Professional Documents

Culture Documents

Materials Chart

Uploaded by

RajaSekarsajjaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials Chart

Uploaded by

RajaSekarsajjaCopyright:

Available Formats

Suhm Spring Works

Materials

Suhm purchases only the highest quality material, because the superior caliber of each spring

produced depends on it. Suhm keeps over 52,000 square feet of popular and exotic raw

materials in stock to ensure prompt delivery of your order. Many sizes of virtually all materials

listed in the Wire Properties Chart are held in inventory.

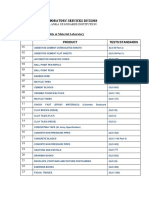

Wire Properties Chart

The following chart is a general spring design reference. Because this chart is only a simple

reference, and every spring application has its own particular parameters, we suggest you

contact a Suhm sales staff member for more information on spring design application and

customization.

The Suhm Spring Materials: Sizes and Strength Values book, which consists of the information

in this chart along with sizes and tensile strengths for most materials, is available by contacting

a Suhm sales staff member.

Material Material Properties

Maximum

Working

Temp.

Ultimate

Tensile

Range

(ksi min)

Modulus of

Elasticity

Approx.

Design

% of

Ultimate

Tensile

(torsional)

Common

Sizes

(inches)

Alloy Steel

Music Wire

ASTM A228

UNS K08500 &

G10860

Cold drawn. Constant tensile strength.

High-quality and good for high cycle spring

applications.

250F 449/230

(E) 30

(G) 11.5

45%

.012" to

.250"

High Carbon Steel Wire/bar

Oil Tempered

Wire, Class I

ASTM A229

UNS K07001 &

G10650

Cold drawn. All purpose spring material. Heat

treated before fabrication. Susceptible to

hydrogen embrittlement when plated.

250F

323/125

(class I)

(E) 30

(G) 11.5

45%

.032" to

.625"

Chrome

Vanadium

ASTM A-231

Valve Quality:

ASTM A-232

AMS 6450

Cold drawn. Good for shock loads and medium

elevated temperature applications. Susceptible to

hydrogen embrittlement when plated.

425F 325/190

(E) 30

(G) 11.5

45%

.043" to

.500"

Chrome Silicon

Wire

ASTM A401

UNS G92540

Cold drawn. Good for shock loads and medium

elevated temperature applications. Susceptible to

hydrogen embrittlement when plated.

475F 300/226

(E) 30

(G) 11.5

45%

.024" to

.438"

1

Material Material Properties

Maximum

Working

Temp.

Ultimate

Tensile

Range

(ksi min)

Modulus of

Elasticity

Approx.

Design

% of

Ultimate

Tensile

(torsional)

Common

Sizes

(inches)

Hot Rolled Alloy Bar

5160-H

.468" to 1.25"

ASTM A689,

A29

UNS G516000

Hot-rolled special bar quality, fine grained. Good

fatigue life.

400F 242/211

(E) 29

(G) 10.5

45%

.468" to

1.250"

51B60-H

1.25" to

1.937"

ASTM A689,

A29

UNS 51601

Hot-rolled special bar quality, fine grained. Good

fatigue life.

400F 242/211

(E) 30

(G) 11.0

45%

1.250" to

1.937"

4161-H

2.00" to

2.875"

ASTM A689,

A29

UNS 41610

Hot-rolled special bar quality, fine grained. Good

fatigue life.

400F 242/211

(E) 30

(G) 11.0

45%

2.00" to

2.875"

Stainless Steel

AISI 302/304

Stainless

Steel Wire

ASTM A313

AMS 5688

UNS S30200

Cold drawn. Low cost. Good for general purpose

corrosion and elevated temperature applications. Has

some magnetism in a spring temper.

500F 325/130

(E)28

(G)9.8

40%

.015" to

.500"

AISI 316

Stainless

Steel

Wire

ASTM A313

UNS S31600

Cold drawn. Better corrosion resistance than 302/304.

Good for elevated temperatures. No magnetism.

550F 245/110

(E) 28

(G) 9.8

40%

.017" to

.500"

T-316 SS Bar

ASTM A276

Cond B

UNS S31600

Cold drawn. Better corrosion resistance than 302/304.

