Professional Documents

Culture Documents

Adobe - Construction - V1

Uploaded by

lokiyo1965Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adobe - Construction - V1

Uploaded by

lokiyo1965Copyright:

Available Formats

MUD BRICK (ADOBE) CONSTRUCTION

Contents

Background .......................................................................................................................................... 2

Resources ............................................................................................................................................ 3

Advantages and Disadvantages ...................................................................................................... 4

Structural Considerations ............................................................................................................... 6

Resistance to Erosion by Rainfall .................................................................................................. 8

Case Studies ..................................................................................................................................... 12

The information presented in this module is for general guidance only for those considering the

use of mud brick construction and Engineers Without Borders strongly recommends that advice

be sought from a suitably qualified engineer for particular projects.

This module has been prepared by Dr Kevan Heathcote (Kevan.Heathcote@gmail.com) based on

his experience in earth building and his research into earth wall durability. He was a member

of the standards committee which produced New Zealand standard NZS 4297 Engineering

Design of Earth Buildings. The sections on structural considerations and resistance to erosion

have been based on that standard and on Dr Heathcotes experience and have been simplified

to reflect the low technology inherent in mud brick construction.

Background

Unstabilised mud bricks are made by mixing wet clayey soil with straw and forming them into

brick shaped molds. The molds are then removed and the bricks allowed to dry in the sun.

Adobe bricks are typically 250mm by 350mm by 100mm and are laid flat to produce 250 mm

thick walls. Their mass is around 14 kg (density around 1600 kg/m

3

) and mortar of similar

material is used to build walls. Mud bricks are made from low clay content soils stabilised with

bitumen emulsion in New Mexico but in other areas unstabilised bricks are made from higher

clay content soils.

Next to timber mud brick construction is the oldest construction technique in the world,

originating in biblical times in Mesopotamia. Whilst it is a common form of low cost

construction in low rainfall areas such as the Middle East (Egypt, Yemen, Iran, Irak, Pakistan,

India and Afganistan) and parts of China it is also historically common in higher rainfall regions

such as the Andes regions of South America, Spain and Portugal. Adobe itself is an Arabic

word and we can assume that this type of construction was transferred to Spain by the Arab

conquest and was then taken by the Spanish to their colonies in South America. Mud brick

construction is prevalent in New Mexico and the style of construction there is commonly

referred to as the Adobe style. More recently mud brick construction has been revived as an

environmentally sympathetic material in places such as the southern states of Australia and

New Zealand.

900 Year Old Taos Pueblo in New Mexico Mud Brick House in Australia

Traditionally mud brick construction has relied on external renders for protection from the

weather in relatively low rainfall areas (repaired each year in the case of the Taos Pueblo) or

on large roof overhangs in higher rainfall areas to prevent rainfall damage.

Resources

Building with earth bricks & rammed earth in Australia, Earth Building Association of

Australia (EBAA), no date. EBAA has been established for some time and has a lot of

experience in this area. See http://www.ebaa.asn.au/

Bulletin 5 Earth-Wall Construction (4

th

Ed) National Building Technology Centre, 1987.

Used to be referenced in the Building Code of Australia as the de-facto standard but

removed in 2008. Earth building for BCA now requires an earth building to be certified

by an expert person

Adobe bricks in New Mexico, Edward W. Smith, New Mexico Bureau of Mines and

Mineral Resources, 1982 Comprehensive technical coverage of adobe building in New

Mexico.

The Earthbuilders Encyclopedia by Joseph M. Tibbets, Southwest Solaradobe School,

New Mexico, 1988. Detailed coverage of all aspects of earth building with particular

reference to New Mexico.

Dirt Cheap The Mud Brick Book, John and Jerry Archer,Compendium, 1976. Practical

construction handbook from Australia

Making the Adobe Brick, Eugene H. Boudreau, Fifth Street Press, 1971. Practical

construction handbook from the USA

New Zealand Earth Building Standards NZS 4297:1998 Engineering Design of Earth

Buildings, NZS 4298:1998 Materials and Workmanship For Earth Buildingsand NZS

4299:1998 Earth Buildings Not Requiring Specific Design very comprehensive set,

NZS 4297 probably too detailed for mud brick construction though.

http://www.youtube.com/watch?v=qCEdDM-c7RQ Video of owner builder construction

of mud brick house in South Africa.

Mud Bricks Drying (Source virginmedia.com)

Advantages and Disadvantages

The advantages of mud brick construction are

Well designed mud brick buildings look warm and inviting

Mud brick manufacture utilises the natural material of the site and requires no

artificial additives (except bitumen when that is used as a stabiliser).

