Professional Documents

Culture Documents

Water Moniter Spec

Uploaded by

Sami Thirunavukkarasu0 ratings0% found this document useful (0 votes)

65 views4 pagesff

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentff

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views4 pagesWater Moniter Spec

Uploaded by

Sami Thirunavukkarasuff

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

1/4

"UL LISTED - SHOOTFIRE-2000/1000" JRCP TYPE AQUA FOAM NOZZLE 2000/1000

Variable Flow Monitor Fixed at 2000/1000 GPM

TECHNICAL DATA SHEET

1. GENERAL DESCRIPTION

The manually operated non-aspirating Foam Monitor fully made of Stainless

Steel, capable to discharging 2000 / 1000 US GPM (7570 & 3785 LPM) at 100

PSI (7 bar) inlet pressure over a range of 70 to 80 meters in horizontal direction

and 35 to 40 meters in vertical direction. The Foam Monitor has adjustable

flow discharge capacity of 2000 US GPM / 1000 US GPM in single Nozzle.

Foam monitors are very compact in construction and gives good flexibility of the

operation while fighting with fire. Foam proportioning 3 % is done with help of

water operated Jet Ratio Controller Pump (JRCP) suitable for feeding foam

concentrate solution to the moni tor nozzle from a distance of 100 mtrs. The

Foam Monitor has facility for converting Water/Foam jet to fog and vice-versa

very quickly and easily, even during continuous operation. Foam Monitor is

provided with two numbers of self-locking swivel gear bearing for rotation in

horizontal and vertical direction through hand wheel operation even under high

operating pressures. A single fire fighter can manually operate the Foam Monitor

with large flow & long-range capability. The monitor assembly is designed to

withstand the nozzle reaction force experienced during the operation of jet/ fog.

The MONITOR and JRCP having the variable discharge capacity of 2000 &

1000 GPM is approved & listed by UL (USA).

FOAM

2/4

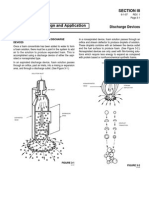

General Arrangement Drawings for 1000/2000 GPM Foam Monitor.

2. SALIENT FEATURES

Certified and Approved by (UL) Underwriters Laboratory USA for use with variable flow.

High Discharge Capacity of 2000 & 1000 US GPM (7570 & 3785 LPM) with Single Nozzle at 100 PSI inlet pressure.

Excellent Horizontal throw of 70 to 80 Meter long and above

Excellent Full Fog & Semi Fog Coverage.

Variable flow of 2000 & 1000 GPM in single nozzle (benefit of two monitor in single monitor)

JRCP is Capable to induct foam from a distance of 100 to the monitor nozzle.

JRCP with 3% induction to match variable flow (1000 & 2000 GPM) of monitor nozzle.

Very compact in construction and gives good flexibility of the operation while fire fighting

Low Expansion, so less loss of foam & more cooling effect on burning surface.

Quick change over from jet to fog even under water pressure with single firefighter.

Easy maneuverability in horizontal and vertical plane

Fully Stainless Steel Construction

Almost maintenance free

Available In Fixed and Mobile Version

Various Metallurgy Option

3. APPLICATION

The Monitor is highly effective with water and foam for fast knockdown of Fires at Oil & Gas Plants, Off-Shore & On Shore

Platforms, Oil Refineries, Petroleum Storage Tanks & Depots, Chemical & Fertilizer Plants, Steel Plants, Power Plants,

Ammunition Depots, Defense Stores, Naval Ships And Submarine, Ships & Oil tankers Ports & Jetties Etc.

4. TECHNICAL SPECIFICATION

Flow at 100 psi (7 bar) pressure : 2000 & 1000 US GPM

Nozzle : Non-aspirating type

Induction Type : JRCP Type

Induction Rate : 3 % (As Per UL Guidelines)

Monitor Elevation : + 90

0

& -10

0

Vertical

Rotation : 360

0

Horizontal.

