Professional Documents

Culture Documents

PR 427 Zowarka Publications

Uploaded by

Nikhil Singh0 ratings0% found this document useful (0 votes)

35 views10 pagesbook for induction motor..

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbook for induction motor..

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views10 pagesPR 427 Zowarka Publications

Uploaded by

Nikhil Singhbook for induction motor..

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

INDUCTION MOTOR PERFORMANCE TESTING WITH AN

INVERTER POWER SUPPLY, PART 2

By:

R.C. Zowarka

T.J. Hotz

J.R. Uglum

H.E. Jordan

Center for Electromechanics

The University of Texas at Austin

PRC, Mail Code R7000

Austin, TX 78712

(512) 471-4496

PR 427

13th Electromagnetic Launch Technology Symposium, Potsdam (Berlin), Germany, May 22-25,

2006

IEEE Transactions on Magnetics, vol. 43, no. 1, January 2007, pp. 275-278

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

Induction Motor Performance

Testing With an Inverter

Power Supply: Part 2

Raymond C. Zowarka, Thomas J . Hotz, J ohn R. Uglum, and Howard E. Jordan

The University of Texas at Austin Center for Electromechanics

Abstract -- The development of high power density electrical machines

continues to accelerate, driven by military, transportation, and industrial

needs to achieve more power in a smaller package. Higher speed

electrical machines are a recognized path toward achieving higher

power densities.

Existing industry testing standards describe well-defined

procedures for characterizing both synchronous and induction machines.

However, these procedures are applicable primarily to fixed frequency

(usually 60 or 50 Hz) power supplies. As machine speeds increase well

beyond the 3,600 rpm limitation of 60 Hz machines, a need for

performance testing at higher frequencies is emerging.

An inverter power supply was used to conduct a complete series of

tests on two induction motors (0.5 MW and 1.0 MW) with speeds up to

~5,000 rpm. The use of a non-sinusoidal power supply with limited

power output capability required the development of measurement

techniques and testing strategies quite different than those typically used

for 60/50 Hz testing.

Instrumentation and techniques for measuring voltage, current and

power on harmonic rich waveforms with accuracies approaching 1% are

described. Locked-rotor and breakdown torque tests typically require

large kVA input to the motor, much higher than the rated load

requirement. An inverter sized for the rated load requirements of the

motor was adapted to perform locked-rotor and breakdown torque tests.

Inverter drive protection features such as anti-hunting and current limit

that were built into the inverter had to be factored into the test planning

and implementation.

Test results are presented in two companion papers. Part 1

correlates test results with the results of an algorithmic induction motor

analysis program. Part 2 (this paper) presents the test results compared

with a Matlab simulation program and also provides a comprehensive

discussion of the instrumentation that was essential to achieve testing

accuracy.

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

I. INTRODUCTION

Testing practices for synchronous and induction machines have been developed

over the years and documented in detail in IEEE Standards [1,2]. Since the vast

majority of electrical machines are applied at electrical power frequencies, it is to be

expected that the testing procedures are based on a fixed frequency power supply,

usually 50 or 60 Hz. An increasing number of induction motors are now being designed

to operate from inverters and, therefore, are not constrained to 50 or 60 Hz power.

Testing at 50 or 60 Hz does not provide the performance information needed for the

inverter-powered motors operating at higher frequencies.

An inverter rated to power the induction motors being tested was used as the

power supply for a complete series of tests which included:

No-load saturation

Locked-rotor saturation

Breakdown torque

Load performance

Temperature test

II. TEST RESULTS COMPARED TO SIMULATION

In designing the motor characterization procedure using a pulse width

modulated (PWM) drive, a commercial motor with known parameters was tested first.

As part of that testing, a simulation of the system was developed using Matlab. The

comparison of experiment to simulation is presented in this section of the paper. The

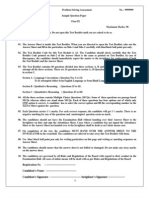

overall experimental setup is shown in Fig. 1.

Fig. 1. Instrumentation diagram for testing 500 hp Toshiba motor

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

The inverter drive is a Magnetek model GPD515 1,600 hp motor drive. The

induction motor is a 500 hp Toshiba model 3F4500L3C9632 motor.

The nameplate data for the Magnetek motor drive is:

Model #: G5U-5C00

S/N: 223319-1687

hp/kVA: 1,600

FLA: 1,600

Input volts: 600

Phases: 3

Hertz: 60

Fault kA: 10

Input amps: 1,800

In simulation, a three-phase PWM voltage source inverter with unipolar voltage

switching logic was used to model the Magnetek motor drive [3]. The motor is rated at

500 hp, 3,580 rpm, 460 V, and 60 Hz. The induction motor was modeled with the

Matlab SimPowerSystems software asynchronous machine in the dq rotor reference

frame. This software contains several motor modeling packages. The asynchronous

machine in the dq rotor reference frame [4] was used here. Nameplate information of

importance for the simulation is given in Table 1.

