Professional Documents

Culture Documents

AB Forging Eng

Uploaded by

tetirichie0 ratings0% found this document useful (0 votes)

39 views24 pagesdie forging materials

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdie forging materials

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views24 pagesAB Forging Eng

Uploaded by

tetirichiedie forging materials

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 24

UDDEHOLM STEEL FOR FORGING 1

UDDEHOLM TOOL STEEL

FOR FORGING APPLICATIONS

TOOLING APPLICATION HOT WORK

UDDEHOLM STEEL FOR FORGING 2

This information is based on our present state of knowledge and is intended to provide general

notes on our products and their uses. It should not therefore be construed as a warranty of

specific properties of the products described or a warranty for fitness for a particular purpose.

Classified according to EU Directive 1999/45/EC

For further information see our Material Safety Data Sheets.

Edition: 1, 08.2010

The latest revised edition of this brochure is the English version,

which is always published on our web site www.uddeholm.com

UDDEHOLM STEEL FOR FORGING 3

CONTENTS

Hot forging of metals 4

Warm forging 7

Progressive forging 8

Effect of forging parameters on die life 10

Die design and die life 11

Requirements for die material 14

Manufacture and maintenance of forging die 16

Surface treatment 17

Tool steel product programme

general description 19

chemical composition 20

quality comparison 20

Tool steel selection chart 21

Cover photo: Part to an universal joint, Arvika Smide AB.

Most of the photos coming from Arvika Smide AB, Sweden and

Fiskars Brands Finland Oy Ab. Some figures coming from IVF, Sweden.

Selecting a tool steel supplier is a key decision for all parties, including the tool maker, the tool

user and the end user. Thanks to superior material properties, Uddeholms customers get

reliable tools and components. Our products are always state-of-the-art. Consequently, we have

built a reputation as the most innovative tool steel producer in the world.

Uddeholm produce and deliver high quality Swedish tool steel to more than 100,000 customers

in over 100 countries. Some markets are served by ASSAB, our wholly-owned and exclusive

sales channel in Asia, Africa and South America. Together we secure our position as a world

leading supplier of tool steel.

Wherever you are in the manufacturing chain, trust Uddeholm to be your number one partner

and tool steel provider for optimal tooling and production economy.

Quite simply, it pays to go for a better steel.

UDDEHOLM STEEL FOR FORGING 4

Hot forging of metals

In hot forging a heated up billet is pressed

between a die set to a nearly finished product.

Large numbers of solid metal parts are produced

in aluminium alloys, copper alloys, steel or super-

alloys where irregular shapes need to be com-

bined with good mechanical properties. The main

methods of drop forging are hammer forging and

press forging.

Hammer forging

Hammer forging is characterized by a very short

contact time and very rapid rate of increase of

force with time (impact loading). The cumulative

contact time for the bottom die can be fairly long

if one includes the time between blows. However,

since a lubricant with blow-out effect is nor-

mally used with hammers, effective contact be-

tween the part and the die only occurs during the

actual forging blow.

These features imply that impact toughness and

ductility are important properties for die steel to

be used in hammer dies. This does not mean to

say that wear resistance is not important, particu-

larly in smaller dies, which in fact normally fail as

a result of wear. In hammer forging, there is a lot

to be said for using inserts of a more wear-

resistant die steel which are shrink fitted into a

tough holder material.

For larger, high-production hammer dies, which

may be resunk a number of times, it is important

that the die steel used has sufficient hardenability

that the later cavities are not sunk in softer

material with inferior wear resistance.

Press forging

In press forging, the contact time under pressure

is much longer, and the impact load is much

lower than in hammer forging. In general terms,

this means that the heat resistance and elevated

temperature wear resistance of the die steel are

relatively more important than the ability to

withstand impact loading. However, one must

optimize impact toughness and ductility in rela-

tion to wear resistance; this applies particularly

for large press dies which are not supported

from the sides. Since the surface temperature of

press dies will during service generally be higher

than for hammer dies, it is important that the die

UDDEHOLM STEEL FOR FORGING 5

GROSS CRACKING

Forging dies might fail as a result of some form

of gross cracking. This may occur during a single

cycle or, as is most common, over a number of

cycles; in the latter instance, the crack growth

proceeds via a high-stress fatigue mechanism.

Gross cracking is more frequent in hammer

blocks than in press tooling, because of the

greater degree of impact.

surface is not excessively chilled by lubrication.

Otherwise, premature heat checking or even

thermal shock cracking may result.

WEAR

If all other damage mechanisms are suppressed, a

forging die will ultimately wear out (parts out of

tolerance). Wear occurs when the work material

plus oxide scale glide at high velocity relative to

the cavity surface under the action of high

pressure. It is most pronounced at convex radii

and in the flash land. Wear is increased drastically

if the forging temperature is reduced (higher flow

stress for the work material). The explosion

Typical die failures

The deterioration of forging dies is usually

associated with several processes which may

operate simultaneously. However, one of these

normally dominates and is the ultimate cause of

failure. In general, four distinct damage mecha-

nisms can be distinguished:

wear

mechanical fatigue and gross cracking

plastic deformation

thermal fatigue cracking (heat checking)

Different damage mechanisms can dominate in

different parts of the cavity.

Thermal fatigue Wear Wear

which occurs via combustion of oil-based

lubricant in the confined space between forging

and die can also give rise to a type of erosive

wear.

Wear.

Thermal Cracking Wear Plastic

fatigue deformation

UDDEHOLM STEEL FOR FORGING 6

Gross cracking is a failure condition which can

almost always be rectified. Normally, cracking lies

in one or more of the following:

overloading, e.g. work material temperature

too low

die design, e.g. too sharp radii or too thin wall

thickness

inadequate preheating of the die

inadequate toughness of die steel (wrong

selection)

too high hardness of die material

poor quality heat treatment/surface treatment

inadequate die support/alignment

PLASTIC DEFORMATION

This occurs when the die is locally subjected to

stresses in excess of the yield strength of the die

steel. Plastic deformation is quite common at

small convex radii, or when long thin tooling

components e.g. punches, are subjected to high

bending stresses.