Water way size : 150 NB

Inlet Flange Size : 6 NB 150# S.O.R.F Flange

Hydrostatic Test Pressure : 21 bar.

Finish/ Paint : Fire red shade of Epoxy / Powder Coating

5. MATERIAL OF CONSTRUCTION FOR MONITOR AND NOZZLE

Foam Inlet

Hose

Swivel

Joint

Monitor

Body

Nozzle

Spring

Foam

Control

Valve

Lifting Hook

3/4

Base Flange : SS 304

Monitor Body : SS 304

Swivel joint : SS 304 / Gun Metal / Bronze

Worm Shaft : SS 304

Hand Wheel : SS 304

Neck Ring : SS 304

Foam Intake coupling : SS 304

Foam Nozzle : SS 304 / Bronze / Aluminum / Gun Metal

Lifting Hook : SS 304

JRCP : SS 304

Foam Control Valve : SS 304

MONITOR ALSO AVAILABLE IN METALLURGY OF SS 316 FOR SPECIAL APPLICATION.

6. AQUA FOAM JET CONTROL PUMP

Water operated foam inductor (JRCP) is suitable for feeding foam concentrate solution to the monitor nozzle from a distance

of 100 mtrs & above in horizontal plane. The inlet & outlet of JRCP are provided with 63 mm. Male & female coupling

respectively. The monitor comes with 1 Nos. of JRCP for its use at 2000 GPM & 1000 GPM with a control valve for selecting

the induction of 2000 and 1000 GPM at induction rate of 3%.

1. Material of Aqua Powered Pump : SS 304

2. Inlet & Outlet Coupling : 2 1/2 mm Male/Female coupling (SS 304)

3. Foam Induction Rate : 3% (as per UL Guidelines) for 2000 & 1000 GPM

4. Pick up tube : PVC 3 Mtrs Long

5. Delivery Distance : Aqua Foam Jet Controller is capable to

feed foam solution to the monitor nozzle from a

distance of 100 mtrs & above in horizontal plane.

7. PERFORMANCE OF MONITOR AT 100 PSI (IN STILL AIR CONDITION) at Nozzle at 1000

GPM

a) Water jet at 30 from Horizontal plane : 70 mtrs.

b) Foam jet at 30 from Horizontal plane : 65 mtrs.

c) Fog jet at 30 from Horizontal plane : 20 mtrs.

d) Water jet at 85 from Horizontal plane : 35 mtrs.

8. PERFORMANCE OF MONITOR AT 100 PSI (IN STILL AIR CONDITION) at Nozzle at 2000

GPM

a) Water jet at 30 from Horizontal plane : 80 mtrs.

b) Foam jet at 30 from Horizontal plane : 75 mtrs.

c) Fog jet at 30 from Horizontal plane : 20 mtrs.

d) Water jet at 85 from Horizontal plane : 40 mtrs.

9. APPROVAL: UL LISTED WITH FOLLOWING FEATURES (Applied But Pending)

a) Nozzle : Non Air Aspirating Nozzle

Hand

Wheel

Base Flange

Worm Shaft

JRCP

4/4

b) Monitor Solution Flow : 2000 / 1000 GPM (single nozzle)

c) Operating Pressure : 100 PSI

10. Induction : 3% Using JRCP able to feed foam from a distance of

100 mtrs to nozzle for variable monitor flow of 1000 &

2000 gpm.

