Professional Documents

Culture Documents

ESD Ethernet

Uploaded by

Vishwanath GaonkarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESD Ethernet

Uploaded by

Vishwanath GaonkarCopyright:

Available Formats

2013 Littelfuse, Inc.

Specications are subject to change without notice.

Revised: 11/25/13

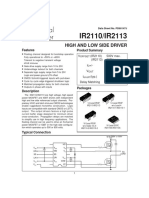

TVS Diode Arrays (SPA

Diodes)

Lightning Surge Protection - SRV05 Series

Description

Applications

The SRV05 integrates low capacitance rail-to-rail diodes with

an additional zener diode to protect each I/O pin against

ESD and high surge events. This robust device can safely

absorb surge current per IEC61000-4-5 (t

P

=8/20s) without

performance degradation and a minimum 20kV ESD

per IEC61000-4-2. Their very low loading capacitance also

makes them ideal for protecting high speed signal pins.

Features

ESD, IEC61000-4-2,

20kV contact, 30kV air

EFT, IEC61000-4-4, 40A

(5/50ns)

Lightning, IEC61000-4-5,

10A (8/20s)

Low capacitance of 2pF

(TYP) per I/O

Low leakage current of

0.5A (MAX) at 5V

Small SOT23-6 (JEDEC

MO-178) packaging

LCD/PDP TVs

Monitors

Notebooks

10/100/1000 Ethernet

Firewire

Set Top Boxes

Flat Panel Displays

Portable Medical

Pinout

I/O 1

GND

I/O 2

I/O 4

V

CC

I/O 3

Functional Block Diagram

1 2 3

6 5 4

Life Support Note:

Not Intended for Use in Life Support or Life Saving Applications

The products shown herein are not designed for use in life sustaining or life saving

applications unless otherwise expressly indicated.

RoHS Pb GREEN

Application Examples

V

BUS

V

BUS

V

BUS

V

BUS

D +

D +

D -

D -

GND

GND

C

T

R

T

R

T

R

T

R

T

C

T

C

T

C

T

USB

Port

USB

Port

USB

Controller

VBUS

SRV05-4HTG

USB Dual Port Protection

VCC

10/100

Ethernet

PHY

TX +

TX -

RX +

RX -

VCC

GND

SRV05-4HTG

TX +

TX -

RX +

RX -

Unused

Unused

Unused

RJ45

Unused

T

o

T

w

i

s

t

e

d

-

P

a

i

r

N

e

t

w

o

r

k

75 75 75 75

1

2

3

6

5

4

10/100 Ethernet Differential Protection

VCC

10/100/1000

Ethernet

PHY

TX +

TX -

RX +

RX -

VCC

GND

TX +

TX -

RX +

RX -

Unused

Unused

Unused

RJ45

Unused

T

o

T

w

i

s

t

e

d

-

P

a

i

r

N

e

t

w

o

r

k

75 75 75 75

10/100/1000 Ethernet Protection

SRV05-4HTG

1

2

3

6

5

4

SRV05 Series 6V 10A Diode Array

Additional Information

Datasheet Samples Resources

2013 Littelfuse, Inc.

Specications are subject to change without notice.

Revised: 11/25/13

TVS Diode Arrays (SPA

Diodes)

Lightning Surge Protection - SRV05 Series

CAUTION: Stresses above those listed in Absolute Maximum Ratings may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specication is not implied.

1

Non-repetitive pulse per waveform on page 3

Absolute Maximum Ratings

Symbol Parameter Value Units

I

PP

Peak Current (t

p

=8/20s)

1

10 A

P

PK

Peak Pulse Power (t

p

=8/20s) 150 W

T

OP

Operating Temperature 40 to 125 C

T

STOR

Storage Temperature 55 to 150 C

Thermal Information

Parameter Rating Units

Storage Temperature Range 55 to 150 C

Maximum Junction Temperature 150 C

Maximum Lead Temperature

(Soldering 20-40s)

260 C

Electrical Characteristics (T

OP

=25C)

Parameter Symbol Test Conditions Min Typ Max Units

Reverse Standoff Voltage V

RWM

I

R

1A 6.0 V

Reverse Voltage Drop V

R

I

R

= 1mA 8.0 V

Reverse Leakage Current I

LEAK

V

R

=5V 0.1 0.5 A

Clamp Voltage

1

V

C

I

PP

=1A, t

p

=8/20s, I/O to GND

2

8.8 10.0 V

I

PP

=5A, t

p

=8/20s, I/O to GND

2

11.5 13.0 V

I

PP

=8A, t

p

=8/20s, I/O to GND

2

13.2 15.0 V

Dynamic Resistance R

DYN

(V

C2

- V

C1

) / (I

PP2

- I

PP1

) 0.7

ESD Withstand Voltage

1

V

ESD

IEC61000-4-2 (Contact) 20 kV

IEC61000-4-2 (Air) 30 kV

Diode Capacitance

1

C

I/O-GND

Reverse Bias=0V 2.4 3.0 pF

Reverse Bias=1.65V 2.0 pF

Diode Capacitance

1

C

I/O-I/O

Reverse Bias=0V 1.2 pF

Notes:

1

Parameter is guaranteed by design and/or device characterization.