The following can be the cause of plastic

deformation in forging dies:

too low billet temperature (high flow stress of

work material)

inadequate hot strength of die steel

die temperature too high

die material too soft

THERMAL FATIGUE CRACKING

This results if the surface of the cavities is

subjected to excessive temperature changes

during the forging cycle. Such temperature

changes create thermal stresses and strains at

the die surface which eventually lead to cracking

via a low-cycle fatigue mechanism (heat checking).

Totally cracked die.

Heat checked die surface.

Thermal fatigue cracking is increased by the

following factors:

cavity surface at too high temperature

(excessive billet temperature and/or long

contact time)

excessive cooling of die surface between

forgings

inadequate preheating of die

wrong selection of die steel and/or poor heat

treatment

All these factors will increase the difference

between maximum and minimum temperature in

the die surface.

UDDEHOLM STEEL FOR FORGING 7

Warm forging

Warm forging is a precision forging operation

carried out at a temperature range between

550950C (10201740F). It is useful for forging

of details with intricate shapes, with desirable

grain flow, good surface finish and tighter dimen-

sional tolerances than if hot forged.

The weight of the forged piece is between

0.150 kg (0.22110 lbs) and the production rate

about 1040 pieces per minute. The contact time

is about 200 ms and the mechanical loads at

600C (1110F) are 3 to 5 times higher than in

hot forging. Automatic multi-station presses with

integrated cooling/lubricating systems are often

used.

UPSETTING

Tube

Rod

FORWARD EXTRUSION

Punch

Die

IRONING

LATERAL EXTRUSION

HEADING

OPEN DIE EXTRUSION

Reducing

BACKWARD EXTRUSION

Can

Typical processes in warm forging.

Die material properties

The properties profile required for tool steel in

forging dies depends to some extent on the type

of forging operation, on the work material and

on the size of the part, depth of cavity etc.

However, a number of general characteristics will

always be required in all forging operations. The

particular die damage mechanisms are given in

parentheses.

Sufficient hardness and ability to retain this at

elevated temperaturestemper resistance

(wear, plastic deformation, thermal fatigue

cracking).

Enhanced level of hot tensile strength and hot

hardness (wear, plastic deformation, thermal

fatigue cracking).

Good toughness and ductility at low and

elevated temperatures (gross cracking, thermal

shock cracking, thermal fatigue cracking). It is

important that the die steel exhibits adequate

toughness/ductility in all directions.

Adequate level of fatigue resistance (gross

cracking).

Sufficient hardenability (retention of wear

resistance etc. if the die is resunk).

Amenability to weld repair.

Good machinability, especially prehardened

die blocks.

Work

material

UDDEHOLM STEEL FOR FORGING 8

Progressive forging

In progressive forging a large number of sym-

metrical, precision-forged parts with forged

weights of up to about 5 kg (11 lbs) are pro-

duced. The fully automatic process involves

supplying hot rolled bars at one end of the line,

heating them inductively, cutting them to the

required size, shaping them in 34 stages and

discharging finished forgings at the other end of

the line.

Depending on the weight of the forgings,

production capacity is between 50 and 180 per

minute.

Typical failures

Tool parts used in the progressive forging, such as

die, stem, stem holder, punch and counter punch-

ejector are subjected to very high stresses.

As the production speed is very high, the die

parts need to be water-cooled to protect them

against overheating. Nevertheless, despite inten-

sive cooling, the tool surfaces can be strongly

heated, even by the brief contact, with the hot

metal being forged.

As a result of this alternate heating and cooling

the die parts are subjected to extremely high

thermal fatigue. The degree of the thermal fatigue

cracking constitutes a measure of the material

life.

An additional factor is the degree of hot wear

of the material, which depends on the surface

temperatures and the mechanical stresses on the

die.

Tool material properties

The required properties profile of the hot

forming die and die parts are:

high temperature strength and good temper

resistance to withstand hot wear and thermal

fatigue cracking

good thermal conductivity to withstand thermal

fatigue cracking

good hot ductility and toughness to resist

initiation and rapid spread of thermal fatigue

cracking

Typical failures

During the warm forging operation the tool parts

are exposed to rather high temperature, high

mechanical loads and intensive cooling.

As a result of this alternate heating and cooling

the tool parts are subjected to high thermal

fatigue.

An additional factor is the degree of hot wear

of the material, which depends on the surface

temperatures and the mechanical stresses on the

tool.

Tool material properties

The tool parts are subjected to both high

mechanical stresses and high thermal stresses.

For these reasons a tool steel has to be chosen

which has a good temper resistance, good wear

resistance, high hot yield strength, good thermal

conductivity and good thermal fatigue resistance.

A warm forging steel must exhibit a properties

profile which is in between the typical properties

profiles for hot work and cold work steel.

UDDEHOLM STEEL FOR FORGING 9

1

1

2

5

7

3

4

6

8

5

9

6

6a

6

6a

8

7a

5

8

9

11

10

1

2

3

4

5

6

6a

7

7a

8

9

10

11

Two-part cutting bush

Work metal

Stopper

Cutter

Blank

Stem/Punch

Hollow punch

Bolster

Counter punch-ejector

Die

Waste metal

Piercer

Product

FORGING IN A FULLY AUTOMATIC PROCESSS

UDDEHOLM STEEL FOR FORGING 10

Effect of forging

parameters on die life

Apart from the influence of the actual die mate-

rial and its heat treatment/surface treatment, a

number of parameters related to the forging

operation affect die life:

billet temperature

billet shape and surface condition

work material

cavity stress level and contact time

type of forging operation

type of lubricant

Billet temperature

Reduced billet temperature in forging is favour-

able from the viewpoint of mechanical properties

in the forged part itself. This is particularly impor-

tant if the components are not heat treated after

forging. However, the higher flow stress of the

work material, which is associated with a re-

duced forging temperature, results in both in-

creased wear and a higher risk for plastic defor-

mation. Further, since the forging loads increase,

the probability for gross cracking is enhanced.