Good for elevated temperatures. No magnetism.

550F 245/110

(E) 28

(G) 9.8

40%

.562" to

1.750"

17-7PH

Stainless

Steel Wire

ASTM A313

AMS 5678

UNS S17700

Age hardened. High tensile strength. Good for

general corrosion resistance. No magnetism.

550F 365/230

(E) 29

(G) 11.0

45%

.017" to

.562"

17-4PH Bar

ASTM A564

UNS S17400

Age hardened. High tensile strength. Good for

general corrosion resistance. No magnetism.

550F 365/230

(E) 29

(G) 11.2

45%

.562" to

2.875"

Alloy 20

Spring

Tempered

Wire

ASTM B473

UNS N08020

Excellent mechanical properties and easily fabricated.

Moderate to good corrosion resistance. Used

extensively in petrochemical and refining applications.

- 200/125

(E) 29

(G) 10.9

45%

.025" to

.362"

A-286 Spring

Tempered

Wire

AMS 5734

and others

UNS S66286

Age hardened. Good corrosion resistance. Good for

use in elevated temperature applications. No

magnetism.

900F 200/160

(E) 29.1

(G) 10.4

45%

.040" to

.295"

2

Material Material Properties

Maximum

Working

Temp.

Ultimate

Tensile

Range

(ksi min)

Modulus of

Elasticity

Approx.

Design

% of

Ultimate

Tensile

(torsional)

Common

Sizes

(inches)

Copper Base Alloy

Phosphor Bronze

Wire Grade A

ASTM B159 H08

UNS C51000

Cold drawn. Good electrical conductivity.

Good corrosion resistance.

200F 145/105

(E) 15

(G) 6.25

40%

.010" to

.468"

Beryllium Copper

Wire

ASTM B197

Cold drawn. Good electrical conductivity.

Good corrosion resistance

400F 230/150

(E) 18.5

(G) 7.2

45%

.010" to

.468"

Nickel Base Alloy Wire/bar

Inconel X-750

Spring Tempered

Wire

AMS 5698,

AMS 5699

UNS N07750

Cold drawn, age hardened. Good corrosion

resistance. Good for use in elevated

temperature applications. Good for use in

Sour-Gas applications.

700F 230/180

(E) 29

(G) 11.2

45%

.005" to

.750"

Inconel X-750

Bar

ASTM B637

UNS N07500

Cold drawn. Good corrosion resistance.

Good for use in elevated temperature

applications. Good for use in Sour-Gas

applications.

700F 170

(E) 29

(G) 11.2

45%

.750" to

2.500"

Inconel 600

QQ-W-390

UNS N06600

Cold drawn. Good corrosion resistance.

Good for use in elevated temperature

applications.

700F 205/120

(E) 29

G) 11.0

45%

.005" to

.750"

Inconel 625 Spring

Tempered Wire

ASTM B446

UNS N06625

Cold drawn. Good corrosion resistance.

Good for use in elevated temperature

applications.

700F 205/120

(E) 29

(G) 11.0

45%

.012" to

.175"

Inconel 718 Spring

Tempered Wire

ASTM B637

UNS N07718

Age hardened. Good corrosion resistance.

Good for use in elevated temperature

applications. No magnetism

1200F 250/210

(E) 29

(G) 11.2

45%

.012" to

.275"

Inconel 718 Bar

ASTM B637

UNS N07718

Age hardened. Good corrosion resistance.

Good for use in elevated temperature

applications. No magnetism

1200F 250/210

(E) 29

(G) 11.2

45%

.234" to

1.500"

MP35N Spring

Tempered Wire

AMS 5844

UNS R30035

Cold drawn, age hardened. High strength.

High modulus value and corrosion resistance.

Great choice for severe spring applications.

Good for applications involving the presence of

Hydrogen Sulfide.

600F 330/230

(E) 34

(G) 11.74

45%

.005" to

.750"

Elgiloy Spring

Tempered Wire

AMS 5834

UNS R30003

Cold drawn. Very high fatigue strength and

long life.