The first test simulated was the

no-load test. Figs. 2 and 3 demonstrate

that the long term behavior of the

simulation results match the

experimental data. Figs. 4 and 5

expand the detail of the PWM and once

again demonstrate a good match of

simulation to experiment. The second

series of tests simulated were the

locked-rotor tests. Figs. 6 and 7 show

that the long term behavior of the

simulation matches experiment with no

offset or drift. Figs. 8 and 9 demonstrate

that the detailed switching of the PWM

was captured well in simulation. For the

locked rotor test a torque of 186 ft-lb

was measured in the experiment. The

simulation predicted a torque of 178 ft-

lb.

TABLE 1. TOSHIBA MOTOR SIMULATION INPUT DATA

Parameter and units Value

Nominal power (VA) 436,000

Voltage line-line (V) 460

Frequency (Hz) 60

Stator resistance (ohm) 0.00306

Stator inductance (H) 83.82e-6

Rotor resistance referred

to stator (ohm)

0.01507

Rotor inductance referred

to stator (H)

168e-6

Mutual inductance (H) 6.14e-6

Inertia (kg-m

2

) 5.85

Friction factor (N-m-s) 0.05

Pole pairs 1

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

Fig. 2. No-load test inverter PWM voltage, simulation, and measured values

Fig. 3. No-load test inverter output current, simulation, and measured values

Fig. 4. Expanded view of no-load voltage, simulation and measured values

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

Fig. 5. Expanded view of no-load current, simulation, and measured values

Fig. 6. Locked-rotor test inverter PWM voltage, simulation, and measured values

Fig. 7. Locked-rotor test inverter output current, simulation, and measured values

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

Fig. 8. Expanded view of locked-rotor voltage, simulation, and measured values

Fig. 9. Expanded view of locked-rotor current, simulation, and measured values

The good comparison of simulation to experimental results gave confidence that

this was a good tool for predicting the performance of the prototype motor. In addition,

the simulation could be used to accurately predict the harmonics that would be

introduced into the motor.

III. INSTRUMENTATION SELECTION

Several iterations were required to arrive at an instrumentation set that would

reliably measure the PWM output. Four different voltage probes were used and two

current monitors were evaluated. The first voltage probe used was a North Star 500:1

divider. These probes are designed for single-ended compensation, but it can be seen

from Fig. 1 that a differential measurement is required to measure the line to line

voltage. Next, LEM Instrument Company's voltage monitors were used, but were found

to have too narrow a bandwidth to collect the 2 kHz switching frequency of the drive.

Tektonix voltage probes were used, but once again the need to compensate the probes

differentially proved problematic. The probe could be compensated at one square wave

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

frequency, but it would not hold compensation for a range of frequencies as required to

measure the PWM voltage output.

Subsequently, voltages were measured using a voltage divider built by The

University of Texas at Austin Center for Electromechanics (UT-CEM) that had been

used on high voltage measurements for railgun testing for years. The high voltage leads

are connected to two series 1 k resistors and then looped 10 times around a Pearson

current transformer. The output is isolated and fairly immune to noise. The problem

with this instrument is that the power resistors change their value with heating. The

final probe used was a Test Precision Instruments battery operated unit specifically

designed for measuring the output of PWM drives. This instrument was found to work

well. A similar evaluation was performed for the current measurement. The testing

commenced using Pearson current transformers, but they did not provide noise

immunity in the PWM environment. From here LEM Instrument Company's current

sensors were tested and found to perform well with good noise characteristics. A

discussion of the instrumentation is presented in Table 2.

IV. ACCURACY OF MOTOR CHARACTERIZATION USING A PWM

Two complete sets of no-load and locked-rotor tests were run on the Toshiba

500 hp, 3,580 rpm motor using the Magnetek inverter [5] as the power supply. All of

the data was taken by transducers interfacing to Nicolet digital oscilloscopes and then

downloaded to the computer. The data was computer-analyzed to obtain both the

fundamental and rms values of the following parameters.

TABLE 2. INSTRUMENTATION LIST

Instrument Model Discussion

VOLTAGE

North Star 500:1 voltage divider PVM-10 Not designed to be compensated

as differential pair

LEM voltage sensor #LV100-

2000

Not enough bandwidth

Tektronix 1000X high voltage prove P6015A Not designed to be compensated

as differential pair

UT-CEM voltage divider Difficult to size power resistor for

continuous operation

Test Precision Instruments voltage probe ADF25A Performed well, battery

maintenance an issue

CURRENT

Pearson Electronics wide band current

transformer pulse current transformer

301X Noise susceptibility in PWM

environment

LEM current sensors #HAX-

2500S

Performed well

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

Phase voltage

Phase current

Power per phase

All three phase powers summed to provide the total power

The torque was also measured during the locked-rotor test. The torque signal

was averaged to smooth out the instantaneous variations.