Mud brick manufacture need not require mechanical equipment and has negligible

embodied energy if material sourced at site.

The technology is very simple and almost anyone can build in this material.

Because they have high thermal mass mud brick buildings are very effective in reducing

temperature swings in climates where the daily temperature swings are large. When

combined with good passive solar design mud brick houses are extremely comfortable,

warm in winter and cool in summer.

Unreinforced round mud brick buildings have good earthquake resistance. See B.

Samali, W. Jinwuth, K. Heathcote, and C. Wang, Seismic Capacity Comparison between

Square and Circular Plan Adobe Construction, The Twelfth East Asia-Pacific

Conference on Structural Engineering and Construction, January 26-28, 2011, Hong

Kong SAR, China

The main disadvantages are

Unreinforced rectangular mud brick buildings perform extremely poorly in earthquakes.

In the 2003 earthquake in Bam, Iran many mud brick buildings were completely

destroyed. Note however that Dominic Dowling of UTS in Sydney has devised a system

of reinforcing rectangular mud brick buildings with bamboo to withstand earthquakes.

See http://www.thinkbigmagazine.com/mindset/258-earthquake-proof-housing and

www.world-housing.net/uploads/WHETutorial_Adobe_English.pdf

The insulation properties of earth walls is not good (R approximately 0.5 m

2

K/W for

250 thick walls) and therefore thermal performance is poor in very hot or very cold

climates with small daily temperature fluctuations.

Local soils are not always suitable for use or straw or bitumen may not be readily

available.

Can require frequent maintenance if exposed to extreme weather unless stabilised or

rendered.

Drying of bricks prior to laying can be a problem in areas of high humidity.

Structural Considerations

Soil Composition In general mud bricks can be made with most soils having clay

contents between 5% and 45% and with at least 30% sand and not more than 50% silt.

In Australia and New Zealand mud brick soils tend to have clay contents in the upper

range with straw added to reduce shrinkage cracks. In New Mexico there is a

requirement for soils to have at least 50% sand to reduce cracking and clay contents

are generally in the lower range. These bricks are typically stabilised with bitumen

emulsion (5-12% by mass) to prevent excessive water absorption. The figure below

shows the general range of soil types used but in the end an acceptable soil is one that

produces bricks which are suitable for their exposure environment (see rainfall erosion

resistance below)

Foundations Foundations can be the most expensive part of the construction if made

of concrete. For stable soils 400 wide by 300 deep footings are needed with 2 /12 mm

diameter reinforcement bars top and bottom. For moderately reactive soils the depth

needs to be 600 mm with 4 bars top and bottom. For more detail see AS2870

Residential Slabs and Footings. Alternatives to concrete on stable soils can be stone

slabs or small pieces placed in wire boxes (gabions) and in some cases the natural soil

stabilised with 10-15% cement may be suitable. For all footings a durable plinth such as

fire clayed bricks, rendered stone or mud bricks with 10-15% cement should be

constructed to provide protection from splashing rain at the base of the wall. Such a

plinth should be at least 225 mm above ground level.

Compressive Strength of Walls the overall compressive strength of load bearing

walls is generally not a problem with light roof loads. The compressive strength of mud

brick walls may be assumed to be 0.5 MPa, provided individual bricks do not break when

dropped from waist high onto a hard surface (See EBAA reference in Resources

section). Load factors of 1.2 for dead load and 1.5 for live load should be used together

with a capacity reduction factor () of 0.6 (If all loads are dead loads this gives an

allowable stress of 0.25 MPa). Reduction factors of [1-2.3(eccentricity of load/wall

thickness)] should be applied for eccentric loads and [1.18-0.03(wall height/wall

thickness)] for wall height (maximum 1.0). Wall heights should not be greater than [12

wall thickness] for walls supported at the top and bottom and 6 for free standing walls.

For localised bearing stresses such as lintels compressive stress of 1 MPa can be

assumed but it must be remembered that lintels should be stiff enough to provide an

even bearing. A timber top plate is usually provided on the top of walls to spread the

roof loads and concentrated loads should receive special attention.

In-Plane Shear Strength of Walls a wall shear stress of 0.035 MPa can be assumed

for determining resistance to wind loading (shear walls) and low earthquake loading.

