include:

Separation of liquid hydrocarbon from a hydrocarbon vapour (2-phase vapour liquid separation!

Separation of a two liquids differing in their respective densities (2-phase" liquid liquid

separation!

Separation of a feed stream consisting of vapour" liquid hydrocarbon and water into # separate

components. (#-phase separation!.

Some e$amples of separators are as follows:

2-Phase Separators 3-Phase Separators

%uel gas &' drum (lycol Separator

)ompressor &' drum *ydrotreater high pressure separator

+elief gas &' drum ,et column reflu$ drum

)rude unit desalter -roduction separator

.mine absorber &' drum

)oalescer units

This design guide presents the basic principles and methods involved with si/ing vertical and

hori/ontal separators for both 2-phase and #-phase separation. It is important to note" however" that

this guide does not cover the separation of solids from either liquids or vapour.

,hilst theoretically" it may be important to ta0e into consideration dynamic operating conditions of

the separation process" such as variation in fluid properties with time1 and the transient start-up and

shut-down characteristics of separation operation when underta0ing the design" this presents a near

impossible tas0 in reality. .s such" this design guide uses steady-state operation of the separator as its

basis.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 1 ' 5ev B ' 7-Feb-2000

'$ DES%GN CONS%DERAT%ONS

.s is the case with the design of any vessel" the associated system properties and process

requirements must first be defined. In the case of separator design" these may include:

System Properties

%low rates of each phase to be separated.

-hysical properties of each phase (viscosity" density" etc.!

Identification of continuous phase(s! (see following table!

.

System Continuous / discontinuous phase distinction

2apour 3iquid The vapour is the continuous 4light5 phase" with liquid being the heavy"

discontinuous phase which settles out as droplets.

*) liquid ,ater. The *) liquid is the continuous phase" with water settling out as droplets

,ater *) liquid The water is the continuous" 4heavy5 phase" with *) liquid being the light

discontinuous phase rising up through the water as droplets.

Process Requirements

The required throughput and composition of feed mi$ture to be purified will ultimately determine

the si/e and type of separator selected.

6egree of separation required. The minimum droplet si/es required to be separated from each

phase need to be specified. This is generally set by factors such as purity of product required for

sale or purity required to avoid upsets to downstream equipment 7 processes. %or e$ample:

In *) liquid vapour separation" efficient liquid separation from vapour is needed" particularly in

situations where the vapour subsequently flows downstream to a compressor. Separators for this

purpose often include mist eliminators to enhance their separation performance.

In water *) liquid separation" efficient separation of water from the *) is needed to avoid

over-loading downstream water treatment facilities. This is particularly important if the liquid

*) is then fed to a downstream distillation column.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 2 ' 5ev B ' 7-Feb-2000

($ )OR%*ONTA! +S +ERT%CA! SE,ARATOR SE!ECT%ON

8efore a 9udgement is made regarding the type of separator most suitable for use in a specific

application" there are number of factors that need to be ta0en into consideration. The following

sections outline the general characteristics of both hori/ontal and vertical separators and where they

are most useful. It is important to note" however" there are e$ceptions to these recommendations and

each specific case should be evaluated before any decision is made.

%or ease of reading" when comparing the performances of vertical and hori/ontal separators in this

section" the light phase will be referred to as 4vapour5 and the heavy phase as 4liquid5" even in the

case of liquid-liquid systems.

($# Theor y o- )orizontal Separators

In terms of equivalent vapour flow areas" hori/ontal separators are more efficient than are their

vertical counterparts" due largely to the fact that the liquid settles out perpendicular to the direction of

vapour flow" rather than in a direction countering the vapour flow (as is the case with vertical

separators!.

If the residence time

:

of the vapour is greater than the time ta0en for the liquid droplets to reach the

liquid surface" then the liquid will undergo satisfactory disengagement from the vapour. It is this

relationship which ultimately determines the ma$imum allowable vapour velocity through the

separator" as follows:

H

L v

v

s

.

ma$

;quation #.:

,here 3 < distance between feed inlet and vapour outlet.

2

s

< liquid droplet settling velocity (details of calculation method to follow in section =!

* < distance between top of drum and >ormal 3iquid 3evel (>33!

2

ma$

< ma$imum allowable vapour velocity

Thus" for hori/ontal separators with a 37* ratio greater than :" the ma$imum velocity can e$ceed the

liquid settling velocity without affecting the vessel?s ability to achieve satisfactory separation. .s

will be shown in section #.2" however" this is not the case with vertical separators.

*ori/ontal separators are most efficient where large volumes of liquids are present with the vapour or

alternatively" when large volumes of vapour are dissolved in the liquid phase(s!. They are generally

:

The vapour residence time refers to the time ta0en for vapour to flow from the feed inlet to vapour outlet

no//le.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e * ' 5ev B ' 7-Feb-2000

used in applications such as #-phase separators" high-pressure vapour-liquid separators" relief &'

drums and liquid-liquid separators" although there are frequent e$ceptions.

($' Theor y o- +er tical Separators

In the case of a vertical separator" the liquid droplets settle out in a direction opposite to the direction

of vapour flow. Therefore" the liquid will not disengage from the vapour unless the vapour velocity is

lower than the liquid settling velocity. That is"

s

v v

ma$

;quation #.2

6espite the fact that vertical separators are a less efficient alternative than hori/ontal ones with an

appropriate 37* ratio" they do offer some distinct advantages which have seen them favoured for

applications as fuel gas and compressor suction &' drums. Such advantages are detailed in section

#.=.

($( Theor y o- Separators Applied To +.! Systes

In reality" the ma$imum allowable vapour velocity for liquid-vapour systems is highly dependent on

the specific separator application and indeed is vastly different" for e$ample" in cases where a

demister pad is installed and cases where one is not. Such fle$ibility is not catered for using

;quations #.: and #.2" where it is not possible to effectively ta0e into consideration any variation in

separator characteristics. Instead" a more appropriate equation to use for calculating the ma$imum

allowable vapour velocity for vapour-liquid systems is as follows:

v

v l

K v

! (

ma$

=

;quation #.#

,here v

ma$

< @a$imum allowable vapour velocity" m7s

& < ;mpirical constant" m7s

l

< 6ensity of liquid phase" 0g7m

#

v

< 6ensity of vapour phase" 0g7m

#

. range of values for & are available for use in the above equation" as illustrated in the following

table (Table-#.:! ta0en from figure A-B of (-S. (SI units! 2olume :" Section A" page A-A.

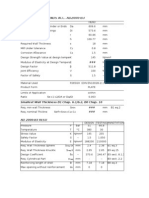

Table- 3.1

Typical K C !actors "or Si#in$ %o&en %ire 'emisters

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e " ' 5ev B ' 7-Feb-2000

Separator Type K !actor (m/s) C !actor (m/hr)

*ori/ontal C.:2 to C.:D =2C to D=C

2ertical C.CD to C.:: 2CC to =CC

Spherical C.CD to C.:: 22C to =CC

,et Steam C.CAE 2AC

@ost vapours under vacuum C.CE: 22C

Salt F )austic ;vaporators C.C=E :EC

.d9ustment of & F ) %actor for

-ressure - G of design value.

