Professional Documents

Culture Documents

6m Moxon

Uploaded by

wcantrell0 ratings0% found this document useful (0 votes)

233 views4 pages6 Meter Moxon

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document6 Meter Moxon

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

233 views4 pages6m Moxon

Uploaded by

wcantrell6 Meter Moxon

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

April 2004 1

By Allen Baker, KG4JJH

I

was amazed by the response to my Black Widow antenna

in the May 2003 QST.

1

I subsequently helped quite a few

builders locate the hard-to-find fishing pole spreaders and

I also addressed several details about its construction. Many

had never heard of this antenna configuration and enjoyed build-

ing it. While the wire version of the Moxon rectangle is a proven

performer, a tubular version provides broader bandwidth and

more gain. The two antennas presented here are based on an

article by L.B. Cebik, W4RNL.

2

The first is horizontally po-

larized for CW and SSB use at the low end of the 6 meter band

(50-51 MHz) and the second is vertically polarized for FM use

at the upper portion (52-54 MHz). For ease of reference, I

refer to the first as H-POL and the second as V-POL. All mate-

rials have been chosen to withstand the elements and are avail-

able locally or via the Internet for under $100.

The Moxon Rectangle

I used the program MoxGen

3

to generate models at 50.5

and 53.0 MHz, using

5

/8

inch OD aluminum tubing. I then fine-

tuned them with EZNEC

4

to allow for the different tubing sizes.

A 6 Meter Moxon Antenna

Discover 6 meters for the first time or enhance your existing operation

with a rugged but portable version of this novel 2 element antenna.

The 6 met er Moxon i s bui l t from

5

/ 8 i nch OD and

1

/2 inch OD aluminum tubing with

3

/8 inch OD solid aluminum

for the corners. The detailed construction drawings, sheets and

EZNEC models for both versions are available at www.arrl.

org/files/qst-binaries/6 meter moxon.zip. A basic outline

drawing of the antenna is shown in Figure 1, while the full

material list is available on the Web site. I built the antenna to

the dimensions in the EZNEC model listed on Sheet 1.

Construction

Drawing Sheet 1 presents an overview of the antenna

assembly. Each component of the antenna is identified by a

letter designation (A

0

, A

1

, A

2

, etc). After choosing which ver-

sion you want to build, follow the Material Cutting Schedule to

get the correct quantity, material and length. All materials are

easi l y cut wi t h a t ubi ng cut t er, hacksaw or band saw.

After cutting, use a

3

/4 inch countersink bit and a file to deburr

the inside and outside edges of the tubing. Add the common

components (such as channel and stainless steel hardware) and

you will be ready to begin assembly. All of the necessary mate-

rials are listed on Sheet 7 along with sources for each. Figure 2

gives a view of the completed antenna, without the mast.

1

Notes appear on page 00.

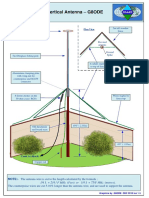

Figure 1The 6 meter antenna design is based on a Moxon rectangle. Its basic dimensions are shown. Definitive construction

details can be found on the ARRL Web site (www.arrl.org/files/qst-binaries/6 meter moxon.zip).

2 April 2004

Mounting Plates

The driven element, reflector and boom to mast plates are

fashioned from structural aluminum channel. This material is

overkill for this application, but this method of mounting is

sturdy enough to be used on tubular Moxons up to 20 meters

or more (by scaling the mounts and tubing upward). There is

absolutely no flexing or bending of the mounts and the fin-

ished antenna is very solid.

The channel is easily cut with a band saw and a metal cut-

ting blade. Cut three pieces 8 inches long and lay out all holes

according to the dimensions shown on Sheets 4 through 6. Its

a good idea to smooth all sharp edges on the channel with a

file. I use a center punch and a drill press with a

1

/16 inch bit to

get accuracy, then go back and enlarge each hole to its final

dimension. Be sure to size the mast saddle clamps to match

your mast and use the chart on the drawing for a drill guide.

