Professional Documents

Culture Documents

2013 - BestPractices For HLD

Uploaded by

Daniela CirnatuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2013 - BestPractices For HLD

Uploaded by

Daniela CirnatuCopyright:

Available Formats

Best Practices for

High-Level Disinfection

(HLD)

Objectives

At the end of this program, participants will be able to:

explain the Spaulding classification system for the

reprocessing of reusable medical devices,

understand the importance of effective cleaning and

decontamination prior to HLD,

identify commonly used agents for HLD,

discuss SGNA recommended steps for the HLD of

flexible endoscopes.

Spaulding Classification System

In 1968, Dr. Earle Spaulding devised a rational

approach to disinfection and sterilization that is

still in use today. He believed that instruments

and equipment should be reprocessed according

to the nature of the item and the level of risk

associated with their intended use.

This is referred to as Spaulding's classification system

and it has been refined and retained over the years,

because it is so clear and logical. The three (3) categories

he described were critical, semi-critical and non-critical.

Spaulding Classification System

Critical items are medical devices that enter sterile tissue

or the vascular system. These items should be sterile

when used. Examples include, but are not limited to:

surgical instruments, cutting endoscopic accessories that

break the mucosal barrier, endoscopes used in sterile body

cavities, cardiac, vascular or urinary catheters, implants,

needles and ultrasound probes used in the sterile body

cavities.

Spaulding Classification System

Semi-critical items are medical devices that come into

contact with non-intact skin or mucous membranes.

These items should be high level disinfected when used.

Examples include, but are not limited to: vaginal and

rectal probes, anesthesia equipment, laryngoscopes,

bronchoscopes and gastrointestinal endoscopes (and

accessories).

Spaulding Classification System

Non-critical items are medical devices that come into

contact with only intact skin. These items should receive

intermediate level disinfection, low-level disinfection or

cleaning. Intact skin acts is considered an effective

barrier to most organisms. Examples of non-critical item

include, but are not limited to: tourniquets and blood

pressure cuffs, linens, bed pans and stethoscopes.

The terminology adopted by the CDC and widely used,

describes disinfectants in terms of their activity as set out

below. This program will focus on high-level disinfection

(HLD).

High-level disinfectants are chemical sterilants, which when

used for a shorter exposure period than would be required

for sterilization, kill all microorganisms with the exception

of high numbers of bacterial spores.

Intermediate-level disinfectants may kill mycobacteria,

vegetative bacteria, most viruses, and most fungi but do not

necessarily kill bacterial spores

Low-level disinfectants may kill most vegetative bacteria,

some fungi, and some viruses.

Three Levels of Disinfection

Pre-cleaning must occur at point of use in order to keep

blood and other organic material from drying. Blood and

body fluids, as well as saline, are highly corrosive and can

damage instruments. Dried blood and debris is difficult, if

not impossible to clean during decontamination, which can

cause disinfection or sterilization not to be achieved.

Surgical instruments should be wiped as needed with

sterile surgical sponges moistened with sterile water during

the procedure to remove gross soil. Instruments with

lumens should be irrigated with sterile water.

Cleaning and Decontamination

Flexible endoscopes used on the sterile field should be

pre-cleaned to the following recommended steps:

1. Wipe external surfaces with a lint-free cloth saturated

with sterile water.

2. Alternate suctioning the channels with sterile water

and air.

3. Hand the endoscope and accessories to the circulator

as soon as possible, so he/she may pre-clean (follow

the steps on the next slide).

Cleaning and Decontamination

Flexible endoscopes used in GI/Endoscopy Centers

should be pre-cleaned in the Procedure Room wearing

appropriate PPE and using the following recommended

steps:

1. External surface of insertion tube should be cleaned

with a soft cloth or sponge and an enzymatic detergent.

2. Internal suction/biopsy channels cleaned by suctioning

copious amounts of enzymatic detergent and air.

3. Air/water channels flushed with enzymatic solution,

then flushed using low-pressure compressed air or a

syringe if air is not available.

Cleaning and Decontamination

4. Complex design components or channels should be

flushed or purged with water and/or enzymatic

detergent solution per the MFGs IFU.

5. The tip of the endoscope should be inspected for

damage to any surface and any working part, and for

cleanliness.

6. The video protective cap (if applicable) should be

attached after removing the endoscope from the light

source and suction.

7. Remove all detachable parts and immerse in enzymatic

detergent solution until transport.

