Professional Documents

Culture Documents

Natural Farming in Asia

Uploaded by

Eduardo SolimaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Farming in Asia

Uploaded by

Eduardo SolimaCopyright:

Available Formats

An introduction to Asian Natural

Farming

A Local and Microbial Approach to Agriculture

ECHO Asia Regional Impact Center

Chiang Mai, Thailand

Natural Farming

Natural Farming Basics

Natural farming is an integrated approach to farming which includes management of the

following in various combinations:

Soil and plant microbes

Plant hormones

Larger soil flora and fauna, i.e., earthworms

Soil organic matter

Garden, fruit and field crops

Livestock

Water, fish and other aquatic animals

The basis of the natural farming is healthy soil.

Natural Farming Topics

Effective Microorganisms (EM)

Indigenous microorganisms (IMO)

Fermented crop production products (Bio-Solutions)

Fermented livestock feeds

Fertilizers made from livestock bedding

Vermiculture

Carbonized rice husks

Household bokashi

Institutional bokashi

Farm bokashi

Wood Vinegar

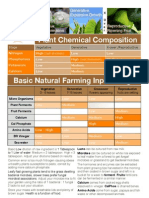

Natural Farming Basics

Natural Farming Microbial Level

Natural Farming Basics

Natural farming, on the microbial level, generally makes use of cultured

mixtures of microorganisms consisting mainly of:

lactic acid bacteria

purple bacteria

yeast

These beneficial bacterial are managed and introduced within crop, livestock

and aquaculture systems to enhance overall health and production.

Lactic Acid Purple Bacteria Yeast

Natural Farming Benefits at Soil Level

Improvement of the biodiversity and population of soil flora and fauna by

adding/supplementing aerobic and anaerobic microbes that degrade

organic matter which in turn release amino acids, vitamins and enzymes

for the benefit of crops.

Enabling the delivery of plant nutrients (by direct and indirect means) to

the soil.

Supplying organic matter from various natural fertilizers, composts and

degraded plant/animal residues which ultimately improves and maintains

soil structure.

Natural Farming Basics

Direct Natural Farming Benefits for

Plants

Boosts levels of beneficial leaf surface microbes such as lactic acid and

yeast which reportedly increases the ability of plants to defend against

disease.

Supplements availability of proteins, amino acids, vitamins, secondary

nutrients and beneficial plant hormones that stimulate improved growth

and production.

Natural Farming Basics

Direct Natural Farming Benefits for

Livestock

Enables the production of fermented feeds.

Maintains comfortable animal bedding that can later be used as organic

fertilizer.

Reduces odors in animal production areas.

Natural Farming Basics

Natural Farming Which Kind?

Effective Microorganisms

Effective Microorganisms

EM was developed by Japanese

horticulturist Teruo Higa, from the

University of the Ryukyus in Okinawa

Prefecture, Okinawa, Japan. The

technology is now a trademarked term now

commonly used to describe a proprietary

blend of 3 or more types of predominantly

anaerobic organisms that was originally

marketed as EM-1 Microbial Inoculant but

is now marketed by a plethora of

companies under various names, each with

their own proprietary blend

(http://en.wikipedia.org/wiki/Effective_mic

roorganism).

Natural Farming- Which Kind?

Asian Natural Farming

Korean Professor, Han Kyu Cho, is considered the father of Korean Natural

Farming. Like EM-based natural farming, KNF emphasizes the

management and use of microbes to enhance the environment that they

are released into. However, Cho and his associates, focus upon the use of

indigenous microorganisms as opposed to commercial EM.

Professor Cho has preached the gospel of NF throughout the Asia/Pacific

and has attracted considerable interest in the approach.

With widespread interest and adoption

throughout the region, depending on the

locality, various versions of NF are referred

to as Korean Natural Farming, Thai Natural

Farming and Asian Natural Farming among

others.

EM vs. NF

Comparisons and Contrasts

EM and NF both use stock solutions

comprised of lactic acid bacteria, purple

bacteria and yeast. And both basic types

of solutions are used similarly for various

farming applications including:

compost production

odor reduction related to livestock

production

stimulation of flower/fruit production

EM solutions are commercially

available and expandable for extensive

application.

EM vs. NF

Comparisons and Contrasts

Indigenous Microorganisms refer to

various homemade solid and liquid

cultures of beneficial microbes. To

culture beneficial indigenous

microbes, these are materials are

concocted from various local

materials such as forest/field plant

materials as well as fruit, vegetables

and even fish scraps and snails.

Therefore, few, outside or

purchased inputs are required.

EM/NF Cafeteria Approach is Common

A blended approach

Both EM and NF have staunch

advocates and promoters.