.tmospheric

:CCC 0-a

2CCC 0-a

=CCC 0-a

HCCC 0-a

:CC

BC

HD

HC

AD

%or glycol and amine solutions" multiply & by C.E to C.H.

Typical use one-half of the above & or ) values for appro$imate si/ing of vertical separators

without wire demisters.

%or compressors suction scrubbers and e$pander inlet separators multiply & by C.A to C.H.

($/ Ad0antages & Disad0antages o- )orizontal 1 +ertical

Separators

There are many factors

Horizontal Separators - Advantages:

*igh separation efficiency due to higher vapour space volumes and vapour residence times.

3ower no//le outlet elevations

@ore applicable for use as reflu$ accumulators" which can be more readily attached to and

supported by hori/ontal separators.

@ore suitable than vertical separators for handling large total liquid volumes.

@ay be used in applications requiring #-phase separation.

Horizontal Separators Disadvantages:

3arger footprint area required than for vertical separators.

8ecome less economical than vertical separators for high vapour 7 liquid ratios.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 4 ' 5ev B ' 7-Feb-2000

Vertical Separators Advantages

3ess potential for entrainment of liquid in vapour stream. Inli0e a hori/ontal separator" the area

available for vapour flow is not reduced when the liquid level rises during operation.

3ess footprint area required.

;asier installation and operation of level alarms and shutdown control systems.

(enerally a lower cost option than hori/ontal separators.

@ore efficient than hori/ontal separators for high vapour 7 liquid ratios.

Vertical Separators Disadvantages

>ot generally recommended for three-phase separation unless the total liquid fraction present in

the feed stream is very low (:C 2CG by weight!.

3ess suitable for a feed with a high liquid7vapour ratio.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e ) ' 5ev B ' 7-Feb-2000

/$ SETT!%NG +E!OC%T2 CA!C&!AT%ONS

-erhaps the most important criterion used in si/ing phase separators is the velocities at which

entrained droplets of a discontinuous" dispersed phase settle out in a continuous medium. The settling

velocity of such droplets is dependent upon factors such as droplet si/e and shape" phase densities and

the droplets? resistance to settling. Infortunately" due to the fact that the droplet?s resistance to

settling is in fact a function of the settling velocity itself" various appro$imations are required in any

solution method and a precise determination of the settling velocity is not possible. In order to

minimise the errors associated with any appro$imations made" however" two independent approaches

to calculating the settling velocity are used in this design guide.

/$# Con0entional Approach

The conventional approach ta0en by the ma9ority of literature sources in the past to calculate settling

velocities has been to use one of three laws" namely 4Sto0es 3aw5" the 4Intermediate 3aw5 or

4>ewton?s 3aw5. These laws are given below" referenced from figure A-= of (-S. (SI Inits!"

2olume :" Section A" page A-=:

:H

! ( J J :CCC

2

v l p

t

D g

V

= Sto*es +a, (;quation =.:!

=# . C

2B . C

A: . C

:= . :

A: . C

! ( J J D= . #

v

v l p

t

D g

V

= -ntermediate +a, (;quation =.2!

v

v l p

t

D g

V

! ( J J

A= . :

= .e,ton/s +a, (;quation =.#!

,here: 2

t

< Settling velocity of droplet (m7s!

g < (ravitational acceleration constant (B.H: m7s

2

!

6

p

< 6roplet diameter (metres!

v

< 6ensity of continuous phase (0g7m#!

l

< 6ensity of discontinuous phase (0g7m#!

< 2iscosity of continuous phase (-a.s!

.ote: @a$imum settling velocity shall not e$ceed C.CC=2 m7s.

The law that is selected for use in a specific situation depends upon the si/e range of settling droplets.

The ma$imum droplet si/e for which each respective law applies is given by the following:

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 7 ' 5ev B ' 7-Feb-2000

#

:

2

ma$ "

! ( J J

=

v l v

CR p

g

K D

(;quation =.=!

,here: 6

p"ma$

is the ma$imum droplet si/e for which each respective law applies (metres!.

&

)+

is a dimensionless constant.

It is seen then from the above equation that &

)+

is in fact the quantity which determines which of the

three laws is applicable. 2alues for &

)+

are as follows:

0pplicable Settlin$ +a, 1alue o" K

CR

Sto0e?s 3aw C.C2D

Intermediate 3aw C.##=

>ewton?s 3aw :H.:#

The law to be used is then selected by substituting the &

)+

values shown above sequentially into

equation =.= for each law and determining for which law the actual droplet si/e is lower than the value

of 6

p"ma$

calculated.

/$' Alternati0e Approach

.n alternative approach which can be used to calculate the settling velocity of the droplets was

developed by *aider F 3evenspiel" (:BHB!. This approach introduces two useful quantities a

dimensionless droplet si/e" d

p

J

and a dimensionless droplet settling velocity" u

t

J

" defined as follows:

#

:

2

J

! (

g

d d

v l v

p p

(;quation =.D!

#

:

2

J

! (

=

g

u u

v l

v

t t

(;quation =.E!

%or the direct evaluation of u

t

J

" *aider F 3evenspiel present the following appro$imation (valid for

spherical droplets!" which e$presses u

t

J

as a function of d

p

J

.

( ) ( )

:

D . C

J

2

J

J

DB: . C :H

+ =

p p

t

d d

u (;quation =.A!

(iven the appropriate physical properties of the system under consideration" d

p

J

is first calculated

(using equation =.D! followed by u

t

(using bac0 substitution in equation =.H!" as follows:

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 8 ' 5ev B ' 7-Feb-2000

( ) ( )

#

:

2

:

D . C

J

2

J

! (

DB: . C :H

+ =

g

d d

u

v l

v

p p

t

(;quation =.H!

6ue to the fact that the 4conventional5 methods described in section =.: are more widely used and

trusted by industry world-wide than the 4alternative5 method" it is the method of choice used in the

calculation of droplet settling velocities for the purposes of actually si/ing the separator in this design

guide. ,hile the droplet settling velocities are calculated using both methods" this is merely to ensure

that the values calculated for the settling velocities do not differ substantially from one another. This

is designed to ensure that the potential errors associated with the appro$imations made in each method

are reduced.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 9 ' 5ev B ' 7-Feb-2000

3$ SE,ARATOR S%*%NG ,R%NC%,!ES

3$# +er tical +apour.!i"uid Separators

3$#$# Sizing Diaeter

%or a vertical separator" the vessel diameter required is determined by first calculating the ma$imum

allowable vapour velocity" (using equation #.#! before using the following equation:

ma$

min

.