Cleaning and Decontamination

Cleaning and Decontamination

Flexible endoscopes are some

of the most complex devices

for health care workers to

reprocess, due to their unique

design and multiple reprocessing

steps.

Strict adherence to the scope

MFGs validated instructions

for use (IFU) is required.

After pre-cleaning at point of use, contaminated items

should be immediately transported to the decontamination

area before any remaining organic material dries on the

surface, box lock, crevices or channels of the instruments.

Surgical instruments should be covered with a wet towel

or treated with an instrument cleaner prior to transport.

Contaminated items can expose health care workers and

can contaminate the environment during transport. A

sealed container should be used to avoid contaminating

the environment or exposure to health care workers. Per

OSHA, the transport container must be labeled to indicate

biohazardous contents.

Transport

Meticulous cleaning and decontamination must proceed

HLD or sterilization. Medical device manufacturers are

required to provide healthcare facilities with validated

reprocessing instructions for use (IFU).

It is important to have and follow each device MFGs IFU

to ensure worker and patient safety. This is especially true

for complex devices with multiple pieces that have joints,

crevices, lumens, ports and channels. Proper PPE is

required for all cleaning and decontamination steps.

Cleaning and Decontamination

Pasteurization is a heat-automated HLD process that uses

time and heat (i.e. 160-170F/21.7-25C) for 30 minutes

for HLD of heat-sensitive semi-critical devices. Medical

washer/pasteurizers have wash, rinse and pasteurization

cycles. Some pasteurizers offer quality assurance data

recorders that document the temperature and cycle time.

Heat HLD

For chemical HLD, health care facilities must purchase

FDA cleared HLD products as listed on the FDA website.

Products selected should be compatible and efficacious

with the materials or items to be disinfected.

The use of incompatible chemicals can damage the

surfaces of the instrument, causing corrosion, scratches

and other surface irregularities. Such damage can be a

challenge for cleaning, HLD, interfere with proper

function, and reduce the life and cosmetic appearance

of the device.

Chemical HLD

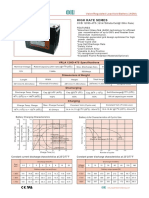

FDA-cleared Chemical sterilants and HLDs

Device Type # of Registered

Products

Chemical

Sterilization

High Level

Disinfection

Glutaraldehyde 17 X X

Hydrogen Peroxide 4 X X

Ortho-phthaldehyde

(OPA)

3 X

Peracetic Acid 2 X X

Sodium Hypochlorite 1 X

Chemical Vapor

w/Formaldehyde

2 X

Hydrogen Peroxide Gas

Plasma

1 X

Hydrogen Peroxide

without Plasma

1 X

Ozone Gas 1 X

Source: www.fda.gov/MedicalDevices/DeviceRegulationandGuidance/ReprocessingofSingle-UseDevices/ucm133514.htm

HLD requires appropriate temperature, contact time, and

length of use following solution activation. MFGs IFU

should be followed when preparing disinfectant solutions,

calculating expirations dates, and labeling solution soaking

containers.

Chemical HLD

Glutaraldehyde has been widely used for a long time in

health care facilities as a HLD for reusable medical devices.

Most solutions are acidic and must be activated to become

sporicidal. There are a variety of brand names available in

a variety of concentrations, with and without surfactants.

Chemical HLD

HLD and Steriliant

requires no mixing or

activation

Ortho-phthaladehyde (OPA) has demonstrated superior

mycobactericidal activity compared to glutaraldehyde and

requires no mixing or activation. OPA has been shown to

last longer before reaching its MEC and the concentration

of the active ingredient does not decrease with age alone.

Chemical HLD

Other solutions FDA-cleared for HLD include hydrogen

peroxide, peracetic acid and sodium hypochlorite in a

variety of concentrations and combinations. The FDA

website has a listing of manufacturers, active ingredients

and contact conditions for each cleared solution.

Chemical HLD

Because most HLDs are reused, they must be tested and

recorded prior to each use to assure that they remain

above their MEC. If the test strip fails, the HLD solution

should not be used, even if its within the reuse life.

Chemical HLD

Reprocessing of Flexible Endoscopes

Chemical HLD is recognized as the standard for the

reprocessing of flexible gastrointestinal endoscopes by

SGNA, ASGE, ACG, AGA, APIC and AST. Also, the

CDC and The Joint Commission recognize HLD as

appropriate for gastrointestinal endoscopes.