However, many farmers and

gardeners use components of

both systems. For instance,

NF practitioners might

sometimes buy commercial

EM out of convenience for use

in NF approaches but brew

their own IMO products at

other times. And often the

term, EM, is used to refer to

similar approaches, such as

NF.

EM/NF Concerns

Broad claims about the potential benefits of EM and NF are often made. However,

scientific evidence for many of these is still lacking or inconsistent.

Based on joint EM research, Higa and soil USDA soil microbiologist James F. Parr,

acknowledged the problem of reproducibility and lack of consistent results.

They also dismiss the effectiveness

of 'silver bullet' single organism

EMs due to the host of uncertainty

about the conditions a single

microorganism would be effective

in. But they cite broader scientific

acknowledgment that multiple

microorganisms in coordination

with good soil management

practices positively influence soil

microorganisms and plant growth

and yield.

Mae Jos NF Research and Promotion

Encouraged by Professor Cho and

other advocates of Thai Natural

Farming, Dr. Arnat Tancho of Mae Jo

University in Chiang Mai has been

conducting research on the science of

Natural Farming since 2000.

With support from the Thai National

Science and Technology Development

Agency, Dr. Arnat has produced several

Natural Farming publications.

Natural Farming is widely promoted by

Thai Government agencies such as the

Land Development Department and

the Royal Project. With such high

exposure, Farmers throughout

Thailand and neighboring countries

have adopted NF/EM approaches to

small-scale farming.

Asian Natural Farming Applications

IMO Method 1 refers to the procedure of collecting and using

microorganisms indigenous to forest settings.

Fill a wooden box (or split bamboo internode) up to 7 cm long

with steamed rice (do not compact). Cover the box with porous

paper tied snugly with a rubber band . Place the covered container

into a shallow hole in the forest so that leaves can accumulate on

top (but without pressing down in contact with the rice).

During the rainy season, protect the box by covering the layer of

fallen leaves with a plastic sheet. Leave out for two to 10 days

depending on the temperature.

When you retrieve the rice from the forest, you should see a white

mold growing on it. This harvested IMO 1 material (including the old

rice) can be mixed with molasses (at a 1:1 rate) and fermented in a

paper-sealed ceramic crock for at least one month.

The resulting fermented IMO material can be used to make various

IMO solutions and products. For instance, the fermented IMO

product can be mixed with water (0.1-0.2%) and sprayed onto

transplanted seedlings to help them with their establishment.

Another IMO 1 product is called IMO soil. It is produced by first

mixing the fermented material with water and then applying the

solution to new batches of compost. The solution helps to increase

microbial activity in compost piles, thereby shortening the

composting period. The finished IMO 1 compost can then be

applied as a culture to activate a larger batch of IMO soil. Such

IMO soil is recommended for application to areas previously farmed

with chemicals but still have soil organic matter rates higher than

4%. This amendment will help restore microbial balance and

improve soil structure.

IMO Method 1 (Forest Source)

Asian Natural Farming Applications

IMO 1 (method 2) is a product harvested from the

stubble of freshly harvested rice fields.

After placing freshly steamed rice inside a wooden

box, the box is placed upside down on top of the

stubble. A plastic sheet should cover the box to

protect the rice from rain. Also, a covering of wire

mesh will help keep mice away.

Sap inside of the rice stubble will make contact with

rice inside of the box. After the white fungus appears,

the rice and fungus should be mixed with brown

sugar at a 1:1 ratio and stored in a paper-sealed

ceramic crock for at least one week (but can ferment

up to one year).

The moist, solid product can be mixed with water to

produce a 0.1 solution for application to rice seedlings

in the nursery or at a 0.2 solution to benefit rice

growing in the paddy.

Such IMO applications serve to boost microbial

presence and activity, which mainly help to break

down plant residues in the field, leading to healthier

soil and better nutrient access for crops.

IMO Method 2 (Rice Stubble Source)

Asian Natural Farming Applications

Fermented Bio-Solutions

Fermented bio-solutions can be made from

various readily available materials such as fruit,

vegetables and even fish scraps and snails.

Brown sugar or molasses is mixed with these

various materials . High sugar concentration

reportedly helps increase osmotic pressure

which causes plant/meat cells to burst and

release beneficial bio-ingredients (e.g.

hormones and nutrients).

The mixture is placed into crocks about 2/3 full.

Porous paper, such as newsprint, should be

fastened over the mouth of the container. The

environment inside the container will be

partially anaerobic.

Microbes in the mixture also produce enzymes

that break down the fruit and meat tissues and

release the beneficial bio-ingredients from the

cells.

