Professional Documents

Culture Documents

Schimbator de Caldura

Uploaded by

Pop Ionut0 ratings0% found this document useful (0 votes)

36 views15 pagesschimbator de caldura

Original Title

Schimbator de caldura

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentschimbator de caldura

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views15 pagesSchimbator de Caldura

Uploaded by

Pop Ionutschimbator de caldura

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

SUBMITTAL DATA

4 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

4DS-SUB REV:C 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS424(*)A 29.40 14.75 3.19 3.19

DS436(*)A 41.40 26.75 4.79 4.79

DS448(*)A 53.40 38.75 6.39 6.39

DS460(*)A 65.40 50.75 7.98 7.98

DS472(*)A 77.40 62.75 9.58 9.58

DS484(*)A 89.40 74.75 11.18 11.18

DS496(*)A 101.40 86.75 12.77 12.77

DS4108(*)A 113.40 98.75 14.37 14.37

DS4120(*)A 125.40 110.75 15.97 15.97

Model

No.

3.59 5.00 4.50 9.00

2"

NPT

1" NPT

1.25"

NPT

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

1"

NPT

HEAT EXCHANGER 2 PASS 4 PASS

2.62

1.25"

NPT

2.00 1.00

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 300 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

SUBMITTAL DATA

6 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

6DS-SUB REV:B 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS624(*)A 30.89 12.75 8.00 8.00

DS636(*)A 42.89 24.75 12.80 12.80

DS648(*)A 54.89 36.75 17.60 17.60

DS660(*)A 66.89 48.75 22.40 22.40

DS672(*)A 78.89 60.75 27.10 27.10

DS684(*)A 90.89 72.75 31.90 31.90

DS696(*)A 102.89 84.75 36.70 36.70

DS6108(*)A 114.89 96.75 41.50 41.50

DS6120(*)A 126.89 108.75 46.30 46.30

1.5"

NPT

Model

No.

4.04 6.00 6.63 11.00

3"

NPT

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

1.5"

NPT

HEAT EXCHANGER 2 PASS 4 PASS

3.75

2"

NPT

2.69 1.25

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 300 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

SUBMITTAL DATA

8 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

8DS-SUB REV:F 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 300 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

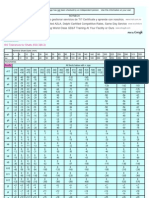

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS824(*)A 31.68 9.75 15.20 15.20

DS836(*)A 43.68 21.75 24.00 24.00

DS848(*)A 55.68 33.75 32.70 32.70

DS860(*)A 67.68 45.75 41.50 41.50

DS872(*)A 79.68 57.75 50.30 50.30

DS884(*)A 91.68 69.75 59.10 59.10

DS896(*)A 103.68 81.75 67.90 67.90

DS8108(*)A 115.68 93.75 76.60 76.60

DS8120(*)A 127.68 105.75 85.40 85.40

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

2"

NPT

HEAT EXCHANGER 2 PASS 4 PASS

4.75

3"

NPT

3.50 1.75 13.50

1.5"

NPT

3"

NPT

4"

FLG

6"

FLG

Model

No.

4.30 9.00 8.63

SUBMITTAL DATA

10 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

10DS-SUB REV:C 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS1024(*)A 33.38 8.75 27.10 24.80

DS1036(*)A 45.38 20.75 42.30 39.90

DS1048(*)A 57.38 32.75 57.50 54.30

DS1060(*)A 69.38 44.75 72.70 68.70

DS1072(*)A 81.38 56.75 87.80 83.00

DS1084(*)A 93.38 68.75 106.00 97.40

DS1096(*)A 105.38 80.75 118.20 11.80

DS10108(*)A 117.38 92.75 133.30 126.10

DS10120(*)A 129.38 104.75 148.50 140.50

** 3" NPT OPTION @ 150 PSI FOR C.I. HEAD ONLY

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

3"

NPT

4"

FLG

1.5"

NPT

6"

FLG

2"

NPT

2 PASS 4 PASS

5.88

4"**

NPT

4.50 2.12

Model

No.

