Professional Documents

Culture Documents

MM1DM1 Exam 2012-13 With Solutions

Uploaded by

Leslie LaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MM1DM1 Exam 2012-13 With Solutions

Uploaded by

Leslie LaiCopyright:

Available Formats

MM1DM1-E1

MM1DM1-E1

The University of Nottingham

DEPARTMENT OF MECHANICAL, MATERIALS AND MANUFACTURING ENGINEERING

A LEVEL 1 MODULE, SPRING SEMESTER 2012-2013

DESIGN AND MANUFACTURE 1

Time allowed ONE Hour THIRTY Minutes

Candidates may complete the front cover of their answer book and sign their desk card but

must NOT write anything else until the start of the examination period is announced

Answer ONE question from each Section

Only silent, self contained calculators with a Single-Line Display or Dual-Line Display are

permitted in this examination.

Dictionaries are not allowed with one exception. Those whose first language is not English

may use a standard translation dictionary to translate between that language and English

provided that neither language is the subject of this examination. Subject specific translation

dictionaries are not permitted.

No electronic devices capable of storing and retrieving text, including electronic dictionaries,

may be used.

DO NOT turn examination paper over until instructed to do so

ADDITIONAL MATERIAL: None

INFORMATION FOR INVIGILATORS: None

Turn Over

2

MM1DM1-E1

MM1DM1-E1

Section A

1.

(a) The following types of lubrication types are available:

Boundary

Dry

Hydrodynamic

Hydrostatic

None

For each application below (i-v), choose the most suitable lubrication type.

i) A car wheel

[2 marks]

Answer

Boundary

ii) A car crankshaft

[2 marks]

Answer

Hydrodynamic

iii) A barrel lock in a door

[2 marks]

Answer

Dry

iv) A toddlers bike wheel (A steel axle running in a polymeric bearing)

[2 marks]

Answer

None

v) A slowly rotating shaft which experiences a high radial load

[2 marks]

Answer

Hydrostatic

(b) Explain why a cylindrical roller bearing can support a greater radial load than a

ball bearing.

[5 marks]

Answer

The cylindrical roller distributes the load across a line contact rather than a point

contact.

(c) Sketch a deep groove ball bearing mounted on a shaft with a fixed inner race

and a floating outer race.

[10 marks]

3

MM1DM1-E1

MM1DM1-E1

Answer

(d) A shaft of 20mm running in a plain bearing rotates at 100 RPM in a journal that

is 30mm long. A radial load of 500N is carried by the bearing. Calculate the

limiting PV value for the bearing.

[25 marks]

Answer

The Pressure is calculated as

=

= 833,333

(10 marks)

The operating Velocity is calculated as

2

(10 marks)

The limiting PV is calculated as

(5 marks if units are correct else 2 marks )

(e) A pulley (75 mm) on a crankshaft is used to drive an alternator pulley (30

mm) using a vee belt. The distance between the pulley centres is 500 mm. The

crankshaft rotates at 3000 RPM. The vee belt has a cross sectional area of

1.44x10

-4

m

2

and the maximum permissible strength of the belt is 12 MPa. The

coefficient of friction between the belt and the pulleys is 0.8.

You may find the following equations useful:

Belt length

+

1

2

(

)

Angle of contact on smaller pulley

Angle of contact on larger pulley

Eytleweins Formula

e

F

F

2

1

4

MM1DM1-E1

MM1DM1-E1

i.) Determine the speed of the alternator pulley in RPM.

[5 marks]

Answer

= 3000

75/2

30/2

= 7500

ii.) Determine the maximum power that can be transmitted from the crankshaft to

the alternator assuming no belt slippage

[35 marks]

Answer

The tight side load in the belt is limited by the maximum permissible strength of the

belt.

= 1210

1.4410

= 1728

(5 marks)

To transfer the power, no slippage can occur, so Eytleweins formula must be satisfied

e

F

F

2

1

Where slippage is likely to occur on the smallest pulley as it has the least contact area,

so

= (

) = 2 sin

2

= 2 sin

0.075 0.030

2 0.500

180

= 3.052

(10 marks)

The Eytleweins formula can be solved for the slack side force, F

2

=

1728

..

= 150

(10 marks)

The belt speed is calculated as

=

2

= 3000

1

60

2

1

0.075

2

= 11.781 /

(5 marks)

So the maximum power transmitted is

= (

) = (1728 150) 11.781 = 18,590

(5 marks)

iii.) Determine the torque produced at the crankshaft

[10 marks]

Answer

= (

= (1728 150)

0.075

2

= 59

2.