Asian Natural Farming Fermented

Products

Fermented Green Vegetable

Solution

Fresh vegetables and sugar are combined and

fermented to take advantage of high levels of

plant hormones in the cells of the plants as

well as secondary/supplemental nutrients, lactic

acid producing bacteria and yeast.

Vegetable shoots, which are better than lower

leaves, should be harvested in the morning

when microbe and hormone levels are at their

highest.

Chop the vegetables finely and mix them with

brown sugar (3:1 rate). Supplemental IMO

solution will help culture indigenous microbes.

Fill container about 2/3 full and press mixture

down with stone. Allow to ferment over 15-20

days. The finished product should have a

sour but not smelly odor.

Mix 20-40 ml of the product per 20 liters of

fresh water and apply to crop foliage to

increase the presence and activity of

beneficial plant microbes.

Asian Natural Farming Fermented

Products

Fermented Fruit Solution

Fermented fruit solution

provides a hormone/enzyme

solution which helps stimulate

improved fruit production.

Ripe, sweet fruit are mixed with

brown sugar at a 3:1 ratio and

placed in crock (2/3 full).

Allow mixture to ferment for 5-15

days (depending on

temperatures; hotter=shorter).

A 0.1% solution of the

fermented fruit liquid can be

applied to young

flowering/fruiting crops to assist

in good fruit development.

Asian Natural Farming Fermented

Products

Fermented Fish/Cherry Snail Solution

A solution made from fermented fish or cherry

snails is an effective nitrogen source which

stimulates effective microbes for plants grown

in natural farming systems.

Fish scraps or crushed snails are placed in

earthen or plastic crocks with an equal part of

sugar added on top.

Minerals and amino acids will break down within

7-10 days. Add a couple of handfuls of IMO 2 to

dissolve fats on the surface of the solution. A

sour odor will be present when fermentation is

finished.

Apply to plants and soil at a rate of 20 mm/20

liters of water (1000 parts). Can also be

applied to compost to stimulate microbes.

The fish/snail IMO is 1.1% N, 1.12% P, 1.03% K,

1.66% Ca and 0.24% Mg.

Everybody Loves Compost

but.

Composting Is Not Easy

Challenges:

Finding green and brown

materials

Maintaining proper moisture is an

art

Considerable labor and follow up

in keeping the pile aerated

Asian Natural Farming lets livestock do

the composting for us

Natural Bedding

Bedding 1 meter deep comprised of 100

parts bedding (e.g. sawdust, rice husks),

10 parts local soil and 0.3 parts sea salt.

Apply IMO to the top of the bedding to

help with the breakdown of animal

wastes. This will reduce odors and

eliminate the need for frequent cleaning.

Pigs are more content to laze and root

around in such natural bedding. Also,

reportedly little or no risk of skin diseases

compared to pigs raised on other

surfaces.

Preparing the natural bedding

Add rice husks

local soil and sea salt

and a few pigs.

Rice husks, saw dust, dried leaves,

etc. provide the brown material

and happy pigs provide the rest

Using Natural Bedding for Other

Agricultural Uses

Like other good composts, rich natural

bedding is full of plant nutrients. It is

beneficial for crop production, resulting in

vigorous plants.

After 4 months of use as livestock

bedding, the material can be used as

natural fertilizer. However, in Thailand,

minimum levels of plant nutrients are

required in commercial natural fertilizers.

As a result, such fertilizer must have

been used as bedding for a minimum of

8 months (two pig production cycles).

The material can be mixed directly with

soil as a crop fertilizer.

After several months

a great fertilizer/compost material for gardens,

orchards and fields

Traditional Pig Feeding

Traditionally, pigs have been allowed to forage on their own for

food in addition to being fed kitchen waste and whatever else

that might be seasonally available (grain, chopped paper

mulberry leaves, wild/cultivated vegetables, forage grasses,

fruit, etc.)

Finely sliced banana stalk, though offering minimal nutrition,

makes up the bulk of traditional pig feed in parts of SE Asia.

Banana stalk, leaves and grains are either soaked to soften or

cooked (using fuel and time).

Commercial feeds are usually too expensive to be fed

exclusively.

Fermented Pig Feed

Local feed sources are a major means of reducing

the cost of raising hogs.

Feed materials that are usually easy to find include

banana stalks, water convolvulus, papaya fruit

and other vegetables/fruits. These should be

sliced finely. Mix fruit/vegetable portion with 4 kg

brown sugar and 1 kg salt.

Ferment 3-7 days in a covered barrel. Finished

silage can be stored/fed over1 week (lactic acid

keeps silage from spoiling). Silage older than 1

week is less acidic and will begin to spoil. Spoiled

feed has strong alcohol smell and pigs will refuse to

eat. However, old feed can be given to ducks,

chickens and catfish or refermented with fresh

materials.