. =

v

Q

d

=

;quation D.:

,here d

min

< @inimum 2essel 6iameter (m!

K < 2apour %lowrate (m

#

7s!

v

ma$

< @a$imum 2apour 2elocity (m7s!

The vessel diameter should be selected as the ne$t largest pipe7drum si/e to the d

min

value calculated"

where deemed practical.

3$#$' Sizing +essel !ength

.mongst the most important factors required for consideration when designing the length of a

proposed vertical separator" are:

The location of various liquid levels inside the vessel (33S6" 333" >33" *33" *3S6" etc.!

The location of inlet and outlet no//les

The surge volume required to permit corrective action to be ta0en by plant operators in times of

unsatisfactory plant operation. Such information is usually provided by the vendor" or based upon

e$perience gained in si/ing similar vessels in the past.

,hether or not a demister pad is to be installed.

The following recommendations can be made regarding vessel shell lengths which will assist the

process engineer in addressing the important issues listed above.

The low liquid level (333! should be a minimum of #CC mm above the bottom vessel tangent

line. The precise level height may depend on the nature of level control instruments available.

The high liquid shutdown (*3S6! level should be no less than #CC mm below the inlet feed

distributor 7 no//le.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 10 ' 5ev B ' 7-Feb-2000

The shell length between the *33 and 333 should be set so as to provide sufficient liquid surge

volume.

The shell length between the *3S6 and *33 should be made sufficient to provide the operator

with sufficient time to shut down the separator before the performance and operation of

downstream processes and equipment is compromised.

The minimum T7T length of the vessel should be 2DCC mm.

The clearance between the bottom of the demister pad and the top of the feed distributor should

be set at ACG of the vessel diameter or ADC mm" whichever of the two is greater.

The clearance between the upper tangent line and the top of the demister pad should be :CG of

the vessel I6 or #CC mm" whichever of the two is greater.

%ollowing figure-D.:" adapted from (-S. (SI Inits! 2olume :" Section A" depicts an e$ample of a

typical vertical separator containing a wire mesh mist e$tractor" in which the above-mentioned

recommendations have been adhered to.

!i$ure 2 3.1

:DC mm

6v or ECC mm (min!

Inlet 6i 2 6i

#CC mm (min!

3S* (S76!

6v #CC mm (min!

3(73)

Slug )apacity #CC mm (min!

3$' Sizing Deister ,ads

@ist e$tractors of the mesh-type are typically constructed of a pad of compact stainless steel wire

designed to capture entrained liquid droplets or those droplets too small to settle by gravity. The

liquid droplets impinge on the mesh pad" coalesce and fall downward as larger droplets" bac0 through

the rising vapour. 6emister pads are generally aligned hori/ontally in both vertical and hori/ontal

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 11 ' 5ev B ' 7-Feb-2000

separators" with the vapour and entrained liquid passing vertically upward through the pad. In fact"

the pad performance is found to be adversely affected if tilted at an angle of greater than #C degrees

from the hori/ontal.

.s reported by (-S. (SI! volume :" most installations use a :DC mm thic0 pad with the minimum

recommended thic0ness being :CC mm. In order to si/e the diameter of a demister pad" the following

correlation may be used:

2

:

.

. =

=

v

v l

K

Q

d

(;quation D.=!

,here: I

v

< Superficial velocity of vapour through the demister pad (m7s!.

& < ;mpirical constant" provided by vendor" but usually in the range of C.:

C.:2 m7s.

K < 2apour flowrate (m

#

7s!

l

< 6ensity of liquid phase (0g7m

#

!

v

< 6ensity of vapour phase (0g7m

#

!

The diameter of the mist e$tractor is usually substantially less than the diameter of the separator. In

the case of vertical separators with diameters less than :CCC mm" a mesh diameter equivalent to the

vessel diameter should be used. In addition" the demister pads are typically located #CC mm below

the vapour outlet no//le of a hori/ontal separator.

%or any variety of service" the material of construction for the mesh pad should be at least #C= ss. %or

application in corrosive service" either #:E ss or @onel mesh pads should be used.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 12 ' 5ev B ' 7-Feb-2000

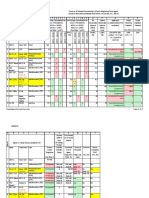

Appendi4 A 5 Separator Sizing Spreadsheet

%nstructions

In order to allow for designs of separators to be generated rapidly" an ;$cel ?BA spreadsheet file

(Separator Si/ing.$ls! has been developed. This spreadsheet allows for the following types of

separator to be si/ed:

4ori#ontal Separators 1ertical Separators

2-phase" vapour-liquid 2-phase" vapour-liquid

2-phase" liquid-liquid 2-phase" liquid-liquid

#-phase" liquid-liquid-vapour (with weir" no boot!

#-phase" liquid-liquid-vapour (with boot" no weir!

In the sections that follow" a brief outline is given for each type of separator on each of the following

topics:

Inputs required by the spreadsheet"

%inal outputs provided by the spreadsheet"

,arnings provided by the spreadsheet" and

. chronological procedure for using the spreadsheet.

A$# +ertical !i"uid.+apour Separator

A$#$# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

.ctual 6ensities (0g7m

#

!

2iscosities (c-!

2. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable vapour velocity and specified liquid

residence times are not e$ceeded.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 1* ' 5ev B ' 7-Feb-2000

3iquid level heights (mm! heights of 33S6" 333" >33" *33 and *3S6 are varied by

spreadsheet user until no warnings regarding insufficient liquid residence times are

encountered.

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

:DCC 0g7ms

2

where half-open pipe inlet present!

(

m

v

m

2

!

ma$

vapour outlet no//le #ADC 0g7ms

2

v

ma$

liquid outlet no//le : m7s

6roplet si/e (liquid in gas! :DC m without demister pad installed

DCC mm with demister pad installed

3iquid +esidence Times See .ppendi$-8.

33S6 height above bottom tangent line :DC mm (minimum!

*3S6 height above bottom tangent line . value such that the *3S6 is no less than :DC

mm below the inlet feed no//le.

Thic0ness of 6emister -ad :CC mm (minimum!" but usually :DC mm.

&-value :. @ay be supplied by vendor and manually

inputted into spreadsheet.

2. If not supplied by vendor" may be obtained

using information from %ig A-B" (-S. (SI!

2olume :" Section A" -age A-A.

A$#$' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable vapour velocity

.ctual ma$imum vapour velocity

3iquid droplet settling velocity F the settling law used in the calculation

3iquid residence times between specified liquid levels.

2. 2essel 6imensions

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 1" ' 5ev B ' 7-Feb-2000

@inimum vessel diameter

2essel height (T7T! ta0en as a minimum of 2DCC mm.

@inimum inlet no//le I6

@inimum vapour outlet no//le I6

@inimum liquid outlet no//le I6

)learance between inlet feed no//le and bottom of demister pad (if fitted! shall be ta0en as

the greater of C.A6 or ADC mm.