2

Repetitive pulse per waveform on page 3.

Clamping Voltage vs. I

PP

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

1 2 3 4 5 6 7 8 9 10

Peak Pulse Current-I

PP

(A)

C

l

a

m

p

V

o

l

t

a

g

e

(

V

C

)

Product Characteristics

Lead Plating Matte Tin

Lead Material Copper Alloy

Lead Coplanarity 0.0004 inches (0.102mm)

Substitute Material Silicon

Body Material Molded Epoxy

Flammability UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold fash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte fnish VDI 11-13.

2013 Littelfuse, Inc.

Specications are subject to change without notice.

Revised: 11/25/13

TVS Diode Arrays (SPA

Diodes)

Lightning Surge Protection - SRV05 Series

Pulse Waveform Capacitance vs. Reverse Bias

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DC Bias (V)

C

a

p

a

c

i

t

a

n

c

e

(

p

F

)

V

CC

=Float

V

CC

=5V

V

CC

=3.3V

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (s)

P

e

r

c

e

n

t

o

f

I

P

P

Time

T

e

m

p

e

r

a

t

u

r

e

T

P

T

L

T

S(max)

T

S(min)

25

t

P

t

L

t

S

time to peak temperature

Preheat Preheat

Ramp-up Ramp-up

Ramp-down Ramp-do

Critical Zone

TL to TP

Critical Zone

TL to TP

Reow Condition Pb Free assembly

Pre Heat

- Temperature Min (T

s(min)

) 150C

- Temperature Max (T

s(max)

) 200C

- Time (min to max) (t

s

) 60 180 secs

Average ramp up rate (Liquidus) Temp

(T

L

) to peak

3C/second max

T

S(max)

to T

L

- Ramp-up Rate 3C/second max

Reow

- Temperature (T

L

) (Liquidus) 217C

- Temperature (t

L

) 60 150 seconds

Peak Temperature (T

P

) 260

+0/-5

C

Time within 5C of actual peak

Temperature (t

p

)

20 40 seconds

Ramp-down Rate 6C/second max

Time 25C to peak Temperature (T

P

) 8 minutes Max.

Do not exceed 260C

Soldering Parameters

Ordering Information

Part Number Package Marking Min. Order Qty.

SRV05-4HTG SOT23-6 L*4 3000

Part Numbering System

Part Marking System

SRV05 4 H T G

Series

Number of

Channels

Package

H: SOT23-6

T= Tape & Reel

G= Green

L*4

L * 4

Product Series

L = SRV05

Number of Channels

Assembly Site

(Varies)

L = S

(Varies)

2013 Littelfuse, Inc.

Specications are subject to change without notice.

Revised: 11/25/13

TVS Diode Arrays (SPA

Diodes)

Lightning Surge Protection - SRV05 Series

Embossed Carrier Tape & Reel Specication SOT23-6

8mm TAPE AND REEL

GENERAL INFORMATION

1. 3000 PIECES PER REEL.

2. ORDER IN MULTIPLES OF FULL REELS ONLY.

3. MEETS EIA-481 REVISION "A" SPECIFICATIONS.

2.0mm

4.0mm

C

L

1.75mm

1.5mm

DIA. HOLE

8mm

4.0mm

8.4mm

180mm

14.4mm

13mm

60mm

ACCESS HOLE

COVER TAPE

USER DIRECTION OF FEED PIN 1

SOT-23 (8mm POCKET PITCH)

Package Dimensions SOT23-6

Package SOT23-6

Pins 6

JEDEC MO-178

Millimeters Inches

Notes

Min Max Min Max

A 0.900 1.450 0.035 0.057 -

A1 0.000 0.150 0.000 0.006 -

A2 0.900 1.300 0.035 0.051 -

b 0.350 0.500 0.0138 0.0196 -

C 0.080 0.220 0.0031 0.009 -

D 2.800 3.000 0.11 0.118 3

E 2.600 3.000 0.102 0.118 -

E1 1.500 1.750 0.06 0.069 3

e 0.95 Ref 0.0374 ref -

e1 1.9 Ref 0.0748 Ref -

L 0.100 0.600 0.004 0.023 4,5

N 6 6 6

a 0 10 0 10 -

M 2.590 0.102 -

O 0.690 .027 TYP -

P 0.990 .039 TYP -

R 0.950 0.038 -

O

P

R

M

Recommended Solder Pad Layout

Notes:

1. Dimensioning and tolerances per ANSI 14.5M-1982.

2. Package conforms to EIAJ SC-74 (1992).

3. Dimensions D and E1 are exclusive of mold fash, protrusions, or gate burrs.

4. Footlenth L measured at reference to seating plane.

5. L is the length of fat foot surface for soldering to substrate.

6. N is the number of terminal positions.

7. Controling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Instrument Transformer: Electrical Measuring Instruments & Instrumentation 4 Semester Electrical EnggDocument63 pagesInstrument Transformer: Electrical Measuring Instruments & Instrumentation 4 Semester Electrical EnggMatt WrightNo ratings yet

- 00 GEN-IMAN EXC HMG 6KW 10KW Manual PDFDocument24 pages00 GEN-IMAN EXC HMG 6KW 10KW Manual PDFjrincon26No ratings yet

- Coelmo'S Gen Sets DM Series: WWW - Jeepsea.Co - IlDocument25 pagesCoelmo'S Gen Sets DM Series: WWW - Jeepsea.Co - IlMedrouaNo ratings yet

- Ir53h420 Mosfet1Document9 pagesIr53h420 Mosfet1Gilson Mendes SilvaNo ratings yet

- Endurabay HPK138Document5 pagesEndurabay HPK138wilber ticona0% (1)

- Edc TransistorDocument113 pagesEdc TransistorsanthinathNo ratings yet

- 140B Final Exam 2015 SolutionDocument9 pages140B Final Exam 2015 SolutionGerardo SanchezNo ratings yet

- 2520 995 RevBDocument52 pages2520 995 RevBgovindarulNo ratings yet

- General Description Product Summary: 30V P-Channel MOSFETDocument6 pagesGeneral Description Product Summary: 30V P-Channel MOSFETluis alberto perez monteroNo ratings yet

- Energy Saving Choke - LED LightsDocument10 pagesEnergy Saving Choke - LED LightsSabhaya ChiragNo ratings yet

- Kabal NayyDocument3 pagesKabal NayyL TrNo ratings yet

- Master'S Thesis Protection of The High-Voltage Equipment With Reduced Inslation StrenghtDocument76 pagesMaster'S Thesis Protection of The High-Voltage Equipment With Reduced Inslation StrenghtlalitbickNo ratings yet

- Ir 2113Document16 pagesIr 2113hassan adoumNo ratings yet

- Lundahl: Tube Amplifier Interstage Transformer / Line Output Transformer LL1692ADocument2 pagesLundahl: Tube Amplifier Interstage Transformer / Line Output Transformer LL1692AKemboya LuigiNo ratings yet

- Systems: All Rights ReservedDocument3 pagesSystems: All Rights ReservedMohamed ElhossenyNo ratings yet

- 1 MW MTG Tech DatasheetDocument1 page1 MW MTG Tech DatasheetAlem Mestas TolaNo ratings yet

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDocument4 pagesConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NNo ratings yet

- Monitoring RelaysDocument8 pagesMonitoring Relayskhalithmansoor1950No ratings yet

- Electronic Products Assembly and Servicing (EPAS) Grade 9Document33 pagesElectronic Products Assembly and Servicing (EPAS) Grade 9Berlin AlcaydeNo ratings yet

- Solution Tutorial 2 Ent162 PDFDocument10 pagesSolution Tutorial 2 Ent162 PDFer denice catamoraNo ratings yet

- YSA Arctic Welding CableDocument1 pageYSA Arctic Welding CableWahyu RamadaniNo ratings yet

- Safari: Kashaf Lighting FixturesDocument2 pagesSafari: Kashaf Lighting FixturesEmad AdelNo ratings yet

- Sepam SolutionsDocument36 pagesSepam SolutionsThức VõNo ratings yet

- Manual Inverter 380Document158 pagesManual Inverter 380Natan LiróNo ratings yet

- 936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetDocument3 pages936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetNataša Mihić BoskovićNo ratings yet

- Abb # A16-40-00Document8 pagesAbb # A16-40-00kjrise62No ratings yet

- Application Note: Vishay General SemiconductorDocument1 pageApplication Note: Vishay General SemiconductorMk KmNo ratings yet

- PRCMDocument5 pagesPRCMMin ZayarNo ratings yet

- Unit Sub-Station 160kvaDocument2 pagesUnit Sub-Station 160kvaasifaliabidNo ratings yet

- Sb60 08 ElectricalDocument39 pagesSb60 08 ElectricalMgc Elektronik100% (1)