Tap the holes as specified and assemble using the stainless

steel saddle clamps and radio support blocks listed. This

was my first encounter with the support blocks and they

provided a great way to support the elements rigidly while

providing isolation from the metal brackets and boom. These

blocks, actually industrial insulated tubing clamps, may also

be found at hydraulic and piping distributors. Figures 3 and 4

show top and bottom views, respectively, of the completed

mounting plates.

Insulators

A pair of insulators that maintain a fixed distance between

the tubing ends supports the ends of the antenna elements

(within dimension C on Drawing Sheet 1). The insulators are

made from

3

/8 inch OD 10 inch solid fiberglass and slide

inside the

1

/2 inch OD aluminum tubing. Similarly, a

1

/2 inch

OD 10 inch solid fiberglass rod is used to join the

5

/8 inch

OD tubing at the feed point. (Because tubing and fiberglass

materials are usually sold in 6 foot lengths, the shipping costs

can be more than the material itself. I recommend ordering

enough material for a group of builders to keep the costs down.)

An installed insulator can be seen in Figure 5.

Feed Point

The installation of an SO-239 coax connector on the 6 meter

Moxon adds a bit of reactance to the feed and it is best to

attach the coax directly to the driven element.

5

Unfortunately,

this was not practical for me, as I use this antenna for portable

use and prefer to separate the coax from the antenna. I tried

several methods and ended up using the channel as a mount

for the SO-239 connector. In the interest of isolating the

feed from the antenna, I made an insulator from the end of a

1

1

/2 inch PVC cap and fastened this and the connector to the

channel using nylon screws. Short pieces of 14 gauge insu-

lated wire connect the SO-239 to the driven element. Apply a

weatherproof sealant to the solder joints. Figure 6 shows the

driven element connection.

An alternate method is to fabricate a bracket that mounts

the SO-239 directly on the driven elements (see Drawing Sheet

7 for details). The brackets are made from 1

1

/2 inch 1

1

/2 inch

1

/8 inch aluminum angle. The connector is mounted on one

bracket, which is attached to one side of the driven element.

Cut the head off of a 6-32 1 inch copper screw, file one end

down to fit inside the SO-239 center pin and solder. Use 6-32

nuts on either side to clamp the second bracket, which is at-

tached to the other side of the driven element. Apply a weath-

erproof sealant to the solder joint and copper materials.

Corners

Cut the

3

/8 inch OD aluminum rod into four 8 inch lengths

Figure 5One of the insulators that separates the reflector

from the driven element.

Figure 2A bottom

view of the com-

pleted antenna

clearly shows the

fiberglass insulators

separating the driven

element from the

reflector.

Figure 3A top view of the antenna mounting plates.

Figure 4A bottom view of the mounting plates. Note the

insulated element support blocks that are discussed in the text.

April 2004 3

and chuck each into your drill or drill press. While rotating

the rod, use a file to smooth the edges to ensure a smooth fit

inside

1

/2 inch OD aluminum tubing. The

3

/8 inch OD solid

aluminum rod is fairly soft and easy to bend. My method is to

mark the center and place a scrap piece of

1

/2 inch OD 12

inch aluminum tubing over each end (to give some leverage)

and slide it near the mark. I then place the

3

/8 inch rod over a

vise-mounted

1

/4 inch drill bit and smoothly push the tubing

down until I have a 90 bend. See Sheet 7 for a corner detail.

A completed corner can be seen in Figure 7.

Fasteners

The 6-32 stainless steel fasteners were chosen to provide

reasonable strength and corrosion resistance without having

to drill very large holes in the tubing. The stop nuts provide a

vibration-proof fastener without using lock washers.