Standards of Infection Control in

Reprocessing of Flexible

Gastrointestinal Endoscopes

Are you following the updated 2012 SGNA Standards?

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5. Manual HLD:

1. Completely immerse the endoscope and all

removable parts in a basin of HLD.

a. The basin must be of a size to accommodate the

endoscope without undue coiling, and must have a

tight-fitting lid to contain the chemical vapors.

b. To prevent damage, the endoscope should be not

be soaked with other sharp instruments.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5. Manual HLD

2. Flush disinfectant into all channels of the

endoscope until it can be seen exiting the opposite

end of each channel. Take care that all channels are

filled with the chemical, and that no air pockets

remain within the channels.

SGNA Standards of Infection Control in

Reprocessing of Flexible Endoscopes

5A. Manual HLD:

a. Complete microbial destruction cannot occur

unless all surfaces are in complete contact with the

chemical.

b. Since internal contact cannot be visually confirmed

because of scope design, purging until a steady flow

of solution observed is necessary.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5A. Manual HLD:

3. Cover the soaking basin with a tight-fitting lid

to minimize chemical vapor exposure.

Note that:

a. Exposure to chemical vapors may present a

health hazard.

b. The reprocessing area should have engineering

controls to ensure good air quality.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5A. Manual HLD:

4. Soak the endoscope in the HLD solution for

the time/temperature required to achieve HLD.

Use a timer to verify soaking time.

5. Purge all channels completely with air before

removing the endoscope from the HLD solution.

Note that purging the channels preserves the

concentration and volume of the chemical, and

prevents exposure from dripping and spilling.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5A. Manual HLD:

6. RINSE (same as after Manual Cleaning)

a. Thoroughly rinse the endoscope and all removable

parts with clean water to remove residual debris and

detergent.

b. Purge water from all channels using forced air.

Dry the exterior of the endoscope with a soft, lint-

free cloth to prevent dilution of the liquid chemical

germicide used in subsequent steps.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

6. Drying:

a. Purge all channels with air until dry.

Note that:

1) Bacteria such as Pseudomonas aeruginosa have been

identified in both tap and filtered water, and may multiply

in a moist environment.

2) Avoid the use of excessively high air pressure which

can damage the internal channels of flexible endoscopes.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

6. Drying:

b. Flush all channels, including accessory channels,

with alcohol until the alcohol can be seen exiting the

opposite end of each channel.

1) 70% isopropyl alcohol is used to assist in drying the

interior channel surfaces.

2) It must be properly stored in a closed container

between uses, because when exposed to air, it rapidly

evaporates, and if less than recommended % level,

cannot be relied upon to assist in the drying process.

3) Alcohol flushes should be used even when sterile

water is used for rinsing.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

6. Drying:

c. Purge all channels with air. Note that alcohol

mixes with the remaining water on the channel

surfaces and acts to encourage evaporation of the

residual water as air flows through the channel.

d. Remove all channel adapters.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

6. Drying:

e. Dry the exterior of the endoscope with a soft,

clean lint-free towel.

f. Thoroughly rinse and dry all removable parts.

Do not attach removable parts (e.g. valves, etc.)

to the endoscope during storage as this can trap

liquid inside.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

7. Storage:

Hang the endoscope in a vertical position to facilitate

drying (with caps, valves, and other detachable components

removed, per MFGs IFU).

a. The storage area should be clean, well

ventilated and dust free.

b. Correct storage will prevent damage.

c. The interval of storage before use has

limited investigations and warrants further

data.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5B. Automated HLD:

Automated Endoscope Reprocessors (AERs)

standardize the disinfection process and decrease

personnel exposure to HLDs.

NOTE:

It is necessary to follow

all steps for the manual

cleaning prior to using

an AER.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

5B. Automated HLD:

An AER should have the following features:

a. Circulate fluids through all endoscope channels at an equal

pressure without trapping air. Channel flow sensors provide

an added measure of compliance.

b. Detergent and disinfectant cycles should be followed by

thorough rinse cycles and forced air to remove all used

solutions.

c. Disinfectant should not be diluted with any fluids.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

An AER should have the following features:

d. Machine should be self-disinfecting.

e. No residual water should remain in hoses and reservoirs.

f. Cycles for alcohol flushing and forced air drying are desirable.

g. Should also feature a self-contained or external water

filtration system.

In addition, a method to automatically store or print data

verification of cycle completion, is desirable.