)learance between top of demister pad (if fitted! and upper tangent line ta0en as the greater

of C.:6 or #CC mm.

A$#$( Warnings ,ro0ided

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The calculated vapour velocity e$ceeds the ma$imum allowable vapour velocity calculated by the

&-factor method.

2. The specified liquid level heights are inadequate to provide the required liquid residence times.

#. The vessel height 7 diameter ratio does not fall in the range of 2 D.

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

A$#$/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..:.:" e$cept for the vessel I6 and liquid level

elevations.

2. Set the vessel diameter to the calculated value for the 4minimum vessel diameter5 as a starting

point.

L

The minimum value for any no//le diameter is considered to be DC mm.

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 14 ' 5ev B ' 7-Feb-2000

#. ;nter arbitrary values for the various liquid level elevations and vary them to meet the required

liquid residence times.

=. ;$amine the vessel height 7 diameter ratio to ensure that it lies between 2 D.

(i! If the ratio is greater than D" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing one or all of

the 33S6" 333" >33" *33 and *3S6 elevations specified in step #. If the latter

approach is ta0en" it must be ensured that all required liquid residence times remain

satisfied and that the 33S6 elevation is a minimum of :DC mm above the bottom

tangent line.

(ii! If the ratio is less than 2" on the other hand" the elevations of the 33S6" 333" >33"

*3S6 may be increased to e$tend the height of the vessel and increase the ratio. The

vessel diameter may not be decreased from the value selected in step 2. In step 2" the

minimum vessel diameter was selected" which cannot be decreased in order to increase

the *76 ratio without the ma$imum allowable vapour velocity being e$ceeded.

A$' +ertical !i"uid.!i"uid Separator

A$'$# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

.ctual 6ensities (0g7m

#

!

2iscosities (c-!

2. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable light liquid velocity and specified liquid

residence times are not e$ceeded.

3iquid level heights (mm! heights of 3I3S6" 3I3" >I3" *I3" *I3S6 are varied by

spreadsheet user until no warnings regarding insufficient liquid residence times are

encountered.

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 1) ' 5ev B ' 7-Feb-2000

:DCC 0g7ms

2

where half-open pipe inlet present

v

ma$

light liquid outlet no//le : m7s

v

ma$

heavy liquid outlet no//le : m7s

6roplet si/e (heavy liquid in light liquid! ECC m

6roplet si/e (light liquid in heavy liquid! :CCC m

3iquid +esidence Times See .ppendi$-8

3I3S6 height above bottom tangent line :DC mm (minimum!

*I3S6 height above bottom tangent line . value such that the *I3S6 is no less than :DC

mm below the inlet feed no//le.

A$'$' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable light liquid velocity (assumed equal to C.HD J settling velocity of heavy

liquid droplets in the light liquid phase!

.ctual ma$imum light liquid velocity

3ight liquid droplet settling velocity F the settling law used in the calculation

*eavy liquid droplet settling velocity F the settling law used in the calculation

3iquid residence times between specified liquid levels.

2. 2essel 6imensions

@inimum vessel diameter

2essel height (T7T! ta0en as a minimum of 2DCC mm.

@inimum inlet no//le I6

@inimum light liquid outlet no//le I6

@inimum heavy liquid outlet no//le I6

A$'$( Warnings ,ro0ided

L

The minimum value for any no//le diameter is considered to be DC mm.

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 17 ' 5ev B ' 7-Feb-2000

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The calculated light liquid velocity e$ceeds the ma$imum allowable light liquid velocity.

2. The residence time of the heavy liquid between the vessel bottom and the >I3 is less than the

light liquid droplet 4fall5 time in the heavy liquid medium.

#. The specified liquid level heights are inadequate to provide the required liquid residence times.

=. The vessel height 7 diameter ratio does not fall in the range of 2 D.

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

A$'$/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..2.:" e$cept for the vessel I6 and elevations of 3I3S6"

3I3" >I3" *I3 and *I3S6.

2. Set the vessel diameter to the calculated value for the 4minimum vessel diameter5 as a starting

point.

#. ;nter arbitrary values for the various liquid level elevations (i.e. 3I3S6" 3I3" >I3" *I3 and

*I3S6! and vary them to meet the required liquid residence times. .lso ensure in specifying

these levels that the residence time of the heavy liquid between the vessel bottom and the >I3 is

less than the light liquid droplet 4fall5 time in the heavy liquid medium.

=. ;$amine the vessel height 7 diameter ratio to ensure that it lies between 2 D.

(i! If the ratio is greater than D" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing one or all of

the 3I3S6" 3I3" >I3" *I3 and *I3S6 elevations specified in step #. If this approach

is ta0en" it must be ensured that all required liquid residence times remain satisfied and

that the 3I3S6 elevation is a minimum of :DC mm above the bottom tangent line.

(ii! If the ratio is less than 2" on the other hand" the elevations of the 3I3S6" 3I3" >I3"

*I3S6 may be increased to e$tend the height of the vessel and increase the ratio. In

doing so" it is again vital to ensure that the light liquid droplet fall time is less than the

heavy liquid residence time between the vessel bottom and the >I3. The vessel

diameter may not be decreased from the value selected in step 2. In step 2" the

minimum vessel diameter was selected" which cannot be decreased in order to increase

the *76 ratio without the ma$imum allowable light liquid velocity being e$ceeded.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 18 ' 5ev B ' 7-Feb-2000

A$( )orizontal +apour.!i"uid Separator

A$($# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

.ctual 6ensities (0g7m

#

!

2iscosities (c-!

2. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable vapour velocity and specified vapour and

liquid residence times are not e$ceeded.

2essel length (T7T! (mm! ad9usted such that the minimum length is 2DCC mm and that the

length 7 diameter ratio is between 2 = for the final design. The vessel length must also be

ad9usted such that the required vapour and liquid residence times are not e$ceeded. 'f

particular importance in this regard is ensuring that the vapour residence time provided is

sufficient to allow a liquid droplet to fall from the top of the vessel to the >33.

3iquid level heights (mm! heights of 33S6" 333" >33" *33 and *3S6 are varied by

spreadsheet user until no warnings regarding insufficient liquid residence times are

encountered. The >33 is in fact one of the first inputs required as it is needed to calculate the

minimum vapour flow area and subsequently the vapour residence time (once vessel length is

specified!.

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

:DCC 0g7ms

2

where half-open pipe inlet present

(

m

v

m

2

!

ma$

vapour outlet no//le #ADC 0g7ms

2

v

ma$

liquid outlet no//le : m7s

6roplet si/e (liquid in gas! :DC m regardless of whether or not a demister

pad is installed

3iquid +esidence Times See .ppendi$-8

33S6 height above vessel bottom :DC mm (minimum!

