Professional Documents

Culture Documents

Maintenance of Deep Manhole

Uploaded by

Srinivasan DeviCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance of Deep Manhole

Uploaded by

Srinivasan DeviCopyright:

Available Formats

Recently installed complex sewer system access chambers (or parts thereof) were designed as reinforced concrete

structures in accordance with AS3600-2009 (Concrete Structures) and in some cases as water retaining structures in

accordance with AS3735-2001 (Concrete Structures Retaining Liquids). Design to these Australian Standards requires a

significant amount of reinforcement at significant cost.

Sinclair Knight Merz (SKM) were engaged by Yarra Valley Water to review current industry best practice and prepare

guidelines for where reinforcement is required within sewer access chambers. A copy of SKMs guidelines is attached in

Appendix A.

SKMs investigation into industry best practice highlighted the following key points

Sewer manholes across Australia have been constructed from unreinforced concrete in accordance with accepted

industry practice extending back over many decades

Yarra Valley Water's sewerage system access chambers are primarily unreinforced, some as large as 3.6 metres

in diameter and 30 metres deep

Historically, our design guidelines have been based on the Colombo Plan Lectures (MMBW, 1977) which

recommended the following for manholes on main sewers

"as far as practicable, manhole shafts are designed to avoid the use of reinforcement"

This historic design approach adopted within the Colombo Plan Lectures has served Yarra Valley Waters system

very well over many years

more broadly, considerable diversity exists in sewerage infrastructure across Australian cities

The attached SKM guidelines represent a risk-based approach to facilitate an understanding of when access chamber

reinforcement is required. The guidelines focus on the shaft structure of circular manholes where 'shaft' refers to the

cylindrical part of a manhole (below the 'top' or cone and above the 'table'). The SKM guidelines address the following

items -

potential elements of risk associated with access chamber design which should be considered when assessing

the need for reinforcement

a summary view of design criteria required for -

Deep Sewer Access Chamber Reinforcement Guidelines

Recent design and installation of complex Yarra Valley Water access chambers (manholes) has highlighted

some deficiencies in our adopted standards and understanding regarding where reinforcement may be required.

In order to address this issue, Yarra Valley Water has engaged Sinclair Knight Merz to prepare guidelines for

where reinforcement is required within sewer access chambers.

Issue date : September 2010

general design

design of un-reinforced concrete

design of reinforced concrete in accordance with AS3600-2009

design of reinforced concrete in accordance with AS3735-2001

a set of conclusions that establish some context of where access chamber reinforcement may be required

In summary

Many sewer shafts exist and perform adequately in Melbourne, without any reinforcement in extensive areas of

the cylindrical shell and the use of plain, unreinforced concrete in shaft walls has been accepted practice for many

decades

In thick unreinforced concrete sections, if temperatures and shrinkage are not controlled, there is some risk of

wider cracks and greater groundwater inflow (when compared to reinforced concrete in which the reinforcement

would control the crack widths). However the absence of reinforcement has other benefits such as improved

access for concrete placement

Plain concrete has lower risk of structural deterioration over the long-term and durability advantages because of

the absence of steel reinforcement. In terms of cost, the savings gained by adopting plain concrete need to be off-

set against additional cost items such as grouting.

Reinforced concrete sections may be required to sustain unbalanced loading, significant traffic/live loads

Based on SKMs Guidelines and subsequent acceptance by Yarra Valley Water, the following design principles shall be

adopted for all sewer access chambers -

SKMs Sewer Manhole Reinforcement Guidelines, dated 1 March 2010, be adopted as a key reference for

sewer access chamber design

design and installation of unreinforced access chambers is preferred

the use of reinforcement in manholes shall be avoidable wherever practical

use of reinforcement within manholes shall only be considered where either, infiltration, unbalanced loads, traffic

loads, safety or risk issues cannot be addressed more effectively using unreinforced concrete

where there is potential for concrete temperature and shrinkage to occur, appropriate control measures need to

be defined to avoid concrete cracks;

where perimeter shrinkage is possible, specify appropriate grouting for unreinforced manholes to ensure contact

between the concrete and the surrounding ground

For more information

Contact ........................................................ Kevin Dawson

Telephone ......................................................... 9872 1474

Email ..................................... Kevin.Dawson@yvw.com.au

APPENDIX A Report by Sinclair Knight Merz Sewer Manhole Reinforcement Guidelines

8ewer Hanho|e Re|nforcement

Cu|de||nes

VCV123, 2ZJuNE 200

Rev C

1 Varcr 2010

Tre 3KV |ogo lrade rar| |s a reg|slered lrade rar| ol 3|rc|a|r Kr|grl Verz Ply Lld.

8ewer Hanho|e Re|nforcement

Cu|de||nes

Rev C

1 Varcr 2010

3|rc|a|r Kr|grl Verz

A8N 3Z 001 021 095

590 0rrorg Road, Arrada|e 3113

P0 8ox 2500

Va|verr vlC 3111 Auslra||a

Te|: 1 3 9218 3100

Fax: 1 3 9218 331

weo: WWW.s|rcorsu|l|rg.cor

COPYRGHT: The concepts and information contained in this document are the property of Sinclair

Knight Merz Pty Ltd. Use or copying of this document in whole or in part without the written

permission of Sinclair Knight Merz constitutes an infringement of copyright.

LMTATON: This report has been prepared on behalf of and for the exclusive use of Sinclair

Knight Merz Pty Ltd's Client, and is subject to and issued in connection with the provisions of the

agreement between Sinclair Knight Merz and its Client. Sinclair Knight Merz accepts no liability or

responsibility whatsoever for or in respect of any use of or reliance upon this report by any third

party.

8|N6LA|R KN|ChT HERZ

V:\3u3TAlNA8LE 0EvEL0PVENT\Assel Creal|or 0|v|s|or\0e||very 3erv|ces\5 Projecls\Vl Re|rlorcererl

0u|de||res\Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E |

Contents

1. Summary 1

1.1. Aims 1

1.2. Background 1

1.3. Risks 1

1.4. Recommendations 3

2. Introduction 5

2.1. Scope 5

2.2. Reference Documentation 5

2.3. Abbreviations 6

2.4. Definitions 6

3. Risk Considerations for ManhoIe Design 7

4. Risks Expressed in Standards 8

5. Risk Assessment 12

5.1. ManhoIe depth 12

5.2. ManhoIe diameter 12

5.3. Concrete thickness (i.e. risk of earIy age shrinkage cracking) 12

5.4. GeoIogy 12

5.5. Ground Loads 12

5.6. Traffic Ioads 13

5.7. Surcharge 13

5.8. Groundwater LeveI 13

5.9. Groundwater Chemistry 13

5.10. H2S 13

5.11. ManhoIe Shape/ Contents 14

6. Design of ManhoIes 15

6.1. GeneraI 15

6.1.1. Design for Temperature and Shrinkage Cracking 15

6.1.2. Design for nternal 'Surcharge' Pressure 15

6.1.3. Design of Manhole Tops and Top Slabs 15

6.1.4. Strength of Concrete 16

6.2. Design in Un-Reinforced, PIain Concrete 16

6.2.1. General 16

6.2.2. Compression 17

8|N6LA|R KN|ChT HERZ

V:\3u3TAlNA8LE 0EvEL0PVENT\Assel Creal|or 0|v|s|or\0e||very 3erv|ces\5 Projecls\Vl Re|rlorcererl

0u|de||res\Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E ||

6.2.3. Tension 17

6.2.4. Grouting 17

6.2.5. Wall/Base Joint 17

6.2.6. Exceptions 17

6.2.7. Serviceability of Plain Concrete 18

6.2.8. Thermal and Drying Shrinkage 18

6.3. Design in Reinforced Concrete to AS3600 19

6.4. Design in Reinforced Concrete to AS3735 19

7. ConcIusions 20

8. Recommendations 22

Appendix A Existing Unreinforced ManhoIes 23

8|N6LA|R KN|ChT HERZ

V:\3u3TAlNA8LE 0EvEL0PVENT\Assel Creal|or 0|v|s|or\0e||very 3erv|ces\5 Projecls\Vl Re|rlorcererl