This test data was then further analyzed to determine the equivalent circuit

parameters and also the locked-rotor and no-load performance. Most of the information

obtained from this series of tests can be compared against data on this motor, which was

provided by Toshiba. The results are summarized in Table 3.

TABLE 3. SUMMARY OF NO-LOAD AND

LOCKED-ROTOR TEST RESULTS

Item UT-CEM Toshiba Error %

a

R1 (ohms) 0.00337 0.00306 10.1

R2 (ohms) 0.00218

b

0.00297 -26.6

X

1

+X

2

(ohms) 0.08674

c

0.1128 -23.1

X

0

(ohms) 2.31496 3.27 -29.2

Z

LOCKED

(ohms) 0.08691 0.11296 -23.1

T

LOCKED

(lb-ft) 1,212.8

d

1,319.4 -8.1

I

LOCKED

(Amperes) 3,689

d

3,625 1.7

I

NO-LOAD

(Amperes) 114.3 97.0 17.8

W

NO-LOAD

(Watts) 6,476

F & W (Watts) 3,500

Core loss (Watts) 2,976

NOTES

a. Based on Toshiba data

b. Measured @ 10 Hz

c. Measured @ 10 Hz and corrected to 60 Hz

d. Measured @ 60 Hz and reduced voltage

extrapolated to 460 V

All of the equivalent circuit parameters except for R1 and Xm depend upon the

measurements made during the locked-rotor test. The secondary circuit parameters,

namely, R2 and X2 are quite frequency-dependent for a motor in the 500 hp size range.

This is because of the current crowding effect in the rotor bars, often referred to as

deep-bar effect. The Toshiba-provided equivalent circuit parameters are likely the

parameters under full-load operating condition where the rotor frequency (slip

frequency) is approximately 0.3 Hz.

The inverter will not operate satisfactorily at that low frequency. The first series

of tests was run at 60 Hz., which is the usual industrial practice. The tested value of R2

varied from Toshibas value by 400%. Therefore a second set of tests was run using a

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

10 Hz frequency for the locked-rotor tests and, as shown in Table 1, the measured value

of R2 correlated within 27% against Toshibas value.

V. CONCLUSIONS

A commercial 500 hp motor was tested using the inverter powered test

facility described in both the Part 1 and Part 2 papers. The 500 hp motor

was also simulated using Matlab.

A comparison of the simulated results and the experimental data for both no-

load tests and locked-rotor test has been presented. The results are in very

good agreement and inspire confidence in the testing instrumentation and

procedures.

The final instrumentation assembly was the result of several iterations trying

different combinations of measurement equipment. The final instrumen-

tation list is presented.

VI. REFERENCES

1. IEEE Standard Test Procedure for Polyphase Induction Motors and Generators,

New York, IEEE Standard 112-1996, The Institute of Electrical and Electronics

Engineers, Inc.

2. IEEE Guide: Test Procedures for Synchronous Machines, IEEE Standard 115-

1995, New York, The Institute of Electrical and Electronics Engineers, Inc.

3. N. Mohan, T. M. Undeland, and W. P. Robbins, Power Electronics Converters,

Applications and Design, J ohn Wiley and Sons, Inc., 1995.

4. P.C. Krause, Analysis of Electric Machinery, McGraw-Hill, 1986.

5. Magentek (now Yaskawa) G5-HHP drive, 575 V class, 1,600 hp.

2007 IEEE. Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution to servers or lists, or to reuse any copyrighted component of this work

in other works must be obtained from the IEEE.

You might also like

- NIT Warangal Circuit Theory Lecture PlanDocument2 pagesNIT Warangal Circuit Theory Lecture PlanNikhil SinghNo ratings yet

- Heat TransferDocument32 pagesHeat TransferAmit Chambial100% (1)

- Class IX - 2012-13 - Problem Solving Assessment - Sample Paper - CBSEDocument21 pagesClass IX - 2012-13 - Problem Solving Assessment - Sample Paper - CBSESulekha Rani.R.No ratings yet

- S.C. Gupta, V.K. Kapoor Fundamentals of Mathematical Statistics A Modern Approach, 10th Edition 2000Document1,303 pagesS.C. Gupta, V.K. Kapoor Fundamentals of Mathematical Statistics A Modern Approach, 10th Edition 2000Nikhil Singh80% (193)

- Solar Thermal EnergyDocument34 pagesSolar Thermal EnergyAditya RaiNo ratings yet

- Exhibitor ListDocument34 pagesExhibitor ListNikhil SinghNo ratings yet

- Std11 Acct EMDocument159 pagesStd11 Acct EMniaz1788100% (1)