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 19 ' 5ev B ' 7-Feb-2000

*3S6 height above vessel bottom . value such that the *3S6 is no less than :DC

mm below the inlet feed no//le.

Thic0ness of 6emister -ad :CC mm (minimum!" but usually :DC mm.

&-value :. @ay be supplied by vendor and manually

inputted into spreadsheet.

2. If not supplied by vendor" may be obtained

using information from figure A-B" (-S. (SI!

2olume :" Section A" -age A-A..

A$($' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable vapour velocity

.ctual ma$imum vapour velocity

3iquid droplet settling velocity F the settling law used in the calculation

3iquid droplet fall time (from top of vessel to >33!

2apour residence time (from top of vessel to >33!

3iquid residence times between specified liquid levels.

2. 2essel 6imensions

@inimum vessel diameter

@inimum inlet no//le I6

@inimum vapour outlet no//le I6

@inimum liquid outlet no//le I6

)learance between inlet feed no//le and bottom of demister pad (if fitted! shall be ta0en as

the greater of C.A6 or ADC mm.

)learance between top of demister pad (if fitted! and upper tangent line ta0en as the greater

of C.:6 or #CC mm.

L

The minimum value for any no//le diameter is considered to be DC mm.

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 20 ' 5ev B ' 7-Feb-2000

A$($( Warnings ,ro0ided

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The calculated vapour velocity e$ceeds the ma$imum allowable vapour velocity calculated by the

&-factor method.

2. The liquid droplet fall time (from top of vessel to >33! e$ceeds the vapour residence time (also

from top of vessel to >33!.

#. The specified liquid level heights are inadequate to provide the required liquid residence times.

=. The vessel length 7 diameter ratio does not fall in the range of 2 =.

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

A$($/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..#.:" e$cept for the vessel I6" vessel length and

elevations of 33S6" 333" >33" *33 and *3S6.

2. .s a starting point" set the vessel diameter to an arbitrary value and the vessel length initially as #

times this quantity.

#. ;nter arbitrary values for the various liquid level elevations (i.e. 33S6" 333" >33" *33 and

*3S6!.

(i! If the liquid droplet fall time e$ceeds the vapour residence time (warning number 2!" the

vapour residence time may be increased by:

Increasing vessel diameter as needed the most successful measure if the vapour

residence time is significantly lower than the liquid droplet fall time (i.e. M2DG

lower!.

Increasing the length of the vessel the most successful measure if the vapour

residence time is only slightly lower than the liquid droplet fall time (i.e. N2DG

lower!

(ii! If the specified liquid level heights are inadequate to provide the required liquid residence

times" the residence times may be increased by employing either of the two above measures

or alternatively increasing the height difference between the liquid levels where residence

time is calculated to be insufficient.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 21 ' 5ev B ' 7-Feb-2000

=. If warning : occurs" the available cross-sectional area available to vapour flow may be increased

by an increase in vessel I6" or by a decrease in liquid level elevations.

D. ;$amine the vessel length 7 diameter ratio to ensure that it lies between 2 =.

(iii! If the ratio is greater than =" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing the vessel

length. If this approach is ta0en" it must be ensured that none of the warnings listed in

..#.# occur and that the length of the vessel does not become lower than 2DCC mm.

(iv! If the ratio is less than 2" on the other hand" the vessel length may be increased as a

remedy" while decreasing the vessel diameter from the value selected in step 2.

A$/ )orizontal !i"uid.!i"uid Separator

A$/$# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

.ctual 6ensities (0g7m

#

!

2iscosities (c-!

#. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable vapour velocity and specified vapour and

liquid residence times are not e$ceeded.

2essel length (T7T! (mm! ad9usted such that the minimum length is 2DCC mm and that the

length 7 diameter ratio is between 2 = for the final design. The vessel length must also be

ad9usted such that the required vapour and liquid residence times are not e$ceeded. 'f

particular importance in this regard is ensuring that the vapour residence time provided is

sufficient to allow a liquid droplet to fall from the top of the vessel to the >33.

3iquid level heights (mm! heights of 3I3S6" 3I3" >I3" *I3 and *I3S6 are varied by

spreadsheet user until no warnings regarding insufficient liquid residence times are

encountered. The >I3 is in fact one of the first inputs required as it is needed to calculate the

minimum light liquid flow area and subsequently the light liquid residence time (once vessel

length is specified!.

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 22 ' 5ev B ' 7-Feb-2000

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

:DCC 0g7ms

2

where half-open pipe inlet present

v

ma$

light liquid outlet no//le : m7s

v

ma$

heavy liquid outlet no//le : m7s

6roplet si/e (heavy liquid in light liquid! ECC m

6roplet si/e (light liquid in heavy liquid! :CCC m

3iquid +esidence Times See .ppendi$-8

3I3S6 height above vessel bottom :DC mm (minimum!

*I3S6 height above vessel bottom . value such that the *I3S6 is no less than :DC

mm below the inlet feed no//le.

A$/$' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable light liquid velocity

.ctual ma$imum light liquid velocity.

3ight liquid droplet settling velocity in heavy liquid medium F the settling law used in the

calculation

3ight liquid droplet fall time (from bottom of vessel to >3!

*eavy liquid droplet settling velocity in light liquid medium F the settling law used in the

calculation.

*eavy liquid droplet fall time (from top of vessel to >I3!.

3iquid residence times between specified liquid levels.

#. 2essel 6imensions

@inimum vessel diameter

@inimum inlet no//le I6

@inimum light liquid outlet no//le I6

@inimum heavy liquid outlet no//le I6

L

The minimum value for any no//le diameter is considered to be DC mm.

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 2* ' 5ev B ' 7-Feb-2000

A$/$( Warnings ,ro0ided

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The calculated light liquid velocity e$ceeds the ma$imum allowable light liquid velocity.

2. The heavy liquid droplet fall time (from top of vessel to >I3! e$ceeds the light liquid residence

time (also from top of vessel to >I3!.

#. The heavy liquid residence time is less than the light liquid droplet fall time (from bottom of

vessel to >I3!.

D. The specified liquid level heights are inadequate to provide the required liquid residence times.

E. The vessel length 7 diameter ratio does not fall in the range of 2 =.

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

A$/$/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..=.:" e$cept for the vessel I6" vessel length and

elevations of 3I3S6" 3I3" >I3" *I3 and *I3S6.

2. Set the vessel diameter as an arbitrary value and the vessel length as # times this value. ;nter

arbitrary values for the various liquid level elevations (i.e. 3I3S6" 3I3" >I3" *I3 and *I3S6!.

(i! If the heavy liquid droplet fall time e$ceeds the light liquid residence time (warning number

2!" the light liquid residence time may be increased by:

Increasing vessel diameter as needed the most successful measure if the light liquid

residence time is significantly lower than the heavy liquid droplet fall time (i.e.

M2DG lower!.