You might also like

- Vimal FireDocument4 pagesVimal FireVisas SivaNo ratings yet

- Technical Data Sheet: Remote Controlled Monitor 1000 To 4000 US GPM (Electric / Hydro-Electric Operated)Document3 pagesTechnical Data Sheet: Remote Controlled Monitor 1000 To 4000 US GPM (Electric / Hydro-Electric Operated)Vasant Kumar VarmaNo ratings yet

- Remote Control Monitor: High-Capacity Foam Nozzle for FiresDocument3 pagesRemote Control Monitor: High-Capacity Foam Nozzle for Firesdebu1985No ratings yet

- Vimal Fire PDFDocument3 pagesVimal Fire PDFVipin SomasekharanNo ratings yet

- Water Monitor SpecificationDocument26 pagesWater Monitor SpecificationVishal PatoliyaNo ratings yet

- Angus (Fire Monitor)Document2 pagesAngus (Fire Monitor)Zack LeeNo ratings yet

- Ijemsv9n2 01Document14 pagesIjemsv9n2 01HugoJordaoNo ratings yet

- 6424-1 LMS30 PDFDocument2 pages6424-1 LMS30 PDFadventure11111100% (1)

- Liq TurbineFM Series1500 DSDocument12 pagesLiq TurbineFM Series1500 DSElinton De Jesus SarmientoNo ratings yet

- Liquid Turbine Flowmeter ManualDocument32 pagesLiquid Turbine Flowmeter ManualHammad AshrafNo ratings yet

- Philmac Orbitor Challenger - Spec SheetDocument4 pagesPhilmac Orbitor Challenger - Spec SheetOki OktafNo ratings yet

- Ziegler Monitor CatalogDocument28 pagesZiegler Monitor CatalogHusein BhinderwalaNo ratings yet

- Magnetic Flow Meter 1 - 6f9aDocument16 pagesMagnetic Flow Meter 1 - 6f9aSilvaACANo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Au4000 LeafletDocument2 pagesAu4000 LeafletAndré QuirinoNo ratings yet

- SDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMDocument4 pagesSDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMramiro alvarezNo ratings yet

- Fluid Mechanics & Hydrology: FM 675 Educational Compact Subsonic Wind TunnelDocument3 pagesFluid Mechanics & Hydrology: FM 675 Educational Compact Subsonic Wind Tunnelzivko13No ratings yet

- RotametrosDocument6 pagesRotametrosAlberto SubelzaNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationhumayun mdNo ratings yet

- Jet Grouting Equipment Catalog: YBM Co., Ltd. JapanDocument8 pagesJet Grouting Equipment Catalog: YBM Co., Ltd. JapanGeorge VNo ratings yet

- Monitor - M 211: (Carbon Steel, Hot Dip Galvanized) Technical DataDocument4 pagesMonitor - M 211: (Carbon Steel, Hot Dip Galvanized) Technical DataDHAVAL PANCHALNo ratings yet

- PN427448-04 Sec 3Document70 pagesPN427448-04 Sec 3newnse2008No ratings yet

- Edm HXR 40: Reverse Circulation Horizontal Drill RigDocument2 pagesEdm HXR 40: Reverse Circulation Horizontal Drill RigGlobal SaltilloNo ratings yet

- Spraymec NorRunner Technical SpecsDocument9 pagesSpraymec NorRunner Technical SpecsHukiro ItachiNo ratings yet

- Medidor de Flujo MagneticoDocument4 pagesMedidor de Flujo MagneticoAngel NajarroNo ratings yet

- Spraymec 8100 VC 100075525 USA & CanadaDocument11 pagesSpraymec 8100 VC 100075525 USA & CanadaEzequielNo ratings yet

- Baño de Recirculacion Lab CompanionDocument6 pagesBaño de Recirculacion Lab CompanionGabriela FrancoNo ratings yet

- Spraymec 8100 VC: FeaturesDocument12 pagesSpraymec 8100 VC: FeaturesSanjeev Roy100% (1)

- SONDAR 5000 ManualDocument44 pagesSONDAR 5000 ManualovadircNo ratings yet

- G761 SeriesDocument8 pagesG761 SeriesDipti BhanjaNo ratings yet

- D631 Series Servo Control Valves ISO 4401 Size 05Document12 pagesD631 Series Servo Control Valves ISO 4401 Size 05José OlaveNo ratings yet

