Professional Documents

Culture Documents

Condensate Return Stations

Uploaded by

Royerts Leo Callo Palomino0 ratings0% found this document useful (0 votes)

29 views2 pagesECOTHERM steam solutions condensate return stations are designed to handle high quantities at 98degC. They can handle pump delivery heads up to 30 - 35 metres. Pumps are designed for operation under conditions of low NPSH. They are directly coupled to motors having class F insulation (class B temperature rise) and motor enclosure rating IP54 minimum.

Original Description:

Original Title

Condensate Return Stations (1)

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentECOTHERM steam solutions condensate return stations are designed to handle high quantities at 98degC. They can handle pump delivery heads up to 30 - 35 metres. Pumps are designed for operation under conditions of low NPSH. They are directly coupled to motors having class F insulation (class B temperature rise) and motor enclosure rating IP54 minimum.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesCondensate Return Stations

Uploaded by

Royerts Leo Callo PalominoECOTHERM steam solutions condensate return stations are designed to handle high quantities at 98degC. They can handle pump delivery heads up to 30 - 35 metres. Pumps are designed for operation under conditions of low NPSH. They are directly coupled to motors having class F insulation (class B temperature rise) and motor enclosure rating IP54 minimum.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Products: Condensate Return Stations

Condensate Return Stations

Description

The condensate recovery units are designed to handle hot

condensate, which is commonly returned for use as boiler

feedwater. They can handle high quantities at 98C with

pump delivery heads up to 30 - 35 metres. A unit comprises

three main parts - receiver, pump/pumps and control panel.

Receivers are manufactured from mild steel or SS

304/316. All sizes are fitted with adequately sized vent,

overflow, drain and inlet connections flanged to PN16 or

screwed. A water level gauge and control is provided.

Pumps are designed for operation under conditions of

low NPSH to handle hot condensate with the minimum

of flooded suction. They are directly coupled to motors

having class F insulation (class B temperature rise) and

motor enclosure rating IP54 minimum.

Control: Receivers are fitted with solid state level

controls which provides on / off cascade pump operati-

on. The control panel incorporates electrical equipment

suitable for 400 volt, 3 phase, 50 Hz, 4 wire supply.

Control equipment is installed in a pre-wired IP54 rated

metal enclosure. Connections for BMS interface are

provided to monitor pump run or tripped condition.

Pump fitting: The motor and pumps are mounted

under the receiver with over size suction inlet pipework

and isolation valves. The pump discharge outlet is fitted

with a non return valve and a pressure gauge.

26

Find technical specifications

on page 63.

Standards

This product fully complies with the requirements of the

European Machinery Directive 98/37/EC, European Low

Voltage Directive 72 / 73 / EEC and European Electro-

magnetic Compatibility Devices Directive 89/336/ EEC.

This product is not a pressurized vessel and therefore

does not need to comply with the European Pressure

Directive 97/23/EC.

ECOTHERM Steam Solutions

Technical Specifications

Condensate Return Stations

N1

N1

E

N2

N5

A

B

Material (Tank):

Function:

Design:

Conditions:

Flange Standards:

Standards:

Certification:

Mild Steel (P235GH)

Stainless Steel (AISI 304 / 316 / DUPLEX)

Return of condensate from consumers back to feed water tank

Horizontal condensate tank pressureless, fitted with pumps, level control, control panel,

for easy installation and operation, ready for start-up

Max. operating pressure 0.5 bars, test pressure 2 bars

Max. operating temperature 120C

acc. to DIN-EN 1092-1, PN6 / 16 / 40

The product fully complies with the requirements of the European Pressure Equipment Directive 97 / 23 / EC and carries the

CE mark when so required.

acc. to EN 10204 certifiable as standard and certificates are available on request.

Note: All certification / inspection requirements must be stated at the time of order replacement

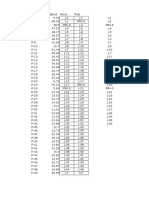

Model

ECR-500

ECR-1,000

ECR-1,500

ECR-2,000

ECR-3,000

ECR-5,000

N1

Vessel inlet

DN40

DN65

DN65

DN65

DN65

DN65

N2

Vent

DN50

DN80

DN80

DN100

DN100

DN100

Connections

N3

Overflow

DN25

DN40

DN40

DN40

DN50

DN65

N4

Drain

1" BSP

1" BSP

1" BSP

DN40

DN40

DN50

N5

Pumped

condensate

DN32

DN32

DN40

DN65

DN65

DN65

A

mm

2,400

2,400

2,600

2,800

3,500

4,000

B

mm

1,000

1,100

1,300

1,500

1,700

2,000

C

mm

1,700

1,700

1,800

2,000

2,000

2,200

D

mm

900

1,100

1,200

1,400

1,500

1,700

E

mm

2,000

2,100

2,100

2,200

2,400

3,000

Condensate

capacity

m/h

0.5-1

1-2

2-3

3-4

4-5

5-6

Sizing in accordance to customer requirements

Subject to change without change

ECOTHERM Steam Solutions

63

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cat 3306 Ta - Spec PDFDocument12 pagesCat 3306 Ta - Spec PDFAdrian Cojocaru100% (1)

- Maintaining Your Agilent 1100 Series HPLC SystemDocument56 pagesMaintaining Your Agilent 1100 Series HPLC SystemMeiNo ratings yet