- Summer Training Project ReportDocument37 pagesSummer Training Project ReportSumit Bansal100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kraus & Naimer C Switches PDFDocument56 pagesKraus & Naimer C Switches PDFJefMur100% (1)

- Integrated Solutions Provider: Energy AutomationDocument16 pagesIntegrated Solutions Provider: Energy AutomationLaurentiu100% (1)

- DS3 DS3E DS3L ManualDocument148 pagesDS3 DS3E DS3L Manualbui tien boNo ratings yet

- Pulse-Width Modulation Inverters: Pulse-Width Modulation Is The Process of Modifying The Width of The Pulses in A PulseDocument7 pagesPulse-Width Modulation Inverters: Pulse-Width Modulation Is The Process of Modifying The Width of The Pulses in A PulseEngrAneelKumarAkhani100% (1)

- Imprtant Problems EE339Document28 pagesImprtant Problems EE339sultanNo ratings yet

- 41 PE MACO 00010 0Z001 D041 Lista de PlanosDocument3 pages41 PE MACO 00010 0Z001 D041 Lista de PlanosChino RHNo ratings yet

- SR-MT2410 User Manual - V1.1 WUNDocument16 pagesSR-MT2410 User Manual - V1.1 WUNVikica KovačevićNo ratings yet

- Cable DiagnosticsDocument42 pagesCable DiagnosticsaqazamNo ratings yet

- Mwe Mid 2Document2 pagesMwe Mid 2Veerayya JavvajiNo ratings yet

- RF Product Selector GuideDocument49 pagesRF Product Selector GuideZamir HussainNo ratings yet

- Mixed-Signal ASIC Design For Digital RF Memory Applications: Michael J. Groden James R. MannDocument5 pagesMixed-Signal ASIC Design For Digital RF Memory Applications: Michael J. Groden James R. MannmdalkilicNo ratings yet

- Alat Geolistrik Buatan Jerman PDFDocument6 pagesAlat Geolistrik Buatan Jerman PDFYudha AgungNo ratings yet

- Home Automation EvolutionDocument52 pagesHome Automation EvolutionJohn Forbes NashNo ratings yet

- SIS-Preventive Maintenance For BatteriesDocument2 pagesSIS-Preventive Maintenance For BatteriesmkNo ratings yet

- TP10 Fundamentals of Power System Modeling v2018-11-12 43rd ANC (FCLeynes)Document37 pagesTP10 Fundamentals of Power System Modeling v2018-11-12 43rd ANC (FCLeynes)Edwin LoquinaNo ratings yet

- 2018 Winter BEE 3I - M - 22310 - MEDocument12 pages2018 Winter BEE 3I - M - 22310 - MEketanpawar322No ratings yet

- Kit 17. LM386 Low Voltage Audio Amplifier: Circuit DescriptionDocument2 pagesKit 17. LM386 Low Voltage Audio Amplifier: Circuit Descriptionszolid79No ratings yet

- IEC-E04-S02 Rev 3 Sep 2020 Dry Type Transformers up to 500 kVADocument9 pagesIEC-E04-S02 Rev 3 Sep 2020 Dry Type Transformers up to 500 kVA15150515715No ratings yet

- BZX85 - C62Document5 pagesBZX85 - C62Luis Enrique PariapazaNo ratings yet

- Frenic vg7sDocument50 pagesFrenic vg7sramon navaNo ratings yet

- TelarisDocument1 pageTelariszeljkoNo ratings yet

- (S1) SP025 KMKT (Q)Document10 pages(S1) SP025 KMKT (Q)nur afrina andridonasNo ratings yet

- Riyadh Telephone CablesDocument37 pagesRiyadh Telephone CablesMuhammad YousufNo ratings yet

- Gpu 18 Om-2084a Series 500392aDocument214 pagesGpu 18 Om-2084a Series 500392aCRISTIAN MOLANO100% (1)

- Electron Configuration Lesson 2Document9 pagesElectron Configuration Lesson 2brian catianNo ratings yet

- 21FU6RLX - Service ManualDocument20 pages21FU6RLX - Service ManualLuis Galo Benavides Flores100% (1)

- Questions & Answers On Commutation Process & Excitation MethodsDocument23 pagesQuestions & Answers On Commutation Process & Excitation Methodskibrom atsbhaNo ratings yet

- Full ReportDocument26 pagesFull ReportMohammad FaisalNo ratings yet

- Split-Phase Control Achieving Complete Soft-Charging Operation of A Dickson Switched-Capacitor ConverterDocument3 pagesSplit-Phase Control Achieving Complete Soft-Charging Operation of A Dickson Switched-Capacitor ConverterLeMeniz InfotechNo ratings yet

- Validate Logic Gate Truth TablesDocument8 pagesValidate Logic Gate Truth Tablesshivansh50% (2)