Assembly

I prefer to assemble the antenna parts loosely and then go

back and install the fasteners. Mark the center of the

1

/2 inch OD

fiberglass rod (A

0

) and

1

/8 inch on either side. Slide the fiber-

glass inside both pieces of

5

/8 inch OD tubing (A

1

) up to the

1

/8

inch marks and place inside the radio support blocks on the driven

element mounting bracket. Center the assembly in the bracket

and drill holes and install the feed line screws. Mark the center

of the

5

/8 inch OD aluminum tube (A

3

) and mount it in the Re-

flector Mounting Bracket. Place a line 3 inches from the end on

the four

1

/2 inch OD tubing lengths (A

2

) and slide each into the

previously mounted

5

/8 inch OD tubing (A

1

and A

3

) up to the

mark. Place a mark 1 inch from the centerline on each of the

four

3

/8 inch OD bent corners (A

4

) and insert each inside the

1

/2

inch OD tubing (A

2

) up to that mark. Mark the centerline and a

point 3 inches from each end on the

3

/8 inch OD fiberglass (C

1

)

and insert each into the

1

/2 inch OD aluminum (B

1

and D

1

).

At this point you should have a complete antenna layout. Re-

ferring to the Moxon dimensional chart, check each ABCDE

measurement and adjust the assembly until you are satisfied.

Keep in mind that there should be at least a 3 inch overlap on all

tubing-to-tubing and rod-to-tubing transitions. When you are sat-

Figure 6The driven element SO-239 wiring details. The driven

element can also be wired directly, as outlined in the text.

Figure 8The

completed 6 meter

Moxon in the

horizontal position.

Figure 7A corner of

one of the elements.

Figure 9The Moxon mounted for

vertical polarization.

isfied, clamp the tube

positions (I used tape)

and dri l l st rai ght

through, installing the

stainless steel hardware

as you go. Disassemble

and clean all metal-to-

metal joints. Then, ap-

ply an aluminum anti-

oxidant compound to

the joints to maintain

good electrical contact

by preventing oxidation.

Reassemble and use an

ohmmet er t o ensure

feedpoint isolation from

the boom and mounting

brackets.

Antenna Models

H-POLThe reso-

nant frequency is 50.5

MHz at a height of 15

feet. This antenna is

intended to cover the

lower end of the 6 meter

band with less than a

1.3:1 SWR, and tests

conduct ed wi t h an

MFJ-259B antenna ana-

lyzer verified this. The

EZNEC model predicts

the antenna to have a

gai n of 11 dBi and

front-to-back ratio of 25

dB at resonance. The H-

POL antenna completed

and moun-ted is shown

in Figure 8.

V-POLThe resonant frequency is 53 MHz at a height of

15 feet. This antenna is intended to cover the upper end of the

6 meter band with less than a 1.6:1 SWR. The EZNEC model

predicts the antenna to have a gain of 6.7 dBi and front-

to-back ratio of 36 dB at resonance. The completed V-POL

antenna is shown in Figure 9.

4 April 2004

SWR Measurement

Upon completion of the H-POL version, I wanted to com-

pare the SWR curve predicted by EZNEC with my MFJ-259B

analyzer. At first, I was completely baffled by the results. The

analyzer showed a much broader curve than I thought pos-

sible. W4RNL provided the following explanation:

If you made the measurements at the end of a length of

coax, they will be flatter than at the antenna itself, due to losses

in the coax. These losses increase with thinner coaxes and are

less with 1.2 inch diameter low loss coax cables. Hence, RG-

58/U will show a flatter SWR than some of the latest coax

types. This is normal behavior. As well, the longer the coax

run, the greater the losses and, hence, the flatter the curve. If

you are measuring the low SWR at the antenna terminals, then

it becomes more likely that the flat curve is a function of equip-

ment limitations.

Armed with this knowledge, I replaced the 50 feet of RG-

8X coax that I had been using with a 3 foot run and got much

better results with the analyzer. Figure 10 shows the antenna

mounted and ready for testing.