5.00 10.00 10.75

HEAT EXCHANGER

16.00

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE** 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

**3" NPT HAS 150 PSI WORKING PRESSURE

AND 300 PSI TEST PRESSURE

SUBMITTAL DATA

10 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

10BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS1024(*)B 48.25 8.75 27.10 24.80

DS1036(*)B 60.25 20.75 42.30 39.90

DS1048(*)B 72.25 32.75 57.50 54.30

DS1060(*)B 84.25 44.75 72.70 68.70

DS1072(*)B 96.25 56.75 87.80 83.00

DS1084(*)B 108.25 68.75 103.00 97.40

DS1096(*)B 120.25 80.75 118.20 111.80

DS10108(*)B 132.25 92.75 133.30 126.10

DS10120(*)B 144.25 104.75 148.50 140.50

3"

FLG

10.38 10.88

4"

FLG

20.75

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

10.75 16.00

0.75"

NPT

4"

FLG

10.88

6"

FLG

1.5"

NPT

2"

NPT

Model

No.

19.88 10.00 4.50

SUBMITTAL DATA

12 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

12DS-SUB REV:C 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS1224(*)A 34.75 8.75 41.00 38.00

DS1236(*)A 46.75 20.75 62.00 59.00

DS1248(*)A 58.75 32.75 84.00 80.00

DS1260(*)A 70.75 44.75 106.00 100.00

DS1272(*)A 82.75 56.75 128.00 121.00

DS1284(*)A 94.75 68.75 150.00 142.00

DS1296(*)A 106.75 80.75 172.00 163.00

DS12108(*)A 118.75 92.75 194.00 183.00

DS12120(*)A 130.75 104.75 216.00 204.00

** 3" NPT OPTION @ 150 PSI FOR C.I. HEAD ONLY

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

3"

NPT

6"

FLG

8"

FLG

2"

NPT

2.5"

NPT

2 PASS 4 PASS

6.38

4"**

NPT

5.00 2.75

Model

No.

5.38 10.00 12.75

HEAT EXCHANGER

19.00

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE** 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

**3" NPT HAS 150 PSI WORKING PRESSURE

AND 300 PSI TEST PRESSURE

SUBMITTAL DATA

12 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

12BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS1224(*)B 50.18 8.75 41 38

DS1236(*)B 62.18 20.75 62 59

DS1248(*)B 74.18 32.75 84 80

DS1260(*)B 86.18 44.75 106 100

DS1272(*)B 98.18 56.75 128 121

DS1284(*)B 110.18 68.75 150 142

DS1296(*)B 122.18 80.75 172 163

DS12108(*)B 134.18 92.75 194 183

DS12120(*)B 146.18 104.75 216 204

6"

FLG

8"

FLG

2"

NPT

2.5"

NPT

Model

No.

20.81 10.00 4.50

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

12.75 19.00

0.75"

NPT

11.06

3"

FLG

11.38 11.06

4"

FLG

22.75

SUBMITTAL DATA

14 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

14DS-SUB REV:C 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS1436(*)A 52.81 24.50 87.00 83.00

DS1448(*)A 64.81 36.50 117.00 112.00

DS1460(*)A 76.81 48.50 147.00 141.00

DS1472(*)A 88.81 60.50 177.00 169.00

DS1484(*)A 100.81 72.50 207.00 198.00

DS1496(*)A 112.81 84.50 237.00 227.00

DS14108(*)A 124.81 96.50 266.00 256.00

DS14120(*)A 136.81 108.50 296.00 284.00

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

4"

NPT

6"

FLG

2"

NPT

8"

FLG

10"

FLG

2.5"

NPT

2 PASS 4 PASS

8.00

6"

NPT

5.88 3.31

Model

No.

