Professional Documents

Culture Documents

Base Plate Design

Uploaded by

Manoj KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate Design

Uploaded by

Manoj KumarCopyright:

Available Formats

Steel structures are designed by elastic method as per IS: 800.

Grade of steel considered for the primary members having minimum yield strength of

250 MPa. & hence the permissible stresses for the same is taken as 0.66x250= 165 MPa.

LOAD CALCULATIONS:

1. Dead load:

a. Self weight of structure is taken by Staad except purlins & sheeting.

1.3Kg/m

2

= 0.06 KN /m

2. Live load :

0.2 Kn/m

2

= 1.16 KN /m

on the rafters.

3. Wind load:

As per IS 875 part - 3

Vz = vbxk1xk2xk3

Here

K1 = 1.0

K2 = 1.0

K3 = 1.0

Vb = basic wind speed = 33m/s

Vd = Design wind speed = k1 x k2 x k3 x Vb = 1 x 1.05 x 1 x 33 = 33m/s.

Pz = 0.6x33^2/1000 = 0.65 kn/m

2

.

These data have been input in staad for computation

STAAD ANALYSIS has been carried out with the above forces with all possible load

combinations and DESIGN CHECK as per IS: 800 have also been run in STAAD.

STAAD INPUT file, Support Reactions, and Design Check tables are furnished here

below.

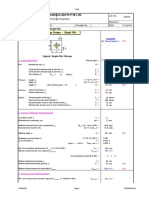

8. DESIGN OF BASE PLATE AND ANCHOR BOLTS (TYP):

From Staad Pro, we have calculated the support reactions as under.

For C1:

Fx = 0.136 Kn.

Fy = 365.171 Kn.

Resultant Force at support = R = Sq. RT (0.136

2

+ 365.171

2

)

= R = 365.17 Kn.

Assume the Bearing strength of concrete as 4 Mpa.

Total Resultant Load on base plate = 365.17 Kn.

Area of Base Plate required = 365.17x 1000 / 4 = 91292.5 mm

2

DESIGN OF BASE PLATE

Plate size = 750 x 750 mm

Maximum compressive force = 365.17 KN.

Area of Base Plate = 365.17 x 1000 / 4 = 91,292.5 mm

2

We take base Plate as 750mm x 750 mm.

Area of base plate = 5, 62,500 mm

2

Projections of the base plate beyond the overall dimensions 220 mm x 420mm are

750 620 / 2 = 65mm = b

750 620 / 2 = 65mm = a

Upward Pressure on the base plate = w = 365.17 x 1000 / 750x750 = 0.65 Mpa.

Thickness of Base Plate = t = sq.rt [3w /dbs (a2 b

2

/ 4)

Where dbs = Permissible stress in the steel slab bases = 185 Mpa.

Thickness of base plate = t = sq.rt [3 x 0.65/ 185 (25

2

-5

2

/4)]

t = 5.63 mm

Hence take the base plate = t = 20mm.

DESIGN OF ANCHOR BOLTS:

As per Staad-Pro, the maximum forces acting on the node 479 as under

Total Load = 365.17 Kn.

Lets provide 12-20dia high tensile bolts.

Permissible stress in shear = 100 Mpa.

Load Taken by each bolt = 365.17 / 12 = 30.43 Kn.

Strength of each bolt against shear = 3.14 x 20x20 /4 x 100 = 31.4 Kn > 30.43 Kn

Hence safe and stable.

You might also like

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- Car Park Shade StructureDocument14 pagesCar Park Shade Structuremsiddiq1100% (2)

- Pile Cap Design PDFDocument4 pagesPile Cap Design PDFอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Base Plate Design BSDocument4 pagesBase Plate Design BSvinujohnpanickerNo ratings yet

- Foundation 2Document333 pagesFoundation 2akem mig100% (1)

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- Base Plate INDIA CODEDocument4 pagesBase Plate INDIA CODEbama sankari100% (1)

- Slab Designer As Per IS 456-2000Document7 pagesSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Pile Cap DesignDocument28 pagesPile Cap Designpwd2007No ratings yet

- End Plate ConnectionDocument3 pagesEnd Plate ConnectionibrahimNo ratings yet

- Pile Cap Design - ColumnsDocument7 pagesPile Cap Design - ColumnsMohit VatsNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- RC Corbel Design EC2Document3 pagesRC Corbel Design EC2Tommaso PasconNo ratings yet