For a balanced feed, the fermented portion can be

offered along with a supplemental mixed feed

comprised of 30 kg red soil, 30 kg cow manure, 120

kg rice bran, 50 kg corn meal, 20 kg soybean

residue meal, 5 kg fish meal, 5 kg bone meal and

liquid IMO.

No Matter How You Slice it

Traditional hand slicing of banana

stalks is time consuming but still very

common

Recently innovated automatic banana

slicers get the job done in a fraction of

the time

Time to Ferment

Sliced materials are mixed with

sugar, salt and IMO solution

and left to ferment for 3-7 days. The

finished product should have a pleasant

fermented smell.

packed tightly

into barrels and

covered

What Makes Fermented Plant

Material Nutritious?

Similar to the production of digestible

bacteria in the stomachs of ruminants

(enabling cows to survive off even a diet of

rice straw), the fermentation process

converts sugars to acids; mainly lactic. In

the presence of lactic acid, fermentative

bacteria that proliferate in the process

become a significant source of protein.

In addition to fermented feeds, typical upland

hog rations include rice brain, fruit,

vegetables and portions of commercial feed.

This process offers adequate animal

growth/production and considerable feed

savings as well as less grain and fuel

dependency.

UHDPs Fermented Feed Ration

Everyday, the Upland Holistic Development Project (Thailand) feeds each of its

breeding sows the following daily ration (split into morning and evening feedings):

4-5 kg of fermented banana

600 gm of ground corn

600 gm of rice bran

400 gm of commercial pellet feed

400 gm of dried paper mulberry leaves

UHDP staff report that a 1 grown pig will consume1 med-large sized banana

stalk per week and that a 1 small pig will eat 1 small stalk per week.

How Much Land to Produce Pig Feed?

(An Estimate)

1 med-large sized stalk a week for each sow equals approx.

4 stalks per month. That's 48 stalks per sow per year.

Recommended planting distance of 2 m (within rows) x 3

(between rows) m. With 1600 square meters per rai (Thai

land unit), that should come out to 266 banana plants

established per rai.

Too thick? Try 3 x 3 m = 178 plants per rai.

If the soil is fairly fertile and moisture is adequate, then

according to UHDPs estimates, these 177 to 266 plants

established in 1 rai should become an equal number of

healthy clumps.

It is estimated that a healthy clump of local banana should

produced 6-7 stalks a year. 6.5 x 178 is 1,157 stalks per rai

per year. 6.5 x 266 is 1,729 stalks per rai per

year. According to UHDP's calculations, that ought to

produce enough stalks to feed between 24-36 sows per rai

per year.

Given Murphy's law, bad weather and possibly overly

optimistic expectations, perhaps we should lower the

estimate to a carrying capacity of 20 sows per year per rai

(1600 square meters).

Dont Forget the Worms

Benefits of Vermiculture

Food waste disposal Growing market for worms

Demand for vermi-compost and leachate

Carbonized Rice Husks

Open-Type Carbonizer

Carbonized rice husks

Uses of Carbonized Rice Husks

Substrate to organic fertilizer.

Soil conditioner and ameliorant (a substance added

to the soil to improve growing conditions for plant

roots.

Water purifier and waste water filter.

Base material for making microbial inoculants (IMO

and rhizobia).

Pest control agent (silica helps repel snails).

Can be used to make charcoal.

Deodorizer/odor suppressant .

Rice Technology Bulletin (PhilRice)

Household Bokashi

Household bokashi is a method of intensive composting which has

application in both home and institutional settings, particularly in the

management of kitchen waste. Food scraps and other kitchen wastes

are placed into a container which can be sealed with an air tight lid.

These scraps are then inoculated with a bokashi/EM mix.

This mix usually takes the form of a carrier, such as rice hulls, wheat

bran or saw dust, that has been inoculated with composting micro-

organisms, often derived from EM (e.g. natural lactic acid bacteria,

yeast, and phototrophic bacteria).

Under mostly anaerobic conditions, these microbes expand throughout

the kitchen scraps, fermenting and accelerating breakdown of the

organic matter. The user would place alternating layers of food scraps

and bokashi mix until the container is full. If done correctly, there are no

putrid odors.

The bokashi is allowed to ferment within the airtight container for two

weeks before burial. After weeks of burial, the bokashi will break down

into soil-like compost /soil amendment.

Besides providing a never-ending supply of soil conditioner, household

/institutional waste is decreased with broader benefits for the

environment.