Out-Of-Plane Loads - for determining resistance to wind loading it is suggested that a

yield line approach be used with = 0.6 and a flexural tensile strength of 0.1 MPa

(100 kPa). [For a long wall the yield line method gives M

y

= wH

2

/8 and for a square

panel M

y

= wH

2

/24]

As an example consider a 3 metre by 3 metre panel which is 250 thick

M

capacity

= 0.61000.25

2

/6 = 0.625 kN.m/m

M

yield

= w3

2

/24 = 0.375w

Equating the two gives an ultimate wind load resistance of 1.67 kPa (0.5 kPa for a long

3 metre high wall).

This approach can also be adopted to give a guide to the resistance of rectangular

buildings to low earthquake loading, bearing in mind that the corners of rectangular

buildings are the main weak points in out of plane loading (and need to be well

reinforced).

For example the above wall has a mass of around 400 kg/m

2

(Density of 1600kg/m

3

)

In this case w = 400a/9.8 = 40.82a giving M

yield

of 15.3a kN.m which when equated

to a wall capacity of 0.625 kN.m gives an earthquake resistance of 0.04g

For a more detailed analysis of earthquake loading refer to Appendix B of NZS

4287:1998

Quality Control at least one brick for every 1000 used should be subjected to the

drop strength test (see above) and one brick in every 2500 should be assessed for

resistance to rainfall (see below) where walls are to be exposed to the weather.

Resistance to Erosion by Rainfall

The resistance of mud brick walls to rainfall depends on the composition of the soil, the

intensity of wind-driven rain and on the exposure of the wall. In general it is best to avoid

exposure by providing wide eaves to buildings, although some soils produce bricks that are

remarkably resistant to erosion by wind-driven rain. External coatings such as renders or

linseed oil may be used to improve erosion resistance but these may require frequent renewal.

Walls that are not protected from the weather or otherwise coated with a proven erosion

resistant coating shall be of sufficient durability to withstand the effect of driving rain

appropriate to their exposure situation. Such durability may be verified as follows.

a) Wall exposure situations shall be classified as Exposure Category 1 to 7 according to the

following Table.

Typical Wind Speed During Rainfall

Annual Rainfall (mm) Low Medium High

<600 mm 1 3 5

600-899 mm 2 4 6

900-1300 mm 3 5 7

Where eaves extend away from the wall greater than one quarter of the wall height an

Exposure Category one less than given by the above table may be assumed with a minimum

Exposure Category of 1. Where eaves extend away from the wall greater than one half of

the wall height an Exposure Category two less than given by the above table may be

assumed with a minimum Exposure Category of 1.

b) Resistance of walls to erosion due to driving rain shall be indicated by a Test

Resistance Number (TRN) determined for samples subjected to the Geelong Drip test in the

case of walls of Exposure Categories 1-3 and by the UTS Spray Test for Exposure

Categories 4-7 Wall samples shall have a TRN greater than or equal to their Exposure

Category to be considered acceptable.

NOTE: To the best of available knowledge walls that meet the above criteria may in

normal circumstances be expected to have an acceptable (less than 15 mm) erosion over a

50 year period. In the event that the Designer of the building requires a better

performance the required TRN of the wall material shall be stated on the drawings.

GEELONG DRIP TEST

a) The specimen is mounted inclined at 27 degrees to the horizontal.

b) The specimen shall be tested without any surface coating.

c) lOO ml of water is discharged vertically 400mm onto the sloped surface of the

sample.

d) The water must be discharged onto the sample within 20 - 60 minutes.

e) The pit depth is to be measured with a cylindrical probe with an end diameter of

3mm.

(Sourced from EBAA Publication)

Classification of Results

Pit Depth <5 mm TRN = 3

Pit Depth > 5mm but < 10 mm TRN = 2

Pit Depth >10 mm but< 15 mm TRN = 1

Pit Depth >15 mm Sample suitable for Internal Use Only

10

UTS SPRAY TEST

a ) G e n e r a l

The test consists of spraying the face of a sample of the material (brick or rammed earth

wall) with water for a period of one hour

b) Test Detai l s

The spray nozzle to be used shall be a Fulljet 1550 nozzle (Available from

Spraying Systems Company)

Water pressure shall be 70 kPa measured with a reliable pressure guage

The specimen shall be positioned 350 mm from the nozzle and at right angles to

it. The nozzle shall be horizontal and the specimen face vertical.

The specimen is to be protected with a 150 mm diameter shroud with the gap

between brick and shroud sealed with a gasket

The erosion depth shall be measured by placing a straight edge across the erosion

crater and measuring the deepest extent of the crater using a pencil as a depth

guage.