TYPICAL HOT FORGING TEMPERATURES

STEEL 10501250C (19202100F)

CU-ALLOYS 650800C (12001470F)

AL-ALLOYS 350500C (660930F)

TI-ALLOYS 8001000C (14702010F)

Billet shape and surface condition

The greater the difference between the shape of

the billet and that of the final forging, the greater

is the degree of wear because the relative

movement between work material and die must

increase. Likewise, hard, adherent scale on the

billet surface will increase wear, especially if the

gliding distance is large.

Work material

The higher the flow stress of the work material,

the faster is die deterioration due to wear and/or

plastic deformation, at the same time as the risk

for gross cracking is increased. Hence, stainless

steel is more difficult to forge than carbon steel

at the same temperature.

Forgeability of different types of material.

Low Moderate High

High

Moderate

Low

Constructural

AlMg-alloys

Stainless

Ti-alloys

Ni- and

Co- alloys

FORGEABLILITY

IMPACT ENERGY OR PRESS POWER

UDDEHOLM STEEL FOR FORGING 11

Die design and die life

Assuming that the forging equipment is in good

condition (properly adjusted and without exces-

sive play in the ram guide system), then adher-

ence to the following die design principles will

reduce the risk for catastrophic die failure:

proper die support

dovetails, if used, should be properly dimen-

sioned, have sufficiently large radii and be

properly finished (grinding marks should be

tangential and not axial), see figure below.

sufficient wall thickness, and sufficient material

below the cavity and between individual

cavities

adequate radii and fillets in the cavity

proper dimensioning of flash land and gutter

proper design of parting plane and, if used, die

locks

correct use and design of setting plugs,

punches and knockout pins

sufficiently large cushion-face area in hammer

forging in relation both to die block thickness

and to the capacity of the hammer used

Improper die support, insufficient material thick-

ness in the die and too small radii are all very

common reasons for a die failing catastrophically

by cracking, and will be further enlarged upon.

Cavity stress level

and contact time

An increased stress level in the cavity, can be

found, for example, in high precision forging, and

has the following consequences:

increased stress in the tool with higher risk for

deformation or gross cracking

increased heat transfer from billet to die

(heat checking)

more pronounced wear

Prolonged contact, between billet and die during

forging, results in accelerated wear and a greater

risk for heat checking. For very long contact

times, the surface layer of the tool may become

so hot that it transforms to austenite. Cracking

problems can then be experienced if this layer

rehardens during the cooling part of the cycle.

Type of forging operation

Because of the much higher impact load, hammer

dies tend to fail by cracking to an extent which is

greater than in press forging where the loading

rate is lower. Thermal fatigue (heat checking) is

more common in powder forging and other

near-net-shape forging processes involving long

contact times.

Type of lubricant

Oil-based lubricants can give rise to excessive

wear/erosion due to the explosion-like combus-

tion of the oil between billet and cavity. On the

other hand, water base lubricants cool the die

surface to a greater extent which increases the

risk of thermal fatigue cracking.

Grinding of dovetail radii.

UDDEHOLM STEEL FOR FORGING 12

Die support

It is very important that the die is properly

supported underneath by a perfectly flat backing

surface with sufficient hardness. Concave depres-

sions in the support surface immediately under

the die cavity are particularly deleterious because

they exaggerate the tensile stresses at radii.

Proper backing is especially important in

hammer forging because there is usually no side

support in this case. When dies of greatly

different dimensions are used on the same press

or hammer, it is essential to remove any cavities

in the backing block or plate when switching

from a small to a large die.

For press forging, side support of the die is

desirable but this is not always possible. Shrink

fitting of inserts into a massive holder provides

the best security against cracking in press dies.

Fillet radii

The greatest tensile stresses in a forging die

occur at the radii between the sides and bottom

of the cavity. The smaller the radius, the higher

the stresses. In general, the forging should be

designed so that die fillet radii less than 2 mm

(0.08 inch) can be avoided. For deeper cavities,

>50 mm (>2 inch), this radius limit needs to be

increased to 5 mm (0.2 inch).

It is especially important during die making that

radii are ground and polished with grinding

marks, if any, in the tangential direction. In par-

ticular, EDM residues, which may contain cracks,

must be removed completely at radii (and prefer-

ably from the rest of the die as well). If this is not

possible, then the die should at least be retem-

pered at 25C (50F) below the previous tem-

pering temperature.

Die material and wall thickness

A number of more or less empirical methods or

dimensioning of forging dies are available, which

range in complexity from simple rule of thumb

to fairly advanced nomograms with a theoretical

base. However, there is no doubt that the

stresses imparted to the die by a given forging

machine increase profoundly as the die dimen-

sions are decreased.

Minimum height (Hmin) of hammer dies with a

maximum depth of cavity (h

max

).

h

max

H

min

Hmin,

inch mm

16 400

14 350

12 300

10 250

8 200

6 150

4 100

10 25 50 75 100 125 150 mm

0.4 1 2 3 4 5 6 inch

h

max

As a rule of thumb for solid die blocks in press

forging the thickness below the cavity should be

at least 1.5 x cavity depth.

As a minimum wall thickness in hammer

forging the recommendations are according to

the table below.

t

h

Depth of cavity (h)

mm inch

Distance

cavity to outer

edge of a die (t)

mm inch

6 0.2 12 0.5

10 0.4 20 0.8

16 0.6 32 1.3

25 1.0 40 1.6

40 1.6 56 2.2

63 2.5 80 3.2

100 3.9 110 4.3

125 4.9 130 5.1

160 6.3 160 6.3

Minimum wall thickness (t) recommended in hammer

dies between cavity and outer edge.