0u|de||res\Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E |||

Document history and status

Revision Date issued Reviewed by Approved by Date approved Revision type

A 5/8/2009 D. Franklin D. Spackman 5/8/2009 Working Document

B 31/8/2009 D. Franklin D. Spackman 31/8/2009 Final

C 1/3/2010

Distribution of copies

Revision Copy no Quantity Issued to

Printed: 1 July 2010

Last saved: 1 March 2010 03:50 PM

FiIe name:

:\VWES\Projects\VW04301\Deliverables\CDA Projects\Sewer Manhole Reinforcement

Construction\090831 Sewer MH Reinforcement Guidelines.doc

Author: Daniel Spackman

Project manager: Daniel Spackman

Name of organisation: Yarra Valley Water

Name of project: Sewer Manhole Reinforcement Guidelines

Name of document:

Document version: Rev C

Project number: VW04301

8|N6LA|R KN|ChT HERZ

V:\3u3TAlNA8LE 0EvEL0PVENT\Assel Creal|or 0|v|s|or\0e||very 3erv|ces\5 Projecls\Vl Re|rlorcererl

0u|de||res\Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 1

1. Summary

1.1. Aims

Yarra Valley Water aims to develop 'business rules' for sewer manholes to; define acceptable limits

in terms of size or risk for unreinforced concrete manholes, and to determine design requirements

for reinforced concrete manholes. Sinclair Knight Merz was engaged to prepare a brief, desktop

study.

1.2. Background

Some recently constructed manholes (or parts thereof) were designed as reinforced concrete

structures (to AS3600), and even as water retaining structures (to AS3735). Design to these

Australian Standards requires a significant amount of reinforcement at significant cost.

However, sewer manholes are also constructed from unreinforced concrete in accordance with

accepted practice extending back over many decades. Yarra Valley Water's system includes many

unreinforced sewer manholes, some as large as 3.6 metres in diameter and 30 metres deep (refer

Appendix A for details). The Colombo Plan Lectures (MMBW, 1977) recommends for manholes

on main sewers: "as far as practicable, manhole shafts are designed to avoid the use of

reinforcement". The historic design approach adopted within the Colombo Plan Lectures has served

Yarra Valley Waters system well.

The design practice of other authorities such as ActewAGL, indicates standard drawings for

unreinforced manholes can be subject to specified limits such as:

Diameter no more than 1050 or 1200 mm;

Depth no more than 6.0 or 8.0 metres;

Wall thickness no less than 150 or 225 mm;

Sewers no larger than DN675.

However, there is considerable diversity in sewerage infrastructure across Australian cities and the

limits above do not reflect Melbourne experience.

1.3. Risks

This report presents a risk-based approach to the need for reinforcement. The report is focussed on

the shaft structure of circular manholes where 'shaft' refers to the cylindrical part of a manhole

(below the 'top' or cone and above the 'table').

The table below summarises the main potential risks.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 2

Risk Comments

Manhole

depth

Depth >= 15m. Increased manhole depth does not, by itself, justify a change from

unreinforced to reinforced concrete (there is no clear 'line in the

sand'). Increasing the depth of a manhole would be unlikely to

increase the probability of a structural failure; however the

consequences of failure would increase due to the extra depth.

Manhole

diameter

MH diameter >

5000mm.

In unreinforced manholes with wall thicknesses equal to 10% of

the diameter, walls 500mm thick (or more) are at risk of cracking

due to the heat of hydration of the cement. Consequently,

manholes with a diameter > 5 metres need either reinforcement to

control cracks, or control over concrete temperatures to prevent

early-age cracking.

Concrete

thickness

(i.e. risk of

early age

shrinkage

cracking)

Shaft wall thickness

>500mm;

Peak temperature

>60C;

Temperature

differential >20C

Restraint is also relevant to early age cracks, however CIRIA

C660, A5.3.1 includes: "Cylindrical structures in which the walls

are cast in complete rings are further complicated by the fact that

the diameter of the ring attempts to reduce as the concrete cools

down to the ambient temperature. In theory, this could result in a

horizontal crack between the new and old sections in addition to

any vertical cracks, but such cracks are rarely seen in practice."

Geology Rock with fracture

zones, slip planes,

intersecting joint planes

etc.;

Soft or variable clay;

"Floaters";

Silt, Sand, Fill;

Erodible material.

Non-uniform geology is a major risk to unreinforced manholes.

Ground Loads > 10 % out of balance

Point loads (e.g.

floaters);

Unbalanced loads;

Voids that do not

provide support.

Unbalanced loading induces bending and tensile stresses in shaft

walls. If these tensile stresses exceed the allowable value,

reinforcement or increased shaft wall thickness would be

necessary.

Traffic loads M/H located in a

trafficable area;

Subject to heavy, road

vehicle loads;

High speeds and high

frequency.

Vehicle loads represent a risk, mainly to the manhole top and the

upper few metres of shaft. Reinforcing the upper few metres of

shaft walls would mitigate this risk.

Unreinforced shafts located away from traffic may still be subject

to mowers/tractors with low pressure tyres.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 3

Surcharge Surcharge above

groundwater level;

Surcharge to natural

surface.

Surcharge higher than groundwater creates the potential for tension

in shaft walls. Grouting to ensure contact with the surrounding

ground, or reinforcement of the shaft walls, would be necessary to

mitigate this risk.

Surcharge to natural surface creates a risk of unseating the top slab.

The manhole shaft could be reinforced as part of a structural

system designed to hold the top slab in place.

Limiting surcharge to sewer obvert level, a common design

criterion, may avoid air pockets in sewers, but is not necessary for

the structural stability of shafts.

Groundwater

Level

Groundwater above

invert in dry weather

(risk of continuous

infiltration).

Groundwater above

invert in wet weather

(risk of intermittent

infiltration).

High groundwater creates a risk of infiltration but tends to put shaft

walls into compression.

Construction joints or cracks in shaft walls, and joints around

incoming sewer pipes, would be susceptible to infiltration.

Attention to detail at joints and reinforcement to control cracks in

shaft walls would mitigate the risk of infiltration.

Groundwater

Chemistry

Salinity > 10 ppt;

pH < 4.5;

Corrosive or

contaminated;

Langelier Index < - 2.0;

Potential acid sulphate

soil.

Acidic groundwater would react with the alkaline cement mortar in

shaft concrete. Groundwater with a Langelier Index less than -2

tends to dissolve calcium carbonate and soften concrete.

Reinforcement would not mitigate this risk and the reinforcement

itself would be at risk of eventual corrosion.

Contaminated or saline groundwater is a risk for downstream

treatment plants. Reinforcement could be used to control cracks in

shaft walls and reduce this risk.

H

2

S H

2

S levels > 20 PPM;

No effective

ventilation;

Turbulence with

possible hydraulic

jumps (Fr>1.7);

Drops (tributary

sewers)

H

2

S corrosion is a risk to reinforcement (as the concrete cover over

the reinforcement is reduced with time). Reinforcement should be

avoided where practicable, especially where H

2

S corrosion may

ultimately expose it.

Manhole

Shape/

Contents

Cylindrical shaft with

major wall

penetrations, drop

structures or additional

chambers.

Complex manholes are more likely to require reinforcement.

1.4. Recommendations

It is recommended that YVW should:

a) Avoid the use of reinforcement in sewer manholes where uniform geology and balanced

loading ensure that concrete stresses remain within appropriate limits;

b) Specify appropriate controls on concrete temperature and shrinkage (to avoid cracks);

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 1

c) Specify appropriate grouting for unreinforced manhole at risk from perimeter shrinkage

gaps (to ensure contact between the concrete and the surrounding ground);

d) Provide reinforcement in manholes where infiltration, unbalanced loads, traffic loads,

safety or risk issues cannot be addressed more effectively in other ways (such as by

increasing concrete thickness).