(a) If you wanted to prevent axial and rotational movement of a gear on a shaft

would you make the connection with a roll pin or a plain key?

5

MM1DM1-E1

MM1DM1-E1

[2 marks]

Answer

Roll pin

(b) Name 2 advantages and 2 disadvantages of keys for attaching elements to

shafts.

[8 marks]

Answer

Advantages

1. Inexpensive

2. Provide positive drive

Disadvantages

1. Shafts requires a keyway to be machined

2. The keyway gives rise to a stress concentration in the shaft

(2 marks/answer)

(c) Name 5 ways of achieving an interference fit between the hub of a gear and a

shaft

[10 marks]

Answer

1. Cool the shaft prior to assembly

2. Heat the hub prior to assembly

3. Use a combination of 1 and 2 above

4. Press the hub onto the shaft

5. Expand the hub using high pressure oil

(2 marks/answer)

(d) A hub is secured onto a shaft using an interference fit. Pressure, P, is developed

between the hub and shaft which keeps the hub from slipping on the shaft when

a torque is applied. Show that the expression for the maximum torque capacity

of this hub to shaft connection is

2

Where

= coefficient of friction between shaft and hub

l = hub length in contact with the shaft

D = shaft diameter

[30 marks]

Answer

The interface pressure, P, sets up a frictional force, N, between the hub and shaft surface

which acts tangentially to the surface and along the contacting length of the shaft, l. When

this frictional force is overcome, the hub will slip on the shaft, therefore the maximum torque

at the point of slip can be defined as

(5 marks)

The normal force, N acts everywhere normal to the interface surface, A which is related to the

6

MM1DM1-E1

MM1DM1-E1

interface pressure as

=

(5 marks)

Where the interface surface is defined as

= 2

2

(5 marks)

So

= = 2

2

(5 marks)

Substituting for the normal force and simplifying

2

=

2

(10 marks)

(e) Estimate the fastener pre-load, F, required in the tapered hub-shaft connection shown

below to achieve a maximum torque capacity, T

max

, of 500 Nm, assuming a friction

coefficient of 0.2 on all surfaces. An M24 thread is employed. The taper angle is 12,

the shaft end diameter, D

1

is 30 mm and the hub length is 45 mm. Include the torque

capacity associated with the hexagonal nut having a major thread diameter of 24 mm

and a distance across its flats of 36 mm.

(f)

Recall that the maximum torque carrying capacity for the tapered region only is

expressed as

Where

=coefficient of friction between the shaft and hub as well as between the nut

and hub

l = hub length

D

t

= mean shaft diameter along the taper

[50 marks]

Answer

As stated, the maximum torque capacity generated in the tapered region is given by the

=12

45 mm

D

1

D

2

7

MM1DM1-E1

MM1DM1-E1

expression

The additional torque capacity resulting from the nut is

2

(15 marks)

The total torque capacity is

+

+

(10 marks)

Solving for the pre-load force

=

2

+

+

(5 marks)

Where

2

(5 marks)

And

= 2 (0.045 12) +

= 2 (0.045 12) +0.030 = 0.049

=

0.030 +0.049

2

= 0.040

(5 marks)

Also the average of the major nut thread diameter and the distance across the flats is

=

0.024 +0.036

2

= 0.030

(5 marks)

Finally

=

2

+

+

=

2 500

0.2

0.040

0.2 12 +12

+0.030

= 38,723

(5 marks)

8

MM1DM1-E1

MM1DM1-E1

Section B

3.

(a) Using a detailed figure in each case, demonstrate how 3 forms of milling tool

wear occur. Your answer should also include some commentary on the defects

to the machined surface which may result from this.

[30 marks]

Answer

Any three figures and discussion with three comments relating to

surface properties of the workpiece.

(b) Modern machine tools which are used to mill complex geometries are

9

MM1DM1-E1

MM1DM1-E1

capable of 5-axis machining. Using a fully labelled diagram discuss the

principal features of such a machine tool.

[30 marks]

Answer

Discussion of principle features (6 features for 5 marks each).

Candidates may also choose to discuss trunion type arrangements and

horizontal machine tools

(c) Discuss the typical stages involved in developing a CNC program for a machine tool

using generic CAD/CAM software. Your answer should go on to make mention of the

stages involved in setting up a job on a modern machining centre.

[40 marks]

Answer

Import of CAD data

Perhaps some mention of CAD formats and method of importing into the CAD package

Placing the part inside a stock block

Selection of tool type and profile

Defining cutting conditions (feed and spindle speeds)

Post processing to translate to the machine dialect

G-Code created in readable format

Typical commands may include: spindle ON (M05), Spindle speed (S4000) for 4000rpm

or M00 for all stop. Accept any sensible suggestion with meaning.