UDDEHOLM STEEL FOR FORGING 13

UDDEHOLM STEEL FOR FORGING 14

Requirements

for die material

Hardenability

In large press or hammer dies made from pre-

hardened die steel, it is important that the hard-

ness is uniform throughout the block. If the die

steel has too low hardenability, the block will

become softer away from its outer surface and

die life for deep cavities or after progressive

resinking will be impaired.

Toughness and ductility

The surface of the cavity can during use easily

develop small cracks or other blemishes which

may propagate in an unstable manner under the

action of the high forging stresses, especially at

radii etc. Notch toughness indicates the ability of

the die material to resist crack development

from such defects.

All products, in the Uddeholm tool steel pro-

gramme for the forging industry, are character-

ized by the highest levels of toughness and duc-

tility in all directions in the bar or block. Hence,

the forger can rest assured that the resistance to

gross cracking is the highest possible in dies

made from Uddeholm die steel.

Proper die preheating will considerably reduce

the risk for catastrophic failure via cracking.

Temper resistance

The better the steel retains its hardness as the

temperature or the time increases, the better its

temper resistance.

Temper resistance can be assessed from the

tempering curve for a hardened tool steel. In this,

the hardness at room temperature is plotted

against tempering temperature for given temper-

ing time. Another method of presenting temper

resistance data is to plot room temperature

hardness against time at a given tempering tem-

perature.

Hot strength and hot hardness

In contrast to temper resistance, which is defined

in terms of hardness at room temperature, hot

strength and hot hardness refer to properties at

high temperature. In general, improved temper

resistance is associated with increased hot

strength and hot hardness. It can be pointed

out that good hot hardness and hot strength are

important prerequisites for enhanced wear

resistance at elevated temperatures.

A high level of hot hardness and hot strength is

also important in order to achieve adequate re-

sistance to thermal fatigue cracking.

Fatigue resistance

Uddeholm tool steel for forging dies are pro-

duced to the highest possible quality standards,

especially with regard to freedom from non-

metallic inclusions. This imparts a degree of

fatigue resistance which is adequate for even the

most demanding applications where forging dies

are subjected to cyclic loading with high maxi-

mum loads.

UDDEHOLM STEEL FOR FORGING 15

QRO 90 SUPREME

DIEVAR

ORVAR SUPREME

VIDAR SUPERIOR

ORVAR SUPERIOR

HOT STRENGTH

100 200 300 400 500 600C

200 400 600 800 1000 1200F

TESTING TEMPERATURE

DIEVAR

ORVAR SUPREME

and ORVAR SUPERIOR

VIDAR SUPERIOR

NOTCH TOUGHNESS

100 200 300 400 500C

200 400 600 800 1000F

TESTING TEMPERATURE

QRO 90 SUPREME

UDDEHOLM STEEL FOR FORGING 16

Manufacture and

maintenance of forging die

Machinability, weldability and, when applicable,

response to heat treatment and surface treat-

ment are important parameters influencing the

relative ease of manufacture and maintenance of

forging dies.

Machinability

Machinability is a vital consideration when forging

dies are machined from prehardened die blocks.

The tool steel for forging applications from

Uddeholm are characterized by freedom from

oxidic inclusions and a uniform microstructure.

These features, in combination with the low

hardness in the annealed condition usually 170

200 HB, are to ensure excellent machinability.

Grinding of tool steel and Electrical Discharge

Machining (EDM) of tool steel.

Heat treatment

If forging dies are manufactured from die steel in

the annealed condition, then the tool must subse-

quently be heat treated in order that the steel

develops its optimum combination of hardness,

toughness, heat resistance and wear resistance.

These properties are controlled through

proper choice of austenitizing temperature, cool-

ing conditions during hardening and tempering

temperature and time. The Uddeholm brochure

Heat treatment of tool steel will be worth

consulting.

For forging dies, where toughness is of the

utmost importance, it is essential that the cooling

rate during hardening is sufficiently rapid that

undesirable microconstituents such as

Even if these grades are supplied prehardened,

the extreme cleanliness and microstructural

homogeneity ensure that machining can normally

be carried out without difficulty.

For all products, advanced process control

guarantees that the variations in machining

characteristics are minimal from batch to batch.

Uddeholms product brochures give detailed

information regarding machining of the products.

Other Uddeholm publications worth consulting

in the context of forging die manufacture are

pronounced grain-boundary carbide precipitation,

pearlite and coarse upper bainite can be avoided.

Furthermore, the austenitizing conditions should

be such that excessive grain growth can not

occur, since this is detrimental as regards to

toughness. Because forging dies are sometimes

EDMd extensively after heat treatment, there is

generally no problem to cope with the greater

dimensional change and distortion which results

when the rate of cooling during hardening is

rapid. Remember, however, that EDMd dies

10 15 25 35 65 600C/min.

50 60 75 95 150 1110F/min.

NOTCH TOUGHNESS

Notch toughness of Uddeholm Orvar Supreme, 4446 HRC, as a function of quench rate.

UDDEHOLM STEEL FOR FORGING 17

Bending strength of Uddeholm Orvar Supreme as a function of nitriding depth.

should always be given an additional temper at

about 25C (50F) below the previous tempering

temperature. Detailed heat treatment recom-

mendations for the various grades, in Uddeholms

tool steel programme for forging dies, are given

in the product brochure for each individual

product.

Weld repair of forging dies

Cracked or worn forging dies are often refur-

bished via welding. This is especially true in the

case of large dies where the tool steel itself rep-

resents a considerable portion of the total die

cost.

Further information can be obtained from the

Uddeholm publication Welding of tool steel.

Surface treatment

The cavity in forging dies is quite often surface

treated in order to enhance wear resistance.

Nitriding

Nitriding is a thermochemical treatment giving a

hard surface layer which is very resistant to wear.

In favourable cases, the process also renders a

compressive residual stress in the surface of the

die which helps counteract heat checking.