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 5

2. Introduction

2.1. Scope

This report considers:

Risks and design criteria relevant to concrete manholes;

The circumstances, or level of risk, that would justify reinforcement;

Functional requirements for sewer manholes (i.e. are 0.2 mm shrinkage cracks

acceptable?); and

Typical limits for unreinforced manholes (some authorities specify upper limiting

sewer diameter or manhole depth/diameter etc.).

The report aims to present different risks and criteria underpinning business rules appropriate to

YVW, and present a recommended option for discussion at a presentation/workshop. This

workshop should involve key internal YVW stakeholders in order to consider the recommendation,

and develop business rules for YVW.

The following are not included in the scope of this assignment:

Sub-structures such as landings, top slabs, drops, penetrations;

The preparation of any drawings;

Considerations for corrosion lining options;

Integration of business rules with WSAA.

2.2. Reference Documentation

The following resources were reviewed as part of the development of this report:

Sewerage Code of Australia Melbourne Retail Water Agencies Edition Version

1.0 (WSA 02-2002);

Water Industry Technical Standards Technical Standards Manual Volume 2

Sewerage;

AS3600 2001 Concrete Structures;

AS3735 2001 Concrete Structures Retaining Liquids;

Colombo Plan Lectures, (International Training Course in Water Supply and

Sewerage Practice - Sewerage, Melbourne and Metropolitan Board of Works,

1977);

BS5911-200:1994; Specification for Unreinforced and Reinforced Manholes and

Soakaways of Circular Cross-section.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E

Sewers for Adoption, 5th ed., WRc (note, the 6th ed, 2006);

The ActewAGL website: Technical Requirements for Sewerage

(http://www.actewagl.com.au/water/standards/standards3.aspx)

Example drawings from past projects.

2.3. Abbreviations

Abbreviations used in this report include:

ActewAGL The entity that manages sewerage in the ACT

AS Australian Standard

BS British Standard

DN Nominal Diameter

HGL Hydraulic Grade Line

ID Internal Diameter

MPa Mega-Pascals (usually the strength of concrete)

WSA Water Services Association

YVW Yarra Valley Water

2.4. Definitions

Terms relevant to manholes and reinforcement include:

Benching Flat surface, also known as the 'table', at the bottom of a manhole but

above the sewer channel;

Depth The vertical distance from access cover level to sewer invert;

Invert The lowest point inside a pipe (at a specific cross-section);

Main sewers Non-reticulation sewers, including intercepting and trunk sewers, but

excluding major, deep tunnel sewers;

Manhole Access chamber, also known as Maintenance Hole or M/H;

Reinforcement Steel bars, or wire fabric/mesh, used to reinforce concrete;

Surcharge The internal hydrostatic pressure within a manhole when the HGL is

above the sewer obvert;

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E Z

3. Risk Considerations for ManhoIe Design

The following general risks were identified in the reference documents listed above and elsewhere.

Unbalanced earth/ground loads;

Heavy vehicle loads;

Wall thickness < 10% manhole diameter;

Early-age thermal and drying shrinkage crack control;

A tensile stress in plain concrete > 1.4 MPa;

Internal surcharge pressure/hydrostatic loads;

Transients such as those resulting from power failure at pumping stations;

Turbulence and erosion from high velocity flows in steep sewers;

Air entrapment and release during wet weather;

High groundwater or flood levels;

Presence of seawater or saline groundwater;

Hydrogen sulphide related concrete corrosion;

Unbalanced forces arising during installation and backfilling;

Differential settlements between the sewer pipelines and manholes;

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 8

4. Risks Expressed in Standards

RISK STANDARDS REFERENCES (MRWA, WITS, AS3600, AS3735)

Trench fill

loadings and

manhole depth

WSA02 Section 18.1

Referenced drawings SEW-1310, SEW-1311, SEW-1312 (Please note

that drawings SEW-1311 and SEW-1312 are not endorsed for use by

MRWA.)

SEW-1310 refers to permanent formwork greater than DN375

SEW-1311 refers to maintenance holes with a depth to invert 6m to 15m

(Reinforcement to be as detailed in design drawings)

SEW-1312 refers to maintenance holes with a depth to invert greater

than 15m:

o Design of MH to be in accordance with AS3735 exposure

condition as defined in AS3735 to be not less than condition

C and shown on design drawing

o Construction details, eg. Concrete thickness, reinforcement,

horizontal and vertical alignment to be shown on design

drawing

WSA02 Standard drawing SEW-1300-V

Precast concrete MHs are not approved for use in trafficable areas,

industrial areas, water charged ground, areas subject to surcharge, where

greater than 6m in depth or on surcharged sewers

Surcharge

WSA02 Standard drawing SEW-1300-V

Precast concrete MHs are not approved for use in trafficable areas,

industrial areas, water charged ground, areas subject to surcharge, where

greater than 6m in depth or on surcharged sewers

Assume that reinforcement is required where sewers are to be surcharged,

unless sewer is completely surrounded by rock.

AS3600 - 2001

AS3600 Section 15 has no serviceability requirements for plain concrete

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 9

Consideration should be given to likely groundwater inflow rates

High water table will cause more infiltration

Temporary and/or

fluctuating

groundwater levels

WSA02 Standard Drawing SEW-1300-V

Precast concrete MHs are not approved for use in trafficable areas,

industrial areas, water charged ground, areas subject to surcharge, where

greater than 6m in depth or on surcharged sewers.

In water charged ground or where there is significant risk of surcharge

use only cast in-situ MHs.

AS3600 - 2001

AS3600 Section 15 has no serviceability requirements for plain concrete

Consideration should be given to likely groundwater inflow rates

High water table will cause more infiltration

Traffic and

transient loads

WSA02 Section 8.4

Traffic loads must be considered when calculating external forces that

act on a pipeline

Sewer diameter

WSA02 Standard Drawing SEW-1309-V

Maintenance holes for sewers of diameter DN375 DN750 should be

reinforced.

Reinforcement as per structural design with 65 minimum cover.

Precast maintenance holes not permitted on >375 mm sewers.

Drawing only applies to maximum MH depth of 6000mm (from top of lid to

invert of pipe).

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 10

Surrounding soil

conditions

AS3600 - 2001

Where the shaft is not to be constructed in solid rock, the shaft walls are

potentially subject to stress conditions other than symmetrical

compression. Drying shrinkage cracks could also occur.

AS3600 Section 15

This describes members in which a crack will not induce a collapse,

and is also limited to plain concrete floors and pavements resting on the

ground, footings and bored piers.

Unreinforced concrete walls can therefore not be designed to the letter

of AS3600

Designing for strength

Compression shaft would be designed for axial (hoop) compression in

accordance with the strength limits specified in AS3600 Section 15

Tension arising from internal surcharging

Exceptions to non-reinforcement (where shafts must be reinforced)

Shaft walls must be reinforced near the top

Near drop inlets

At anchorage points for landings

Around openings

At the base of stilling chambers

Corrosion

prevention

WSA02 Section 4.7.2 Internal corrosion

Septic sewage gives rise to production of hydrogen sulphide (H2S),

which is released through turbulence as hydrogen sulphide gas. H2S will

corrode some metals. It can also be further converted to sulphuric acid

on walls of the sewer by bacteria, leading to attack of cementitious

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 11

products.

The Water Agency may therefore require lining or coating of

maintenance holes of sewers with diameters greater than DN450.