Mounting

The finished antenna weighs 8

1

/2 pounds and is light enough

for my trusty painters pole at a height of 15 feet. The antenna

will mount horizontally or vertically by loosening the boom

to mast plate saddle clamps and rotating the antenna (see Sheets

2 and 3). If youre industrious, you could mount the H-POL

and V-POL on the same boom with different feeds.

6

6 Meter Activity

Listen for beacons at the lower end of the band. If you hear

one, chances are the band is open. Here is a short list of where

I have found the most activity:

CW 50.000 to 50.100 MHz

SSB 50.100 to 50.200 MHz

PSK 50.290 MHz

FM 52.000 to 54.000 MHz (simplex and repeaters)

Testing

I decided the best way to test the antenna was to go camp-

ing during the July 4 holiday. As luck would have it, tropical

storm Bill was passing through our area, so it was raining

heavily. We set up camp in a light drizzle and then mounted

the Moxon on the painters pole. A quick check with NG4T

(about 50 miles away) told me that the antenna was working. I

was S7 on his dipole while running 30 W SSB. Our contact

was quickly joined by WB4GBI, who give me a 20 dB over S9

report. It continued to rain throughout the night and the next

day brought some welcome sunshine and NG4T (my brother)

to the campsite. Thanks to an unusual 6 meter opening that

weekend, we logged numerous contacts to California, Colo-

rado and Texas on SSB and PSK. On FM, 6 meter repeaters

were easily worked with full quieting. I am still on the look-

out, however, for that first 6 meter DX contact!

Results

The antenna easily withstood the wet weather and the per-

formance was flawless, with excellent gain, directivity and

F/B ratio. The fact that the assembled antenna is small enough

to fit in a pickup truck makes it a great portable for camping,

Field Day, or an afternoon in the park. So start buildingand

discover why 6 meters is called the Magic Band.

Acknowledgments

I would like to thank L.B. Cebik for his advice and exper-

tise, my wife Ann for her continued encouragement and sup-

port, and the late Oddis Baker, my father, for his quest for

knowledge that he passed on to me.

Notes

1

A. Baker, KG4JJH, The Black WidowA Portable 15 Meter Beam,

QST, May, 2003, pp 35-39.

2

www.cebik.com/6m.html.

3

www.qsl.net/ac6la/moxgen.html.

4

www.eznec.com.

5,6

See Note 2.

All photos by the author.

Allen Baker, KG4JJH, received his license in September 2000,

after a lifelong dream of becoming a ham. He holds a BS in In-

dustrial Engineering from Tennessee Technological University and

works as an Instrument and Controls Engineer for the Depart-

ment of Energy in Oak Ridge, Tennessee. Allen is active on the

digital modes (6 through 40 meters) and loves to experiment with

antenna designs. He can be reached at kg4jjh@arrl.net.

Figure 10A temporary lash-up for testing and adjustment

purposes at the authors location.

You might also like

- 300 To 50 BalunDocument3 pages300 To 50 BalunprochitayNo ratings yet

- AntennaDocument12 pagesAntennaechopiolo100% (1)

- Breadboarding The Darlington PairDocument7 pagesBreadboarding The Darlington Pairmarius_danila8736No ratings yet

- How To Start Modeling Antennas Using EZNECDocument106 pagesHow To Start Modeling Antennas Using EZNECDalyskNo ratings yet

- w4zcb - Helical Resonator OscillatorsDocument12 pagesw4zcb - Helical Resonator Oscillatorssushisensei100% (1)

- Four-Square Antenna Experiences for Low Band ContestingDocument5 pagesFour-Square Antenna Experiences for Low Band ContestingTRYONLANHOUSENo ratings yet

- Build A 9dB, 70cm Collinear AntennaDocument3 pagesBuild A 9dB, 70cm Collinear Antennadr3x100% (1)

- Improving The Super J-Pole Antenna PDFDocument13 pagesImproving The Super J-Pole Antenna PDFvinu0% (1)

- Balun Short VersionDocument30 pagesBalun Short VersionIngnote MaxNo ratings yet