- Excellent Spraying Performance: 30L Tank For Spraying Efficiency of FP300 Has Been Increased To 14.6Document8 pagesExcellent Spraying Performance: 30L Tank For Spraying Efficiency of FP300 Has Been Increased To 14.6Adel Abdullah QashmariNo ratings yet

- Remote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceDocument1 pageRemote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceKrishna N HNo ratings yet

- HW Series CatalogueDocument10 pagesHW Series CatalogueRohat SharmaNo ratings yet

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- Vortex Flow Meter Yokogawa CatalogueDocument5 pagesVortex Flow Meter Yokogawa CataloguepsaayoNo ratings yet

- Data Sheet: Blowers - SUC-E For Industrial PurposesDocument4 pagesData Sheet: Blowers - SUC-E For Industrial PurposesCarlos Ramon Brito RaveloNo ratings yet

- SC440-P Four Inch Hydrocyclone 2016Document2 pagesSC440-P Four Inch Hydrocyclone 2016Tobias De SomerNo ratings yet

- G Style - Pneumatic DatasheetDocument2 pagesG Style - Pneumatic DatasheetMehemmed MelikovNo ratings yet

- SM TM 1.5-4 Guardsman (G) Series02002Document4 pagesSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconNo ratings yet

- Pedrollo 2CPDocument8 pagesPedrollo 2CPBenicio Joaquín Ferrero BrebesNo ratings yet

- Bulletin 99 Valve Regulator FisherDocument20 pagesBulletin 99 Valve Regulator FisherLuis MoranNo ratings yet

- Arc VISIONDocument4 pagesArc VISIONBASNo ratings yet

- Wilroy Brochure 30952Document6 pagesWilroy Brochure 30952rudrakrNo ratings yet

- Comprehensive Bill of Materials for Cleanroom FacilityDocument3 pagesComprehensive Bill of Materials for Cleanroom FacilityJustin GarciaNo ratings yet

- SpecificationsDocument4 pagesSpecificationsSebastian VasquezNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNo ratings yet

- Pneu-Hydro Products' Sand Probe ValvesDocument2 pagesPneu-Hydro Products' Sand Probe ValvesdwpurnaNo ratings yet

- Technical Proposal for Olympic Pool Filtration SystemDocument10 pagesTechnical Proposal for Olympic Pool Filtration SystemAlma DerajNo ratings yet

- BrocherDocument12 pagesBrochermustaqeem khanNo ratings yet

- Sauermann Si82 Pack2Document2 pagesSauermann Si82 Pack2Farhaan SajjadNo ratings yet

- Drilling Rig ZBO S15Document8 pagesDrilling Rig ZBO S15Maksim100% (1)

- Features, Specification and Application of Reducing StationsDocument6 pagesFeatures, Specification and Application of Reducing StationsPeter JonesNo ratings yet

- Water Motor Gong (EA) DatasheetDocument4 pagesWater Motor Gong (EA) DatasheetsalesNo ratings yet

- Geotextile Testing Instruments 2020Document14 pagesGeotextile Testing Instruments 2020lakshya bagriNo ratings yet

- Potopna Crpka PEDROLLO Top Floor BrosuraDocument4 pagesPotopna Crpka PEDROLLO Top Floor Brosurajose03No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- 07 01 RV CPVCDocument7 pages07 01 RV CPVCSami ThirunavukkarasuNo ratings yet

- R404A Safety Data SheetDocument5 pagesR404A Safety Data SheetSami ThirunavukkarasuNo ratings yet

- HDPE Pipe Fittings - 2Document5 pagesHDPE Pipe Fittings - 2Sami ThirunavukkarasuNo ratings yet

- 01 03 UlfDocument12 pages01 03 UlfSami ThirunavukkarasuNo ratings yet

- Typical Processing Conditions For Dupont Engineering PolymerDocument21 pagesTypical Processing Conditions For Dupont Engineering PolymerSami ThirunavukkarasuNo ratings yet