- Eccentric FootingDocument13 pagesEccentric FootingMegatech Engineering Consultants100% (1)

- Design of Concrete Stump With Axial Load and Minimum MomentDocument4 pagesDesign of Concrete Stump With Axial Load and Minimum MomentIbrahim A.L100% (1)

- Monolithic Staircase DesignDocument5 pagesMonolithic Staircase DesignAzraiAzizNo ratings yet

- Composite Beam ExampleDocument7 pagesComposite Beam ExampleFong Pei TyngNo ratings yet

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- Wind Load Calculation (Based On CP3)Document2 pagesWind Load Calculation (Based On CP3)Darshan ShahNo ratings yet

- Deck SheetDocument2 pagesDeck SheetmaheshbandhamNo ratings yet

- Design Calculation of Falsework For Construction of 1800mm Thick Slab - r3Document14 pagesDesign Calculation of Falsework For Construction of 1800mm Thick Slab - r3Chan Kin Cheung100% (1)

- Crack Width CalculationDocument2 pagesCrack Width CalculationprabhuNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodePre SheetNo ratings yet

- Hoarding DesignDocument6 pagesHoarding DesignBhavin JoshiNo ratings yet

- Flat Slab DesignDocument6 pagesFlat Slab DesignforbeskaNo ratings yet

- Pile Cap DesignDocument35 pagesPile Cap Designعصام السامرائي100% (2)

- Splice 03Document15 pagesSplice 03LexNo ratings yet

- Indian Codes - Steel Design Per IS 800:2007Document3 pagesIndian Codes - Steel Design Per IS 800:2007dineshNo ratings yet

- Base Plate DesignDocument9 pagesBase Plate DesignprashantkothariNo ratings yet

- Design of DomeDocument5 pagesDesign of DomeAmarjeet SinghNo ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- Slab Design As Per IS 456Document7 pagesSlab Design As Per IS 456RitaBiswas100% (1)

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Base Plate Design As Per Is 800Document3 pagesBase Plate Design As Per Is 800K SrikanthNo ratings yet

- Welded Splice ConnectionDocument14 pagesWelded Splice Connectionamitkukna0% (1)

- Check For Requirement of Boundary ElementDocument9 pagesCheck For Requirement of Boundary ElementJai ThakkarNo ratings yet

- Is - 875 Wind LoadDocument1 pageIs - 875 Wind Loadvk100% (1)

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Document4 pagesDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Purlin DesignDocument20 pagesPurlin Designarif_rubin100% (1)

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Slab Design Full Report: Material and Design DataDocument22 pagesSlab Design Full Report: Material and Design DataazwanNo ratings yet

- Structural Design of Pile 400 MM DIADocument3 pagesStructural Design of Pile 400 MM DIAkarthik_iit100% (2)

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Design of Underground Water TankDocument6 pagesDesign of Underground Water TankAlfred PatrickNo ratings yet

- Pilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Document25 pagesPilecap Design EC2 (1) (Autosaved) (Strut and Tie Method)Thaung Myint OoNo ratings yet

- Retaing Wall L ShapedDocument2 pagesRetaing Wall L ShapedvanshajNo ratings yet

- Jurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesDocument34 pagesJurutera Perunding Bersama SDN BHD Free Standing RC Retaining Wall Project Date Designed by Assumptions / PreamblesKokKeiNo ratings yet

- Railing DesignDocument2 pagesRailing DesignSutha100% (1)

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduNo ratings yet

- End Plate Moment Connection (Bolt)Document72 pagesEnd Plate Moment Connection (Bolt)mengxiao74No ratings yet

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 pagesDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNo ratings yet

- Design of Piping SupportsDocument15 pagesDesign of Piping SupportsWaleed EzzatNo ratings yet

- Design of Steel Truss MembersDocument6 pagesDesign of Steel Truss MembersSaim WaqarNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikk Suriya100% (1)

- Https:/bpmis - Gov.rw/asset Data/form 201251/files/element 77 3d9990a970Document22 pagesHttps:/bpmis - Gov.rw/asset Data/form 201251/files/element 77 3d9990a970emuan vanessaNo ratings yet

- Tank Design As Per IS803 and API650Document36 pagesTank Design As Per IS803 and API650Vikash Kumar Singh100% (1)