However, the nitrided layer is very brittle and

may crack or spall when subjected to mechanical

loading, especially impact loading. Nitriding is

usually carried out by one of four methods, nitro-

carburizing in salt-bath or gas, gas nitriding or

plasma (ion) nitriding.

Before nitriding, the tool should be hardened

and double tempered, the latter at a temperature

at least 2550C (5090F) above the nitriding

temperature.

The surface hardness attained, and the thick-

ness of the nitrided layer, depend on the nitriding

method, nitriding time and the character of the

steel being treated. Typical data can be found in

the Uddeholm product brochures for the differ-

ent tool steel.

Nitriding to layer thicknesses >0.3 mm

(>0.012 inch) is not to be recommended for

forging dies. The reason is that the nitrided layer

is brittle and easily cracks during service. The

underlying steel can not resist the propagation of

such surface cracks if the layer thickness is too

great and the entire die may fail catastrophically.

0.3 mm (0.012 inch) maximum nitride layer thick-

ness is a general recommendation; this maximum

value should be decreased if the impression has

very sharp radii or if the die steel is used at high

hardness.

The formation of the so-called white layer

should also be avoided because of brittleness.

BENDING STRENGTH

0.05 0.15 0.30 0.45 mm

0.0016 0.006 0.012 0.018 inch

NITRIDING DEPTH

200C (390F)

20C (70F)

UDDEHOLM STEEL FOR FORGING 18

UDDEHOLM STEEL FOR FORGING 19

UDDEHOLM

TOOL STEEL

DIEVAR

UNIMAX

ORVAR 2 MICRODIZED

ORVAR SUPREME/

ORVAR SUPERIOR

VIDAR SUPERIOR

QRO 90 SUPREME

HOTVAR

ALVAR 14

VANADIS 23

VANADIS 30

A premium Cr-Mo-V-alloyed hot work die steel with good high temperature

strength and excellent hardenability, toughness and ductility. It meets the

requirements of NADCA #207-2008.

A premium Cr-Mo-V alloyed steel with a good toughness and ductility up to

a hardness of 58 HRC.

Cr-Mo-V-alloyed hot work die steel (H13) with good high temperature

strength and hot wear resistance.

Premium Cr-Mo-V-alloyed hot work die steel (H13) with good resistance to

thermal fatigue. The steel are produced by a special melting and refining

technique. They meet the requirements of NADCA #2072008.

A premium Cr-Mo-V alloyed hot work die steel (H11 modified) with good

resistance to cracking. It meets the requirements of NADCA #2072008.

A premium hot work die steel with high hot yield strength and good temper

resistance. It also has good thermal conductivity.

A premium hot work die steel with very good high temperature properties.

Can be hardened and tempered to 58 HRC, giving an outstanding hot wear

resistance. Recommended for applications where hot wear and/or plastic

deformation are the dominating failure mechanisms.

Cr-Ni-Mo-alloyed hot work steel. Normally delivered in prehardened

condition for solid die blocks.

PM-produced high speed steel. Recommended for forging applications where

very good wear resistance is needed.

Tool steel product programme for forging applications

GENERAL DESCRIPTION

UDDEHOLM STEEL FOR FORGING 20

SUPPLIED

AISI ANALYSIS % HARDNESS

(W.-Nr.) C Si Mn Cr Mo V Others Brinell

DIEVAR 0.35 0.2 0.5 5.0 2.3 0.6 ~160

UNIMAX 0.50 0.2 0.5 5.0 2.3 0.5 ~185

ORVAR 2

MICRODIZED H13 0.39 1.0 0.4 5.3 1.3 0.9 ~180

(1.2344)

ORVAR SUPREME H13 0.39 1.0 0.4 5.2 1.4 0.9 ~180

(1.2344)

ORVAR SUPERIOR H13 0.39 1.0 0.4 5.2 1.4 0.9 ~180

(1.2344)

VIDAR SUPERIOR H11 modified 0.36 0.3 0.3 5.0 1.3 0.5 ~180

(1.2340)

QRO 90 SUPREME 0.38 0.3 0.8 2.6 2.3 0.9 Micro-

alloyed ~180

HOTVAR 0.55 1.0 0.8 2.6 2.3 0.9 ~210

ALVAR 14 (1.2714) 0.55 0.3 0.7 1.1 0.5 0.1 Ni 1.7 !250 or

prehardened

CHEMICAL COMPOSITION

UDDEHOLM

TOOL STEEL

QUALITATIVE COMPARISON OF RESISTANCE OF BASIC PROPERTIES

The longer the bar, the better.

UDDEHOLM

TOOL STEEL

DIEVAR

UNIMAX

ORVAR 2 M

ORVAR SUPREME

ORVAR SUPERIOR

VIDAR SUPERIOR

QRO 90 SUPREME

HOTVAR

ALVAR 14

PLASTIC PREMATURE HEAT

HOT WEAR DEFORMATION CRACKING CHECKING

UDDEHOLM STEEL FOR FORGING 21

Tool steel selection chart

GENERAL RECOMMENDATIONS

FORGING UDDEHOLM HARDNESS CAVITY

APPLICATION STEEL GRADE RANGE DEPTH

HAMMER

FORGING Solid die blocks ALVAR 14 Prehardened 400440 HB max 20 mm

(0.8 inch)

360400 HB max 50 mm

(2 inch)

320360 HB max 150 mm

(6 inch)

!320 very deep

Inserts VIDAR SUPERIOR

DIEVAR

ORVAR SUPREME

ORVAR SUPERIOR 3850 HRC

PRESS FORGING Dies DIEVAR

VIDAR SUPERIOR

ORVAR SUPREME

ORVAR SUPERIOR

QRO 90 SUPREME

HOTVAR

UNIMAX 3857 HRC

WARM FORGING Tools HOTVAR

UNIMAX

DIEVAR 5058 HRC

*

PROGRESSIVE

FORGING Tools QRO 90 SUPREME

HOTVAR

UNIMAX

DIEVAR 4854 HRC

*

HOT STAMPING Dies/Inserts QRO 90 SUPREME

HOTVAR

DIEVAR

UNIMAX 4656 HRC

UPSET FORGING Tools UNIMAX

HOTVAR

DIEVAR 4656 HRC

* Uddeholm PM grades can be used in some tool parts. Higher hardnesses can be used.