- 01 01 F300Document16 pages01 01 F300Sami ThirunavukkarasuNo ratings yet

- r407c Boc MsdsDocument4 pagesr407c Boc MsdsSami ThirunavukkarasuNo ratings yet

- 01 02 F111Document6 pages01 02 F111Sami ThirunavukkarasuNo ratings yet

- Refrigrant R 134aDocument28 pagesRefrigrant R 134aThiruThirunavukkarasuNo ratings yet

- R 134 AjDocument6 pagesR 134 AjSami ThirunavukkarasuNo ratings yet

- Refrigerant Blends: Composition Changes During Transfer and ChargingDocument15 pagesRefrigerant Blends: Composition Changes During Transfer and ChargingSami ThirunavukkarasuNo ratings yet

- Materials Science 2 - DOEDocument112 pagesMaterials Science 2 - DOEshiv_1987No ratings yet

- Refrigeration CatalogDocument32 pagesRefrigeration CatalogSami ThirunavukkarasuNo ratings yet

- R134a Boc MsdsDocument4 pagesR134a Boc MsdsSami ThirunavukkarasuNo ratings yet

- OrganicDocument408 pagesOrganicSami ThirunavukkarasuNo ratings yet

- CFD Analysis of R404A Reciprocating Compressor DesignDocument7 pagesCFD Analysis of R404A Reciprocating Compressor DesignSami ThirunavukkarasuNo ratings yet

- Assess Ageing Plant EquipmentDocument15 pagesAssess Ageing Plant EquipmentkzlpNo ratings yet

- R134A - Tetrafluoroethane (Boc Limited - NZ) : Product NameDocument5 pagesR134A - Tetrafluoroethane (Boc Limited - NZ) : Product NameSami ThirunavukkarasuNo ratings yet

- CFD Analysis of R404A Reciprocating Compressor DesignDocument7 pagesCFD Analysis of R404A Reciprocating Compressor DesignSami ThirunavukkarasuNo ratings yet

- Material ScienceDocument20 pagesMaterial ScienceSami ThirunavukkarasuNo ratings yet

- ISPE NJChH2OSystemDesignPlanPracticesDocument50 pagesISPE NJChH2OSystemDesignPlanPracticesSami ThirunavukkarasuNo ratings yet

- Welding Operator Performance Qualifications FormDocument1 pageWelding Operator Performance Qualifications FormSami ThirunavukkarasuNo ratings yet

- Practical Guidelines For The Fabrication of High Performance Austenitic SSDocument72 pagesPractical Guidelines For The Fabrication of High Performance Austenitic SSlram70No ratings yet

- Instrumentation Training Tutorial Part1Document6 pagesInstrumentation Training Tutorial Part1Gary8100% (1)

- Cut GasketDocument2 pagesCut GasketSami ThirunavukkarasuNo ratings yet

- Ammonia Code Guide FinalDocument230 pagesAmmonia Code Guide FinalSami ThirunavukkarasuNo ratings yet

- Word List 04Document5 pagesWord List 04Upendra Kumar SinghNo ratings yet

- V15 A45.pdf0 1ADocument44 pagesV15 A45.pdf0 1ASami ThirunavukkarasuNo ratings yet

- SI FM 2e SM Chap06Document74 pagesSI FM 2e SM Chap06ttaerack80% (5)

- Wrap Around Packer DetailsDocument24 pagesWrap Around Packer DetailsUmair Younus100% (1)

- Tutorial Letter 101/0/2015: Hydraulic Machines III (Theory) FMA3602Document15 pagesTutorial Letter 101/0/2015: Hydraulic Machines III (Theory) FMA3602anthonytichaonaNo ratings yet

- 6424-1 LMS30 PDFDocument2 pages6424-1 LMS30 PDFadventure11111100% (1)

- Gas Turbines and Jet Engines ExplainedDocument55 pagesGas Turbines and Jet Engines ExplainedDigonto ChowdhuryNo ratings yet