Increasing the length of the vessel the most successful measure if the light liquid

residence time is only slightly lower than the heavy liquid droplet fall time (i.e.

N2DG lower!

(ii! If the specified liquid level heights are inadequate to provide any other required liquid

residence times (including that related to warning #!" the appropriate residence times may be

increased by employing either of the two above measures" or alternatively increasing the

height difference between the liquid levels where residence time is determined to be

insufficient.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 2" ' 5ev B ' 7-Feb-2000

#. If warning : occurs" the available cross-sectional area available to vapour flow may be increased

by an increase in vessel I6" or by a decrease in liquid level elevations.

=. ;$amine the vessel length 7 diameter ratio to ensure that it lies between 2 =.

(i! If the ratio is greater than =" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing the vessel length.

If this approach is ta0en" it must be ensured that none of the warnings listed in ..=.# occur

and that the length of the vessel does not become lower than 2DCC mm.

(ii! If the ratio is less than 2" on the other hand" the vessel length may be increased while

increases to the diameter of the vessel are made. In decreasing the diameter" it is important

to ensure that the ma$imum allowable velocity is not e$ceeded.

A$3 )orizontal (.,hase Separator7 With Boot7 No Weir$

A$3$# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

6ensities (0g7m

#

!

2iscosities (c-!

2. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable vapour velocity and specified vapour and

liquid residence times are not e$ceeded.

8oot diameter (mm! varied to ensure that all liquid residence times in the boot are

sufficient.

2essel length (T7T! (mm! ad9usted such that the minimum length is 2DCC mm and that the

length 7 diameter ratio is between 2 = for the final design. The vessel length must also be

ad9usted such that the required vapour and liquid residence times are not e$ceeded.

8oot height (mm! ad9usted such that the required liquid residence times in the boot are not

e$ceeded.

3iquid level heights (mm! in both the main hori/ontal section of the vessel (heights of 33S6"

333" >33" *33 and *3S6! and also in the boot section (heights of 3I3S6" 3I3" >I3" *I3

and *I3S6! are varied by spreadsheet user until no warnings regarding insufficient liquid

residence times are encountered.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 24 ' 5ev B ' 7-Feb-2000

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

:DCC 0g7ms

2

where half-open pipe inlet present

(

m

v

m

2

!

ma$

vapour outlet no//le #ADC 0g7ms

2

v

ma$

light liquid outlet no//le : m7s

v

ma$

heavy liquid outlet no//le : m7s

6roplet si/e (light liquid in gas! :DC m regardless of whether or not a demister

pad is installed

6roplet si/e (light liquid in heavy liquid! :CCC m

6roplet si/e (heavy liquid in light liquid! ECC m

3iquid +esidence Times See .ppendi$-8.

3I3S6 height above vessel bottom :DC mm (minimum!

*3S6 height above vessel bottom C.H 6

8oot diameter (enerally ta0en as :7# of the main vessel inner

diameter.

Thic0ness of 6emister -ad :CC mm (minimum!" but usually :DC mm.

&-value :. @ay be supplied by vendor and manually

inputted into spreadsheet.

2. If not supplied by vendor" may be obtained

using information from (-S. (SI! 2olume :.

A$3$' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable vapour velocity

.ctual ma$imum vapour velocity

3ight liquid droplet settling velocity in vapour F the settling law used in the calculation.

3ight liquid droplet settling velocity in heavy liquid F the settling law used in the calculation.

*eavy liquid droplet settling velocity in light liquid F the settling law used in the calculation.

3ight liquid droplet fall time in vapour (from top of vessel to >33!

*eavy liquid droplet fall time in light liquid (from >33 to >I3!

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 2) ' 5ev B ' 7-Feb-2000

2apour residence time (from top of vessel to >33!

3iquid residence times between specified liquid levels.

*eavy liquid velocity in boot section.

2. 2essel 6imensions

@inimum vessel diameter

@inimum inlet no//le I6

@inimum vapour outlet no//le I6

@inimum light liquid outlet no//le I6

@inimum heavy liquid outlet no//le I6

)learance between inlet feed no//le and bottom of demister pad (if fitted! shall be ta0en as

the greater of C.A6 or ADC mm.

)learance between top of demister pad (if fitted! and upper tangent line ta0en as the greater

of C.:6 or #CC mm.

A$3$( Warnings ,ro0ided

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The specified liquid level heights are inadequate to provide the required liquid residence times.

2. The calculated vapour velocity e$ceeds the ma$imum allowable vapour velocity calculated by the

&-factor method.

#. The calculated light liquid droplet fall time (in vapour from top of vessel to >33! e$ceeds the

vapour residence time (also from top of vessel to >33!.

=. The calculated heavy droplet fall time (in light liquid from >33 to >I3! e$ceeds the light liquid

residence time (between >33 and >I3!.

D. The water velocity drawn from the boot e$ceeds the light liquid settling velocity.

E. The vessel length 7 diameter ratio does not fall in the range of 2 =.

L

The minimum value for any no//le diameter is considered to be DC mm. (+;%!

L

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 27 ' 5ev B ' 7-Feb-2000

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

A$3$/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..D.:" e$cept for the vessel I6" vessel length and

elevations of 33S6" 333" etc..

2. Set the vessel diameter to an arbitrary value as a starting point" with the vessel length set initially

as # times this value.

#. ;nter arbitrary values for the various liquid level elevations (i.e. 33S6" 333" etc.!.

=. If warning : occurs and the liquid level elevations are inadequate in the 4main5 hori/ontal section

of the vessel" the liquid residence times may be increased by increasing the length of this

hori/ontal section. If the liquid residence times are insufficient in the boot" however" they may be

increased by increasing the boot diameter. In both cases" the solution may be solved also by

simply increasing the height difference between the liquid levels where residence time is

calculated to be insufficient" which may lead to increases in vessel diameter or boot length. It is

important however" that in underta0ing the latter measure suggested that the *3S6 remains no

higher than C.H times the vessel diameter.

D. If warning 2 occurs" the available cross-sectional area available to vapour flow may be increased

by an increase in vessel I6" or by a decrease in liquid level elevations.

E. If the liquid droplet fall time e$ceeds the vapour residence time (warning number #!" the vapour

residence time may be increased by:

Increasing vessel diameter as needed the most successful measure if the vapour

residence time is significantly lower than the liquid droplet fall time (i.e. M2DG

lower!.

Increasing the length of the vessel the most successful measure if the vapour

residence time is only slightly lower than the liquid droplet fall time (i.e. N2DG

lower!

A. If warning = occurs" the light liquid residence time may be increased by increasing the length of

the vessel. In both steps E and A" the residence times may also be increased by increasing the

height differences between the liquid levels where the residence time is calculated to be

insufficient.

H. If warning D occurs" the heavy liquid velocity drawn from the boot may be decreased by

increasing the si/e of the boot I6.