UDDEHOLM STEEL FOR FORGING 22

www.assab.com www.uddeholm.com www.uddeholm.com

Network of excellence

UDDEHOLM is present on every continent. This ensures you

high-quality Swedish tool steel and local support wherever you

are. ASSAB is our wholly-owned subsidiary and exclusive sales

channel, representing Uddeholm in various parts of the world.

Together we secure our position as the worlds leading supplier

of tooling materials.

UDDEHOLM STEEL FOR FORGING 24

U

D

D

E

H

O

L

M

1

0

0

8

0

1

.1

0

0

0

/

T

R

Y

C

K

E

R

I

K

N

A

P

P

E

N

,

K

A

R

L

S

T

A

D

2

0

1

0

0

4

2

9

6

UDDEHOLM is the worlds leading supplier of tooling materials. This

is a position we have reached by improving our customers everyday

business. Long tradition combined with research and product develop-

ment equips Uddeholm to solve any tooling problem that may arise.

It is a challenging process, but the goal is clear to be your number one

partner and tool steel provider.

Our presence on every continent guarantees you the same high quality

wherever you are. ASSAB is our wholly-owned subsidiary and exclusive

sales channel, representing Uddeholm in various parts of the world.

Together we secure our position as the worlds leading supplier of

tooling materials. We act worldwide, so there is always an Uddeholm

or ASSAB representative close at hand to give local advice and support.

For us it is all a matter of trustin long-term partnerships as well as in

developing new products. Trust is something you earn, every day.

For more information, please visit www.uddeholm.com, www.assab.com

or your local website.

ASSAB

You might also like

- Forging Applications: Uddeholm Tool Steels ForDocument24 pagesForging Applications: Uddeholm Tool Steels ForMin HanNo ratings yet

- Forging ApplicationsDocument24 pagesForging ApplicationsdstifterNo ratings yet

- Sandvik Part - 1 PDFDocument38 pagesSandvik Part - 1 PDFEliel AbadNo ratings yet

- Corrosion Resistant Steels: Stainless Steel AlloysDocument11 pagesCorrosion Resistant Steels: Stainless Steel AlloysPraveen SamarthiNo ratings yet

- InPlant Training at Bharat Forge Limited, Pune.: by Pritam Shahu PawarDocument34 pagesInPlant Training at Bharat Forge Limited, Pune.: by Pritam Shahu PawarpritamspawarNo ratings yet

- Forging PDFDocument16 pagesForging PDFloveguru2512No ratings yet

- Forging FundamentalsDocument23 pagesForging FundamentalsJoNo ratings yet

- Residual Stress in SteelDocument14 pagesResidual Stress in SteelAhmed BdairNo ratings yet

- Pengembangan Energy Consumption To Forging and CastingDocument20 pagesPengembangan Energy Consumption To Forging and CastingRefky FNo ratings yet

- Extrusion ToolingDocument17 pagesExtrusion ToolingSantosh Kumar100% (1)

- Tool WearDocument8 pagesTool WearSai KrishnaNo ratings yet

- Experimental Investigation of Quenching Temperature Influence On The Mechanical Properties of H13 SteelDocument8 pagesExperimental Investigation of Quenching Temperature Influence On The Mechanical Properties of H13 SteelTJPRC PublicationsNo ratings yet

- Mould MaterialsDocument22 pagesMould MaterialsArun PrasadNo ratings yet

- ForgingDocument12 pagesForgingDheeraj KashyapNo ratings yet

- Friction Stir Welding: Principle of OperationDocument12 pagesFriction Stir Welding: Principle of OperationvarmaprasadNo ratings yet

- Spin Casting: Nickunj Eximp Entp P LTDDocument7 pagesSpin Casting: Nickunj Eximp Entp P LTDRoshan NairNo ratings yet

- Elastic Limit Fatigue and CreepDocument11 pagesElastic Limit Fatigue and CreepmdirsanNo ratings yet

- Shahreza Agung AlfatihDocument4 pagesShahreza Agung AlfatihShahreza agungNo ratings yet

- Materials For Forming ToolsDocument40 pagesMaterials For Forming Toolssav33No ratings yet

- Solid State WeldingDocument14 pagesSolid State WeldingRaju_pancal100% (1)

- DoITPoMS - TLP Library Introduction To Deformation ProcessesDocument12 pagesDoITPoMS - TLP Library Introduction To Deformation ProcessesAbdulrahman AlnagarNo ratings yet

- PB Uddeholm Sleipner EnglishDocument12 pagesPB Uddeholm Sleipner EnglishAlfya ChinikamwalaNo ratings yet

- Heat TreatmentDocument20 pagesHeat Treatmentعزت عبد المنعمNo ratings yet

- Fundamentals of Metal FormingDocument37 pagesFundamentals of Metal FormingDeepak LambaNo ratings yet

- Metal Casting Dies: Thoguluva Raghavan VijayaramDocument4 pagesMetal Casting Dies: Thoguluva Raghavan VijayaramcombinationcoffeeNo ratings yet

- WOWLibrary Preheating of Materials ConsumablesDocument4 pagesWOWLibrary Preheating of Materials ConsumableshreerNo ratings yet

- Balancing Wear, StrengthDocument4 pagesBalancing Wear, StrengthStephen MontelepreNo ratings yet

- Share Elements of TechnologyDocument22 pagesShare Elements of TechnologyPriti DixitNo ratings yet

- Selection of GasketsDocument53 pagesSelection of GasketsImtiaz Ali100% (2)