Source: Wikipedia (of course)

http://en.wikipedia.org/wiki/Bokashi_composting#Bokashi_compost

Household Bokashi

Ingredients for a small batch of bokashi carrier (5 kg):

5 kg of rice bran

20 ml EM1

20 ml Molasses

2 liters of water

Procedure:

1. Mix molasses into the 2 liters of the water to dissolve and then mix in the EM1. Allow

the culture solution to set for 5-7 days in a plastic bottle away from direct sunlight.

2. Mix the liquid thoroughly into the bran. You can do this in a bucket .

3. To check moisture content, squeeze some of the bran into a ball. If it holds shape and no

extra liquid comes out then it contains the right amount of correct moisture.

4. If using a bag to store the starter mix, tie the bag tightly, squeezing

out excess air. If using a container, press down the mixture and cover

container tightly.

5. Place mixture somewhere warm and out of the way. Let it ferment for

a minimum of two weeks. Longer is fine.

6. When fermentation is complete, you may notice some white mold

on/in the bokashi. This is good. You can use the material as is, or dry

for long-term storage. Black or green mold means some air got into

the container or it was too moist and is undesirable. Do not use the

starter mix if it has black or green mold in it.

7. Keep airtight during storage, whether dry or wet.

Household Bokashi

Now that we have the starter mix then we can use it in our kitchen

composting system.

Using a plastic bucket with an air-tight lid, begin by laying a

layer of newspaper or cardboard on the bottom. This helps to

soak up excess liquid. Then place a handful of fermented starter

mix in the bottom of the bucket.

Begin layering kitchen waste (as long as it isnt rotten) inside the

bucket and scatter a thin layer of fermented starter mix on top of

the waste. Continue layering until the bucket is full. Push the

food scraps down inside the bucket to compact them every once in a while.

Once the bucket is full then set it aside and allow

it to ferment with the lid tightly closed for two

weeks. Afterward, bury the bokashi in holes or

trenches in the garden under at least 15 cm of

soil. After some weeks (depending on

conditions), the fermented material will convert

into a composted, soil-like material. When the

composting process is done then the former food

waste should not have any bad odor. It will add

nutrients and microbes to the soil and contribute

to improved soil structure.

Institutional Bokashi

A Natural Farming System for Sustainable Agriculture in the Tropics

Keith Mikkelson

Farm Bokashi ARI recipe*

ARI bokashi is a fermented fertilizer made from

local resources in two weeks or less.

Fermentation turns raw materials (manure, rice

bran, etc.) into highly nutritious compost.

Comprised of 70% organic matter and 30% soil.

ARI bokashi has highly concentrated nutrients.

The bokashi is ideal for applying around the roots

of new seedlings as they are transplanted.

Many useful organisms will live close to the crop

roots and play a role of interaction between the

plans and soil.

*Asian Rural Institute based in Tochigi-ken, Japan

Farm Bokashi ARI recipe

Materials

Dried manure (50-60%)

Rice bran (10-20%): food for microbes

rice husk charcoal (5-20%): harbors microbes

Soil from the forest (20-30%)

IMO collected from the forest (a little)

Fermented plant juice (a little) to help with the

fermentation process

Preparation and storage

Mix ingredients well under a sheltered area.

Add water to 50% concentration (enough that when a handful of bokashi is

squeezed that the material will stick together but no water will drip from fingers).

Cover the mixed bokashi with rice straw or grass to help retain moisture and heat.

Turn the mix each time it reaches 60 degrees C (usually once a day).

Maintain moisture at 50%.

Bokashi ready to use when temperature of material is the same as surrounding air

and the manure can no longer be smelled.

Can be dried and stored 6 weeks to one year.

Wood Vinegar

Charcoal production in 200-liter horizontal drum kilns

Two kilns in operation Common, low-quality wood sources (e.g. bamboo)

Finished bamboo charcoal

Collection of Wood Vinegar

Approximately 30 minutes to 1 hour

after having stopped feeding fuel

into the kiln, if the smoke is

yellowish and acrid, close off most

of the outer vent.

Extend a hollow green bamboo pole (far end

elevated to 45) from the flue pipe. Wood

vinegar can be collected with containers

fastened underneath one to two holes,

approximately 2 cm wide, drilled into the

bamboo pole roughly 30 cm from the connection

with the flue pipe.

Thailands Department of Agriculture reports that if wood is burned for 12 to15 hours (or

less, depending on the type and size of wood) in a 200-liter oil drum kiln, that 2 to 7 liters

of raw wood vinegar can be produced.

Leave the raw wood vinegar sealed in a bottle for approximately three months to allow

sediments to settle.