Clause 4.7.3 External Corrosion

External corrosion of sewer items is mainly affected by aggressive

environments through which the sewer may traverse. Ground

contaminated by organic compounds (eg hydrocarbons, and chlorinated

hydrocarbons) may have an adverse effect on:

Properties of materials

Corrosion resistance of metallic components

Corrosion prevention measures may include:

Selection of corrosion resistant materials

Coatings for metallic components

Acidic soils, very high salinity soils and sulphate bearing groundwater will

attack concrete pipe and maintenance structures. Sulphate resistant cement

will provide resistance to neutral sulphates. Use of calcareous aggregates

combined with increased cover will reduce the rate of attack in acidic ground

conditions.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 12

5. Risk Assessment

5.1. ManhoIe depth

Increasing manhole depth does not, at any depth, cause a 'step-change' in risk (just a pro-rata

change). However, external loading and the associated thickness of shaft walls increase with

depth, so the risk of early age shrinkage and thermal cracking also increases.

5.2. ManhoIe diameter

Similarly, increasing manhole diameter does not, at any diameter, cause a 'step-change' in risk.

However the required thickness of shaft walls increases with diameter, so the risk of early age

shrinkage and thermal cracking also increases.

5.3. Concrete thickness (i.e. risk of earIy age shrinkage cracking)

Concrete sections thicker than 500mm are regarded as 'thick' and susceptible to early age shrinkage

and temperature cracking. However there are several mitigation strategies as follows:

Include supplementary cementitious materials (such as fly-ash) in the concrete mix to mitigate

the heat of hydration and reduce thermal shrinkage;

Control the temperature of the concrete on placement by scheduling thick pours early in the

morning, using chilled mix water, cooled aggregate or limiting temperatures in the

specification;

Use water curing to ensure a humid atmosphere and avoid drying the concrete; and

Include expansion additives in the concrete mix.

5.4. GeoIogy

Non-uniform geology represents a significant risk to unreinforced manholes. Rock with fracture

zones, slip planes, intersecting joint planes etc.; soft or variable clay; basalt "floaters"; silt or sand

lenses and fill all introduce the possibility of out of balance loading on the shaft. Erodible material

could also lead to voids and uneven loading around a manhole, especially where infiltration carries

silt into the sewer from where it is transported away.

5.5. Ground Loads

The Colombo Plan Lectures recommend the calculation of horizontal ground and hydrostatic

pressures on a shaft using the equation:

Horizontal Pressure (P) = k

soil

.

Soil

.g.H

Soil

+

Water

.g.H

Water

Maximum and minimum values for this pressure are calculated in orthogonal directions using

upper and lower limiting values for 'k' as shown in the following table.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 13

Case k

min

k

max

Description

1 0.3 0.5 Variable ground

2 0.3 to 0.35 0.45 to 0.5 Normal ground

3 0.35 0.45 Uniform ground

The method finds that for shaft walls: "In normal ground, the stresses in a lining with thickness

10% of the shaft diameter are found satisfactory at depths to 15 metres assuming that ground

pressure is developed by the full depth from the surface without arching, and the maximum

permissible tensile stress is 1.4 MPa."

Based on the above, manhole depths in excess of 15 metres would need careful analysis.

5.6. Traffic Ioads

Traffic loads and the associated risk to sewer manholes must be carefully evaluated. Manholes in

roadways would be subject to impact and vibration. Manholes at some distance from roads may

still be subject to heavy earthmoving or construction equipment.

5.7. Surcharge

Internal surcharge will only occur in exceptional circumstances. Crack width control is not

required for internal surcharge reasons;

AS3735 applies mainly to structures acting in tension to 'retain' the liquid (i.e. tanks). This is

directly the opposite of the normal shaft condition where external water pressures tend to put

the cylindrical shell into compression (tending to close cracks);

5.8. Groundwater LeveI

High groundwater levels represent a risk of infiltration. Groundwater above invert in dry weather

creates a risk of continuous infiltration. Groundwater above invert in wet weather creates a risk of

intermittent infiltration.

5.9. Groundwater Chemistry

Geotechnical investigations should include an assessment of the risk of saline or acidic

groundwater.

5.10. H2S

The bacterial conversion of H

2

S gas delivers sulphuric acid to the internal surfaces of sewer

structures. This sulphuric acid reacts with the alkaline cement matrix in concrete and the resulting

corrosion products can be effortlessly washed away. The addition of steel reinforcement to sewer

manholes only serves to increase the risk of deterioration of the manhole.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 11

5.11. ManhoIe Shape/ Contents

Complex manholes, containing additional structural elements, would be more likely to involve

some risk of structural failure and should therefore be reinforced.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 15

6. Design of ManhoIes

6.1. GeneraI

6.1.1. Design for Temperature and Shrinkage Cracking

Concrete elements thicker than about 500mm are generally regarded as 'thick' and subject to

significant temperature rise due to the heat of hydration of the cement and, subsequently, greater

cooling back to ambient temperature.

Combined with drying shrinkage, thermal shrinkage represents a risk of early age cracking and

needs to be addressed through:

Controlling the cement content of the concrete;

Limiting the temperature of concrete on placement and during hydration; and

Considering other issues such as shading, water curing, restraint, removal of forms etc.

Drying shrinkage is more likely if:

Concrete is exposed to an above ground environment and subject to the drying effects of sun,

wind, and higher humidity (not likely in an underground manhole);

Parameters such as water:cement ratio and slump are not controlled by the specification; or

Concrete curing is inadequate.

6.1.2. Design for InternaI 'Surcharge' Pressure

In unreinforced concrete manholes, internal surcharge pressures must be transferred directly to the

surrounding ground to avoid any tensile stresses in the concrete. Grouting is used to ensure the

cylindrical concrete shaft remains in contact with the surrounding ground.

6.1.3. Design of ManhoIe Tops and Top SIabs

Manhole tops (conical) and top slabs (flat) should be designed to meet the expected loads in

accordance with Australian Standards such as AS1170 and with standard drawings and guidelines.

Reference can also be made to past standard drawings such as "Manhole Tops - General

Arrangement", drawing no. S 2.020.30.10. Loads could include:

Uniformly distributed live load e.g. 10kPa; or

Worst case vehicle loads e.g. W80 wheel load, A160 Axle Load or SM1600 Truck Load.

The design of manhole tops and top slabs is not addressed further in this report.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 1

6.1.4. Strength of Concrete

Concrete strength and other parameters should be specified after taking into account the

requirements of Australian Standards such as AS3600 and AS3735 (however some of the

requirements of these standards are focussed on the protection of reinforcement and may not be

relevant). In accordance with AS3735, exposure classifications B1 and B2 can be addressed with

32 MPa concrete. Typically, concrete strength has increased over time and current grades may be

more than sufficient for sewer manholes. For example, the MMBW standard drawing "Manholes -

General Notes" dated 1981 (drawing no. S 2.020.30.01), specifies grade "MJ" concrete. This

concrete had a characteristic strength (f'c) of 20 MPa.

6.2. Design in Un-Reinforced, PIain Concrete

6.2.1. GeneraI

This approach acknowledges past practice for sewer manholes in Melbourne to, as far as

practicable, "avoid the use of reinforcement" (refer Colombo Plan Lectures, Melbourne and

Metropolitan Board of Works, 1977, Lecture 8, p14). Past practice included shaft wall thicknesses

of 10% of shaft diameter in "normal ground" and maximum permissible concrete tensile stresses of

1.4MPa (for elastic analysis with working loads).

Design should be undertaken to the limiting stresses (where applicable) in the Australian Standard

for Concrete Structures (AS3600) Section 15 using limit state design and ultimate load cases (Note

'plain concrete' is the terminology adopted by AS3600 for unreinforced concrete).

The scope of AS3600 Section 15 is limited to "members in which a crack will not induce a

collapse". As manhole shafts are circular and surrounded by solid ground, arching action is

applicable and mechanisms of collapse are limited (as evidenced by numerous unreinforced sewer

manholes in Melbourne). The figure below indicates the support provided by the surrounding

ground.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 1Z

The scope of Section 15 is also limited to "plain concrete floors and pavements resting on the

ground, footings and bored piers". Therefore, plain concrete shaft walls cannot be designed 'to the

letter' of AS3600. The Victorian water industrys past practice is effectively an 'in-house' standard.