Classification of Results

Depth of Erosion <5 mm TRN = 7

Depth of Erosion <10 mm TRN = 6

Depth of Erosion >10 but < 20mm TRN = 5

Depth of Erosion >20 but <30mm TRN = 4

Depth of Erosion >30 mm Suitable for Internal Use Only

11

12

Case Studies

Mud Brick Building in Gaza

See http://ingaza.wordpress.com/2009/05/07/denied-cement-re-building-with-mud/

Small Mud Brick Test Building

You might also like

- Adobe Brick ConstructionDocument19 pagesAdobe Brick ConstructionKoushali Banerjee100% (1)

- A Review On Bricks and Stabilized Compressed Earth BlocksDocument8 pagesA Review On Bricks and Stabilized Compressed Earth Blocksjacobomr1980No ratings yet

- Types of Earth ConstructionDocument2 pagesTypes of Earth Constructionsy100% (1)

- "Rammed Earth": By: Jay Mark C. Sabubu Bsce-5ADocument22 pages"Rammed Earth": By: Jay Mark C. Sabubu Bsce-5AJet Espejon JavierNo ratings yet

- 34.traditional Earth Construction and GlazingDocument9 pages34.traditional Earth Construction and GlazingmariyaNo ratings yet

- Mud BrickDocument3 pagesMud Brickabc50% (2)

- Earth Building (Not Mine) Knowledge Belongs To EveryoneDocument20 pagesEarth Building (Not Mine) Knowledge Belongs To Everyonemorfeas85No ratings yet

- On Strawble ConstructionsDocument17 pagesOn Strawble ConstructionsNanditha Mandava ChowdaryNo ratings yet

- Compressed Earth Building BlocksDocument21 pagesCompressed Earth Building BlocksGinette CasillaNo ratings yet

- The end of concrete: Pros and cons of an unsuccesful technologyFrom EverandThe end of concrete: Pros and cons of an unsuccesful technologyRating: 1 out of 5 stars1/5 (1)

- Earthquake-Resistant Adobe ConstructionDocument19 pagesEarthquake-Resistant Adobe ConstructionNikhil SaxenaNo ratings yet

- 1922 - Building in Cob and Pisé de Terre. A Collection of Notes From Various Sources On The Construction of Earth WallsDocument51 pages1922 - Building in Cob and Pisé de Terre. A Collection of Notes From Various Sources On The Construction of Earth WallsParisTiembiNo ratings yet

- Introduction to CSEB ProductionDocument33 pagesIntroduction to CSEB ProductionsakthivelsvsNo ratings yet

- Adobeconstruct 19 NeubDocument34 pagesAdobeconstruct 19 NeublailanuitNo ratings yet

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- FoundationDocument6 pagesFoundationAnonymous dK9Qi2XjNo ratings yet

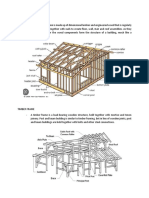

- Framing PDFDocument5 pagesFraming PDFKenneth Ignacio ArcillaNo ratings yet

- Rammed Earth SpecificationsDocument5 pagesRammed Earth SpecificationsBASSANTESSAM90100% (1)

- Stabilized Earth FloorsDocument26 pagesStabilized Earth Floorsrevathi hariharanNo ratings yet

- Topic1 3 Foundations Footings 13Document19 pagesTopic1 3 Foundations Footings 13Hussein JaberNo ratings yet

- Stone Masonry and Brick Stone MasonryDocument3 pagesStone Masonry and Brick Stone MasonryMuhafeez GoolabNo ratings yet

- These Solar Backup Generators Deliver 4 Times More Power Than Other Models!Document35 pagesThese Solar Backup Generators Deliver 4 Times More Power Than Other Models!Athiyo MartinNo ratings yet

- Timber Frame Construction Project PresentationDocument18 pagesTimber Frame Construction Project PresentationscegtsNo ratings yet

- Super Adobe ConstructionDocument3 pagesSuper Adobe ConstructionGilles GautierNo ratings yet

- Adobe Horno: by Blake BuffordDocument3 pagesAdobe Horno: by Blake BuffordGuillermo BustosNo ratings yet

- Bulletin127 Adobe Pressed and Rammed Earth Industries in New MexicoDocument60 pagesBulletin127 Adobe Pressed and Rammed Earth Industries in New Mexicoelias sofikitisNo ratings yet