- Service - Service Manual Code 950 - 994 - 653 (1) Kubota V2203Document30 pagesService - Service Manual Code 950 - 994 - 653 (1) Kubota V2203ynadeem100% (4)

- Fire Pump Itm ChecklistDocument4 pagesFire Pump Itm ChecklistImranNo ratings yet

- HazapDocument51 pagesHazapAvijit MondalNo ratings yet

- Swimming Pool HydraulicsDocument6 pagesSwimming Pool Hydraulicstonyonly100% (1)

- Write Up On Turbine Lube Oil SystemDocument5 pagesWrite Up On Turbine Lube Oil SystemAmit Balot100% (1)

- Mindray BC-2800 Trouble Shooting (Ver.1.1, 2008-4-31)Document26 pagesMindray BC-2800 Trouble Shooting (Ver.1.1, 2008-4-31)Ing Biomédico100% (2)

- Intake StructuresDocument25 pagesIntake StructuresSalabha TG100% (1)

- EPRI-Terry Turbine Maintenance GuideDocument336 pagesEPRI-Terry Turbine Maintenance Guidepadrino0786% (7)

- DOOSAN P086TI Diesel Engine Ratings and SpecsDocument4 pagesDOOSAN P086TI Diesel Engine Ratings and SpecsVu DangNo ratings yet

- Design Methods For Beams and ColumnsDocument12 pagesDesign Methods For Beams and ColumnsRoyerts Leo Callo PalominoNo ratings yet

- Design Methods For Beams and ColumnsDocument12 pagesDesign Methods For Beams and ColumnsRoyerts Leo Callo PalominoNo ratings yet

- Unencrypted EetDocument68 pagesUnencrypted EetRoyerts Leo Callo PalominoNo ratings yet

- Floor Steel Requirements: Concrete Storage FacilitiesDocument1 pageFloor Steel Requirements: Concrete Storage FacilitiesRoyerts Leo Callo PalominoNo ratings yet

- San SalvadorDocument1 pageSan SalvadorRoyerts Leo Callo PalominoNo ratings yet

- ReservDocument2 pagesReservRoyerts Leo Callo PalominoNo ratings yet

- San SalvadorDocument1 pageSan SalvadorRoyerts Leo Callo PalominoNo ratings yet

- ReservDocument2 pagesReservRoyerts Leo Callo PalominoNo ratings yet

- Water CadDocument6 pagesWater CadRoyerts Leo Callo PalominoNo ratings yet

- Reservo Rio 1Document1 pageReservo Rio 1Royerts Leo Callo PalominoNo ratings yet

- Reservo RioDocument1 pageReservo RioRoyerts Leo Callo PalominoNo ratings yet

- 4.1.1 - Dynamic Lateral Forces: W R I CDocument2 pages4.1.1 - Dynamic Lateral Forces: W R I CRoyerts Leo Callo PalominoNo ratings yet

- Sapesco Vaccume RepumpingDocument5 pagesSapesco Vaccume RepumpingIbrahim AhmedNo ratings yet

- Lincoln Helios (India) Limited: Operation & Maintenance ManualDocument50 pagesLincoln Helios (India) Limited: Operation & Maintenance Manualprem sagarNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument10 pagesSciencedirect Sciencedirect SciencedirectRey Miranda QuispirimaNo ratings yet

- LG - GC 151 ManualDocument13 pagesLG - GC 151 ManualadijayptNo ratings yet

- Explaining the fuel oil systemDocument2 pagesExplaining the fuel oil systemLawLietNo ratings yet

- DJ Pump 2021 PDFDocument20 pagesDJ Pump 2021 PDFManuel Armando Salazar BravoNo ratings yet

- Calibration of Peristaltic PumpDocument3 pagesCalibration of Peristaltic PumpMahathir Mohmed75% (4)

- Marketing and Transport of Fish SeedDocument2 pagesMarketing and Transport of Fish SeedNarasimha MurthyNo ratings yet

- TMP CalcDocument3 pagesTMP Calctsk_skr100% (1)

- Adobe Scan May 09, 2023Document8 pagesAdobe Scan May 09, 2023krushna DeshmukhNo ratings yet

- What Is Chemical Engineering?: Ways of Heat TransferDocument8 pagesWhat Is Chemical Engineering?: Ways of Heat TransferFawzan AlkhaldiNo ratings yet

- Manual IQPUMPDocument486 pagesManual IQPUMPLuis Fernando Gomez SalasNo ratings yet

- Test Plan for Perkins T4.401 LP18 Pump 8923A050Document2 pagesTest Plan for Perkins T4.401 LP18 Pump 8923A050veshatNo ratings yet

- CSJ HydraulicDocument43 pagesCSJ HydraulicВаня БойкоNo ratings yet

- Satco LTD: Satco 223 Setup & Testing ManualDocument41 pagesSatco LTD: Satco 223 Setup & Testing ManualHeidi Cuevas VenegasNo ratings yet

- Bobcat E17 E19 E20 BrochureDocument12 pagesBobcat E17 E19 E20 Brochure박재범No ratings yet

- PB 8 40100001.00205 E1Document20 pagesPB 8 40100001.00205 E1Jong JavaNo ratings yet

- SentinelCem Cement H08282Document3 pagesSentinelCem Cement H08282Saavedra NicoNo ratings yet

- Private Fire HydrantDocument4 pagesPrivate Fire HydrantAkilaJosephNo ratings yet