600F 350/220

(E) 29.5

(G) 11.5

45%

.005" to

.750"

Monel 400 Spring

Tempered Wire

AMS 7233 or 4544,

ASTM B164

UNS N04400

Cold drawn. Good corrosion resistance. Good

for elevated temperature applications.

450F 165/120

(E) 26

(G) 9.5

40%

.014" to

.500"

Monel K-500 Spring

Tempered Wire/Bar

QQ-N-286

AMS 4676C

UNS N05500

Cold drawn. Very high corrosion resistance.

Good for use in elevated temperature

applications.

500F 195/140

(E) 26

(G) 9.5

40%

.018" to

2.00"

3

Material Material Properties

Maximum

Working

Temp.

Ultimate

Tensile

Range

(ksi min)

Modulus

of

Elasticity

Approx.

Design

% of

Ultimate

Tensile

(torsional)

Common

Sizes

(inches)

Nickel Base Alloy Wire/bar, continued

Hastelloy C-276

Wire

AMS B574 (Chem.

only),

AMS J 470

UNS N10276

Good corrosion resistance to many acids and

salts.

- -

(E) 29.8

(G) 10.9

-

.012" to

.437"

Hastelloy B-2

ASTM B335

AMS J 470

UNS N10665

Good corrosion resistance to many acids and

salts.

- -

(E) 28

(G) 8.0

-

.018" to

.207

Titanium

Titanium Beta-C

AMS 4957

UNS R58640

Age hardened. Good ductility and toughness.

Good fabricability, and good resistance to

general corrosion. Good for environments

containing Ferric Chloride, Sodium Chloride,

Carbon Dioxide, and Hydrogen Sulfide

600F 190/180

(E) 15.4

(G) 5.9

45%

005" to

.625"

Titanium 6Al-4V

AMS 4965

UNS R56400

Age hardened. Good ductility and toughness.

Good fabricability, and good resistance to

general corrosion.

- 165

(E) 15

(G) 5.0

40%

.020" to

.250"

Tool Steel

H-12 Tungsten Bar

ASTM A681

(Chem. only)

UNS T20812

Good for high temperature applications. 700F 187

(E) 30

(G) 11.0

45%

.500" -

2.250"

These data are provided as a reference guide only and are not intended for design purposes.

Strength values and sizes are subject to change. Please check with a Suhm Spring representative

for confirmation.

4

v9b

You might also like

- Metals, Test Methods and Analytical ProceduresDocument1 pageMetals, Test Methods and Analytical ProceduresSARATH KRISHNAKUMARNo ratings yet

- Pipe & Pipe FittingsDocument10 pagesPipe & Pipe FittingsSalim BakhshNo ratings yet

- Material Carbon Steel Stainless Steel (SS) Low Alloy Steel (Las) Low Temp. Carbon Steel (LTCS)Document2 pagesMaterial Carbon Steel Stainless Steel (SS) Low Alloy Steel (Las) Low Temp. Carbon Steel (LTCS)Jasbir SinghNo ratings yet

- Material Comparison ChartDocument2 pagesMaterial Comparison Chartg_sanchetiNo ratings yet

- 23 - Piping Glossary & DefinitionsDocument22 pages23 - Piping Glossary & DefinitionsAsad KhanNo ratings yet

- Piping MaterialsDocument1 pagePiping Materialslibid_rajNo ratings yet

- Material Properties ChartDocument2 pagesMaterial Properties ChartNick PieperNo ratings yet

- Progress SummaryDocument1 pageProgress SummaryIrwan KurniawanNo ratings yet

- Analysis of Transaction CostDocument383 pagesAnalysis of Transaction CosthjsdNo ratings yet

- Delay Analysis 1Document8 pagesDelay Analysis 1Eslam AshourNo ratings yet

- Material Properties Requirements For Metallic MaterialsDocument70 pagesMaterial Properties Requirements For Metallic Materialsعزت عبد المنعمNo ratings yet

- Laboratory Services Division: Sri Lanka Standards InstitutionDocument4 pagesLaboratory Services Division: Sri Lanka Standards InstitutionAbcNo ratings yet