6.2.2. Compression

Unreinforced concrete shafts should be designed for axial (hoop) compression in accordance with

the strength limits specified in AS3600 Section 15.

Wall thicknesses should be selected to ensure the axial compression (hoop) loads in the shaft wall

do not exceed the ultimate compressive strength of the plain concrete.

6.2.3. Tension

The axial (hoop) tension load case, where shafts may be internally surcharged to natural surface

and external ground water may be at sewer invert level (an extreme load case) is assumed to

transfer loads directly into the surrounding rock.

6.2.4. Grouting

Backfill or contact grouting was specified in past projects to ensure contact between the concrete

walls of the shafts and the surrounding ground. The Specification for the North Western Sewer

Stages 1 & 3 for example includes in Clause 6.5(b): "The Contractor shall backfill grout all spaces

... in the walls of the shafts remaining unfilled after placing the concrete lining against rock has

otherwise been completed".

Grouting should reduce tensile cracking due to internal surcharge loads. Grout 'takes' may be

minimal depending on concrete shrinkage and rock quality. Grouting could be omitted given the

risk of internal surcharge is relatively small.

6.2.5. WaII/Base Joint

The joint between the shaft wall and the manhole base needs to be checked for shear stress as the

external loads are close to their maximum and the cross-sectional area of the wall is limited. Deep

manholes may need thicker walls.

6.2.6. Exceptions

Nominally unreinforced shafts may still need some targeted reinforcement for specific situations

such as:

At the top of the shaft to support out-of-balance soil or vehicle loads;

In flat (planar) elements subject to bending (e.g. landings);

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 18

Around penetrations in the cylindrical shell;

At points of concentrated load such as anchorage points for landings; and

At the manhole base especially around stilling chambers.

6.2.7. ServiceabiIity of PIain Concrete

As AS3600 Section 15 has no serviceability requirements for plain concrete (there is no

reinforcement). Consideration should be given to likely groundwater inflow rates, autogenous

healing of cracks, H

2

S corrosion and groundwater chemistry.

6.2.8. ThermaI and Drying Shrinkage

The potential for shrinkage cracks to form in plain concrete shaft walls during curing was assessed.

The two main factors are (a) thermal shrinkage and (b) drying shrinkage.

a) Thermal shrinkage depends on:

The coefficient of thermal expansion (assumed to be 11 x 10

-6

/C but with basalt

aggregate could be 8 x 10

-6

/C ); and

The fall in temperature from the hydration peak to minimum ambient (a fall of about

30C).

Anecdotal evidence suggests cracks are uncommon. The apparent absence of significant cracks in

similar, previously constructed shafts may be due to the method of construction or the

specification. A review of the specification would be required to ensure appropriate limitations for

heat of hydration and temperature of concrete on placement.

b) Drying shrinkage is not likely to be severe as:

One surface of the shaft wall will be cast against rock (or against the temporary support);

Much of the surface cast against rock will be below the water table;

The other surface will be exposed to an underground environment, with limited exposure

to the drying effects of the sun, wind and low humidity;

The water-cement ratio of the concrete mix is limited in the specification;

The application of water for curing is under the control of the contractor; and

Ultimately the shaft is in a moist environment (unlike most other structures).

Also, Supplementary Cementitious Materials (SCMs) and low water/cement ratios mean that the

quantity of water ultimately lost from the concrete as-placed, is minimised.

It can be concluded that there is potential for shrinkage cracks. It also seems apparent that past

practice resulted in few, if any, reported cracks.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 19

6.3. Design in Reinforced Concrete to AS3600

AS3600 requires reinforcement to be designed for (a) strength, (b) serviceability and (c) durability

as follows:

a) Design for bending and shear strength finds, in most cases, the reinforcement required is less

than the minimum required for serviceability (i.e. reinforcement design is not often determined

by loading);

b) Design for serviceability mainly relates to crack control and basically requires a minimum

reinforcement area of 0.45% to 0.60% of the cross-sectional area of the concrete (with a

maximum depth of 250mm); and

c) The minimum requirements for durability relate mainly to cover and have no impact on

reinforcement quantities.

6.4. Design in Reinforced Concrete to AS3735

The scope of AS3735 specifies that it does not apply to the design of "aqueducts, hydraulic tunnels

or similar structures". AS3735 is aimed mainly at tanks and similar structures in which the walls

retain liquids using tension or flexure. The applicability of AS3735 to shaft structures (which

mainly exclude liquids using compression) is marginal.

AS3735 requires reinforcement to be designed for (a) minimum reinforcement ratio and (b)

limiting stresses.

a) The minimum reinforcement ratio differs for restrained and unrestrained concrete. Based on

an assumption of full restraint, a minimum reinforcement ratio of 0.48% to 1.28% of the cross-

sectional area of the concrete, depending on bar diameter (with a maximum depth of 250mm)

is required. Partial restraint is allowed a 25% reduction in reinforcement ratio. This provision

is intended to achieve a mean crack width of 0.15mm.

b) Reinforcement design to limit stresses specifies stress limits of 110 to 150MPa (compared to

200 to 240MPa in AS3600). This provision is intended to limit mean crack widths to 0.10mm

in direct tension or 0.15mm in flexure.

The above requirements significantly increase the quantity of reinforcement required. However

where reinforcement would be in an oxygen free environment (i.e. in the base of the shaft below

the invert level of the sewer), crack width control and the durability provisions of AS3735 should

not apply.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 20

7. ConcIusions

Many sewer shafts exist and perform adequately in Melbourne, without any reinforcement in

extensive areas of the cylindrical shell and the use of plain, unreinforced concrete in shaft walls has

been accepted practice for many decades.

In thick unreinforced concrete sections, if temperatures and shrinkage are not controlled, there is

some risk of wider cracks and greater groundwater inflow (when compared to reinforced concrete

in which the reinforcement would control the crack widths). However the absence of

reinforcement has other benefits such as improved access for concrete placement.

Plain concrete has lower risk of structural deterioration over the long-term and durability

advantages because of the absence of steel reinforcement. In terms of cost, the savings gained by

adopting plain concrete need to be off-set against additional cost items such as grouting.

It is concluded that:

a) There are numerous examples of unreinforced concrete shafts that have provided

acceptable performance for up to 50 years;

b) There is some risk of shrinkage cracking in concrete shaft walls, particularly where the

wall thickness exceeds 500mm. Shrinkage cracks in a plain concrete manhole would tend

to be wider than in an equivalent reinforced concrete manhole even if the shrinkage was

the same, as reinforcement is designed to limit crack widths and distribute cracks; If

cracks develop, and autogenous healing does not occur, repairs could be implemented

before commissioning the sewer;

c) Past specifications included contact grouting and temperature restrictions on concrete. A

specification for plain concrete in manholes should include temperature limits to reduce the

likelihood of thermal shrinkage (e.g. a specified maximum temperature on placement, a

specified absolute maximum temperature and a specified maximum temperature

differential from interior to surface). The specification could include sufficient water

curing to virtually prevent drying shrinkage;

d) Shrinkage cracks in an unreinforced cylindrical manhole are unlikely to result in any viable

mechanism of collapse as the surrounding ground prevents any outward deflection and

arching action transfers the loads into axial compression within the shaft wall. The cost of

contact grouting and possible crack repairs would reduce savings associated with plain

concrete;

e) As the depth and diameter of manholes increase, so do the consequences of structural

failure. However there is no 'line-in-the-sand' beyond which reinforcement becomes

absolutely necessary.