After settling, the useable layer of wood vinegar (second from the top) can be harvested

with a syringe or siphon after first sucking out the light oil layer on top.

Composition of Wood Vinegar

Wood vinegar is not a microbial product. However, it is

natural and derived from locally available materials.

The product approximately 200 components. These

include:

Alcohol (methanol, butanol, amylalcohol)

Acid (acetic, formic, propioinic, valeric)

Neutral substances such as formaldehyde, acetone,

furfural, valerolactone

Phenols (syringol, cresol, phenol)

Basic substances such as ammonia, methyl amine and

pyridine

Uses of Wood Vinegar*

Repel nematodes Tomatoes, 1:500 (apply to the base of plants); strawberries, 1:200 (apply

to the base of plants); and black pepper vines, 1:1500 (apply in place of water).

Repel insect pests - Cabbage and Chinese cabbage, 1:1500 (apply in place of water); corn

1:300 (spray onto leaves).

Control of fungal diseases Tomato and cucumber, 1:200 (spray onto leaves).

Control of root rot Tomato and cucumber, 1:200 (apply to the base of plants).

Reduce incidence of chili pepper flowers aborting 1:300 (spray onto leaves).

Improve flavor of sweet fruits and stimulate development of crops. Mix solution rates of

1:500 to 1:1000. Wood vinegar prevents excessive nitrogen levels, improves plant

metabolism and contributes to higher fruit sugar levels.

Stimulate compost production. A solution rate of 1:100 will help increase the biological

activity of various beneficial microbes and can decrease composting times.

Combat bad odor. A wood vinegar solution of 1:50 will diminish the production of odor-

causing ammonia in animal pens.

Supplement for livestock feed. Mixed with livestock feed at rates of between 1:200 and

1:300, wood vinegar can adjust bacterial levels in the animal digestive tract which improve

the absorption of nutrients from feed.

Enrich garden soil. Use a strong solution of 1:30 to apply to the garden soil surface at a rate

of 6 liters of solution per 1m to enrich the soil prior to planting crops. To control soil-based

plant pathogens, use an even stronger rate of 1:5 to 1:10.

Repel houseflies. Dilute wood vinegar at a rate of 1:100 and apply to affected areas.

*Appropriate Technology Association of Thailand

Summary

Asian natural farming stresses the use of local

materials and natural inputs for small-scale farm

production.

Microbial processes are exploited as much as

possible.

The concept is still new, evolving and expanding.

Interest has extended beyond small farms to

institutions and governmental agencies.

Scientific support is still rudimentary but growing.

You might also like

- Natural Farming With Organic & Biological TechnologyDocument44 pagesNatural Farming With Organic & Biological TechnologyPrakash VaghasiyaNo ratings yet

- Em Application Manual For Asia PasificDocument32 pagesEm Application Manual For Asia PasificIan IdzmirNo ratings yet

- EM Manual APANDocument68 pagesEM Manual APANemerino_pecis2235No ratings yet

- Lactic Acid Bacteria SerumDocument9 pagesLactic Acid Bacteria Serumapi-369718380% (5)

- Precision Agriculture_ Embracing Technology for Efficient Crop ManagementFrom EverandPrecision Agriculture_ Embracing Technology for Efficient Crop ManagementNo ratings yet

- Seed and Seedling TreatmentDocument29 pagesSeed and Seedling Treatmentapi-3697183100% (2)

- Fermented Plant Juice Guide for Healthy Crop GrowthDocument22 pagesFermented Plant Juice Guide for Healthy Crop GrowthAdrian Stan100% (2)

- Insect Pests of Potato: Global Perspectives on Biology and ManagementFrom EverandInsect Pests of Potato: Global Perspectives on Biology and ManagementAndrei AlyokhinNo ratings yet

- Biofertilizers PDFDocument18 pagesBiofertilizers PDFAmeet Kudche100% (1)

- 2014-SP5-Organic Farming and SustanabilityDocument320 pages2014-SP5-Organic Farming and Sustanabilitynandhakumar100% (2)

- EM Nature Farming Knowledge Base - AgricultureDocument15 pagesEM Nature Farming Knowledge Base - AgricultureEM® Nature Farming100% (1)

- Farmer's Guide to Bio-Organic Inputs from Plants, Fish & Animal ExtractsDocument8 pagesFarmer's Guide to Bio-Organic Inputs from Plants, Fish & Animal ExtractsJoshua RiveraNo ratings yet

- SuperGroW Bokashi FertilizerDocument20 pagesSuperGroW Bokashi FertilizerEM® Nature FarmingNo ratings yet

- Buku Panduan - EM Composting GuideDocument8 pagesBuku Panduan - EM Composting GuideDagangputra100% (2)