SGNA Standards of Infection Control

in Reprocessing of Flexible Endoscopes

To use an AER:

1. Follow steps for manual cleaning of endoscope.

2. Prepare the AER according to the MFGs guidelines.

3. Place the endoscope in the AER and attach all channel

adapters according to the MFGs IFU.

a. The elevator channel of a duodenoscope has a very small

lumen. Since most AERs cannot generate pressure required to

force fluid through the lumen, a 2-5 ml syringe must be used

to manually reprocess (all steps) the elevator channel unless

the AER is validated to perfuse this channel.

To use an AER:

4. Place valves and other removable parts into the

soaking basin of the AER. Unless the AER has a

dedicated space for accessories, reprocess these

items separately.

5. If the AER has a cycle that uses enzymatic

detergent, it should be a product that is compatible

with the AER and the endoscope.

6. Set the AER for the appropriate time and

temperature depending on the chemical used.

7. Start the AER and allow it to complete all

cycles or phases. Note that if cycles or phases

are interrupted, HLD cannot be ensured and

the full cycle must be repeated.

To use an AER:

8. If AER does not include a final alcohol rinse,

this step should be done manually followed by

purging all the channels with air until dry.

The ERCP elevator and elevator channel must

be manually perfused and dried per MFGs

instructions.

9. Drying and storage procedures are the same as

described in the manual disinfection section.

To get a free copy of the complete SGNA

document, go to: www.sgna.org

Healthcare facilities are responsible for providing a safe

work and patient care environment. Patients, visitors, and

health care workers should be protected from injuries or

illnesses caused by hazardous chemicals.

When handling HLDs, personnel should wear protective

apparel that may include, but is not limited to:

100% nitrile rubber or 100% butyl rubber gloves when

handling glutaraldehyde. PVC gloves should not be

worn because they absorb glutaraldehyde.

Protective eye wear, face mask, and impervious gown.

Chemical HLD Safety

Glutaraldehyde should only be used in well ventilated

areas or in freestanding or vented chemical fume hoods.

Vapor generated from glutaraldehyde can may aggravate

preexisting respiratory conditions.

AAMI describes adequate ventilation as:

1. Room large enough to ensure adequate dilution of vapors.

2. 10 air exchanges per hour.

3. Exhaust located at the source of the discharge of vapors.

4. Fresh air return at ceiling level across room from exhaust vents.

5. Routine maintenance and surveillance of system.

6. Elimination of cross draft effects.

7. Air must not be recirculated.

Chemical HLD Safety

Glutaraldehyde can be absorbed by inhalation, ingestion

and through the skin. It has a detectable odor at 0.04 parts

per million volume (ppmv) and is irritating to skin and

mucous membranes at 0.3 ppmv.

Vapors are released whenever solutions are disturbed and

the surface tension is broken, such as mixing, adding and

removing equipment, or disposing of a glutaraldehyde

solution can cause a break in the surface tension.

Whenever the glutaraldehyde solution is not being

accessed, it should be covered with a tight-fitting lid.

Chemical HLD Safety

Glutaraldehyde vapor monitoring is important per

The American Conference of Governmental Industrial

Hygienists (ACGIH) which recommends a ceiling limit

of 0.05 ppm for occupational exposure.

OSHA has not established exposure limits; however,

OSHA can regulate exposure and has recommended

following the ACGIH limit.

Chemical HLD Safety

To avoid these glutaraldehyde issues, many health care

facilities have switched to using an OPA for HLD. The

Rapicide OPA/28 features the fastest disinfection time,

twice the reuse period of other OPA brands and guaranteed

materials compatibility.

Chemical HLD

Exposure monitoring is not required; however, OPA is

still a potential irritant of eyes, skin, nose and other tissues

resulting in symptoms such as stinging, excessive tearing,

coughing, and sneezing. Like glutaraldehyde, OPA fixes

proteins, allows for biofilm formation and exposure causes

staining on linen, skin, instruments and AERs.

Chemical HLD Safety

Personnel should receive initial training and competency

validation on procedures, chemicals used, and PPE and

should receive additional training when new equipment,

instruments, supplies, or procedures are introduced.

Employers must provide a written hazard communication

program, hazard evaluation, hazardous materials inventory,

Safety Data Sheets, labels on all containers of hazardous

chemicals, and employee training.