B. ;$amine the vessel length 7 diameter ratio to ensure that it lies between 2 =.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 28 ' 5ev B ' 7-Feb-2000

(v! If the ratio is greater than =" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing the vessel

length. If this approach is ta0en" it must be ensured that none of the warnings listed in

..E.# occur and that the length of the vessel does not become lower than 2DCC mm.

(vi! If the ratio is less than 2" on the other hand" the vessel length may be increased as a

remedy" while decreasing the vessel diameter as required. The vessel diameter may not

be decreased from the value selected in step 2. In step 2" the minimum vessel diameter

was selected" which cannot be decreased in order to increase the *76 ratio without the

ma$imum allowable vapour velocity being e$ceeded.

A$8 )orizontal (.,hase Separator With Weir7 No Boot

A$8$# %nputs Re"uired

The following lists outline the input data required by the spreadsheet. @any such inputs are highly

sensitive on the precise process requirements of the separator" and include:

:. -hysical properties of both phases -

@a$imum flowrates (0g7hr!

.ctual 6ensities (0g7m

#

!

2iscosities (c-!

2. Separator vessel dimensions

2essel diameter (mm! varied by the spreadsheet user until the vessel cross-sectional area is

sufficient to ensure that the ma$imum allowable vapour velocity and specified vapour and

liquid residence times are not e$ceeded.

'verall vessel length (T7T! (mm! ad9usted such that the minimum length is 2DCC mm and

that the length 7 diameter ratio is between 2 = for the final design. The vessel length must

also be ad9usted such that the required vapour and liquid residence times are not e$ceeded.

3iquid level heights (mm! heights of 33S6" 333" >33" *33" *3S6" 3I3S6" 3I3" >I3"

*I3 and *I3S6 are varied by spreadsheet user until no warnings regarding insufficient liquid

residence times are encountered.

In addition to the required inputs described above" there are also inputs whose values are more or less

standard for the vast ma9ority of vertical vapour-liquid designs" including:

5Standard6 -nputs Required Typical / Su$$ested 1alues

(

m

v

m

2

!

ma$

inlet mi$ture feed no//le :CCC 0g7ms

2

where no inlet device present

(+;%!

:DCC 0g7ms

2

where half-open pipe inlet present

(+;%!

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e 29 ' 5ev B ' 7-Feb-2000

(

m

v

m

2

!

ma$

vapour outlet no//le #ADC 0g7ms

2

(+;%!

v

ma$

light liquid outlet no//le : m7s (+;%!

v

ma$

heavy liquid outlet no//le : m7s (+;%!

6roplet si/e (light liquid in gas! :DC m regardless of whether or not a demister

pad is installed (+;%!

6roplet si/e (light liquid in heavy liquid! :CCC m (+;%!

6roplet si/e (heavy liquid in light liquid! ECC m (+;%!

3iquid +esidence Times See .ppendi$-8

3I3S6 height above vessel bottom :DC mm (minimum! (+;%!

,eir height above vessel bottom (enerally ta0en as the lesser value of C.H 6 or C.E

m. (+;%!

Thic0ness of 6emister -ad :CC mm (minimum!" but usually :DC mm. (+;%!

&-value :. @ay be supplied by vendor and manually

inputted into spreadsheet.

2. If not supplied by vendor" may be obtained

using information from (-S. (SI! 2olume :.

A$8$' 6inal Outputs ,ro0ided

'nce all required input values have been entered" the spreadsheet calculates values for the following:

:. %luid -roperties

%eed mi$ture density

@a$imum allowable vapour velocity

.ctual ma$imum vapour velocity

3ight liquid droplet settling velocity in vapour F the settling law used in the calculation.

3ight liquid droplet settling velocity in heavy liquid F the settling law used in the calculation.

*eavy liquid droplet settling velocity in light liquid F the settling law used in the calculation.

3ight liquid droplet fall time in vapour (from top of vessel to >33!

3ight liquid droplet fall time in heavy liquid (from vessel bottom to >I3!.

*eavy liquid droplet fall time in light liquid (from >33 to >I3!

2apour residence time (from top of vessel to >33!

3iquid residence times between specified liquid levels.

2. 2essel 6imensions

@inimum vessel diameter

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e *0 ' 5ev B ' 7-Feb-2000

@inimum inlet no//le I6

@inimum vapour outlet no//le I6

@inimum light liquid outlet no//le I6

@inimum heavy liquid outlet no//le I6

)learance between inlet feed no//le and bottom of demister pad (if fitted! shall be ta0en as

the greater of C.A6 or ADC mm.

)learance between top of demister pad (if fitted! and upper tangent line ta0en as the greater

of C.:6 or #CC mm.

A$8$( Warnings ,ro0ided

The spreadsheet issues various warnings to help ensure that the design of the separator is adequate for

its desired purpose. These warnings are issued if the following conditions result:

:. The specified liquid level heights are inadequate to provide the required liquid residence times.

2. The calculated vapour velocity e$ceeds the ma$imum allowable vapour velocity calculated by the

&-factor method.

#. The calculated light liquid droplet fall time (in vapour from top of vessel to >33! e$ceeds the

vapour residence time (also from top of vessel to >33!.

=. The calculated heavy droplet fall time (in light liquid from >33 to >I3! e$ceeds the light liquid

residence time (between >33 and >I3!.

D. The calculated light liquid droplet fall time (in heavy liquid from bottom of vessel to >I3!

e$ceeds the heavy liquid residence time (between vessel bottom and >I3!.

E. The vessel length 7 diameter ratio does not fall in the range of 2 =.

.n overall status bo$ that is viewable at the top of the spreadsheet at all times is included which

displays warning messages if any of the above conditions occur. ,hen this status bo$ displays an

4'&" >o ,arnings -resent5 message" all spreadsheet calculations have been completed without any

warnings.

L

The minimum value for any no//le diameter is considered to be DC mm.

L

L

L

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e *1 ' 5ev B ' 7-Feb-2000

A$8$/ ,rocedure -or Spreadsheet &se$

The warnings provided as outlined in the previous section represent one of the most important and

user-friendly tools possessed by the e$cel spreadsheet file to assist the user in sequentially entering all

data required for a successful design. . suggested procedure is as follows:

:. ;nter all the required input data listed in ..D.:" e$cept for the vessel I6" vessel length and

elevations of 33S6" 333" etc..

2. Set an arbitrary value for the vessel diameter and set the vessel length initially as # times this

value.

#. ;nter arbitrary values for the various liquid level elevations (i.e. 33S6" 333" etc.!.

=. If warning : occurs and the liquid level elevations are inadequate" the liquid residence times may

be increased by increasing the overall vessel length or by increasing the height difference between

the liquid levels where residence time is calculated to be insufficient. It is important however"

that in underta0ing the latter measure suggested that the weir height remains no higher than C.H

times the vessel diameter.