- Extrusion Tooling: Uddeholm Tool Steels ForDocument20 pagesExtrusion Tooling: Uddeholm Tool Steels ForRizqi Aulia RamadhaniNo ratings yet

- College of Education Akwanga, Nasarawa StateDocument14 pagesCollege of Education Akwanga, Nasarawa StatePilgrim KaterNo ratings yet

- Welding Technology - Pre and Post Weld Heat TreatDocument19 pagesWelding Technology - Pre and Post Weld Heat TreatNowsherwan MazariNo ratings yet

- Extrusion: Extrusion Is A Process Used To CreateDocument62 pagesExtrusion: Extrusion Is A Process Used To CreateSwapnesh PatelNo ratings yet

- Oğuzhan MURAT - Friction Stir WeldingDocument10 pagesOğuzhan MURAT - Friction Stir WeldingOğuzhan MuratNo ratings yet

- Forging NotesDocument71 pagesForging Notesmaddy_scribd100% (1)

- Unit III - Bulk Deformation ProcessesDocument48 pagesUnit III - Bulk Deformation ProcessesRavitej SuraparajuNo ratings yet

- Forging AluminiumDocument3 pagesForging Aluminiumnadeem_mechNo ratings yet

- Alumec PDFDocument7 pagesAlumec PDFetamil87No ratings yet

- Study of Forging Process Equipemnts-Practical-3Document12 pagesStudy of Forging Process Equipemnts-Practical-3prashantNo ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument19 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- Advantages and Disadvantages of Cold WorkingDocument7 pagesAdvantages and Disadvantages of Cold WorkingFadi Innocent100% (4)

- Weldability of SteelsDocument5 pagesWeldability of SteelsKhalid El Masry100% (1)

- Surface Cladding and Hardfacing MethodsDocument6 pagesSurface Cladding and Hardfacing MethodsEduardo GonzálezNo ratings yet

- Experiment 6Document3 pagesExperiment 6Subhasis BiswalNo ratings yet

- Metal Forging: EDPT 604 Metal Forming Processes and MachinesDocument19 pagesMetal Forging: EDPT 604 Metal Forming Processes and MachinesramyNo ratings yet

- Rice Cooker Lid (Forging Process)Document12 pagesRice Cooker Lid (Forging Process)AzfarFaizNo ratings yet

- FSW of Aluminium AlloysDocument45 pagesFSW of Aluminium AlloysAlexandre Lourenção CaselattoNo ratings yet

- Presentation Explosive Welding (Ew)Document12 pagesPresentation Explosive Welding (Ew)dnatarajanNo ratings yet

- Uddeholm Heat Treatment of Tool Steel 06.2012 E8Document20 pagesUddeholm Heat Treatment of Tool Steel 06.2012 E8tecnico0104No ratings yet

- Minimum Design Metal Temperature PresentationDocument21 pagesMinimum Design Metal Temperature PresentationAleck Vieyra100% (1)

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- OSMI Orientation To Valves Part 1 Forging Vs Castings Ste1Document30 pagesOSMI Orientation To Valves Part 1 Forging Vs Castings Ste1MeoNo ratings yet

- Heat TreatmentDocument2 pagesHeat TreatmentUsman MuhammadNo ratings yet

- Plasticity and Deformation Process: ExtrusionDocument25 pagesPlasticity and Deformation Process: ExtrusionHanaa ElnegmeNo ratings yet

- Project Report: Metal FormingDocument14 pagesProject Report: Metal FormingohcomeonNo ratings yet

- Forging: Training ObjectiveDocument4 pagesForging: Training ObjectiveRajib MandalNo ratings yet

- Welding Domex SteelsDocument16 pagesWelding Domex Steelspozolab100% (1)

- Wear Rate LoescheDocument8 pagesWear Rate LoescheEdson Ricardo Lima100% (2)

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Symbols Lect. No. Tim E: K E E HDocument15 pagesSymbols Lect. No. Tim E: K E E HYuni_Arifwati_5495No ratings yet

- Laura - Suggs@mail - Utexas.edu: Syllabus: BME 382J.4/ CHE 384 Advanced Biomaterials, Fall 2012Document2 pagesLaura - Suggs@mail - Utexas.edu: Syllabus: BME 382J.4/ CHE 384 Advanced Biomaterials, Fall 2012tetirichieNo ratings yet

- 11 Christmals Original 12 3 1Document13 pages11 Christmals Original 12 3 1tetirichieNo ratings yet

- L Crous 684391 PHD FinalDocument257 pagesL Crous 684391 PHD FinaltetirichieNo ratings yet

- Mohr's Circle: Academic Resource CenterDocument23 pagesMohr's Circle: Academic Resource CentersyedamiriqbalNo ratings yet

- 2018 Anec Conference ProgrammeDocument48 pages2018 Anec Conference ProgrammetetirichieNo ratings yet

- Antimony On The Mechanical: OF Proper-OF SN PBDocument12 pagesAntimony On The Mechanical: OF Proper-OF SN PBtetirichieNo ratings yet

- Beng Metallurgical Engineering (12130005) : University of Pretoria Yearbook 2017Document26 pagesBeng Metallurgical Engineering (12130005) : University of Pretoria Yearbook 2017tetirichieNo ratings yet

- Homogeneous vs. Heterogeneous Nucleation Modes of Solidification at Strong Driving Force ConditionsDocument9 pagesHomogeneous vs. Heterogeneous Nucleation Modes of Solidification at Strong Driving Force ConditionstetirichieNo ratings yet

- PTE Academic Tutorial PDFDocument38 pagesPTE Academic Tutorial PDFamitalwarNo ratings yet

- Factors Affecting Utilization of University Health Services in A Tertiary Institution in South-West NigeriaDocument4 pagesFactors Affecting Utilization of University Health Services in A Tertiary Institution in South-West NigeriatetirichieNo ratings yet

- Handouts ConductingEffectivePDRMeetings UpdatedOct08Document17 pagesHandouts ConductingEffectivePDRMeetings UpdatedOct08tetirichieNo ratings yet