Set up of job (may include figure with datum acquisition, fixturing and tooling).

4.

(a) With the aid of a diagram discuss briefly the process of laser cutting. Your

answer should include some comment about the interaction of the laser with the

workpiece.

10

MM1DM1-E1

MM1DM1-E1

[30marks]

Answer

Answer should include some commentary on the conversion of incident radiation to

heat within the substrate, formation of dross and evaporation.

(b) With the aid of a labelled diagram explain the process of electrochemical

machining. You should also discuss a typical application for this process in your

answer.

[30 marks]

Answer

Answers should give a sensible application for this process, most likely finishing of

aero/biomedical components.

(c) The purchase of any machine tool and its incorporation into a manufacturing process

presents a significant challenge to manufacturing companies. Discuss, with the aid of

diagrams the typical stages and considerations involved when selecting and

commissioning a new machine tool.

[40 marks]

11

MM1DM1-E1

MM1DM1-E1

Answer

Some discussion around key points such as (but not limited to):

Cost

Capability/performance

Quality

Environmental

Availability

Flexibility

The outlay associated with machine tools is significant (10K- 1000sK)

Good decisions must be made, SME large multinational. To expand or replace legacy

equipment

Development of business plan/case for investment

Technical justification

Consideration of product life time.

Scientific metrics must often be devised and applied to facilitate these decisions.

12

MM1DM1-E1

MM1DM1-E1

Section C

5.

(a) Describe the process of calibration.

[40 marks]

Answer

[8 marks for each of the steps described below]

1. A second instrument or standard of known accuracy is required for calibration.

2. The value of the quantity being measured is varied over the range of interest.

3. All other parameters (e.g. temperature, pressure, noise) kept constant as far as possible.

4. Readings of both instruments are recorded

a. X - output of the known instrument/standard

b. M - output of the instrument being calibrated.

5. These are plotted on a Calibration Graph as follows, a regression analysis is performed to

create an equation that give X in terms of M

(b) The Vernier callipers listed in Table 1 below are available to measure a steel shaft of

diameter 65 mm 0.2 mm, to ensure the manufacturing process is well controlled the

measurements must be accurate to 10% of the tolerance for the shaft.

i) Select the most appropriate Vernier calliper from those available (A to D) as shown in

Table 1.

[30 marks]

ii) Of the four Vernier callipers state which one appears to be making an unreasonable

claim with respect to accuracy.

[10 marks]

Table 1

Answer

For part (i) there are three steps required as follows

[15 marks] step 1

13

MM1DM1-E1

MM1DM1-E1

From the table first calculate the absolute accuracy of each Vernier:

Absolute accuracy = ( % of range accuracy / 100 ) * Range

[10 marks] step 2

Then calculate 10% of the tolerance for the shaft = 0.2 / 10 = 0.02

[5 marks] step 3

Based on this only Verniers C and D are candidates but Vernier C has a range that is too

small.

Therefore select Vernier D.

For part (ii) [10 marks]

The absolute accuracy calculated in part (i) for each sensor must be compared to the stated

resolution. As the resolution for Vernier A is greater than the stated accuracy this brings into

question the accuracy of the instrument as it would not be possible to resolve measurements

to the stated accuracy.

(c) Based on Taylors Gauge Theory state the difference between a Go Gauge and a

Not-Go Gauge, then describe the benefits of using Go and Not-Go gauges as

compared to taking instrument measurements.

[20 marks]

Answer

[5 marks for each of the following]

The GO gauge checks the maximum material condition and should check as many

dimensions as possible.

The NOT-GO gauge checks the minimum material condition and should check one

dimension.

[5 marks for each of the following statements about the benefits of using Go and Not-Go

gauges]

Limit gauging is faster than direct measurement for giving conformance data

Skill requirement and opportunity for human error is minimised

6.

(a) Describe the meaning of each of the five symbols that may be used on an engineering

drawing as part of the geometric tolerance definition for orientation and location. You

may support your description with sketches to illustrate the description of each symbol.

[40 marks]

14

MM1DM1-E1

MM1DM1-E1

Answer

[4 marks each] for correctly naming the symbol

[4 marks each] for the description which may include an associated sketch as shown below.

(b) Describe the working principle of a stylus based surface texture instrument used to

measure surface form and roughness; you may use a diagram to support your answer.