Training and Education

A quality control program should be established in all

areas where HLD is used. Quality control programs

should be documented and should include, but not be

limited to:

Orientation programs

Competency assurance

Continuing education

Quality control checks

Investigation of adverse events

Monitoring of solution replacement intervals

Quality Control Program

Surfaces of complex instruments require meticulous

cleaning in order to minimize infection control risks

to patients and staff. Inadequate cleaning can potentially

leave residual protein on a surface.

Quality control checks, such as

ATP systems and VERiFIND

Protein Detection Kit, provide

rapid and easy to read

cleaning verification.

Quality Control Program

Health care workers responsible for HLD must maintain

the technical skills needed to establish and maintain a safe

practice environment for patients, visitors and peers.

Administrative personnel must ensure competency

validation of personnel participating in decontamination

and HLD of reusable medical devices. The validation of

competencies should include all types of devices the

individual is authorized to reprocess.

CONCLUSION

THANK YOU!

SPSmedical Supply Corp.

Sterilization Products & Services

6789 W. Henrietta Road

Rush, NY 14543 USA

Fax: (585) 359-0167

Ph: (800) 722-1529

website: www.SPSmedical.com

2013, SPSmedical Supply Corp.

Free CE programs are available in our

Sterilization Classroom on the

SPSmedical website.

References & Resources

Association for the Advancement of Medical Instrumentation. (2010). Chemical sterilization and

high level disinfection in health care facilities (ANSI/AAMI ST58:2005/(R) 2010). Arlington, VA.

Association of periOperative Registered Nurses. (2013 Edition). Recommended Practices for

High-Level Disinfection.

Society of Gastroenterology Nurses and Association, Inc. (2007) Guideline for High-Level

Disinfectants & Sterilants for Reprocessing Flexible Gastrointestinal Endoscopes.

Society of Gastroenterology Nurses and Association, Inc. (2012) Standards of Infection Control

in Reprocessing of Flexible Gastrointestinal Endoscopes.

Occupational Health and Safety Administration (OSHA). (2012). Hazardous waste and emergency

response. www.osha.gov

Rutala, W. A., Weber, D. J., & the Healthcare Infection Control Practices Advisory Committee

(HICPAC). (2008). Guideline for Disinfection and Sterilization in Healthcare Facilities.

You might also like

- Statistical Methods for Evaluating Safety in Medical Product DevelopmentFrom EverandStatistical Methods for Evaluating Safety in Medical Product DevelopmentA. Lawrence GouldNo ratings yet

- Eli Lilly Biotech Pilot Plant, Indianapolis, United States of AmericaDocument5 pagesEli Lilly Biotech Pilot Plant, Indianapolis, United States of AmericaShyam Sunder BudhwarNo ratings yet

- Biological Evaluation of Medical Devices / Biosafety: Applicable ProductsDocument5 pagesBiological Evaluation of Medical Devices / Biosafety: Applicable ProductsAnonymous iqoU1mtNo ratings yet

- Iec62304 3Document5 pagesIec62304 3Abdul RahmanNo ratings yet

- ISO 18113-1 2022 Ed.2 - Id.79866 Publication PDF (En)Document60 pagesISO 18113-1 2022 Ed.2 - Id.79866 Publication PDF (En)Qualidade FrilaboNo ratings yet

- Cleaning and Sterilization GuideDocument48 pagesCleaning and Sterilization GuideFrankArenasNo ratings yet

- Rockwell Software Product CatalogDocument36 pagesRockwell Software Product CatalogAdhemar RodoNo ratings yet

- Lecture7 Introduction To Medical Devices ManagementDocument7 pagesLecture7 Introduction To Medical Devices ManagementRula BastoniNo ratings yet

- ZFP Op Man - EN PDFDocument142 pagesZFP Op Man - EN PDFMohamed Abd El-Fattah GalalNo ratings yet

- Regulatory Samvad Feb 2020Document19 pagesRegulatory Samvad Feb 2020vibhu yadavNo ratings yet

- Bioinformatics CompaniesDocument18 pagesBioinformatics Companiesmy.dear.sirNo ratings yet

- Principles of Software EngineeringDocument2 pagesPrinciples of Software EngineeringKr UthayanNo ratings yet

- Lecture4 Introduction To Medical Devices ManagementDocument9 pagesLecture4 Introduction To Medical Devices ManagementRula BastoniNo ratings yet

- Pacs (Picture Archiving and Communication Systems) & Vna (Vendor Neutral Archives)Document18 pagesPacs (Picture Archiving and Communication Systems) & Vna (Vendor Neutral Archives)LawrenceNo ratings yet