- Adobe Brick SpecificationDocument4 pagesAdobe Brick Specificationc2anNo ratings yet

- Moisture Relations and Physical Properties of Wood - US - DoEDocument20 pagesMoisture Relations and Physical Properties of Wood - US - DoEPeter KimbelNo ratings yet

- The Australian Earth Building HandbookDocument11 pagesThe Australian Earth Building Handbookkukuh kurniawan dwi sungkono0% (3)

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- BIA - Technical Notes On Brick ConstructionDocument1,007 pagesBIA - Technical Notes On Brick ConstructionAdam Greenlaw100% (2)

- Curing Cement PlasterDocument3 pagesCuring Cement PlasterChristian LlagasNo ratings yet

- Build Earthquake-Resistant Homes with GeomeshDocument41 pagesBuild Earthquake-Resistant Homes with GeomeshgkutNo ratings yet

- A Review of Rammed Earth ConstructionDocument118 pagesA Review of Rammed Earth ConstructionLuciana PintoNo ratings yet

- Thatched Roofs and Open Sides - The Architecture of Chickees and Their Changing Role in Seminole SocietyDocument217 pagesThatched Roofs and Open Sides - The Architecture of Chickees and Their Changing Role in Seminole SocietyJohn AbeNo ratings yet

- Ferrocement Construction Technology and Its Applications PDFDocument20 pagesFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)

- AdobeUSA09 PAPER SantosFilhoDocument6 pagesAdobeUSA09 PAPER SantosFilhopliniosantosfilhoNo ratings yet

- Rammed Earth Sample Production: Context, Recommendations and ConsistencyDocument6 pagesRammed Earth Sample Production: Context, Recommendations and ConsistencyTamas VanyiNo ratings yet

- NMAC 14.7.4 New Mexico Earthen Building Materials CodeDocument16 pagesNMAC 14.7.4 New Mexico Earthen Building Materials CodeAlejandro JiménezNo ratings yet

- Utilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentDocument25 pagesUtilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentLarisa ChindrișNo ratings yet

- Straw Bale PrimerDocument8 pagesStraw Bale PrimerVmeupNo ratings yet

- Making BricksDocument45 pagesMaking BricksSasha NashNo ratings yet

- Book Construction of Fills MonahanDocument288 pagesBook Construction of Fills MonahanBill Feng100% (1)

- III. Sill Floor JointsDocument8 pagesIII. Sill Floor JointsCristian Morar-BolbaNo ratings yet

- Slab On GradeDocument59 pagesSlab On GradeAntonysamy SanthanamNo ratings yet

- Producing hollow cement blocks with the CETA-RAM machineDocument17 pagesProducing hollow cement blocks with the CETA-RAM machinecowboyNo ratings yet

- Everything you need to know about skillion roofsDocument2 pagesEverything you need to know about skillion roofsTeodoro Miguel Carlos IsraelNo ratings yet

- Earth and Straw Constructions in CreteDocument90 pagesEarth and Straw Constructions in CreteCosmic BoatripNo ratings yet

- Roof Sheathing FasteningDocument4 pagesRoof Sheathing Fasteningnumber_25No ratings yet

- Sustainable Materials Lab Report-Etale TunyaDocument9 pagesSustainable Materials Lab Report-Etale TunyaEtale TunyaNo ratings yet

- Adobeconstruct1964neub PDFDocument36 pagesAdobeconstruct1964neub PDFRandall HittNo ratings yet

- Natural Stone Masonry inDocument130 pagesNatural Stone Masonry inIdaHodzicNo ratings yet

- Earth BuildingDocument20 pagesEarth BuildingMukesh WaranNo ratings yet

- Principles of ConstructionDocument78 pagesPrinciples of ConstructionY SAHITHNo ratings yet

- The Architect's Portable Handbook: First-Step Rules of Thumb for Building Design 4/eFrom EverandThe Architect's Portable Handbook: First-Step Rules of Thumb for Building Design 4/eNo ratings yet

- Improving Durability and Service Life of Mud HousesDocument8 pagesImproving Durability and Service Life of Mud Housesmarc chucuenNo ratings yet

- How To Make Mud BricksDocument3 pagesHow To Make Mud Bricksskoricmilan100% (1)

- Mud Construction TechnologyDocument14 pagesMud Construction TechnologyTESFA SILNo ratings yet

- Straw Bale Construction ManualDocument151 pagesStraw Bale Construction ManualStrawbale100% (1)