- Itp Skpi NewDocument11 pagesItp Skpi NewvickywijayaNo ratings yet

- EF19D - Inteface Project Data - Updated 05.02.2017-RajDocument250 pagesEF19D - Inteface Project Data - Updated 05.02.2017-Rajrajkamal_eNo ratings yet

- Performance Evaluation of Construction PDocument10 pagesPerformance Evaluation of Construction PMarioNo ratings yet

- AODD Pump Material Selection ChartDocument13 pagesAODD Pump Material Selection ChartthunderNo ratings yet

- En 10025 S235JR SteelDocument2 pagesEn 10025 S235JR SteelAgung Nak OtomotifNo ratings yet

- FRM Index (Revised)Document28 pagesFRM Index (Revised)api-3717306No ratings yet

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoNo ratings yet

- Man Hour EstimationDocument2 pagesMan Hour EstimationSergio SmithNo ratings yet

- Ch2-General Design Considerations Week2Document61 pagesCh2-General Design Considerations Week2ميثة الغيثيةNo ratings yet

- Pocket Companion of Useful Information & Tables For Wrought Iron, C. L. Strobel, 1881Document177 pagesPocket Companion of Useful Information & Tables For Wrought Iron, C. L. Strobel, 1881Sherwood McGowanNo ratings yet

- A FEDS Structural BoltsDocument6 pagesA FEDS Structural BoltsCrimsonPoshNo ratings yet

- Astm A563Document5 pagesAstm A563poerwntiNo ratings yet

- LR5 Cap 9 Cost Estimating - Scott Amos - Skills Knowledge of Cost Engineering - AACEI - 2004Document36 pagesLR5 Cap 9 Cost Estimating - Scott Amos - Skills Knowledge of Cost Engineering - AACEI - 2004apzambonNo ratings yet

- Business MathsDocument7 pagesBusiness MathsAftab HossainNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarNo ratings yet

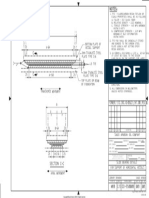

- A6561 Bollard DetailDocument1 pageA6561 Bollard DetailMarvinPatricioNarcaNo ratings yet

- Piping Fabrication & Laing PDFDocument19 pagesPiping Fabrication & Laing PDFSachidananda SwarNo ratings yet

- BS en 10059-2003Document12 pagesBS en 10059-2003Martijn GrootNo ratings yet

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Engineering Data: 2. CV CalculationDocument1 pageEngineering Data: 2. CV Calculationdj22500No ratings yet

- Astm F3125 F3125M 18Document6 pagesAstm F3125 F3125M 18Amine ait talebNo ratings yet

- PTC Test Program For ASTM A351Document3 pagesPTC Test Program For ASTM A351Deepak DasNo ratings yet

- Asme Sa 106 Grade B PipesDocument1 pageAsme Sa 106 Grade B PipesFerroPipENo ratings yet

- HO Manhour SheetDocument6 pagesHO Manhour SheetPrasad GowriNo ratings yet

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- ECI CLP3 Pricing System For PipingDocument133 pagesECI CLP3 Pricing System For PipingWajdi MansourNo ratings yet

- Scheduling ExcelDocument58 pagesScheduling ExcelSafety Inspector Daop 7No ratings yet

- Astm A338-14 PDFDocument2 pagesAstm A338-14 PDFromerobernaNo ratings yet

- SDI COSP-2012: Discover The Easiest Way To Specify Metal DeckingDocument12 pagesSDI COSP-2012: Discover The Easiest Way To Specify Metal DeckingRicardo TorresNo ratings yet

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- ASTM A572 Grade 50 Plate: AnalysisDocument2 pagesASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoNo ratings yet

- A 941 - 04 QTK0MQDocument7 pagesA 941 - 04 QTK0MQTrầnHữuHòaNo ratings yet

- Piping For PDFDocument1 pagePiping For PDFSumañ DašNo ratings yet

- Fiberstrong Wavistrong: Flange GuideDocument1 pageFiberstrong Wavistrong: Flange Guidesiva8000No ratings yet

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- Short List of Applied Piping Standard PDFDocument3 pagesShort List of Applied Piping Standard PDFmohamad3010No ratings yet