6.44 11.00 14.00

HEAT EXCHANGER

21.00

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD* CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE** 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

** FABRICATED STEEL HEAD AVAILABLE TO

INCREASE TUBE SIDE PRESSURE TO 150 PSI

SUBMITTAL DATA

14 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

14BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS1436(*)B 68.25 24.50 87 83

DS1448(*)B 80.25 36.50 117 112

DS1460(*)B 92.25 48.50 147 141

DS1472(*)B 104.25 60.50 177 169

DS1484(*)B 116.25 72.50 207 198

DS1496(*)B 128.25 84.50 237 227

DS14108(*)B 140.25 96.50 266 256

DS14120(*)B 152.25 108.50 296 284

6"

FLG

8"

FLG

10"

FLG

2"

NPT

2.5"

NPT

Model

No.

21.88 11.00 5.00

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

14.00 21.00

0.75"

NPT

11.31

4"

FLG

12.69 11.31

6"

FLG

24.00

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

SUBMITTAL DATA

16 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

16DS-SUB REV:C 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS1636(*)A 54.18 24.00 115.00 111.00

DS1648(*)A 66.18 36.00 155.00 148.00

DS1660(*)A 78.18 48.00 194.00 186.00

DS1672(*)A 90.18 60.00 233.00 223.00

DS1684(*)A 102.18 72.00 272.00 261.00

DS1696(*)A 114.18 84.00 311.00 298.00

DS16108(*)A 126.18 96.00 352.00 336.00

DS16120(*)A 136.18 108.00 389.00 373.00

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

4"

NPT

6"

FLG

2"

NPT

8"

FLG

10"

FLG

2.5"

NPT

2 PASS 4 PASS

9.00

6"

NPT

8.00 4.00

Model

No.

7.06 11.00 16.00

HEAT EXCHANGER

23.50

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

** FABRICATED STEEL HEAD AVAILABLE TO

INCREASE TUBE SIDE PRESSURE TO 150 PSI

SUBMITTAL DATA

16 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

16BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS1636(*)B 70.44 24.00 115 111

DS1648(*)B 82.44 36.00 155 148

DS1660(*)B 94.44 48.00 194 186

DS1672(*)B 106.44 60.00 233 223

DS1684(*)B 118.44 72.00 272 261

DS1696(*)B 130.44 84.00 311 298

DS16108(*)B 142.44 96.00 352 336

DS16120(*)B 154.44 108.00 389 373

6"

FLG

8"

FLG

10"

FLG

2"

NPT

2.5"

NPT

Model

No.

23.31 11.00 5.00

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

16.00 23.50

0.75"

NPT

11.56

4"

FLG

13.75 11.56

6"

FLG

26.00

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

SUBMITTAL DATA

18 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

18DS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS1836(*)A 55.69 24.00 137.00 132.00

DS1848(*)A 67.69 36.00 184.00 178.00

DS1860(*)A 79.69 48.00 232.00 224.00

DS1872(*)A 91.69 60.00 280.00 271.00

DS1884(*)A 103.69 72.00 328.00 317.00

DS1896(*)A 115.69 84.00 376.00 363.00

DS18108(*)A 127.69 96.00 424.00 410.00

DS18120(*)A 139.69 108.00 472.00 456.00

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

5"

NPT

2 PASS 4 PASS

10.50

6"

NPT

8.00 3.88

Model

No.

7.25 11.00 18.00

HEAT EXCHANGER

25.00

10"

FLG

3"

NPT

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

** FABRICATED STEEL HEAD AVAILABLE TO

INCREASE TUBE SIDE PRESSURE TO 150 PSI

SUBMITTAL DATA

18 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

18BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS1836(*)B 72.63 24.00 137.00 132.00

DS1848(*)B 84.63 36.00 184.00 178.00

DS1860(*)B 96.63 48.00 232.00 224.00

DS1872(*)B 108.63 60.00 280.00 271.00

DS1884(*)B 120.63 72.00 328.00 317.00

DS1896(*)B 132.63 84.00 376.00 363.00

DS18108(*)B 144.63 96.00 424.00 410.00

DS18120(*)B 156.63 108.00 472.00 456.00

10"

FLG

3"

NPT

Model

No.