[30 marks]

Answer

A stylus based surface measurement instrument consists of:

[5 marks for each bullet points below, that are included as a description of the stylus

instrument]

a skid that makes contact with the specimen to be measured

protruding from the skid is a pointed stylus that rests on the surface of the specimen

a.

b.

c.

d.

e.

15

MM1DM1-E1

MM1DM1-E1

It is connected to a pivot point and is allowed to move up and down in response to the

local height of the specimen.

The vertical position is measured using a position transducer which converts displacement

into a voltage signal

The voltage is converted to a digital signal using and A/D converter

The digital signal is passed to a computer for analysis and display

(c) A cylindrical shaft must be manufactured with a diameter of 8.5mm 0.03mm. Large

volumes of components are to be manufactured so for speed it is to be inspected using

GO and NOT-GO gauges.

i) Calculate the ideal gauge size required

[10marks]

ii) Calculate the maximum and minimum gauge sizes if the wear limit of the gauge is

0.002 mm, and the gauges can be manufactured with a tolerance of 0.005 mm

[20 marks]

Answer

i) Ideal size for GO gauge : shaft size + tolerance = 8.5 + 0.03 = 8.53

[5 marks]

Ideal size for NOT-GO gauge: shaft size - tolerance = 8.5 - 0.03 = 8.47

[5marks]

ii)

GO maximum: Ideal gauge size gauge wear limit = 8.53 0.002 = 8.528 mm

[5 marks]

GO minimum: Ideal gauge size gauge wear limit gauge tolerance = 8.53 0.002

0.005 = 8.523

[5 marks]

NOT-GO minimum: is the ideal not-go minimum size = 8.47 mm

[5 marks]

16

MM1DM1-E1

MM1DM1-E1

NOT-GO maximum: ideal minimum size + the gauge tolerance = 8.47 + 0.005 = 8.475

mm

[5 marks]

END

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

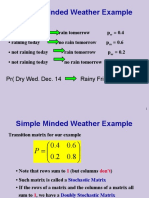

- Simple Minded Weather Example: PR (Dry Wed. Dec. 14 Rainy Fri. Dec. 16) ???Document10 pagesSimple Minded Weather Example: PR (Dry Wed. Dec. 14 Rainy Fri. Dec. 16) ???Leslie LaiNo ratings yet

- Risk Assessment For Shifting of Truss by Double HydraDocument1 pageRisk Assessment For Shifting of Truss by Double HydraLeslie LaiNo ratings yet

- Risk Assessment For Flushing, Hydrostatic Test & Dewatering of PipingDocument15 pagesRisk Assessment For Flushing, Hydrostatic Test & Dewatering of PipingLeslie LaiNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument2 pagesRisk Assesment For Electrical Conducting & Installation WorkAjay kumarNo ratings yet

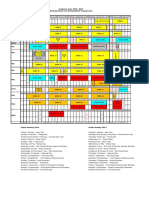

- Academic Calendar 2016 2017 UG and PGDocument1 pageAcademic Calendar 2016 2017 UG and PGLeslie LaiNo ratings yet

- Tin Mining PDFDocument32 pagesTin Mining PDFLeslie LaiNo ratings yet

- Game 1 2 3 4 Polystyren e Cup StackingDocument2 pagesGame 1 2 3 4 Polystyren e Cup StackingLeslie LaiNo ratings yet

- Te-112 Ifu Ver April 2001Document23 pagesTe-112 Ifu Ver April 2001Leslie LaiNo ratings yet

- Primary PlumSet™, Clave™ Y-Site, 104 InchDocument1 pagePrimary PlumSet™, Clave™ Y-Site, 104 InchLeslie LaiNo ratings yet

- Kenny Rogers ROASTERS - OutletsDocument8 pagesKenny Rogers ROASTERS - OutletsLeslie LaiNo ratings yet

- Presentation From MPIADocument52 pagesPresentation From MPIALeslie LaiNo ratings yet

- Kenny Rogers ROASTERS - OutletsDocument8 pagesKenny Rogers ROASTERS - OutletsLeslie LaiNo ratings yet

- Kenny Rogers ROASTERS - OutletsDocument8 pagesKenny Rogers ROASTERS - OutletsLeslie LaiNo ratings yet

- Shuttle Bus Schedule 22 JAN 2014 - 4 MAY 2014 PDFDocument7 pagesShuttle Bus Schedule 22 JAN 2014 - 4 MAY 2014 PDFVashish RamrechaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Emenuhan Kebutuhan Nutrisi Balita Yang Dirawat Inap Di Rumah SakitDocument7 pagesEmenuhan Kebutuhan Nutrisi Balita Yang Dirawat Inap Di Rumah SakitAnnisa Nur Majidah100% (1)