- Mech Malleable Iron Fittings Catalogue PDFDocument12 pagesMech Malleable Iron Fittings Catalogue PDFics companyNo ratings yet

- Structural Steels Equivalent ChartDocument2 pagesStructural Steels Equivalent ChartHamdan PkNo ratings yet

- DD 950008 001Document1 pageDD 950008 001Abu Anas M.SalaheldinNo ratings yet

- Astm A-351 GR CF8MDocument2 pagesAstm A-351 GR CF8MVictor Castellanos AlegriaNo ratings yet

- Specifying The Chemical Compositions and Selecting Sampling Practices and Quantitative Analysis Methods For Metals, Ores, and Related MaterialsDocument3 pagesSpecifying The Chemical Compositions and Selecting Sampling Practices and Quantitative Analysis Methods For Metals, Ores, and Related MaterialsHassan FekiNo ratings yet

- Process Industry Practices Structural: PIP STE01100 Constructability Design GuideDocument22 pagesProcess Industry Practices Structural: PIP STE01100 Constructability Design Guideeng laythNo ratings yet

- Kiss Standard Version 1 1Document21 pagesKiss Standard Version 1 1y_fakoriNo ratings yet

- Astm IndexDocument30 pagesAstm IndexAnshul JainNo ratings yet

- Spec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportDocument16 pagesSpec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportRafeek ShaikhNo ratings yet

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- Suhm Spring Works-Spring Materials Issue 9a en US v1Document37 pagesSuhm Spring Works-Spring Materials Issue 9a en US v1DizzixxNo ratings yet

- Spring Materials: Sizes & Strength ValuesDocument37 pagesSpring Materials: Sizes & Strength ValuesAntonio PerezNo ratings yet

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaNo ratings yet

- Carbon It RidingDocument3 pagesCarbon It RidingRajaSekarsajjaNo ratings yet

- Nitro - CarburizingDocument9 pagesNitro - CarburizingRajaSekarsajjaNo ratings yet

- Heavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticDocument7 pagesHeavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticRajaSekarsajjaNo ratings yet

- Raw 4x4 BrochureDocument1 pageRaw 4x4 BrochureRajaSekarsajjaNo ratings yet

- Evaluation of Coating PerformanceDocument14 pagesEvaluation of Coating PerformanceRajaSekarsajjaNo ratings yet

- Disc Spring SheetDocument2 pagesDisc Spring SheetRajaSekarsajjaNo ratings yet

- 3-D Measurements On PistonsDocument4 pages3-D Measurements On PistonsRajaSekarsajjaNo ratings yet

- Leaf Spring CatalogueDocument1 pageLeaf Spring CatalogueRajaSekarsajjaNo ratings yet

- Tubular Piston RodsDocument1 pageTubular Piston RodsRajaSekarsajjaNo ratings yet

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- Shock Absorber Performance Test Rig: Ubique SystemsDocument1 pageShock Absorber Performance Test Rig: Ubique SystemsRajaSekarsajjaNo ratings yet

- Damping Force at Zero Velocity ExplainedDocument6 pagesDamping Force at Zero Velocity ExplainedRajaSekarsajjaNo ratings yet

- Where The Graphs Come FromDocument7 pagesWhere The Graphs Come FromRajaSekarsajjaNo ratings yet

- Guide To Dyno GraphsDocument10 pagesGuide To Dyno GraphsRajaSekarsajjaNo ratings yet

- JRZ Suspension EngineeringDocument25 pagesJRZ Suspension EngineeringRajaSekarsajja100% (1)

- Automobile Industry in PPT Ankit KumarDocument60 pagesAutomobile Industry in PPT Ankit Kumarkumaripm33% (3)

- Cyclic WeatheringDocument8 pagesCyclic WeatheringRajaSekarsajjaNo ratings yet

- Supergas SpringsDocument2 pagesSupergas SpringsRajaSekarsajjaNo ratings yet

- Suspension Design Rajeev - MokashiDocument16 pagesSuspension Design Rajeev - MokashiJatin351100% (1)