- EZNEC Modeling Tutorial by W8WWVDocument106 pagesEZNEC Modeling Tutorial by W8WWVmicrovacNo ratings yet

- QRP Magnetic Loop Tuner 80-20mDocument5 pagesQRP Magnetic Loop Tuner 80-20mAnonymous yd3nqGC100% (2)

- Balun CompilationDocument62 pagesBalun Compilationcobra148067% (3)

- Transistor Circuits For The Constructor (No-2) - E. Bradley (N. Price, 1957) WWDocument31 pagesTransistor Circuits For The Constructor (No-2) - E. Bradley (N. Price, 1957) WWMark BradshawNo ratings yet

- Low Band Receiving Antennas-1Document37 pagesLow Band Receiving Antennas-1David Bohorquez RamosNo ratings yet

- QRPP Volume 01Document140 pagesQRPP Volume 01helix0rNo ratings yet

- 73 Magazine 03 - March - 1961Document76 pages73 Magazine 03 - March - 1961viajerocanarioNo ratings yet

- Beyond Stubs and TrapsDocument123 pagesBeyond Stubs and TrapsSatadal GuptaNo ratings yet

- Wire AntennasDocument32 pagesWire Antennasmuhammadabid4uNo ratings yet

- moxonMFJ-1890 Manual REV 1ADocument12 pagesmoxonMFJ-1890 Manual REV 1AEnrique Benitez100% (1)

- 20m Elevated Vertical Antenna DesignDocument5 pages20m Elevated Vertical Antenna Designleonardo_manzanoNo ratings yet

- Low Band Receiving AntennasDocument50 pagesLow Band Receiving AntennasDavid Bohorquez RamosNo ratings yet

- SignaLink USB A Review by ZS1JHGDocument2 pagesSignaLink USB A Review by ZS1JHGJohn Howard GreenNo ratings yet

- Dipole Antenna ProblemsDocument3 pagesDipole Antenna ProblemsRawasy TarhuniNo ratings yet

- Baluns and Symmetric BalunsDocument12 pagesBaluns and Symmetric BalunsThemba KaongaNo ratings yet

- 4 85 PDFDocument68 pages4 85 PDFviatr0nicNo ratings yet

- Half Length 80m Loaded DipoleDocument2 pagesHalf Length 80m Loaded DipoleBenjamin Dover0% (1)

- How To Build High-Q Coils PDFDocument2 pagesHow To Build High-Q Coils PDFmiguellm5071No ratings yet

- The Sprat Pixie FileDocument18 pagesThe Sprat Pixie FileMR XNo ratings yet

- Eznec PrimerDocument11 pagesEznec PrimerOttis WillebenNo ratings yet

- 1:1 Voltage Balun For HF Wire DipolesDocument5 pages1:1 Voltage Balun For HF Wire Dipolesetan100% (2)

- 2multifan DipoleDocument4 pages2multifan DipolelokiknoppenNo ratings yet

- 160Vs80 meterIsolatedOff Center Fedantennas PDFDocument11 pages160Vs80 meterIsolatedOff Center Fedantennas PDFΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNo ratings yet

- Several Mixers PDFDocument4 pagesSeveral Mixers PDFRolandoIgorLeivaNo ratings yet

- Homebrew BuddipoleDocument10 pagesHomebrew Buddipole10sd156No ratings yet

- N07Document52 pagesN07StarLink1No ratings yet

- More Radio AntennaeDocument5 pagesMore Radio Antennaenw2sNo ratings yet

- Balun and UnUnDocument15 pagesBalun and UnUnLucienioTeixeira100% (1)

- Antentop 2008-01Document104 pagesAntentop 2008-01Black Onion100% (1)

- HF Balanced Transmiter SystemDocument75 pagesHF Balanced Transmiter SystemwingchaoNo ratings yet

- Multiband Wire AntennasDocument31 pagesMultiband Wire AntennasAriel BecerraNo ratings yet