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 21

f) Balanced soil and hydrostatic loads do not induce bending in shaft walls and reinforcement

is not necessary to support these loads (however axial stresses need to be within

appropriate limits).

g) Direct tension in unreinforced shaft walls (due to internal surcharge) can be addressed by

grouting to ensure contact with the surrounding ground or by reinforcement.

h) The design of unreinforced concrete manholes is addressed in the Colombo Plan Lectures

(MMBW, 1977). The use of AS3600 to design unreinforced manholes would require some

assumptions and interpretation. The Clients or the designer would need to accept any risks

associated with plain concrete (such as the uncertainty as to whether AS3600 Section 15 is

applicable) before approving any design which excludes reinforcing steel in the shaft walls.

i) The geology surrounding a manhole and any unbalanced or concentrated ground loads on

the manhole structure is one of the main issues to consider in determining the need for

reinforcement.

j) Heavy vehicles and associated vibrations or issues of safety or unacceptable risk may

dictate the need for reinforcement, especially in the upper portion of a manhole.

k) Infiltration, and the potential impact on groundwater or on the sewerage system (e.g. salt

water at the treatment plant) could also determine the need for reinforcement.

l) The design of reinforcement in manhole shafts should respond to specific requirements for

infiltration flow rates (including salt load and associated crack widths), ground and vehicle

loads, safety and environmental risks. References such as AS3600, AS3735 and guideline

documents such as CIRIA C660 may be required to achieve a rational design.

m) The inclusion of reinforcement in manholes represents a long-term durability risk as

carbonation, chloride ingress etc. would eventually reduce the protection that concrete

provides reinforcing steel, and corrosion and spalling would result. Possible future costs

for rehabilitation of corroded reinforcement could be substantial;

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 22

8. Recommendations

It is recommended that YVW should:

a) Avoid the use of reinforcement in manholes where practicable;

b) Specify appropriate controls on concrete temperature and shrinkage (to avoid cracks);

c) Specify appropriate grouting for unreinforced manholes at risk from perimeter shrinkage

gaps (to ensure contact between the concrete and the surrounding ground);

d) Provide reinforcement in manholes where infiltration, unbalanced loads, traffic loads,

safety or risk issues cannot be addressed more effectively in other ways (such as by

increasing concrete thickness).

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 23

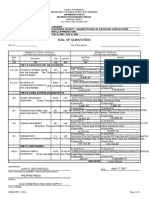

Appendix A Existing Unreinforced ManhoIes

Background data gathered to support the findings of this report is presented in the table below.

Drawings from a range of sewers designed in the past but still in operation were reviewed and

sample data collected. The manholes listed were selected to represent the upper end of the size

range normally managed by Yarra Valley Water.

Item Sewer M/H

no.

Date Depth

(m)

Internal

Dia.

(mm)

Wall

Thickness

(mm)

Un

reinforced

cylindrical

shaft?

Reinforcement

Location

Sewer

Dia

(mm)

1 Balwyn Br. RS 1983 13.5 2100 300 yes Top slab and

drop pipe

surround

525

2 Bolton St. Br. 1982 2.8 1800 300 yes Top slab 300

3 Bower Br. RS 1980 6.3 2400 325 yes Top slab, vortex

and drop pipe

surround

525

5 Cardinal Rd Br.

RS

34A 1982 5.0 2400 min 250 yes Top slab,

landing

750

4 Darling Br. 3 1987 2.5 1500 225 yes Nil (top slab not

shown)

450

6 Eltham MS 26 1980 10.0 1800 300 yes Top slab,

landing

900

7 Gardiners Ck.

Main RS

75 1975 29.5 3650 380 - 450 yes Top slab,

vortex, landings

and base to 2m

above top of

pipe

1800

8 Kew Nth 1976 13.0 1600 225 yes Top slab,

landing, mesh at

table

450

9 Keilor Br. 24 1979 8.0 1070 150 yes Landing (cone

top)

300

10 Koonung Ck.

MS

22 1980 6.6 2400 300 yes Top slab 1200

11 Kororoit Ck

MS

141 1970 9.5 2000 250 yes Top slab,

landing and

around sewer

pipe penetration

975

12 Kyle Rd MS

Sect 4

20 1979 8.5 1800 300 yes Top slab,

landing and

around sewer

pipe penetration

750

13 Merlynston Br.

RS

6 1981 15 2200 300 yes Drop pipe

surround,

internal wall

600

14 Merri Ck. Main

RS

18

29

1964 11.0 1500 225 yes Top slab,

landing, vortex

1050

15 Moreland Br. 1981 3.6 1500 150 yes 600

16 Pascoe Vale Rd

MS

std 1958 3.5 -

4.5

1350 225 yes Around cast

insitu sewer

750

17 Prahran East

Br. RS

1983 9.2 2000 225 yes Drop pipe

surround

450

18 Preston IS 7 1984 30.0 1500 225 yes Landing, vortex 600

19 Queen's Lane

Br. RS

typ 1984 3.0 -

9.0

1220 225 yes Landings 450

20 Trafalgar Av,

Br.

1 1984 10.9 1800 250 yes Landing, top

slab.

700

Yvw3eWerVlRe|rlorcererl0u|de||res.doc PA0E 21

It can be seen from the table above that manholes ranging in size up to approximately 30 metres

deep, 3.6 metres in diameter and on sewers to 1800mm diameter have been successfully

constructed in plain concrete (where "plain concrete" is the term applied in AS3600 to unreinforced

concrete (or concrete containing some reinforcement but assumed to be unreinforced).

It is assumed that the manholes described above have performed satisfactorily as reports on defects

are rare.

Generally, reinforcement is only used in flat/planar elements where bending is possible (i.e.

elements such as landings, top slabs and around penetrations). In circular manholes subject to

uniform loading, the cylindrical shaft of the manhole is mainly subject to compression and

consequently reinforcement would not be stressed.

Larger, basically unreinforced manholes

also exist along many of Melbourne's

trunk sewers.

Zone D3 of Western Trunk Sewer

drawing C.3.250.04.36, 'Old Sneydes

Rd. Shaft Wall Reinforcement Details'

(see adjacent figure), specifies

"reinforcement not required" over much

of the height of the 35 metre high x 6.2

metre diameter shaft.

The drawing is dated 1988 and illustrates

the design approach typically adopted for

the plain, cylindrical portion of trunk

sewer shafts. Reinforcement was

specified at sewer level and at top slab

level.

You might also like

- Concrete Institute of Australia - Recomended Practice - Z7 Durable Concrete StructuresDocument54 pagesConcrete Institute of Australia - Recomended Practice - Z7 Durable Concrete StructurestimNo ratings yet

- Mac GuideDocument16 pagesMac GuideColin SillmanNo ratings yet

- BS EN 771-1 Technical Information Sheet on Engineering BricksDocument1 pageBS EN 771-1 Technical Information Sheet on Engineering Brickshemendraeng100% (1)

- Shotcrete Boiled Water AbsorptionDocument6 pagesShotcrete Boiled Water AbsorptiondjajadjajaNo ratings yet

- PCM For Waterproofing WorksDocument23 pagesPCM For Waterproofing WorksChris AdaminovicNo ratings yet

- C 1012 Length Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionDocument5 pagesC 1012 Length Change of Hydraulic-Cement Mortars Exposed To A Sulfate SolutionCarmen CenzanoNo ratings yet

- Outline Of: Recommendations For The: Inspection, Maintenance and Management of Car Park Structures'Document10 pagesOutline Of: Recommendations For The: Inspection, Maintenance and Management of Car Park Structures'Fyza HoneyNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z40 Super Workable ConcreteDocument30 pagesConcrete Institute of Australia - Recomended Practice - Z40 Super Workable Concretetim100% (1)

- A Guide To Assessing Existing Roofs For The Addition of Solar PanelsDocument5 pagesA Guide To Assessing Existing Roofs For The Addition of Solar PanelsJames BrayNo ratings yet

- (CQHP) Guidelines For Structural & Architectural + Annex PDFDocument43 pages(CQHP) Guidelines For Structural & Architectural + Annex PDFflashtronNo ratings yet

- 2017 .AU ISBN Precast and Tiltup Concrete For Buildings 2001 04Document88 pages2017 .AU ISBN Precast and Tiltup Concrete For Buildings 2001 04alexitomichaelNo ratings yet