- 471 Lab 3Document4 pages471 Lab 3godfree joyNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Performance MeasurementsDocument23 pagesPerformance MeasurementstetirichieNo ratings yet

- Iso 2768-1: 1989Document7 pagesIso 2768-1: 1989jferreiraNo ratings yet

- Iso 2768-1Document1 pageIso 2768-1Roberto Mota100% (1)

- Metal Powder Report: Fifty Years ofDocument2 pagesMetal Powder Report: Fifty Years oftetirichieNo ratings yet

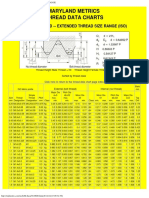

- Thread TablesDocument22 pagesThread TablesMuthukumar VeerappanNo ratings yet

- Tolerancia de Rosca Metrica 6G PDFDocument20 pagesTolerancia de Rosca Metrica 6G PDFRodrigo Tikim0% (3)

- Performance Measurement ProcessDocument32 pagesPerformance Measurement ProcesspawtarlayNo ratings yet

- 464 Requisite Skills AbilitiesDocument7 pages464 Requisite Skills AbilitiestetirichieNo ratings yet

- CPD Policy ECSADocument11 pagesCPD Policy ECSAtetirichieNo ratings yet

- ErrorDocument1 pageErrortetirichieNo ratings yet

- Hydrogen in LaddleDocument2 pagesHydrogen in LaddletetirichieNo ratings yet

- Bititci Et 2007 PMS A Development Quide - TQM MagazineDocument8 pagesBititci Et 2007 PMS A Development Quide - TQM MagazinetetirichieNo ratings yet

- CPD Policy ECSADocument11 pagesCPD Policy ECSAtetirichieNo ratings yet

- Materials DIN Sim Sinterformteile Tabelle E2Document1 pageMaterials DIN Sim Sinterformteile Tabelle E2tetirichieNo ratings yet

- En24 Alloy SteelDocument1 pageEn24 Alloy SteelpraghavannairNo ratings yet

- 464 Requisite Skills AbilitiesDocument7 pages464 Requisite Skills AbilitiestetirichieNo ratings yet

- Network Protocol TutorialDocument43 pagesNetwork Protocol TutorialGiovanni RadiciNo ratings yet

- Design CriteriaDocument6 pagesDesign CriteriaAllyssa Jane ErcillaNo ratings yet

- Honpe CatalogueDocument23 pagesHonpe CatalogueGrupo XDSNo ratings yet

- Nelson Stud CatalogDocument110 pagesNelson Stud CatalogAustin SollockNo ratings yet

- DSV SVDocument1 pageDSV SVPUNITHA KUMARNo ratings yet

- PMAC720Document3 pagesPMAC720felipeNo ratings yet

- Wind Load Analysis For Open StructureDocument3 pagesWind Load Analysis For Open Structurehitesh gandhiNo ratings yet

- Marking and Ordering Code System (Capacitors)Document6 pagesMarking and Ordering Code System (Capacitors)José TurinNo ratings yet

- PICP Manual 3rd Edition PDFDocument62 pagesPICP Manual 3rd Edition PDFanmolNo ratings yet

- WPH02 01 Que 20160120Document24 pagesWPH02 01 Que 20160120Omar HashemNo ratings yet

- Rockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareDocument23 pagesRockwell Automation TechED 2018 - SY10 - Lab Manual - Integrating CENTERLINE® Motor Control Centers With Studio 5000® and IntelliCENTER® SoftwareAlex RivasNo ratings yet

- Under Balanced OperationsDocument104 pagesUnder Balanced OperationsJavier Ignacio Meriles100% (1)

- Atv71 Controller Inside en v3Document25 pagesAtv71 Controller Inside en v3Juan Rodriguez ArevaloNo ratings yet

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- 5 Gaikindo Production Data Jandec2018 Rev HondaDocument3 pages5 Gaikindo Production Data Jandec2018 Rev HondaWira WijayaNo ratings yet

- Ce 506 Prestressed Concrete Design: M R M M MDocument2 pagesCe 506 Prestressed Concrete Design: M R M M Mbadr amNo ratings yet

- 4.0L EngineDocument347 pages4.0L EngineCapssa Oscar100% (2)

- Major Cheat Sheet Chemical EngineeringDocument6 pagesMajor Cheat Sheet Chemical EngineeringtolomontNo ratings yet

- Wire Line Operation and EquipmentDocument122 pagesWire Line Operation and Equipmentmissaoui100% (3)

- 1964 US Army Vietnam War Military Police Traffic Control 203pDocument202 pages1964 US Army Vietnam War Military Police Traffic Control 203pwwwsurvivalebookscom100% (1)

- Explicit Dynamics Chapter 6 Explicit MeshingDocument50 pagesExplicit Dynamics Chapter 6 Explicit MeshingAnonymous 0tqzNTWyy100% (4)

- Transmission - Approved List 26-09-2017Document554 pagesTransmission - Approved List 26-09-2017bkhNo ratings yet

- Isolation Selector GuideDocument12 pagesIsolation Selector GuidesandeepbhallaNo ratings yet

- Cswip QuestionDocument3 pagesCswip Questionfasith9534No ratings yet

- V 112Document4 pagesV 112simon_someone217No ratings yet

- Z4 Multi-Function Button Retrofit KitDocument12 pagesZ4 Multi-Function Button Retrofit KitgioioioiNo ratings yet

- 03 Vetotouch Europa - Group 170821Document2 pages03 Vetotouch Europa - Group 170821HalaNo ratings yet

- Motor TestingDocument26 pagesMotor TestingGas Gas DucatiNo ratings yet

- Design CalculationDocument13 pagesDesign CalculationSunil KumarNo ratings yet

- Kiln Performance - Efficiency FormulasDocument12 pagesKiln Performance - Efficiency FormulasMohamed ZayedNo ratings yet