24.19 11.00 5.00

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

18.00 25.00

0.75"

NPT

12.00

4"

FLG

14.80 12.00

6"

FLG

28.00

SUBMITTAL DATA

20 DIA. STEAM TO WATER

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

20DS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

DOUBLE WALL

A B C D E F INLET OUTLET Y V SQ. FT. X Z U SQ. FT.

DS2036(*)A 56.81 21.00 180.00 174.00

DS2048(*)A 68.81 33.00 245.00 237.00

DS2060(*)A 80.81 45.00 310.00 300.00

DS2072(*)A 92.81 57.00 375.00 363.00

DS2084(*)A 104.81 69.00 440.00 426.00

DS2096(*)A 116.81 81.00 505.00 489.00

DS20108(*)A 128.81 93.00 570.00 552.00

DS20120(*)A 140.81 105.00 635.00 615.00

7.38 13.00 20.00

HEAT EXCHANGER

27.25

12"

FLG

4"

FLG

(*) INSERT NUMBER OF PASSES

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

6"

NPT

2 PASS 4 PASS

11.12

8"

NPT

8.75 4.50

Model

No.

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD CAST IRON CAST BRONZE OR CAST S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD 18 ga Copper

Leak Detector

3/4" OD 18 ga Cu/Ni

Leak Detector

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

MAXIMUM OPERATING CONDITIONS

TUBE SIDE WORKING PRESSURE** 125 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE** 250 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

** FABRICATED STEEL HEAD AVAILABLE TO

INCREASE TUBE SIDE PRESSURE TO 150 PSI

SUBMITTAL DATA

20 DIA. 150PSI, DOUBLE WALL

U-TUBE HEAT EXCHANGER

Job Name

Location

Engineer

Architect

Contractor

Sales Rep.

20BNDS-SUB REV:0 4-2-08 2008 Thrush Co., Inc.

Model Number

Steam Pressure

Ent. Temp.

Tube Side Flow

Fouling Factor

Tube Side

Pressure Drop

Leav. Temp.

Liquid

Sq. Ft.

Velocity Ft. Ft/Sec

WITH FLANGED BONNET HEAD

STEAM TO WATER

MATERIALS OF CONSTRUCTION

PART STANDARD OPTIONAL

HEAD C.I.* FAB STEEL OR FAB S.S.

SHELL STEEL S.S.

TUBE SHEET STEEL BRASS*** OR S.S.

TUBING

3/4" OD

20 ga Copper

18 ga. Copper, 304 S.S., 316 S.S.

90/10 CU/NI, OR 16 Ga. C.S.

CAGE MATERIAL STEEL BRASS OR S.S.

BAFFLES STEEL BRASS OR S.S.

*NOT SHOWN

TUBE SIDE WORKING PRESSURE 150 PSI

SHELL SIDE WORKING PRESSURE 150 PSI

HYDROSTATIC TEST PRESSURE TUBE SIDE 195 PSI

HYDROSTATIC TEST PRESSURE SHELL SIDE 195 PSI

MAXIMUM TEMPERATURE TUBE SIDE*** 375F

MAXIMUM TEMPERATURE SHELL SIDE*** 375F

***DERATE TO 300F WITH BRASS TUBESHEET

MAXIMUM OPERATING CONDITIONS

A B C D E F G H INLET OUTLET W V X SQ. FT. W V Y SQ. FT.

DS2036(*)B 77.06 21.00 180.00 174.00

DS2048(*)B 89.06 33.00 245.00 237.00

DS2060(*)B 101.06 45.00 310.00 300.00

DS2072(*)B 113.06 57.00 375.00 363.00

DS2084(*)B 125.06 69.00 440.00 426.00

DS2096(*)B 137.06 81.00 505.00 489.00

DS20108(*)B 149.06 93.00 570.00 552.00

DS20120(*)B 161.06 105.00 635.00 615.00

12"

FLG

4"

FLG

Model

No.