- CIA Z11 Presentation 2022Document14 pagesCIA Z11 Presentation 2022John Van RooyenNo ratings yet

- Ytl Cement - Kursb 1Document1 pageYtl Cement - Kursb 1الهادي الياس100% (1)

- UWS CompositeBeam ShearConnectionDocument15 pagesUWS CompositeBeam ShearConnectionMuhammad AsroriNo ratings yet

- Lockable Dowels: For Temporary Movement Joints in Post-Tensioned ConcreteDocument12 pagesLockable Dowels: For Temporary Movement Joints in Post-Tensioned ConcreteDaniel ChangNo ratings yet

- Reinforced Concrete CourseDocument25 pagesReinforced Concrete CourseAbdissa BekeleNo ratings yet

- Maintenance Rehabilitation of StructuresDocument7 pagesMaintenance Rehabilitation of StructuresAjith Joel0% (1)

- Guide To Standards and Tolerances 2019 - WA - 17521Document72 pagesGuide To Standards and Tolerances 2019 - WA - 17521RuwiniNo ratings yet

- Reinforcement Corrosion - An OverviewDocument9 pagesReinforcement Corrosion - An OverviewraeggaemanNo ratings yet

- Technological and Higher Institute of Hong Kong SCE5381 - Project ManagementDocument16 pagesTechnological and Higher Institute of Hong Kong SCE5381 - Project ManagementAlfredNo ratings yet

- Shrinkage TestDocument12 pagesShrinkage TestAlsonChinNo ratings yet

- BEAM EXERCISES SFD AND BMDDocument29 pagesBEAM EXERCISES SFD AND BMDMITTAPALLI PAVAN KUMAR REDDYNo ratings yet

- Use of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneDocument14 pagesUse of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneZimit SukhadiaNo ratings yet

- Accuracy of Prediction Models For Shrinkage of Concrete PDFDocument7 pagesAccuracy of Prediction Models For Shrinkage of Concrete PDFSakthivel ThangavelNo ratings yet

- CHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFDocument162 pagesCHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFsochiva pramestiNo ratings yet

- Guidance notes and model clauses for minimising ASR riskDocument33 pagesGuidance notes and model clauses for minimising ASR riskRavi7654No ratings yet

- (New) Retrofitting of Reinforced Concrete Beams Using Rubberized Coir Fibre SheetsDocument8 pages(New) Retrofitting of Reinforced Concrete Beams Using Rubberized Coir Fibre SheetsPrakumarNo ratings yet

- Code of Practice for Crushed Rock Mix RegistrationDocument9 pagesCode of Practice for Crushed Rock Mix RegistrationKai FrankNo ratings yet

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 pagesApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiNo ratings yet

- SCC Guide: Self-Compacting Concrete Mix Design and PropertiesDocument27 pagesSCC Guide: Self-Compacting Concrete Mix Design and PropertiesAbsiye Aden0% (1)

- Project Rundown CDocument2 pagesProject Rundown CLeung FanNo ratings yet

- Foundations: Understanding the Base of any StructureDocument5 pagesFoundations: Understanding the Base of any StructureForbes KambaNo ratings yet

- Construction and Building Materials: Min Wu, Björn Johannesson, Mette GeikerDocument13 pagesConstruction and Building Materials: Min Wu, Björn Johannesson, Mette GeikerKaryne FerreiraNo ratings yet

- TRL144Document59 pagesTRL144ONE SMART LRT3-2No ratings yet

- Sealants For ConcreteDocument20 pagesSealants For ConcreteSiva PrasadNo ratings yet

- Experimental Study On Bond Durability of GFRP Bars in Concrete Exposed To Harsh Environmental Agents Freeze Thaw Cycles and Alkaline Saline SolutionDocument16 pagesExperimental Study On Bond Durability of GFRP Bars in Concrete Exposed To Harsh Environmental Agents Freeze Thaw Cycles and Alkaline Saline SolutionAnonymous QFaKvowNo ratings yet

- Analysis of Large Bracing Connections Designs For Heavy ConstructionDocument25 pagesAnalysis of Large Bracing Connections Designs For Heavy Constructiondaniel.j.mccarthyNo ratings yet

- Ba 3094Document29 pagesBa 3094massive85No ratings yet

- Project Closure Report - New Adelaide Hospital ProjectDocument23 pagesProject Closure Report - New Adelaide Hospital ProjectSahilNo ratings yet

- 5491R 93Document30 pages5491R 93Rene Coronado VacaflorNo ratings yet

- 4 Dygal ST, Mona Vale - Stormwater DrawingDocument8 pages4 Dygal ST, Mona Vale - Stormwater DrawingRohan Dutt SharmaNo ratings yet

- Papworths Concrete NDT Equipment SupplierDocument1 pagePapworths Concrete NDT Equipment SupplierdantranzNo ratings yet

- Notes On Hy-RibDocument20 pagesNotes On Hy-RibMohd Faizal100% (1)

- OKA Concrete Box CulvertDocument12 pagesOKA Concrete Box Culvertujang1988No ratings yet

- Installation of Metal Ceiling Suspension Systems For Acoustical Tile and Lay-In PanelsDocument5 pagesInstallation of Metal Ceiling Suspension Systems For Acoustical Tile and Lay-In PanelsJuan Carlos Huisa ChuraNo ratings yet

- Post Cast Strip PDFDocument2 pagesPost Cast Strip PDFKwoshaba PidsonNo ratings yet

- Concrete Topping SpecificationsDocument7 pagesConcrete Topping SpecificationsTEC PlantNo ratings yet

- Behaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced PolymersDocument22 pagesBehaviour of Axially Loaded Columns Strengthened With Carbon Fiber Reinforced Polymersbariq89No ratings yet

- CIP Section 03Document26 pagesCIP Section 03viksofNo ratings yet

- Anchored Crane Beams in Hydroelectric Caverns PDFDocument14 pagesAnchored Crane Beams in Hydroelectric Caverns PDFSushmit SharmaNo ratings yet

- Waterproofing Structures Installed Below Ground Level PDFDocument50 pagesWaterproofing Structures Installed Below Ground Level PDFDirk BummNo ratings yet

- Self-Compacting Concrete: The Benefits of SCCDocument4 pagesSelf-Compacting Concrete: The Benefits of SCCKhaja MohiddinNo ratings yet

- ESR 2508, Simpson Strong Tie Set XPDocument17 pagesESR 2508, Simpson Strong Tie Set XPtroyscribdNo ratings yet

- Why Do HPC and SCC Require A Longer Mixing Time PDFDocument7 pagesWhy Do HPC and SCC Require A Longer Mixing Time PDFHuseyin OzturkNo ratings yet

- Waterstop For ConcreteDocument8 pagesWaterstop For ConcretefrankytgNo ratings yet

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Precast/Prestressed Piling Design DetailsDocument46 pagesPrecast/Prestressed Piling Design DetailsRajinda BintangNo ratings yet

- The Cracking of StormwaterDocument8 pagesThe Cracking of StormwaterBen SinambelaNo ratings yet

- Large-Diameter VJ Bro Issue-6 0320 EngDocument27 pagesLarge-Diameter VJ Bro Issue-6 0320 EngSrinivasan DeviNo ratings yet

- Large-Diameter VJ Bro Issue-6 0320 EngDocument27 pagesLarge-Diameter VJ Bro Issue-6 0320 EngSrinivasan DeviNo ratings yet

- Viking Johnson Dismantling Project Fujairah EnglishDocument1 pageViking Johnson Dismantling Project Fujairah EnglishSrinivasan DeviNo ratings yet

- Fluid Transients in Complex Systems With Air Entrainment: B.Eng., HCMUT)Document161 pagesFluid Transients in Complex Systems With Air Entrainment: B.Eng., HCMUT)Srinivasan DeviNo ratings yet