- Antenna Half Square ArrayDocument8 pagesAntenna Half Square Arraycarlos_gomes_31No ratings yet

- Inverted V 85 - 87 - Radcom PDFDocument5 pagesInverted V 85 - 87 - Radcom PDFNestor Alberto Escala100% (1)

- Antenna Article Hrry Vpo Spirl LoopDocument2 pagesAntenna Article Hrry Vpo Spirl LoopkedalNo ratings yet

- AM Loop AntennasDocument8 pagesAM Loop AntennasSaung SunnahNo ratings yet

- Balun Design Using Backward Wave Couplers for Impedance TransformationDocument7 pagesBalun Design Using Backward Wave Couplers for Impedance Transformationdew0786No ratings yet

- A Multiband Doublet For 10-18-24 MHZDocument4 pagesA Multiband Doublet For 10-18-24 MHZIrfanJFNo ratings yet

- 2 77 PDFDocument68 pages2 77 PDFviatr0nicNo ratings yet

- 3 77 PDFDocument68 pages3 77 PDFviatr0nic100% (1)

- 40-30m Safari Roach Pole Vertical Antenna - g3rwf1.3Document3 pages40-30m Safari Roach Pole Vertical Antenna - g3rwf1.3Stroie Claudiu CristianNo ratings yet

- AirCraft Band Receiver 2012Document4 pagesAirCraft Band Receiver 2012Smail HondoNo ratings yet

- Buddipole Antenna Tested by ZS1JHGDocument1 pageBuddipole Antenna Tested by ZS1JHGJohn Howard GreenNo ratings yet

- 40 Meter Super Gain AntennaDocument148 pages40 Meter Super Gain AntennaStephen G. Moshe TullosNo ratings yet

- Antentop 2003-03Document104 pagesAntentop 2003-03Black OnionNo ratings yet

- RF Probe How ToDocument3 pagesRF Probe How ToMike YoungNo ratings yet

- Simple Antenna Matching Unit For VHFDocument2 pagesSimple Antenna Matching Unit For VHFBenjamin Dover100% (1)

- Transistor Circuits For The Constructor No-1 - E.N. BradleyDocument34 pagesTransistor Circuits For The Constructor No-1 - E.N. BradleytuwinnerNo ratings yet

- Wideband RF Technologies and Antennas in Microwave FrequenciesFrom EverandWideband RF Technologies and Antennas in Microwave FrequenciesNo ratings yet

- The Radio Amateur's Hand Book: A Complete, Authentic and Informative Work on Wireless Telegraphy and TelephonyFrom EverandThe Radio Amateur's Hand Book: A Complete, Authentic and Informative Work on Wireless Telegraphy and TelephonyNo ratings yet

- High-Power Electronics: Volume 2From EverandHigh-Power Electronics: Volume 2P. L. KapitzaNo ratings yet

- Wire Gain Antennas For 6 MetersDocument3 pagesWire Gain Antennas For 6 MeterswcantrellNo ratings yet

- Africanized Honey Bees Discovered in Albany, Georgia: Vol. 21 No. 2 December, 2010Document14 pagesAfricanized Honey Bees Discovered in Albany, Georgia: Vol. 21 No. 2 December, 2010wcantrellNo ratings yet

- Remington Year of Manufacture CodesDocument2 pagesRemington Year of Manufacture CodeswcantrellNo ratings yet

- Corner Bench PlansDocument4 pagesCorner Bench PlanswcantrellNo ratings yet

- WWW - Manaresults.Co - In: (Common To CSE, IT)Document2 pagesWWW - Manaresults.Co - In: (Common To CSE, IT)Suresh ThallapelliNo ratings yet

- Msp-Exp430G2 Launchpad™ Development Kit: User'S GuideDocument26 pagesMsp-Exp430G2 Launchpad™ Development Kit: User'S GuideJacky MRchanNo ratings yet

- INSTALLATION MANUAL BizhubPRO C6500Document20 pagesINSTALLATION MANUAL BizhubPRO C6500atjones100% (1)