- Auditing Operating Systems Networks: Security Part 1: andDocument24 pagesAuditing Operating Systems Networks: Security Part 1: andAmy RillorazaNo ratings yet

- Defect Tracking SystemDocument21 pagesDefect Tracking Systemmughees1050% (2)

- High Performance Medical Grade Resins PDFDocument11 pagesHigh Performance Medical Grade Resins PDFGeorge CobraNo ratings yet

- ART - 0608 - Improving Ops With EBRDocument4 pagesART - 0608 - Improving Ops With EBRkumar_chemicalNo ratings yet

- Recent Trends in Sterile InspectionsDocument40 pagesRecent Trends in Sterile InspectionsSilke IgemannNo ratings yet

- Data Integrity & SecurityDocument3 pagesData Integrity & SecurityReshma WawhalNo ratings yet

- McKesson Letter of FDA's Proposed Medical Device Data Systems RuleDocument5 pagesMcKesson Letter of FDA's Proposed Medical Device Data Systems RulehuffpostfundNo ratings yet

- Detailed Design Specification TemplateDocument8 pagesDetailed Design Specification Templatemaddy_cooldude6763No ratings yet

- IntegrityDocument25 pagesIntegrityChhatrashal Singh RathoreNo ratings yet

- Glucometer SRSDocument15 pagesGlucometer SRSYisha XiaNo ratings yet

- Competitive Analysis of Market Leaders in Data ModelingDocument24 pagesCompetitive Analysis of Market Leaders in Data ModelingXavier Martinez Ruiz100% (2)

- SBSI CoagulationDocument3 pagesSBSI Coagulationjay primaNo ratings yet

- Global Medical Device Nomenclature: Mark Wasmuth Secretary General GMDN AgencyDocument23 pagesGlobal Medical Device Nomenclature: Mark Wasmuth Secretary General GMDN AgencyluNo ratings yet

- Seven Principles of Software TestingDocument3 pagesSeven Principles of Software TestingpedromoritzNo ratings yet

- Dell EMC Validates Your Virtualized Genetec Video Management System Before It Reaches Your HandsDocument11 pagesDell EMC Validates Your Virtualized Genetec Video Management System Before It Reaches Your HandsPrincipled TechnologiesNo ratings yet

- GMP 2023 - Sessions PresentationsDocument289 pagesGMP 2023 - Sessions PresentationsKamanashish Chowdhury100% (1)

- Automated Packaging Systems Autolabel Pi-4000 In-Line, Programmable, Thermal Transfer PrinterDocument2 pagesAutomated Packaging Systems Autolabel Pi-4000 In-Line, Programmable, Thermal Transfer PrinterEdgar HoowerNo ratings yet

- SharePoint 2013 Qualif. Pack List-1Document2 pagesSharePoint 2013 Qualif. Pack List-1akbarmulangathNo ratings yet

- Software Quality EnginneringDocument26 pagesSoftware Quality EnginneringVinay PrakashNo ratings yet

- Research Paper Artificial Intelligence in Medical JEEV AI-IJRASETDocument8 pagesResearch Paper Artificial Intelligence in Medical JEEV AI-IJRASETIJRASETPublicationsNo ratings yet

- 03 System TestingDocument17 pages03 System TestingramNo ratings yet

- Data Validation, Processing, and Reporting Data ValidationDocument8 pagesData Validation, Processing, and Reporting Data ValidationNaga Ajay Kumar DintakurthiNo ratings yet

- Aplicabilidad 21CFR11Document6 pagesAplicabilidad 21CFR11Aydee RojasNo ratings yet

- Symbient PRD TemplateDocument5 pagesSymbient PRD TemplateBikash Chandra SahooNo ratings yet

- Test Design Specification TemplateDocument4 pagesTest Design Specification TemplateRifQi TaqiyuddinNo ratings yet

- SDLCDocument22 pagesSDLCRishabh AroraNo ratings yet

- What Is JIRA?: Issue: Every Task, Bug, Enhancement Request BasicallyDocument1 pageWhat Is JIRA?: Issue: Every Task, Bug, Enhancement Request Basicallylilithknowsitall6393No ratings yet

- Oven ManualDocument28 pagesOven ManualromwellNo ratings yet

- Backup and Recovery Best Practices For Leadership and PlanningDocument5 pagesBackup and Recovery Best Practices For Leadership and PlanningVijay Jangetti SanjeeviNo ratings yet