- Tomato Growth GuideDocument24 pagesTomato Growth GuideMajda MwauraNo ratings yet

- BiofertilizerDocument33 pagesBiofertilizerrscordova100% (4)

- Homemade Biofertilizer GuideDocument12 pagesHomemade Biofertilizer GuideRoss CaysonNo ratings yet

- Organic FarmingDocument15 pagesOrganic FarmingHo Duc ThamNo ratings yet

- Farmer's Guide On Bio-Organic Inputs From Plants, Fish & Animal Liquid ExtractsDocument8 pagesFarmer's Guide On Bio-Organic Inputs From Plants, Fish & Animal Liquid Extractscdwsg254100% (3)

- Indigenous Micro OrganismDocument2 pagesIndigenous Micro OrganismNikka Nejudne75% (4)

- Food Policy - Devinder Sharma PDFDocument21 pagesFood Policy - Devinder Sharma PDFAshishNo ratings yet

- Orchard Farming and You Part 4Document9 pagesOrchard Farming and You Part 4Antartica AntarticaNo ratings yet

- Bio-Pesticides and Bio-Fertilizers Aid TDocument26 pagesBio-Pesticides and Bio-Fertilizers Aid TDharmarajah Xavier Indrarajan100% (1)

- Biofertilizer Recipe for Remineralizing SoilDocument6 pagesBiofertilizer Recipe for Remineralizing SoilJosé AngelNo ratings yet

- Pro Bio TicsDocument10 pagesPro Bio Ticsapi-369718350% (2)

- Markets For CompostDocument181 pagesMarkets For CompostNeil100% (1)

- CompostingDocument46 pagesCompostingAli ArsalanNo ratings yet

- VERMICOMPOSTINGDocument41 pagesVERMICOMPOSTINGNeha Srivastava100% (1)

- Integrated Fish FarmingDocument7 pagesIntegrated Fish Farmingbiebele2411100% (1)

- Ecologically Based Integrated Pest ManagementDocument474 pagesEcologically Based Integrated Pest ManagementPhorids Our Friend100% (3)

- IMO-EM-BIM Natural Farming Technology and Its TechniquesDocument7 pagesIMO-EM-BIM Natural Farming Technology and Its Techniquesbahasa_280181No ratings yet

- Natural FarmingDocument183 pagesNatural FarmingGerard Baynosa Co100% (1)

- Reduce Greenhouse Gas with Garbage EnzymeDocument13 pagesReduce Greenhouse Gas with Garbage Enzymeewan mntrgNo ratings yet

- Manual On HorticultureDocument168 pagesManual On HorticultureSree MurthyNo ratings yet

- Down To EarthDocument6 pagesDown To EarthVijay Chander100% (1)

- Farmer's Handbook: Natural FarmingDocument24 pagesFarmer's Handbook: Natural FarmingTamil PasangaNo ratings yet

- Organic Lettuce: Production Guide ForDocument55 pagesOrganic Lettuce: Production Guide Forfido_dagemNo ratings yet

- Natural FarmingDocument1 pageNatural FarmingMuhammadHazmiMokhtarNo ratings yet

- Managing Nutrient Cycles To Sustain Soil Fertility in Sub-Saharan AfricaDocument502 pagesManaging Nutrient Cycles To Sustain Soil Fertility in Sub-Saharan AfricaAlchristelNo ratings yet

- KNF RESULTSDocument57 pagesKNF RESULTSdasariramakiranNo ratings yet

- Tomato DiseasesDocument70 pagesTomato Diseasesrdomenzain100% (1)

- Manual On Vegetable Seed Production in BangladeshDocument125 pagesManual On Vegetable Seed Production in BangladeshAravind Kanth100% (2)

- Ulang TG Beta 354749Document32 pagesUlang TG Beta 354749Alex BorjaNo ratings yet

- Agricultural Biotechnology - BiofertilizersDocument38 pagesAgricultural Biotechnology - BiofertilizersDr. Farokh Rokhbakhsh-Zamin100% (17)

- Baja EM BokashiDocument23 pagesBaja EM BokashiNyior Setali100% (3)

- PG WatermelonDocument32 pagesPG WatermelonFadil VencapahNo ratings yet

- Effective Microorganisms For Your Garden Teacher's ManualDocument37 pagesEffective Microorganisms For Your Garden Teacher's Manualz7qd100% (3)

- UC4 - Produce Organic Concoction & ExtractsDocument22 pagesUC4 - Produce Organic Concoction & ExtractsButch DemayoNo ratings yet