- Introduction To Marine Gas Turbines, Rev.1978Document91 pagesIntroduction To Marine Gas Turbines, Rev.1978gnd100No ratings yet

- 065 - ME8792, ME6701 Power Plant Engineering - NotesDocument164 pages065 - ME8792, ME6701 Power Plant Engineering - NotesAnkit Jose AntonyNo ratings yet

- Chapter - : Gas Torbines and Jet PropulsionDocument12 pagesChapter - : Gas Torbines and Jet PropulsionVijay KumarNo ratings yet

- Mini Hydro Power PlantDocument17 pagesMini Hydro Power PlantMuh AdiwNo ratings yet

- Uk-Jet Selection Guide PDFDocument28 pagesUk-Jet Selection Guide PDFAnonymous 4jfgHZd2No ratings yet

- Steam Turbine: A Rotor of A Modern Steam Turbine, Used in ADocument13 pagesSteam Turbine: A Rotor of A Modern Steam Turbine, Used in AAnil Tandon100% (1)

- (Aerospace) Saeed Farokhi - Future Propulsion Systems and Energy Sources in Sustainable Aviation-Wiley (2020) PDFDocument445 pages(Aerospace) Saeed Farokhi - Future Propulsion Systems and Energy Sources in Sustainable Aviation-Wiley (2020) PDFDavid RivadeneiraNo ratings yet

- 1.1 Introduction To PropulsionDocument15 pages1.1 Introduction To PropulsionyoyogiftuNo ratings yet

- Dulfharah Nizam Memth AliDocument24 pagesDulfharah Nizam Memth Aligomoko123No ratings yet

- Engineering TrainingDocument37 pagesEngineering TrainingrefeiNo ratings yet

- Lecture Notes Aerospace PropulsionDocument104 pagesLecture Notes Aerospace PropulsionJuan GarcíaNo ratings yet

- Pelton TurbineDocument8 pagesPelton TurbineHammas Ahmed MirNo ratings yet

- Ata 28Document27 pagesAta 28jontis jasoliyaNo ratings yet

- 889538175Document25 pages889538175Peter Lee Ka HoNo ratings yet

- Water Jet Theory and Practice PHDDocument123 pagesWater Jet Theory and Practice PHDdvfilmspkNo ratings yet

- Abstract CentralDocument53 pagesAbstract Centraltxaicalvoso518No ratings yet

- Gas Turbine Engine MaintenanceDocument7 pagesGas Turbine Engine Maintenancesathesh waranNo ratings yet

- Steam Turbine LectureDocument14 pagesSteam Turbine LectureAbel MisgNo ratings yet

- Aerospace Science and Technology: Joseph A. Schetz, Serhat Hosder, Vance Dippold III, Jessica WalkerDocument10 pagesAerospace Science and Technology: Joseph A. Schetz, Serhat Hosder, Vance Dippold III, Jessica WalkerEsteban ValenciaNo ratings yet

- Electric Armor Against Shaped Charges - Analysis of Jet Distortion With Respect To Jet DynamicsDocument4 pagesElectric Armor Against Shaped Charges - Analysis of Jet Distortion With Respect To Jet DynamicsDhimas AfihandarinNo ratings yet

- TurbochargerDocument286 pagesTurbochargercpiqui100% (2)

- SMK Tat Beng Physics Form 4 2.4 Linear MomentumDocument41 pagesSMK Tat Beng Physics Form 4 2.4 Linear MomentumTee Ting QINo ratings yet

- ChallengeDocument29 pagesChallengeMarconiVianaNo ratings yet

- Chapter 5: MotionDocument74 pagesChapter 5: MotionRafizal Shafiee86% (7)

- Modu 15 - Noise Suppression SystemDocument17 pagesModu 15 - Noise Suppression SystemHAFIDY RIZKY ILHAMSYAHNo ratings yet