- FDA Design Considerations For Devices Intended For Home UseDocument27 pagesFDA Design Considerations For Devices Intended For Home Use0SpYkeNo ratings yet

- Manufacturing Execution System (MES) : ServiceDocument48 pagesManufacturing Execution System (MES) : ServiceNhat Tan MaiNo ratings yet

- Smart Lab E BookDocument24 pagesSmart Lab E BookNaveed MubarikNo ratings yet

- Strategic Management and Project Management: PurposeDocument10 pagesStrategic Management and Project Management: PurposesurapolNo ratings yet

- Road Map To Design Successful Software - Ictms (Integrated Clinical Trial Management System)Document8 pagesRoad Map To Design Successful Software - Ictms (Integrated Clinical Trial Management System)SanjayPravinbhaiVarmaNo ratings yet

- Requirement Engineering SummaryDocument14 pagesRequirement Engineering SummaryBob ChanNo ratings yet

- Seilevel Agile Requirements Document TemplateDocument10 pagesSeilevel Agile Requirements Document TemplateSanoufar ANo ratings yet

- GMP Simatic Pcs7-V90 en En-UsDocument184 pagesGMP Simatic Pcs7-V90 en En-UshuykhiemNo ratings yet

- Broch Biostat-STR-Flexsafe SBI1509-e NeuDocument24 pagesBroch Biostat-STR-Flexsafe SBI1509-e NeuBrian VasquezNo ratings yet

- FDA Pre Submission Cover LetterDocument5 pagesFDA Pre Submission Cover Letteregdxrzadf100% (2)

- Medical Product DevelopmentDocument64 pagesMedical Product DevelopmentIhsanNo ratings yet

- CDRH201461 HomeUseDesign FinalGuidanceDocument27 pagesCDRH201461 HomeUseDesign FinalGuidancerehmanabbasiNo ratings yet

- Unique Device IdentificationDocument15 pagesUnique Device IdentificationSureshNo ratings yet

- AG3110 - Vue PACS and Vue Archive 12.2 Administration GuideDocument177 pagesAG3110 - Vue PACS and Vue Archive 12.2 Administration GuideAndreia Yamamoto MorassutiNo ratings yet

- Sferd Handbook Flexible Endoscopes Cleaning Disinfection - en PDFDocument106 pagesSferd Handbook Flexible Endoscopes Cleaning Disinfection - en PDFmochkurniawanNo ratings yet

- Software ArchitectureDocument30 pagesSoftware ArchitectureMukesh RegmiNo ratings yet

- Labelling Nutrition-Vitamins Minerals-Guidance Tolerances Summary Table 012013 enDocument1 pageLabelling Nutrition-Vitamins Minerals-Guidance Tolerances Summary Table 012013 enDaniela CirnatuNo ratings yet

- 202103011101-Ghid de Prevenire Iaam 2021Document52 pages202103011101-Ghid de Prevenire Iaam 2021Daniela CirnatuNo ratings yet

- Notification File Food Supplement / Fortified Food: OmpanyDocument4 pagesNotification File Food Supplement / Fortified Food: OmpanyDaniela CirnatuNo ratings yet

- Disinfection and SterilizationDocument23 pagesDisinfection and SterilizationDaniela Cirnatu100% (1)

- Mayo Clinic Proceedings: Vitamin D Supplementation During The COVID-19 PandemicDocument2 pagesMayo Clinic Proceedings: Vitamin D Supplementation During The COVID-19 PandemicDaniela CirnatuNo ratings yet

- Patient Identity NicknameDocument2 pagesPatient Identity NicknameDaniela CirnatuNo ratings yet

- 11.5 ArsenicDocument18 pages11.5 ArsenicDaniela CirnatuNo ratings yet

- Hepatorenal and Genotoxic Effects of Genetically Modified Quail Meat in A 90-Day Dietary Toxicity Study in MiceDocument7 pagesHepatorenal and Genotoxic Effects of Genetically Modified Quail Meat in A 90-Day Dietary Toxicity Study in MiceDaniela CirnatuNo ratings yet

- CXS - 197e Norma Codex AVOCADO Draft EnglishDocument6 pagesCXS - 197e Norma Codex AVOCADO Draft EnglishDaniela CirnatuNo ratings yet

- Chemistry Investigatory ProjectDocument19 pagesChemistry Investigatory ProjectDivya Vatsa50% (4)