- Forage Crops of The World, Volume IIDocument377 pagesForage Crops of The World, Volume IIdeNo ratings yet

- Field Guide To Non-Chemical Pest Management in Tomato ProductionDocument48 pagesField Guide To Non-Chemical Pest Management in Tomato Productioncdwsg254No ratings yet

- Biofloc Technology PDFDocument26 pagesBiofloc Technology PDFShafee ShayanNo ratings yet

- Comparison of Fertilizer Cost Between Chemical and Bio FertilizerDocument5 pagesComparison of Fertilizer Cost Between Chemical and Bio FertilizerJohn DAcquisto, D.Sc.No ratings yet

- Jadam MMPDocument61 pagesJadam MMPFlora May Arenga Billena100% (7)

- Tissue Culture Techniques for Banana PropagationDocument52 pagesTissue Culture Techniques for Banana PropagationBrij Mohan SinghNo ratings yet

- EMDocument5 pagesEMAyutin0% (1)

- FR Post-10Document25 pagesFR Post-10kulich545No ratings yet

- Mission Ac Saad Test - 01 QP FinalDocument12 pagesMission Ac Saad Test - 01 QP FinalarunNo ratings yet

- Fernandez ArmestoDocument10 pagesFernandez Armestosrodriguezlorenzo3288No ratings yet

- Hyper-Threading Technology Architecture and Microarchitecture - SummaryDocument4 pagesHyper-Threading Technology Architecture and Microarchitecture - SummaryMuhammad UsmanNo ratings yet

- Preventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Document21 pagesPreventing and Mitigating COVID-19 at Work: Policy Brief 19 May 2021Desy Fitriani SarahNo ratings yet

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet

- Current Diagnosis and Therapy For Head and Neck MalignanciesDocument249 pagesCurrent Diagnosis and Therapy For Head and Neck MalignanciesMara TomaNo ratings yet

- 50 Years of Teaching PianoDocument122 pages50 Years of Teaching PianoMyklan100% (35)

- #### # ## E232 0010 Qba - 0Document9 pages#### # ## E232 0010 Qba - 0MARCONo ratings yet

- Lecture Ready 01 With Keys and TapescriptsDocument157 pagesLecture Ready 01 With Keys and TapescriptsBảo Châu VươngNo ratings yet

- FINAL A-ENHANCED MODULES TO IMPROVE LEARNERS - EditedDocument22 pagesFINAL A-ENHANCED MODULES TO IMPROVE LEARNERS - EditedMary Cielo PadilloNo ratings yet

- Take This LoveDocument2 pagesTake This LoveRicardo Saul LaRosaNo ratings yet

- Nokia MMS Java Library v1.1Document14 pagesNokia MMS Java Library v1.1nadrian1153848No ratings yet

- PointerDocument26 pagesPointerpravin2mNo ratings yet

- Personalised MedicineDocument25 pagesPersonalised MedicineRevanti MukherjeeNo ratings yet

- April 26, 2019 Strathmore TimesDocument16 pagesApril 26, 2019 Strathmore TimesStrathmore Times100% (1)

- Honda Wave Parts Manual enDocument61 pagesHonda Wave Parts Manual enMurat Kaykun86% (94)

- House Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Document4 pagesHouse Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Raphael Eyitayor TyNo ratings yet

- Sharp Ar5731 BrochureDocument4 pagesSharp Ar5731 Brochureanakraja11No ratings yet

- Borello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceDocument10 pagesBorello-Bolted Steel Slip-Critical Connections With Fillers I. PerformanceaykutNo ratings yet

- SEO-Optimized Title for Python Code Output QuestionsDocument2 pagesSEO-Optimized Title for Python Code Output QuestionsTaru GoelNo ratings yet

- Quality Management in Digital ImagingDocument71 pagesQuality Management in Digital ImagingKampus Atro Bali0% (1)

- Case StudyDocument2 pagesCase StudyBunga Larangan73% (11)

- Budgetary ControlsDocument2 pagesBudgetary Controlssiva_lordNo ratings yet

- ABP - IO Implementing - Domain - Driven - DesignDocument109 pagesABP - IO Implementing - Domain - Driven - DesignddoruNo ratings yet

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDocument4 pagesMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeNo ratings yet

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 pagesStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasNo ratings yet

- TDS Sibelite M3000 M4000 M6000 PDFDocument2 pagesTDS Sibelite M3000 M4000 M6000 PDFLe PhongNo ratings yet

- Conv VersationDocument4 pagesConv VersationCharmane Barte-MatalaNo ratings yet

- Exercises 6 Workshops 9001 - WBP1Document1 pageExercises 6 Workshops 9001 - WBP1rameshqcNo ratings yet