- Containers 2012Document97 pagesContainers 2012buddhansamratNo ratings yet

- Containers 2012Document97 pagesContainers 2012buddhansamratNo ratings yet

- Effects Plaster Skin ConfinementDocument12 pagesEffects Plaster Skin Confinementlokiyo1965No ratings yet

- Manual Well Drilling ManualDocument56 pagesManual Well Drilling ManualSulaiman FairusNo ratings yet

- National Design Handbook Prototype On Passive Solar Heating andDocument210 pagesNational Design Handbook Prototype On Passive Solar Heating andlokiyo1965No ratings yet

- Concrete Filled Steel Columns for Tall BuildingsDocument20 pagesConcrete Filled Steel Columns for Tall BuildingstaosyeNo ratings yet

- IRC 112 2011 Concrete Road Bridges PDFDocument289 pagesIRC 112 2011 Concrete Road Bridges PDFShanmuga Sundaram100% (2)

- T-88 Structural Aircraft Adhesive: Technical Data SheetDocument2 pagesT-88 Structural Aircraft Adhesive: Technical Data Sheetanon_271015207No ratings yet

- Reinforced Concrete Design FlowchartsDocument29 pagesReinforced Concrete Design FlowchartsRomulo TindoyNo ratings yet

- 02-01 Chap GereDocument17 pages02-01 Chap GereTortelliniTimNo ratings yet

- Microstructural Aspects of Fracture by Dimpled RuptureDocument24 pagesMicrostructural Aspects of Fracture by Dimpled RuptureWylliam Diel WagnerNo ratings yet

- Types of Failure Failure Theories For Ductile Materials Failure Theories For Brittle MaterialsDocument6 pagesTypes of Failure Failure Theories For Ductile Materials Failure Theories For Brittle MaterialsArturo GonzalezNo ratings yet

- Tall Building Initiative Performance EvaluationDocument30 pagesTall Building Initiative Performance EvaluationOscar Zúñiga CuevasNo ratings yet

- Me328 - Carabiner Project 1Document20 pagesMe328 - Carabiner Project 1api-534925017No ratings yet

- Rotating Steel Shafts Design GuideDocument3 pagesRotating Steel Shafts Design GuideaNo ratings yet

- Design of Silos 2010Document21 pagesDesign of Silos 2010Topaca Paec100% (3)

- Measurement of Fracture Toughness: Standard Test Method ForDocument34 pagesMeasurement of Fracture Toughness: Standard Test Method FortuanNo ratings yet

- Module 3Document51 pagesModule 3Chandru VelNo ratings yet

- 1 - Management Plan (Draft)Document18 pages1 - Management Plan (Draft)Sahil SharmaNo ratings yet

- 3M VHB Window Tape G23Document3 pages3M VHB Window Tape G23philipNo ratings yet

- An Integrated Wellbore Stability Study To Mitigate Expensive WellDocument164 pagesAn Integrated Wellbore Stability Study To Mitigate Expensive WellMangojak SiagianNo ratings yet

- CE4Document20 pagesCE4Memo Ly0% (1)

- Summary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingDocument37 pagesSummary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingBryan Franklin Vilca ChavezNo ratings yet

- IpexDocument110 pagesIpexlucasprojetosNo ratings yet

- Bs Na en 1993 1 1 2005Document16 pagesBs Na en 1993 1 1 2005yogs_184100% (1)

- Materials Testing Lab Brochure 2013.04.18Document2 pagesMaterials Testing Lab Brochure 2013.04.18hali10No ratings yet

- VW - TL 4225-2006-05 - (Alloyed Quenched and Tempered Steel 22MnB5 Uncoat or Precoat)Document11 pagesVW - TL 4225-2006-05 - (Alloyed Quenched and Tempered Steel 22MnB5 Uncoat or Precoat)jorge solisNo ratings yet

- Steering Gear Regulations-LloydsDocument15 pagesSteering Gear Regulations-Lloydsd_damnNo ratings yet

- Academic programs for Mechanical EngineeringDocument31 pagesAcademic programs for Mechanical EngineeringRohit NathNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- General Properties of MaterialsDocument3 pagesGeneral Properties of MaterialsMaricris OntogNo ratings yet

- Uhpc PDFDocument22 pagesUhpc PDFcatia_v5rNo ratings yet

- Factors affecting properties of needlepunched nonwovensDocument15 pagesFactors affecting properties of needlepunched nonwovensvermadeenNo ratings yet

- Quality Control of TabletsDocument11 pagesQuality Control of TabletsshdphNo ratings yet