- Study On Detergent PowderDocument12 pagesStudy On Detergent PowderRamesh Choudhary100% (2)

- Spectracron 110 FD Alkyd Enamel PDFDocument2 pagesSpectracron 110 FD Alkyd Enamel PDFSatish Vishnubhotla0% (1)

- Analysis of Cement by Banana FiberDocument48 pagesAnalysis of Cement by Banana FiberKyaw KhineNo ratings yet

- Chapter 9 The Endocrine SystemDocument1 pageChapter 9 The Endocrine SystemacNo ratings yet

- Chemistry Investigatory Project 2017-18Document29 pagesChemistry Investigatory Project 2017-18Ashok KumarNo ratings yet

- Realistic Well Planning With Dynamic Well Control ModellingDocument7 pagesRealistic Well Planning With Dynamic Well Control ModellingAoun MuhammadNo ratings yet

- 30 Sewage Treatment PlanDocument63 pages30 Sewage Treatment PlanYuri Duri100% (1)

- Final Examination: Your Answer On The Space Provided For. (40 Points)Document5 pagesFinal Examination: Your Answer On The Space Provided For. (40 Points)Wichel AnnNo ratings yet

- Carbon NanotubesDocument15 pagesCarbon NanotubesLaraib HabibNo ratings yet

- Universitas Ahmad Dahlan - JellyDocument15 pagesUniversitas Ahmad Dahlan - JellyMaqfirotul LailyNo ratings yet

- Trepanning Positioning Welding ManualDocument14 pagesTrepanning Positioning Welding ManualGovindan PerumalNo ratings yet

- S Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowDocument30 pagesS Start of Lesson E End of Lesson Grading 1-5: Learning Outcomes Progress ArrowYu Seung KimNo ratings yet

- Mil PRF 9954DDocument8 pagesMil PRF 9954DjhscribdaccNo ratings yet

- Single Phase Heat Transfer and Pressure Drop Characteristics of Micro-Fin TubesDocument2 pagesSingle Phase Heat Transfer and Pressure Drop Characteristics of Micro-Fin TubesGerehNo ratings yet

- 11 - Isomerism in TMCDocument18 pages11 - Isomerism in TMCMohit KambojNo ratings yet

- Eucomex - Eucomex - EnglishDocument2 pagesEucomex - Eucomex - EnglishNelson IbarraNo ratings yet

- Simulation of Reactive Distillation ColumnDocument6 pagesSimulation of Reactive Distillation ColumnthanhndbNo ratings yet

- Special Issue Honoring Don Mackay: Oil Spill Impact Modeling: Development and ValidationDocument16 pagesSpecial Issue Honoring Don Mackay: Oil Spill Impact Modeling: Development and Validationbrice mouadjeNo ratings yet

- 4 Elements, Mixtures and Compounds: WorksheetDocument3 pages4 Elements, Mixtures and Compounds: WorksheetMfanafuthiNo ratings yet

- Toxicity of Common Laboratory Chemicals To Human Red Blood Cells Laboratory ActivityDocument4 pagesToxicity of Common Laboratory Chemicals To Human Red Blood Cells Laboratory ActivityKuven Malig-onNo ratings yet

- High Rate Series: CCB 12HD-475Document1 pageHigh Rate Series: CCB 12HD-475orunmila123No ratings yet

- Rusting WorksheetDocument2 pagesRusting WorksheetSelwah Hj AkipNo ratings yet

- Magnetic Terms and UnitsDocument3 pagesMagnetic Terms and UnitsDeepak Choudhary DCNo ratings yet

- Advanced Inorganic Chemistry (CHM4301) : Alkenes and AlkynesDocument19 pagesAdvanced Inorganic Chemistry (CHM4301) : Alkenes and AlkynesAnonymous lClX1bNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Name: Grade & Section: Teacher: Score: General Direction: This Is A 50-Item Test, Read Each Direction Written in Every Type of Test, Answer ThisDocument4 pagesName: Grade & Section: Teacher: Score: General Direction: This Is A 50-Item Test, Read Each Direction Written in Every Type of Test, Answer ThisMara LabanderoNo ratings yet

- Hot Tap ProcedureDocument6 pagesHot Tap ProcedureNatarajan MurugesanNo ratings yet

- 2002Document38 pages2002B GirishNo ratings yet

- Pulp Mill Odor ControlDocument6 pagesPulp Mill Odor Controlalakazum28No ratings yet