- Mistakes in AuditDocument4 pagesMistakes in AuditRajaSekarsajjaNo ratings yet

- Lecture 1-4 Non Traditional Machining ProcessesDocument44 pagesLecture 1-4 Non Traditional Machining ProcessesRishika Viral PatelNo ratings yet

- GMW14672 ProfileID - 000070128Document15 pagesGMW14672 ProfileID - 000070128Muthu Ganesh100% (1)

- What To Consider When Welding Dissimilar MaterialsDocument8 pagesWhat To Consider When Welding Dissimilar MaterialsWeldPulse100% (2)

- Asme Section Ii A-2 Sa-723 Sa-723mDocument6 pagesAsme Section Ii A-2 Sa-723 Sa-723mdavid perezNo ratings yet

- Atomic MassesDocument5 pagesAtomic MassesJesús CastilloNo ratings yet

- Chloride Stress Corrosion Cracking - SSINADocument4 pagesChloride Stress Corrosion Cracking - SSINADaniel WilliamsNo ratings yet

- Method Statement - Roof VentilatorDocument7 pagesMethod Statement - Roof VentilatorJuwe Pkdo100% (2)

- Salt Contamination Check ISO 8502-6Document2 pagesSalt Contamination Check ISO 8502-6Danar Tri Yurindatama0% (1)

- Aluminum GradesDocument2 pagesAluminum GradesdantoliniNo ratings yet

- Specification For Structural Steel (Materials, Fabrication, Erection)Document24 pagesSpecification For Structural Steel (Materials, Fabrication, Erection)sivagnanam sNo ratings yet

- Directions of Use BDRDocument2 pagesDirections of Use BDRazam RazzaqNo ratings yet

- TOOL AND DIE STEEL FinalDocument73 pagesTOOL AND DIE STEEL FinalSapan KansaraNo ratings yet

- 07 01 METALLURGY Principles and Methods of ExtractionDocument17 pages07 01 METALLURGY Principles and Methods of ExtractionrcraktimcNo ratings yet

- Copper WeightDocument4 pagesCopper Weightmajid_20100% (1)

- Heavy Liquid SeparationDocument4 pagesHeavy Liquid SeparationLeonardo Paul ZavaletaNo ratings yet

- Alcoa Nautic Al Plate PDFDocument8 pagesAlcoa Nautic Al Plate PDFAryNo ratings yet

- Lucrari ISIDocument13 pagesLucrari ISIAndra DenisaNo ratings yet

- Nickel Free High Nitrogen Austenitic Steels - 1996 - ISIJ InternationalDocument9 pagesNickel Free High Nitrogen Austenitic Steels - 1996 - ISIJ Internationalsmith willNo ratings yet

- Some Investigations On The Corrosion of IronDocument6 pagesSome Investigations On The Corrosion of IronHannah MercadoNo ratings yet

- Repair Cast Iron PDFDocument13 pagesRepair Cast Iron PDFClaudiu MorarNo ratings yet

- SP3 Rail For Heavy Haul Railwas 027-36Document3 pagesSP3 Rail For Heavy Haul Railwas 027-36Rakesh KapoorNo ratings yet

- Report On Vietnam's Iron and Steel Imports: Group: 72NKDocument60 pagesReport On Vietnam's Iron and Steel Imports: Group: 72NKDien Truc TienNo ratings yet

- 6010 Metsim Dynamic ApplicationsDocument1 page6010 Metsim Dynamic ApplicationsSenthilkumar PragasamNo ratings yet

- Use O? AllDocument13 pagesUse O? AllHòa NguyễnNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- Catalogue Eng PDFDocument20 pagesCatalogue Eng PDFjojoNo ratings yet

- Quotation of Whole Electric Galvanizing Line - Huarui, Sally WuDocument4 pagesQuotation of Whole Electric Galvanizing Line - Huarui, Sally WuMohsin Ul Amin KhanNo ratings yet

- GB 20 & Astm 106Document2 pagesGB 20 & Astm 106satheshNo ratings yet

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100No ratings yet

- WTI Screw Thread InsertsDocument16 pagesWTI Screw Thread InsertsAce Industrial SuppliesNo ratings yet