D. If warning 2 occurs" the available cross-sectional area available to vapour flow may be increased

by an increase in vessel I6 or a lowering in liquid level elevations.

E. If the liquid droplet fall time e$ceeds the vapour residence time (warning number #!" the vapour

residence time may be increased by:

Increasing vessel diameter as needed the most successful measure if the vapour

residence time is significantly lower than the liquid droplet fall time (i.e. M2DG

lower!.

Increasing the length of available setting section between the inlet feed no//le and

the weir the most successful measure if the vapour residence time is only slightly

lower than the liquid droplet fall time (i.e. N2DG lower!

A. If either of warnings = or D occur" the appropriate liquid residence time may be increased by

increasing the length of the vessel between the feed inlet no//le and the weir.

H. ;$amine the vessel length 7 diameter ratio to ensure that it lies between 2 =.

(i! If the ratio is greater than =" a more economical ratio can be achieved by gradually

increasing the vessel I6 from the value selected in step 2" while decreasing the vessel

length. If this approach is ta0en" it must be ensured that none of the warnings listed in

..E.# occur and that the length of the vessel does not become lower than 2DCC mm.

(ii! If the ratio is less than 2" on the other hand" the vessel length may be increased in

con9uction with a decrease in vessel diameter.

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e *2 ' 5ev B ' 7-Feb-2000

Appendi4 B 5 Recoended !i"uid Residence

Tie

Ser&ice +iquid Residence Time (min)

:! +eflu$ to tower D

2! -roduct to off-plot tan0age or other unit

feed drum (direct!

a! without pump 2

b! with pump D

#! -roduct to off-plot tan0age or other unit # to D

feed drum (via feed-bottom e$changer!

=! 6istillate 7 liquid feed to subsequent tower or furnace

a! drum diameter less than :.2 m 2C

b! drum diameter :.2 to 2 m :D

c! drum diameter more than 2 m :C

D! )ompressor interstage 0noc0out drums D

D! +efrigeration system

a! intermediate stage drums D

b! main accumulators :C

E! *- separator followed by 3- separator =

A! 'ther general services # to :C

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e ** ' 5ev B ' 7-Feb-2000

-var-...-a,,s-0onversion-tm,-s0rat0+34-2**1*0*))/do0 #a2e *" ' 5ev B ' 7-Feb-2000

You might also like

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Process Engineering Manual 005 IDocument81 pagesProcess Engineering Manual 005 Imuktaanand100% (19)

- Foster Wheeler Process Engineering Practices IndexDocument86 pagesFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Manual Drum Vessel Size LummusDocument66 pagesManual Drum Vessel Size Lummusdglightbue100% (6)

- Exxon - EXXON PDC VOL IDocument281 pagesExxon - EXXON PDC VOL IKhalid Iqbal97% (33)

- Blowdown CalculationDocument6 pagesBlowdown CalculationRexx Mexx100% (2)

- Hydraulics & Line SizingDocument20 pagesHydraulics & Line SizingM. Faisal Siddiqui100% (10)

- API-521 Flare KOD Design and Even More - Part 2.desbloqueadoDocument6 pagesAPI-521 Flare KOD Design and Even More - Part 2.desbloqueadoFernando Mendez100% (1)

- Total Process Engineering ManualDocument260 pagesTotal Process Engineering Manualmusabammadkhan86% (7)

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IImuktaanand100% (12)

- Separator SizingDocument11 pagesSeparator Sizingmusaveer50% (2)

- Rules of ThumbDocument105 pagesRules of ThumbEllen DawitriNo ratings yet

- Depressuring Study and Application On BP-A ProjectDocument35 pagesDepressuring Study and Application On BP-A ProjectTruong Minh Hoang100% (6)

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- Process Enginering Design ManualDocument308 pagesProcess Enginering Design Manual136241595% (20)

- Sulfur Plant Design ManualDocument367 pagesSulfur Plant Design ManualLuispajuelo73100% (8)

- Controlled and Non-Controlled Type DepressuringDocument12 pagesControlled and Non-Controlled Type Depressuringgrimdorlf100% (1)

- Tutorial Depressuring 5Document26 pagesTutorial Depressuring 5Zhang Zhaoyang100% (6)

- GasLiquid Separators-Design RulesDocument21 pagesGasLiquid Separators-Design Ruleswahyuriansyah100% (1)

- Flare SystemsDocument10 pagesFlare SystemsMahboob Ur-RahmanNo ratings yet

- Design Low-Temp Separator LPG Jubilee Oil FieldDocument38 pagesDesign Low-Temp Separator LPG Jubilee Oil FieldDela Quarme100% (1)

- Real Separator GuideDocument23 pagesReal Separator GuideMuhammad Athar100% (6)

- API 521 Flare Knockout Drum SizingDocument35 pagesAPI 521 Flare Knockout Drum Sizingnghiemta1892% (13)

- Design and Simulation of Continuous Distillation Columns PDFDocument33 pagesDesign and Simulation of Continuous Distillation Columns PDFnghiemta18No ratings yet

- Depressurisation - A Practical GuideDocument20 pagesDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Natural Gas Hydrates in Flow AssuranceFrom EverandNatural Gas Hydrates in Flow AssuranceCarolyn Ann KohRating: 5 out of 5 stars5/5 (1)

- Separator Design GuideDocument37 pagesSeparator Design GuideSanjay ParmarNo ratings yet

- Separator Design Guide PDFDocument36 pagesSeparator Design Guide PDFAdam RizkyNo ratings yet

- Separator Design GuideDocument3 pagesSeparator Design Guidelaleye_olumideNo ratings yet

- ВведениеDocument47 pagesВведениеЕлнур ИкимбаевNo ratings yet

- Separator DesignDocument8 pagesSeparator Designmohamed_sahnoun_enisNo ratings yet

- Principles of Separation: Production and Test SeparatorsDocument28 pagesPrinciples of Separation: Production and Test SeparatorsهانيزايدNo ratings yet

- Oil& Gas SeparationDocument9 pagesOil& Gas SeparationHomam MohammadNo ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument36 pagesBN-EG-UE109 Guide For Vessel SizingAjith KumarNo ratings yet

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantDocument12 pagesQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluNo ratings yet

- API Separator and Waste WaterDocument5 pagesAPI Separator and Waste Waterbctian2004No ratings yet

- Open Drain Separator SizingDocument23 pagesOpen Drain Separator SizingSuchart TarasapNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Standard ProductsWater Treatment 20-09-13Document179 pagesStandard ProductsWater Treatment 20-09-13american_guy10No ratings yet

- Oil/Water Separation Performance Quantification in Three-Phase SeparatorsDocument12 pagesOil/Water Separation Performance Quantification in Three-Phase SeparatorsRaghulal SethumadhavanNo ratings yet

- CH 09 Processdesignof ROsystemsDocument23 pagesCH 09 Processdesignof ROsystems2402 2003No ratings yet