- Air Pockets in Pipeline Systems: UPB Scientific Bulletin, Series D: Mechanical Engineering May 2008Document11 pagesAir Pockets in Pipeline Systems: UPB Scientific Bulletin, Series D: Mechanical Engineering May 2008Srinivasan DeviNo ratings yet

- 72957d3bb1659d7c77dbf6b6c550abeeDocument41 pages72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNo ratings yet

- Wavi Strong Installation GuideDocument44 pagesWavi Strong Installation Guideumer.shariff87No ratings yet

- Viking Johnson Dismantling Project Fujairah EnglishDocument1 pageViking Johnson Dismantling Project Fujairah EnglishSrinivasan DeviNo ratings yet

- Steel1 PDFDocument79 pagesSteel1 PDFSrinivasan DeviNo ratings yet

- Create A Smart Utility Network Using Existing InfrastructureDocument22 pagesCreate A Smart Utility Network Using Existing InfrastructureSrinivasan DeviNo ratings yet

- Simulation of Flow Transients in A Water Filling Pipe Containing Entrapped Air Pocket With VOF ModelDocument15 pagesSimulation of Flow Transients in A Water Filling Pipe Containing Entrapped Air Pocket With VOF ModelSrinivasan DeviNo ratings yet

- Water: Failure Analysis of A Water Supply Pumping Pipeline SystemDocument17 pagesWater: Failure Analysis of A Water Supply Pumping Pipeline SystemSrinivasan DeviNo ratings yet

- Air Problems in Pipelines PDFDocument90 pagesAir Problems in Pipelines PDFjohndagheNo ratings yet

- Simulation of Flow Transients in A Water Filling Pipe Containing Entrapped Air Pocket With VOF ModelDocument15 pagesSimulation of Flow Transients in A Water Filling Pipe Containing Entrapped Air Pocket With VOF ModelSrinivasan DeviNo ratings yet

- Water: Failure Analysis of A Water Supply Pumping Pipeline SystemDocument17 pagesWater: Failure Analysis of A Water Supply Pumping Pipeline SystemSrinivasan DeviNo ratings yet

- Livestock Watering System DesignDocument12 pagesLivestock Watering System DesignLalit MohanNo ratings yet

- Air Pockets in Pipeline Systems: UPB Scientific Bulletin, Series D: Mechanical Engineering May 2008Document11 pagesAir Pockets in Pipeline Systems: UPB Scientific Bulletin, Series D: Mechanical Engineering May 2008Srinivasan DeviNo ratings yet

- Request For Converting Resident Indian' Savings Bank (SB) Account Into NRO SB AccountDocument4 pagesRequest For Converting Resident Indian' Savings Bank (SB) Account Into NRO SB AccountSrinivasan DeviNo ratings yet

- Water Transmission Pipelines An Updated Design GuideDocument13 pagesWater Transmission Pipelines An Updated Design GuideponjoveNo ratings yet

- Piping HandbookDocument259 pagesPiping Handbookhtunmyinthtay73% (15)

- Specification For Pipeworks: Specification Sajh Ws / PW / 001 (Rev.1.0 / 06.2007)Document166 pagesSpecification For Pipeworks: Specification Sajh Ws / PW / 001 (Rev.1.0 / 06.2007)Shahriman Ibrahim100% (1)

- Guide to Welded Steel Pipe Design, Properties, Installation & StandardsDocument93 pagesGuide to Welded Steel Pipe Design, Properties, Installation & StandardsfileseekerNo ratings yet

- DIPRA - Design of Ductile Iron PipeDocument8 pagesDIPRA - Design of Ductile Iron PipeSrinivasan DeviNo ratings yet

- Chapter Five Network Hydraulics: 5.1 Simple Piping SystemsDocument0 pagesChapter Five Network Hydraulics: 5.1 Simple Piping SystemsAsmaa RamadanNo ratings yet

- University of Mindanao Panabo College: San Francisco, Panabo CityDocument6 pagesUniversity of Mindanao Panabo College: San Francisco, Panabo CityJahn Myrillee0% (1)

- HW 200Document40 pagesHW 200Nguyễn Trọng HùngNo ratings yet

- Brochure Concept House Village EnglishDocument2 pagesBrochure Concept House Village EnglishRDM CampusNo ratings yet

- High performance concrete admixtureDocument2 pagesHigh performance concrete admixturetuski24No ratings yet

- Ramanathan, (2011) - Risk Factors Influencing Time and Cost Overrun in Multiple D&B Projects in Malaysia A Case StudyDocument6 pagesRamanathan, (2011) - Risk Factors Influencing Time and Cost Overrun in Multiple D&B Projects in Malaysia A Case StudyPriyaah KarunakaranNo ratings yet

- Hollow Core Diaphragm DesignDocument49 pagesHollow Core Diaphragm DesignMarcus LindonNo ratings yet

- 3.HYDRANT For TejgaonDocument6 pages3.HYDRANT For Tejgaonmujahid_islam85No ratings yet

- ATP 3-37.10 Base CampsDocument173 pagesATP 3-37.10 Base Campscondorblack2001100% (1)

- 2014 - HEP - FinalEIAReport - Rupin - 1587186650467 3RD PDFDocument371 pages2014 - HEP - FinalEIAReport - Rupin - 1587186650467 3RD PDFD V BHASKARNo ratings yet

- Material Selection For Propane SystemDocument12 pagesMaterial Selection For Propane Systema_c_e100% (2)

- Answers To Common ABAQUS Questions PDFDocument4 pagesAnswers To Common ABAQUS Questions PDFEvgeny ShavelzonNo ratings yet

- Mmse Journal Vol11Document319 pagesMmse Journal Vol11Mmse JournalNo ratings yet

- Candy Cos125d 16sDocument21 pagesCandy Cos125d 16srobNo ratings yet

- 3CCDocument1 page3CCDilon FernandoNo ratings yet

- Mini ProjectDocument42 pagesMini ProjectVamshi ChinthalaNo ratings yet

- 002 Fairmate - PiiDocument4 pages002 Fairmate - PiifairmatechemicalNo ratings yet

- 01.introduction To CorrosionDocument18 pages01.introduction To CorrosionIndah ArdiantiNo ratings yet

- IstanbulDocument10 pagesIstanbullsmnklcNo ratings yet

- Uk Truss BrochureDocument104 pagesUk Truss BrochureJFAFPNo ratings yet

- Effective Length Factor of Gable FramesDocument2 pagesEffective Length Factor of Gable FramesSaeedNo ratings yet

- 17FG0045 BoqDocument2 pages17FG0045 BoqrrpenolioNo ratings yet

- VXS 2016 CatalogueDocument16 pagesVXS 2016 CatalogueUmma NakhlunNo ratings yet

- Dorma Vloerveren Bts 80 75v 84Document16 pagesDorma Vloerveren Bts 80 75v 84mercab15No ratings yet

- Design of Beam SinglyDocument18 pagesDesign of Beam SinglyDCRY JADE DOLLERNo ratings yet

- RX 100Document56 pagesRX 100Alexis Mauricio Rodriguez AguirreNo ratings yet

- PMC Scope of WorkDocument21 pagesPMC Scope of WorkVijaita Vikas Gandhi100% (2)

- Sikacrete - 114: Free Flowing Micro-Concrete For Grouting and RepairDocument3 pagesSikacrete - 114: Free Flowing Micro-Concrete For Grouting and Repairsmartman35No ratings yet

- Zespoly Lozyskowe Do Wentylatorow Serii VRE3Document22 pagesZespoly Lozyskowe Do Wentylatorow Serii VRE3Filozófus ÖnjelöltNo ratings yet

- ARE Structures Cheat Sheet PDFDocument4 pagesARE Structures Cheat Sheet PDFDrewNo ratings yet

- Datasheet 1505 01 ENDocument2 pagesDatasheet 1505 01 ENDaniela Alejandra Chaparro DiazNo ratings yet