- Distributed Object System: Java - Remote Method Invocation (RMI) Remote Method Invocation (RMI)Document22 pagesDistributed Object System: Java - Remote Method Invocation (RMI) Remote Method Invocation (RMI)endaleNo ratings yet

- Life Elementary A2 Teachers Book Resources For TeaDocument1 pageLife Elementary A2 Teachers Book Resources For TeaNguyenhuuhoiNo ratings yet

- Water Specialist WS2H and WS3 Control Valve ManualDocument40 pagesWater Specialist WS2H and WS3 Control Valve ManualjnpaisNo ratings yet

- Kinematic Analysis of Open-Source 5 DoF Robot Arm (#843139) - 1456378Document10 pagesKinematic Analysis of Open-Source 5 DoF Robot Arm (#843139) - 1456378Mohammad GamalNo ratings yet

- Smart Farming SystemDocument52 pagesSmart Farming Systempatikanang100% (1)

- Apollo247 247201631 Labinvoice CompleteDocument1 pageApollo247 247201631 Labinvoice CompleteAjay VanaparthiNo ratings yet

- NGC 8206 Startup GuideDocument24 pagesNGC 8206 Startup Guidelafuria1234No ratings yet

- GTX 3X5 Transponder TSO Installation Manual: 190-01499-02 August 2020 Revision 16Document248 pagesGTX 3X5 Transponder TSO Installation Manual: 190-01499-02 August 2020 Revision 16Василий ПавленкоNo ratings yet

- Integration of Struts, Spring and Hibernate For An University Management SystemDocument8 pagesIntegration of Struts, Spring and Hibernate For An University Management SystemDrajan LamaNo ratings yet

- TopSURV 7 3 Release NotesDocument55 pagesTopSURV 7 3 Release NotesChilo PerezNo ratings yet

- Peran Bumdes Dalam Pengelolaan Limbah Kelapa Sawit Di Desa Talang Jerinjing Kecamatan Rengat Barat Kabupaten Indragiri Hulu Provinsi RiauDocument11 pagesPeran Bumdes Dalam Pengelolaan Limbah Kelapa Sawit Di Desa Talang Jerinjing Kecamatan Rengat Barat Kabupaten Indragiri Hulu Provinsi RiauInnaka LestariNo ratings yet

- Description and Operation: Component Maintenance ManualDocument8 pagesDescription and Operation: Component Maintenance ManualLou Parker100% (1)

- ICT158 Workshop 7Document2 pagesICT158 Workshop 7Jaya MathiNo ratings yet

- 3 Months Look Ahead PlanDocument6 pages3 Months Look Ahead PlananjnaNo ratings yet

- Baby Shark Color by Number Printables!Document2 pagesBaby Shark Color by Number Printables!siscaNo ratings yet

- Surbhi Sharma: at HCL Pvt. LTDDocument1 pageSurbhi Sharma: at HCL Pvt. LTDJaskiran KaurNo ratings yet

- EPM Data Sync With FDMEE 11.1.2.4Document11 pagesEPM Data Sync With FDMEE 11.1.2.4Aravind AllamNo ratings yet

- Bell Canada's Journey with SAP BPCDocument20 pagesBell Canada's Journey with SAP BPCPraveenNo ratings yet

- DatasheetDocument21 pagesDatasheetziya tutuNo ratings yet

- Face RecogDocument26 pagesFace RecogFavasNo ratings yet

- Lecture - 5: DC-AC Converters: Ug - ProgramDocument54 pagesLecture - 5: DC-AC Converters: Ug - ProgramArife AbdulkerimNo ratings yet

- Soltek SL 65meDocument88 pagesSoltek SL 65meBernardo AntunesNo ratings yet

- PDADocument38 pagesPDASaima NazNo ratings yet

- Allwinner H5 DatasheetDocument68 pagesAllwinner H5 DatasheetSuperFly SmithNo ratings yet

- Conversor para PFO (Fibra Optica Plastica)Document2 pagesConversor para PFO (Fibra Optica Plastica)madmax258No ratings yet

- Post Graduate Course Software Systems Iiit HyderabadDocument20 pagesPost Graduate Course Software Systems Iiit HyderabadLipun SwainNo ratings yet

- Chaderton Barbara AS400Document3 pagesChaderton Barbara AS400Sivakumar RajuNo ratings yet

- OAF TrainiingDocument23 pagesOAF TrainiingCoral Shiny0% (1)

- AI QuestionsDocument2 pagesAI QuestionsNarender SinghNo ratings yet