- KVR667D2N5K2 2GDocument1 pageKVR667D2N5K2 2GetendardNo ratings yet

- Introduction To Wearable TechnologyDocument4 pagesIntroduction To Wearable TechnologyFajri SNo ratings yet

- Superman SA InstallationDocument2 pagesSuperman SA InstallationSheikh FahadNo ratings yet

- 01: Computer Parts and Tools: Baessa KDocument74 pages01: Computer Parts and Tools: Baessa KEba TesfaNo ratings yet

- Dictionary of Prepositions PDFDocument3 pagesDictionary of Prepositions PDFseinwinkyiNo ratings yet

- Points & Deviations - A Pattern Language For Fire Alarm SystemsDocument12 pagesPoints & Deviations - A Pattern Language For Fire Alarm SystemsAhmed AhmedabdelrazekNo ratings yet

- The Secret Power by Corelli, Marie, 1855-1924Document199 pagesThe Secret Power by Corelli, Marie, 1855-1924Gutenberg.orgNo ratings yet

- Python and ARCPYDocument61 pagesPython and ARCPYVijay DubeyNo ratings yet

- ISO FORMATS PaperDocument42 pagesISO FORMATS Papermilkbikis1114100% (1)

- SAP IQ Installation and Configuration Windows PDFDocument70 pagesSAP IQ Installation and Configuration Windows PDFJavier PainemalNo ratings yet

- Face Tracking With A Pan - Tilt Servo Bracket - SparkFun ElectronicsDocument24 pagesFace Tracking With A Pan - Tilt Servo Bracket - SparkFun ElectronicsLarasmoyo NugrohoNo ratings yet

- Recommended Psu TableDocument2 pagesRecommended Psu TableFaisal Fikri HakimNo ratings yet

- Any Connect 31 RNDocument34 pagesAny Connect 31 RNxNo ratings yet

- Loop Types and ExamplesDocument19 pagesLoop Types and ExamplesSurendran K SurendranNo ratings yet

- 1 GHZ Frequency Meter Card For PCS: H. KolterDocument4 pages1 GHZ Frequency Meter Card For PCS: H. KolterAg CristianNo ratings yet

- CouplerDocument5 pagesCouplerabdul khaderNo ratings yet

- SINUMERIK ONE The Real CNC For Highest Productiv TechSlides 2020 02 01 ENDocument73 pagesSINUMERIK ONE The Real CNC For Highest Productiv TechSlides 2020 02 01 ENDaniel CamachoNo ratings yet

- Manual Operação Computador PAT DS85Document60 pagesManual Operação Computador PAT DS85EdilsonNo ratings yet

- Mechatronics Lab 10 Studyofswitchesandrelays 20008Document7 pagesMechatronics Lab 10 Studyofswitchesandrelays 20008Kannan MuthusamyNo ratings yet

- ECE 523 Expt No. 1Document5 pagesECE 523 Expt No. 1Jerichson LautaNo ratings yet

- XRD Access and Format ConversionDocument5 pagesXRD Access and Format ConversionDương Minh MẫnNo ratings yet

- xiSWITCH InfographicDocument1 pagexiSWITCH InfographicDominicNo ratings yet

- (JWT) Nvidia Mcp73 Series - Ver10Document40 pages(JWT) Nvidia Mcp73 Series - Ver10manunscribdNo ratings yet

- CYD Outdoor P3.91mm 500x1000mmDocument6 pagesCYD Outdoor P3.91mm 500x1000mmDaniel KristiantoNo ratings yet

- Azure Cloud Design PatternsDocument8 pagesAzure Cloud Design PatternsAdepu RamMohan0% (1)

- Chapter 1 (Blue Boxes) Chapter 2 (Blue Boxes)Document4 pagesChapter 1 (Blue Boxes) Chapter 2 (Blue Boxes)Abegail GarcimoNo ratings yet