27.63 13.00 6.00

DESIGNED & CONSTRUCTED PER ASME SECT VIII DIV 1

HEAT EXCHANGER 2 PASS 4 PASS

(*) INSERT NUMBER OF PASSES

20.00 27.50

0.75"

NPT

14.13

6"

FLG

15.52 14.13

8"

FLG

32.00

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Document58 pagesDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- Golz FS400 Operators and Parts ManualDocument48 pagesGolz FS400 Operators and Parts ManualdrmassterNo ratings yet

- ISO - 286-2 Shaft Limits TolerancesDocument2 pagesISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- Batching Plant Inspection Check ListDocument2 pagesBatching Plant Inspection Check ListKhadar Basha88% (8)

- GMW3359Document4 pagesGMW3359lev501No ratings yet

- Strainoptic Stress ManualDocument9 pagesStrainoptic Stress Manualjsrplc7952No ratings yet

- ASCO Series 230 Automatic Transfer Switch 2017Document18 pagesASCO Series 230 Automatic Transfer Switch 2017Anonymous SDeSP1No ratings yet

- Book 3Document4 pagesBook 3Subas ChandNo ratings yet

- 236D3 Plano EléctricoDocument23 pages236D3 Plano EléctricoFerreira Anibal ParedesNo ratings yet

- (Rev) Electrowinning of Zing From Sulphate Solutions - M Mufti AbdillahDocument27 pages(Rev) Electrowinning of Zing From Sulphate Solutions - M Mufti AbdillahDafi GhifariNo ratings yet

- OCOR Standards 050114Document41 pagesOCOR Standards 050114Carlos Ernesto Flores AlbinoNo ratings yet

- Dehydration SugarDocument2 pagesDehydration SugarAyu Dara KharismaNo ratings yet

- The Effect of ShearDocument11 pagesThe Effect of Shearanakren296No ratings yet

- Struers Application Note - Metallographic Preparation of High Alloy Tool SteelDocument6 pagesStruers Application Note - Metallographic Preparation of High Alloy Tool SteelCan ERTANNo ratings yet

- Impact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanDocument17 pagesImpact of Green Supply Chain Management Practices On Firms' Performance: An Empirical Study From The Perspective of PakistanMaia NovitasariNo ratings yet

- E-Waste Management: A Case Study of Bangalore, IndiaDocument5 pagesE-Waste Management: A Case Study of Bangalore, IndiaJatindra Kumar PradhanNo ratings yet

- DesaltingDocument25 pagesDesaltingOmar GamalNo ratings yet

- Upuuteg Aug2012Document80 pagesUpuuteg Aug2012josipNo ratings yet

- Recycling Market Study ReportDocument132 pagesRecycling Market Study ReportMelih AltıntaşNo ratings yet

- MECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01Document59 pagesMECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01florenceprasadNo ratings yet

- TS-ELEC-04 - Specification of Electric Cables - R1Document23 pagesTS-ELEC-04 - Specification of Electric Cables - R1SUSOVAN BISWASNo ratings yet

- Entrance Canopy Standard-VietLong-LayoutDocument1 pageEntrance Canopy Standard-VietLong-LayoutNguyễn Việt LongNo ratings yet

- en 10213 2007 Steel Castings For Pressure Purposes PDFDocument29 pagesen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNo ratings yet

- PQI FormatDocument6 pagesPQI Formatmurtaza506100% (2)

- Dhanraj P.Judal B.E.Mech Judal - Dhanaraj@yahoo - Co.in Mo 8530618691, 9737989912 (Home)Document3 pagesDhanraj P.Judal B.E.Mech Judal - Dhanaraj@yahoo - Co.in Mo 8530618691, 9737989912 (Home)nairajit_ajit18No ratings yet

- Denver Equipment Company Handbook - IndexDocument6 pagesDenver Equipment Company Handbook - IndexCristiam MercadoNo ratings yet

- Triple Star Fire Catalogue Price List v2.5Document16 pagesTriple Star Fire Catalogue Price List v2.5pastorgeeNo ratings yet

- TdsDocument2 pagesTdsSudipta BainNo ratings yet

- Footings and FoundationsDocument13 pagesFootings and Foundationsg4goharNo ratings yet

- Dimension of IncubatorsDocument3 pagesDimension of IncubatorsSwarali KamathNo ratings yet